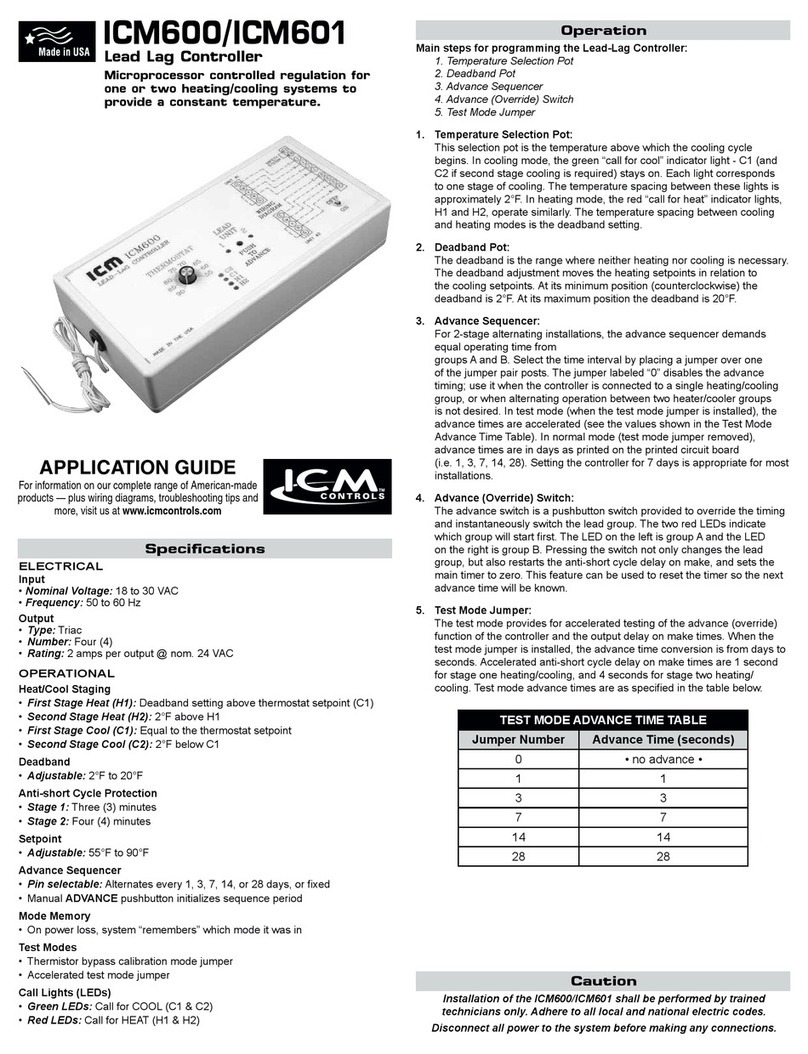

LIAF236-1

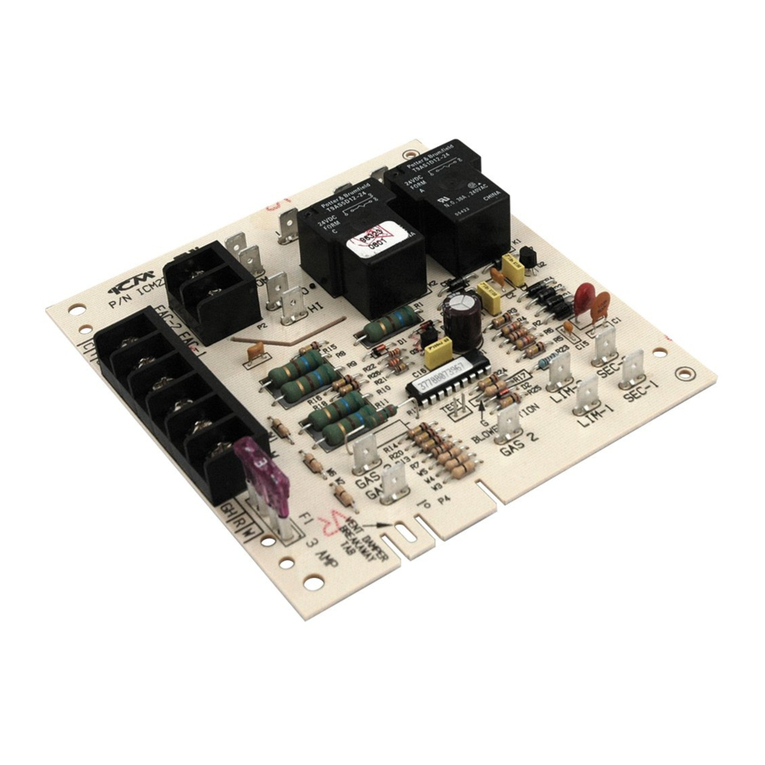

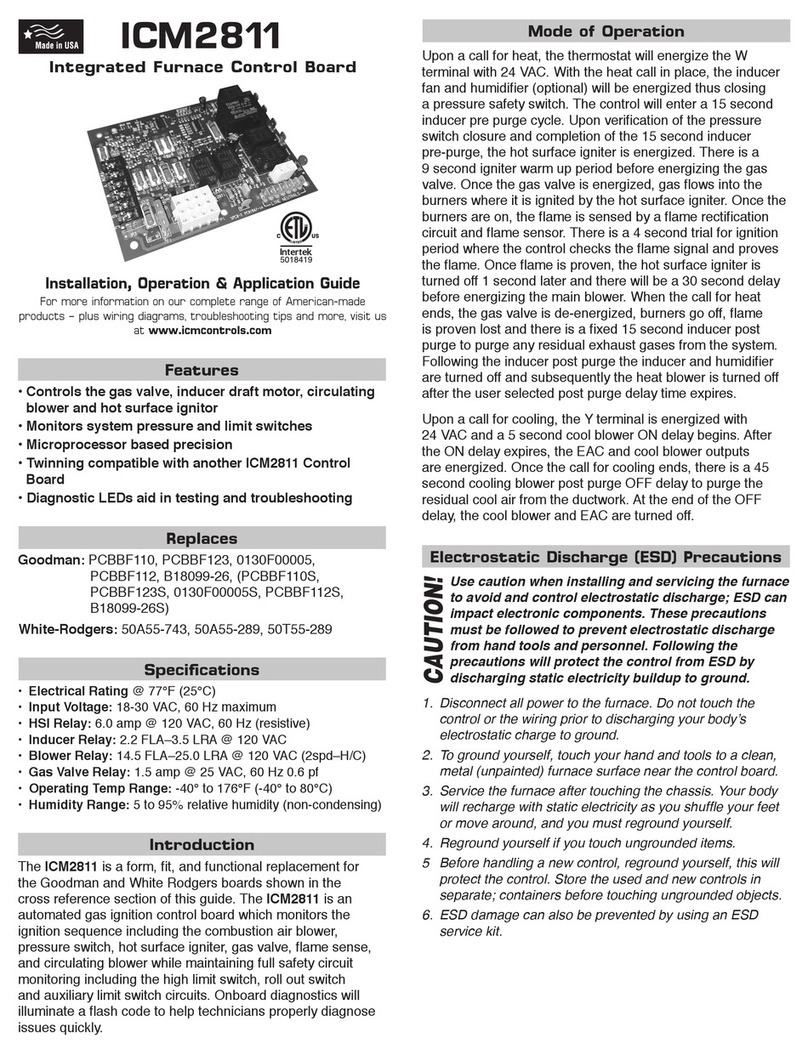

ICM550

DEFROST CONTROL

Replaces

• Grasslin: 010-0011B, DT040, DT140, DTAV40, DTMV, DTSX

• Paragon: 8041, 8045, 8047, 8141, 8143, 8145, 8245, 8247

• Precision: 6041, 6045, 6047, 6141, 6145

• ICM550 defrost control module

• Bracket mount

• Installation guide

• Terminal block & wiring diagram label sheet

• #8 x 1/2” sheet metal screws (3)

• #6 x 1/2” hex head screws (4)

Package Contents

ELECTRICAL SHOCK HAZARD!

Turn off power at the main service panel by removing

the fuse or switching the appropriate circuit breaker

to the OFF position before working on a high voltage

control.

CAUTION!

Installation of the ICM550 shall be performed by trained

technicians only. Adhere to all local and national electric

codes.

WARNING!

Never turn the dial backward, always turn the dial clockwise

to adjust. Do not attempt to touch or adjust the hands of the

clock as this may cause permanent damage to the clock.

