Adaptive AlphaXpress 2020 User manual

PART NUMBER 1523610201 REV. B

Sign Operation and Maintenance Manual

AlphaXpress 2020 Front Access

20mm RGB Full Matrix Displays

© Copyright 2015 Adaptive Micro Systems LLC. All rights reserved.

Adaptive Micro Systems

7840 North 86th Street

Milwaukee, WI 53224 USA

414-357-2020

414-357-2029 (fax)

http://www.adaptivedisplays.com

Adaptive is a registered trademark of Adaptive Micro Systems. All other brand and product names are trademarks or

registered trademarks oftheir respective companies.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at

his own expense.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to

operate the equipment.

ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)1

Contents

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

What is an LED?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

NTCIP compliant error codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Over temperature protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

VMS control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

LED brightness control system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Environmental control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Electrical system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Exterior views. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Sign interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Components. . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Sign controller plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

I/O plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Power panel and power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Display adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

20mm LED module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

•

Mechanical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

•

Physical inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Front lens cleaning (outside of sign) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Filter cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

List of field-replaceable parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1INTRODUCTION

2EQUIPMENT DESCRIPTION

3INSTALLATION

4MAINTENANCE

2ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Contents

Opening a sign. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

I/O module replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Sign controller replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Power supply replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Diode replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Display adapter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

LED driver board replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . 5-12

Circulating fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Venting fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Filter replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . 5-15

Circuit breaker replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Surge suppressor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Circuit breaker replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Surge suppressor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Light sensor replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

•

Short error status conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Error status definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Over-temperature conditions reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

5PART REPLACEMENT

AAPPENDIX

ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)1-1

Introduction 1

Introduction

■System overview

This section contains the LED Variable Message Sign (VMS) systems description and a general explanation of how each system

operates.

Introduction

The Adaptive LED family of Variable Message Signs is considered to be one of the highest visibilitysign systems available. Utilizingthe

latest generation of light emitting diode (LED) technology has allowed us to construct a high-reliability, variable message sign display

system.

The LED Variable Message Signs discussed in this manual are built with a combination of 16 x 16 LED modules with a 20mm pitch

configuredina full matrix. These boards can be arrangedtoformdifferentconfigurations.Thesigns are designed tobe used as outdoor

highway information signs. The signs utilize a corrosion-resistant front-access housing with control circuitry enclosed within. The only

connectionsnecessaryareACpower,Ethernet communication(standard),and three lightsensorconnections;allconnectedtotheback

of the sign.

General system

The entire sign system may be broken down into four basic subsystems:

• VMS control system

• LED brightness control system

• Environmental control system

• Electrical system

In the following sections, we explain each of the above-mentioned systems in general terms for ease of understanding. Referring to the

drawings throughout this manual should help you to gain a general understanding of the LED Variable Message Sign system.

What is an LED?

LED-basedsigns are one ofthemostversatile and visible display systemsavailable.Weuseaclusterof small LEDs toformapixel.The

pixels are arranged in various matrices to form alphanumeric characters. These characters are then linked together to form an LED

display line. The display line format used in AlphaXpress 2020 signs is full matrix, which allows for the display of any alphanumeric

character, including punctuation marks, as well as simple graphics characters.

NTCIP compliant error codes

The NTCIP compliant controllers used in AlphaXpress 2020 signs returninformation on sign health in the form of a binary number. This

number, or code, is received in the form of a short error status when the sign is queried using IDI Intelligent Controls or other software.

Adaptive provides the Short Error Code Status Translator program that quickly translates the returned value into individual error codes

that the sign is reporting.

Short Error Status

Bit 0: Reserved Bit 8: Controller error

Bit 1: Communications error Bit 9: Temperature warning

Bit 2: Power error Bit 10: Fan error

Bit 3: Attached device error Bit 11: Critical temperature error

Bit 4: Lamp error Bit 12: Drum sign rotor error (not applicable to LED signs)

Bit 5: Pixel error Bit 13: Open cabinet door error

Bit 6: Photocell error Bit 14: Humidity warning

Bit 7: Message error

1-2 ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Introduction

SYSTEM OVERVIEW

1

Over temperature protection

VMS control systems are designed to protect LED signs from overheating. The VMS control system monitors the temperature at the

display adapters, NTCIP controller plate, and the power supply plates. The following information describes the conditions in which

protective measures are triggered and the actions the system takes. For information about convertingShort Error Status Error Codes in

Intelligent Controls, over-temperature conditions, and status definitions information, refer to “Short error status conversion” on page A-1.

