Adaptive AlphaEclipse PureColor 3600 User manual

Installer Instructions for AlphaEclipse 3600 Signs (Series B)

(Form number 9711-8028B, February 14, 2006)

Instructions

for the

Sign Installer

© Copyright 2004-2006 Adaptive Micro Systems LLC. All rights reserved.

Adaptive Micro Systems, 7840 North 86th Street, Milwaukee, WI 53224 USA

414-357-2020, 414-357-2029 (fax), http://www.adaptivedisplays.com

Trademarked names appear throughout this document. Rather than list the

names and entities that own the trademarks or insert a trademark symbol

with each mention of the trademarked name, the publisher states that it is using names for editorial purposes and to the benefit of the trademark owner

with no intention of improperly using the trademark. The following are trademarks of Adaptive Micro Systems: Adaptive, Alpha, AlphaLert, AlphaNET,

AlphaNet plus, AlphaEclipse, AlphaEclipse RoadStar, AlphaEclipse StreetSmart, AlphaPremiere, AlphaTicker, AlphaVision, AlphaVision InfoTracker,

Automode, BetaBrite, BetaBrite Director, BetaBrite Messaging Software, Big Dot, Director, EZ KEY II, EZ95, PagerNET, PPD, PrintPak, Serial Clock, Smart

Alec, Solar, TimeNet.

The distinctive trade dress of this product is a trademark claimed by Adaptive Micro Systems LLC. Due to continuing product innovation, specifications

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

2

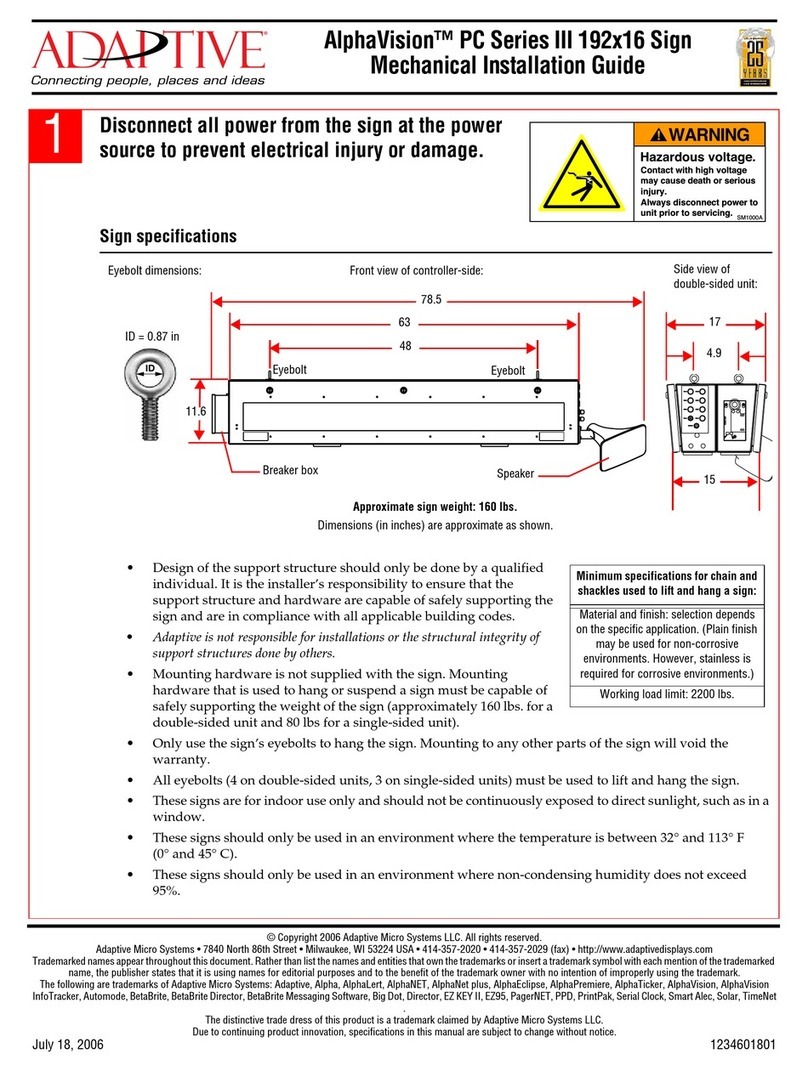

1Determine sign power requirements

65801

CUS

Adaptive Micro Systems LLC

Milwaukee, Wisconsin 53224 USA

MODEL NO.:

CIRCUIT #1: 19.4

CIRCUIT #2: 19.4

CIRCUIT #3: NA

CIRCUIT #4: NA

CIRCUIT #5: NA

CIRCUIT #6: NA

CIRCUIT #7: NA

CIRCUIT #8: NA

CIRCUIT #9: NA

CIRCUIT #10: NA

NEMA TYPE 3R ENCLOSURE

IP44 RATED ENCLOSURE

CONFORMS TO STANDARD:

ANSI/UL 60950-1

CERTIFIED TO:

CAN/USA 22.2 No. 60950-1-03

THE DISTINCTIVE TRADE DRESS OF THIS PRODUCT IS A

TRADEMARK OF ADAPTIVE MICRO SYSTEMS LLC

DATE OF MANUFACTURE:

9/26/2004

PARTS SERVICEABLE BY TRAINED TECHNICIANS ONLY!