> > > CAUTION < < <

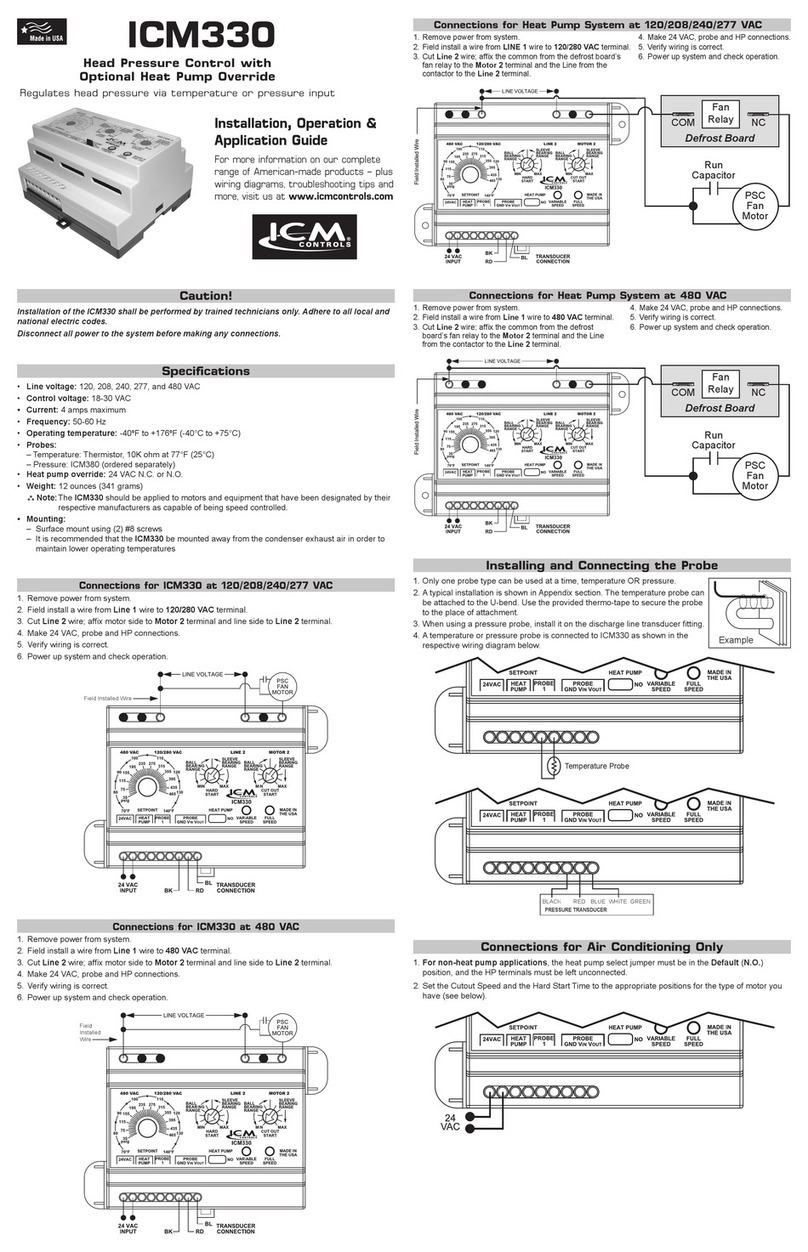

Default Wiring Diagram

Specifications

Inputs:

• Nominal voltage range: 120-240 VAC

• Frequency: 60Hz

Outputs:

• Type: Relay

Contact Ratings:

• Compressor: [2]&[4]: 30A R, 1HP@120VAC, 2HP@240VAC

• Electric heat: [1]&[3]: 40A R, 1HP@120VAC, 2HP@240VAC

• Fan: [1]&[F]: 30A R, 1HP@120VAC, 2HP@240VAC

Environmental

• Operating temperature: -40 to +131°F

• Operating humidity: 0-95%, non-condensing

Mechanical

• Construction: Open board (plastic bracket mounted)

• Mounting: Vertical or Horizontal orientation

Timing

• Minimum defrost time: 15 minutes

• Maximum defrost time: 23 hours 45 minutes

• Terminate defrost: Defrost can be terminated by shorting “X to N”

Status LED

• Defrost mode: (Red LED)

• Refrigeration mode: (Green LED)

Terminal Block

“USE COPPER WIRES ONLY”

Tightening torque 15 in-lb.