Condition 1: Measured at the display adapters

If the temperature measured at the display adapters exceeds 60° C (140° F):

• The sign controller reduces light output to 90% of the current brightness level setting.

•The sign controller keeps the light output at 90% of the current brightness level setting until the temperature falls below 56° C

(133° F). The NTCIP controller will report a Temperature Warning by raising bit 9 of the short error status.

• Additional dimming will result if the temperature continues to increase. Every 4° C increase results in dimming by an additional

10%.

Condition 2: Measured at the display adapters

If the temperature measured at the display adapters exceeds 80°C (176°F):

• The sign controller reduces the light output to 0%.

•The sign controller keeps the light output at 0% until the temperature falls below 76° C (133° F). At this point the sign will be

allowed to display at 50% brightness.

•The NTCIP controller will report a Temperature Warning by raising bit 9 of the short error status.

•The NTCIP controller will report a Critical Temperature Error by raising bit 11of the short error status.

Condition 3: Measured at the controller plate or power supply housings

If the temperature at the NTCIP controller plate or at the power supply plates exceeds 71° C:

• The NTCIP controller will report a Temperature Warning by raising bit 9 of the short error status.

Condition 4: Measured at the controller plate and power supply housings

If the temperature at the NTCIP controller plate and at the power supply plates exceeds 71° C:

• The NTCIP controller will report a Temperature Warning by raising bit 9 of the short error status.

•The NTCIP controller will report a Critical Temperature Error by raising bit 11 of the short error status.

Condition 5: Thermal shutdown

If the temperature at the NTCIP controller plate exceeds 71° C and the temperature at the power supply plates exceeds 71° C for

approximately an hour:

• The NTCIP controller blanks the display and keeps the display blanked until this condition is resolved.

• The NTCIP controller will report a Temperature Warning by raising bit 9 of the short error status.

• The NTCIP controller will report a Critical Temperature Error by raising bit 11 of the short error status.

• The NTCIP controller will report a Message Error by raising bit 7 of the short error status.

ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)1-3

Introduction

1

SYSTEM OVERVIEW

VMS control system

The VMS control system used in the Variable Message Sign consists of the following components:

• NTCIP compliant controller

• LED display board/driver board

• Sign controller

• Display adapter

General operation

The NTCIP controller interfaces with the “Host” computer system, and communicates with the Host through a CAT5 Ethernet cable

(standard) or an RS422 connection (option). Using this network connectionor I/O port, the Host issues commands to, and requests

status information from, the NTCIP controller. The controller monitorsand controls the entire LED VMS system. Communication by the

NTCIP controller to and from the Host is accomplished using industry standard 10/100 Ethernet communications circuitry and NTCIP

protocol.

Placement of controllers

The controllers are located in the lower left modular case of all AlphaXpress 2020 sign configurations. Single row signs have a remote

mounted controller.

LED brightness control system

TheVMS is equipped withabrightnesscontrolsystemfor the LEDs. Thebrightnesscontrolsystemensuresthatthe display isreadable

in all lighting conditions. The photocells are enclosed to protect them from the environment. Three photocells continually monitor the

ambient light conditions. The photocell assembly is constructed in such a manner that adverse weather conditions (such asheavy

snow) should have no effect on its performance. The main components of the brightness control system are the following:

• Sign Controller

•Lightsensorassembly

General operation

The photocells are enclosed in an assembly designed to protect them from the environment. The photocells continuously monitor the

ambient light conditions and the controller constantly polls the photocells for this information. The controller determines exactly how

much ambient light is detected through the light-sensing photocells and sets the light output of the display module for it to adjust duty

cycle of the LED current drive, thus dimming or brightening the LED modules according to the ambient light. (If the on time of the duty

cycleis 50%, then thelight output will be at 50%; ifthe on timeof the duty cycle is 75%,then the light output will beat 75%, and so on.)

Light sensor assembly mounting

Because the function of the photocells depends on ambient lighting, the light sensor assembly should be mounted in a location where

it will receive maximum light exposure throughout the day. When choosing a mounting location for the light sensor assembly, make

sure the assembly can receive ambient light on the front.

I/O plate

Sign controller plate

1-4 ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Introduction

SYSTEM OVERVIEW

1

Environmental control system

To protect the sign components from overheating, two or three fans are mounted in each of the sign's modular cases. A thermostat

dedicated to each fan controls the operation of each fan independently.

•Internal circulating fan - The internal circulating fan(s) turns on when the internal temperature of the sign reaches

43°C (+/- 4.5°C) 110°F), and turns off when the internal temperature falls below 27°C (+/- 5C°) 80°F).

•External air ventilation housing fan -The external air ventilation housingfanturnson when theinternal temperatureofthesign

reaches 54°C (+/- 4°C) 130°F), and turns off when the internal temperature falls below 38°C (+/- 5°C) 100°F).

Electrical system

The electrical supply system is responsible for supplying the necessary power to operate the LED sign system. The sign housing AC

and DC electrical system consists of the following components:

• DC power supply

• Thermostat controlled AC fans

Electrical distribution (DC)

Attached to the back panels in the sign housings are the power supply plates containing two 24VDC switching redundant power

sharing supplies. The electronic power supplies convert the 120VAC to the required DC voltage to power all of the electronics in the

sign. DC power to the electronics is redundant and has a primary and secondary source of DC power. Therefore, failure of a single

power supply will not impact sign performance. The controller monitors the status of the power supplies.

Electrical distribution (AC)

TheACinputto the sign system consists of 120VAC (see thesalesdrawings)single-phase servicewiredtotheinput AC terminalblock

located on the controller plate. AC is internally wired to the DC power supplies and fans. AC power to the power supplies and fans is

controlled by 20 Amp circuit breakers. The quantity of breakers is dependent on the size of the sign.

Depending on the sign size there may be more than one AC power entry. Reference the sales drawing for specifics. Contact Adaptive

support if required.

WARNING Hazardous voltage. Multiple power sources may be present. Risk of electrical

shock. Disconnect all power sources before servicing.

Power supply plate

Signcontroller

plate

AC distribution plate

Customer AC

connection

Power supply plate Power supply plate

I/O plate Circulating

fan Front filter

access

Venting

fan

ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)2-1

Equipment Description 2

Equipment Desc ription

■General description

• Serviceability: Front access

• Pitch (distance between each LED pixel): 20mm

• Reference sales drawings for sign specifications

Figure 2-1. Pitch is 20 mm.

LED pixel composedof 3

individual LED lamps. 1

each of Red, Blue, Green.