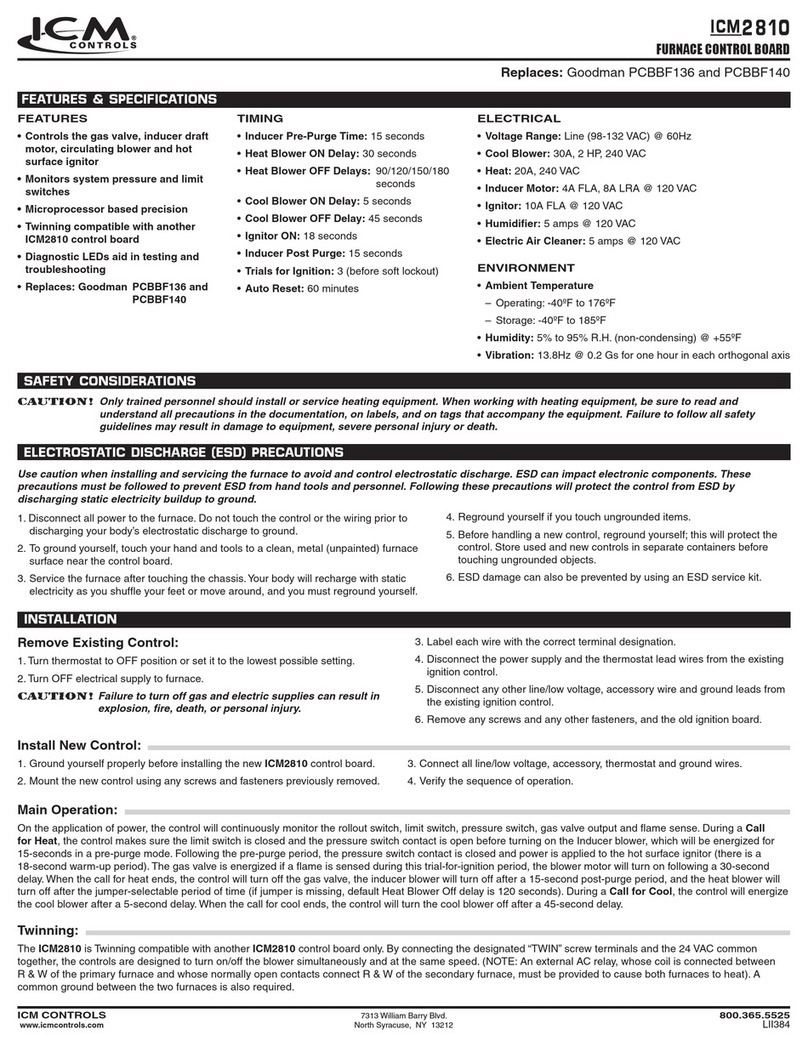

The following example shows the

clock set to 2:30 PM:

Turn the outer dial clockwise

until the inner clock hands

point to the correct time.

Each tick mark on the outer

dial represents 15 minutes.

The inner dial is representative

of conventional clock, with the

printed “hand” showing the hour

and the physical hand showing the

minute. The time displayed on the inner dial will always

correspond with the time on the outer dial.

To Set the Current Time

Decide the amount of defrost time

necessary for your environment

and the hours which you want

defrost to occur. Next, set the

switches for each 15 minute

interval of defrost you require

by moving the switch to the

outer position.

Each switch represents a 15

minute interval of defrost and

there are 4 intervals per hour.

In this example, the system will begin one defrost cycle at

the 5:00 PM, which will last for 45 minutes (3 intervals). The

unit will resume normal operation at 5:45 PM.

If multiple defrost cycles are required, please select the

appropriate dipswitches to represent each 15 minute interval

throughout the 24 hour period where defrost is desired.

To Set Defrost Time

F 3 N X1 2 4

T-Stat

Fan

Defrost

Heater

120

VAC

L1

L2

Defrost

Thermostat

w/ Fan Delay

K1K2

Switch Position

Mode A

Compressor

Contactor Coil

Solenoid Valve