20mm

2-2 ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Equipment Description

EXTERIOR VIEWS

2

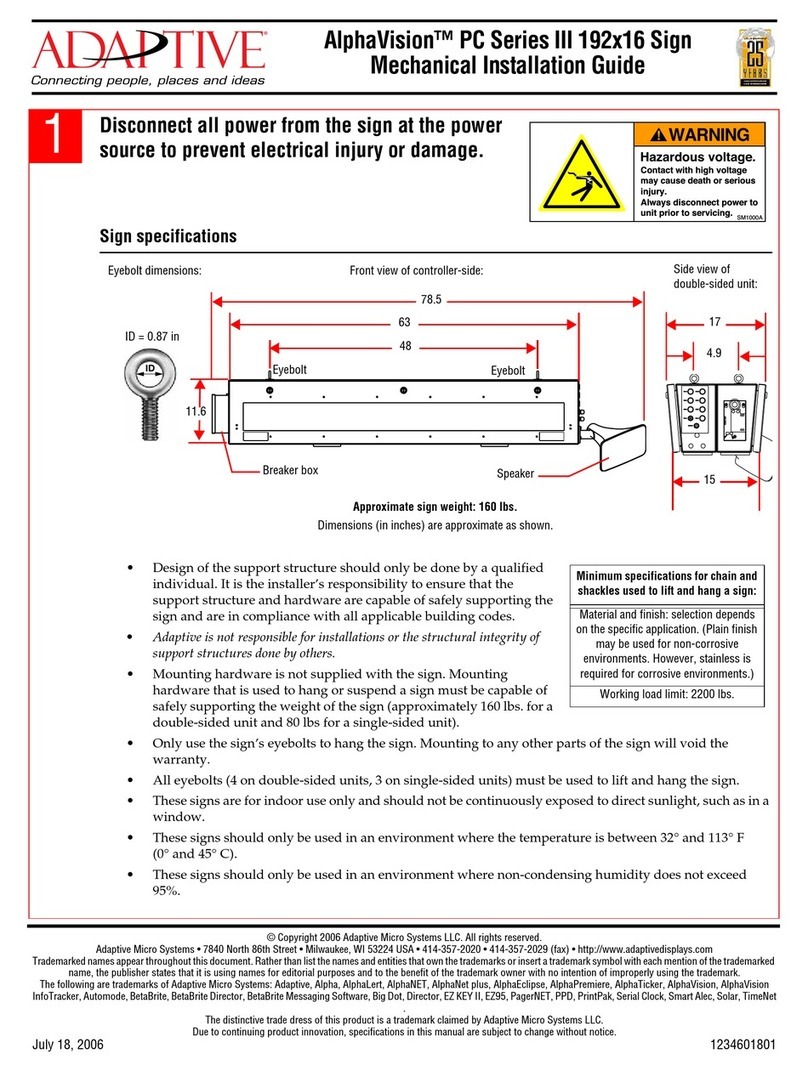

■Exterior views

Top and side views.

Front view

Item Name Description

ALIFTING EYEBOLTS Used to lift the sign into position. Can be removed after the sign has been mounted.

Location varies by sign size. Removal does not impact the integrity of the housing.

BSIGN MOUNTING

STRUCTURE Used to mount display cases. Horizontal Z-bar entire length of sign for mounting to

customer supplied structure (vertical I-beams are not supplied). Varies depending on

sign dimensions.

CLED MODULE Used to display content.

Item Name Description

ALIFTING EYEBOLTS Used to lift the sign into position. Can be removed after the sign has been mounted.

Location varies by sign size.

BLED MODULE Used to display messages

A

A

B

Side view

(with mounting structure) Side view

(doors open)

C

B

A

ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)2-3

Equipment Description

2

EXTERIOR VIEWS

Rear view

Item Name Description

ASIGN MOUNTING

STRUCTURE Used to mount display cases. Horizontal Z-bar entire length of sign for mounting to

customer supplied structure (vertical I-beans are not acceptable). Varies depending

on sign dimensions.

BLIGHT SENSOR

CONNECTION Used to connect the light sensor. Front, top and rear connection.

CGROUND LUG Use toconnect toan earth-groundrod. Sign must begroundedperNEC 250 and local

electrical codes. Never use the sign’s ground lug to ground welding or any other

installation equipment or the warranty will be void.

DPRIMARY POWER ENTRY

ESECONDARY POWER ENTRY Used when required.

FETHERNET

COMMUNICATION ENTRY Water-tight connection external to sign.

GTIE PLATE Used to secure display mountings together vertically.

HFILTER HOUSING (OPTION) Front access filter is standard. Rear access is customer installed option.

FE

A

C

B

G

H

A

D

2-4 ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Equipment Description

SIGN INTERIOR

2

■Sign interior

Item Name Description

APOWER SUPPLY Providespower toallthe componentsinthe sign.Numberandlocation willvary depending

on the size of the sign.

BCIRCUIT BREAKERS Routes line voltage to the sign. There may be more than one circuit breaker in the sign.

CSURGE SUPPRESSOR There is one surge suppressor at each power entry in the sign.

DCUSTOMER AC

CONNECTION Customer AC connection.

EAC ENTRY Customer AC power connection when viewed from the front door.

FSIGN CONTROLLER

PLATE Sign controller location.

GI/O PLATE Contains all I/O connections

HVENTING FAN Prevent overheating of sign components.

ICIRCULATING FAN Internal recirculation fan used to mix air and help cool sign.

JFRONT ACCESS FILTER Standard front access for filter replacement.

KDISPLAY ADAPTER Used to communicate to LED modules from sign controller.

AAA

C

B

FG H I KJ

DE

ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)2-5

Equipment Description

2

COMPONENTS

■Components

Sign controller plate

Item Name Description

ASIGN CONTROLLER Controls display and communicates status information to central communications.

BI/O COM TERMINAL BLOCK Serial I/O to display adapter.

C485 HUB Serial communications distribution and 5V DC power to the sign controller.

DETHERNET SURGE

PROTECTOR Ethernet cable (customer supplied) plugs in to this location.

WINCE

LICENSE

D

B

A

C

2-6 ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Equipment Description

COMPONENTS

2

I/O plate

Item Name Description

AI/O MODULE Controls displays and communicates status information to central communications

BTERMINAL BLOCKS Serial I/O to display Adapter

A

ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)2-7

Equipment Description

2

COMPONENTS

Power panel and power supplies

The size of the sign determines the number of power panels in the sign. Refer to the sales drawings for locationsin each sign size.

There are no user connections to the power supply panels.

Item

Power

supply

label

Name Description

AN/A POWER PANEL AC INPUT AC Power connection to the power supply plate.

BDC POWER FAIL TERMINAL BLOCK Power fail signal to controller.

CHI-LIMIT TEMPERATURE SENSOR Hi Limit temperature warning for controller.

DDC SUPPLY OUTPUT

EV- 24VDC -

FN/A DIODE MODULE Part number 30300003LFSP. See “Diode replacement” on page 5-9.

GV+ 24VDC + DC output.

HDC SUPPLY OUTPUT

IAC INPUT

JN/A SIGNAL CONNECTOR Used for remote control, remote sense, and power good signal.

KN/A DC VOLTAGE ADJUSTMENT Used to fine tune the DC output of power supply. Factory set for

optimal power

LAC/L AC INPUT LINE

MAC/N AC INPUT NEUTRAL

NAC INPUT GROUND AC input (90-264VAC, 47-63Hz).

Power supply DC output (front view)

Power supply AC input (back view)

L M N

F

E

G

AB

C

K

J

D

H

I

2-8 ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Equipment Description

COMPONENTS

2

Display adapter

The number of display adapters in a sign and their locations depends on the size of the sign. Refer to the sales drawings for locations

in each sign size.

Item Name Description

ADRIVER

COMMUNICATION Each of the 6 outputs corresponds to a row of 9 LED modules

BDVI OUT DVI signal routes to next display adapter in chain.

C485 COMMUNICATION RS485 I/O from sign controller and or next display adapter in chain.

DDVI IN DVI Signal from sign controller or from prior display adapter in chain.

A

B

C

D

ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)2-9

Equipment Description

2

COMPONENTS

20mm LED module

The size of the sign determines the number of driver boards. Each board is 6 x 9 pixels, and each pixel is composed of 3 LED lamps,

1 red, 1 green and 1 blue.

Item PCB label Name Description

AP1 P2 DATA Connects to Controller #1 via a ribbon cable.

BBIN LABEL Information on the intensity and wavelength of the LED lamps.

CP4 +V1 Supplies power to the LED driver board.

DP6 Programming port for the LED driver board processor.

ESTATUS 1 POWER On = 24V supplied to LED driver board.

STATUS 2 FAULT On = one or more bad LED lamps on the LED driver board (if in normal operating

mode).

STATUS 3 COMM On = There is NO communication from sign controller.

Off = There is communication from the sign controller.

STATUS 4 RUN Flashing = LED driver board processor operating.

Front view Back view

16 pixels

16 pixels

B

A

C

ED

THIS PAGE INTENTIONALLY BLANK

2-10 ALPHAXPRESS 2020 FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)3-1

Installation 3

Installation

■Mechanical installation

Lifting the sign

WARNINGWARNING Crush hazard. Improperly lifting of a sign can create a crush hazard causing personal injury and damage the

sign. Only use the sign’s lifting eyebolts to lift the sign.

Lift the sign evenly and level, with no more than a 15 degree tilt.

RECOMMENDED

Lifting bar

Front view

Use both eyebolts

to lift the sign.

NOT RECOMMENDED

Front view

Not less

than 60°

Use both eyebolts

to lift the sign.

3-2 ALPHAXPRESS 2020 RGB FRONT ACCESS FULL-MATRIX DISPLAYS SIGN OPERATION AND MAINTENANCE MANUAL (PN 1523610201 REV. B)

Installation

ELECTRICAL INSTALLATION

3

■Electrical installation

AC wiring

AC wiring for typical AlphaXpress 2020

WARNING Hazardous voltage. Contact with high voltage may cause death or serious injury.

Always disconnect power to unit prior to service.

Line

Neutral

Ground

Customer Wiring

Sign circuit

breakers

AC

Table of contents

Other Adaptive Monitor manuals