DISCONNECT POWER BEFORE SERVICING

SERIAL NO.:

EH0002231

1180 - 3601112032RGB

120 ~ VAC

60Hz

38.8 A

B

SERIES:

VOLTS:

Hz:

AMPS:

Look on the bottom back of the

sign’s wireway.

Number of

circuits

required

Model number

Use this to find the sign’s weight.

See “Sign mounting (sheet 2)” on

page 12.

Total

sign

current

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

3

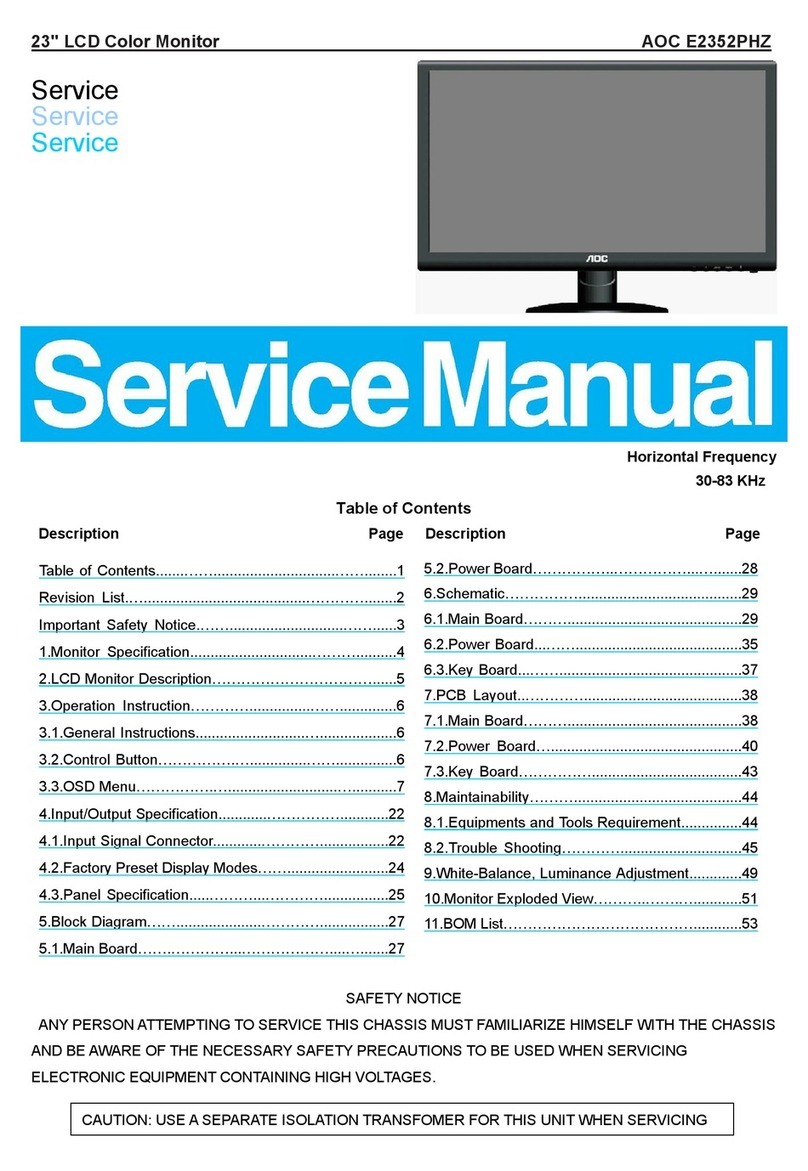

2Mount signs

Observe safety precautions

Create a support structure for the signs

• All installations, superstructure designs, and connections must be designed and approved by a qualified

structural engineer. Call Adaptive Micro Systems at 1-800-558-7022 for contact information for structural

engineering consultants.

• Drill holes as needed in the sign’s steel framework for fasteners, but consult the attached shop drawings for

excluded areas. Drilling holes in any of these excluded areas will void the sign’s warranty. When drilling holes,

follow these guidelines: (1) Connections must be analyzed by a structural engineer. (2) Dissimilar metals

should be isolated to avoid galvanic corrosion.

• Any area on the sign’s frame that had paint removed during mounting must be recoated with a paint

recognized by UL test #1332. Failure to repaint the area will result in accelerated corrosion of the sign’s structure.

Adaptive Micro Systems is not responsible for any failure in the sign’s structure because of this. (POLANE HS Plus

Polyurethane Enamel is used to paint the sign’s frame during manufacturing.)

Ventilate signs adequately

• If the sign is mounted to a solid surface like a wall, then nothing should block the space between the top,

bottom, and sides of the sign and the solid surface.

• If there is an obstruction (as in a monument-style installation), then run duct work (not supplied) from the

bottom side of the sign and laterally to the top of the sign to exhaust hot air. Be sure no rain or snow can

enter the sign through this duct work. To avoid heat build-up and depending on sign size, more space may

be required at the back of the sign to provide ample air flow. Fans can be used to supplement natural air

flow. Adaptive Micro Systems recommends isolating the fresh air intakes from the exhaust air.

Possible crush hazard.

Always use lifting bar

to lift the sign. Otherwise

eyebolts may break and

sign may fall, causing

serious injury or death.

WARNING

SM1015

Possible crush hazard.

Always use eyebolts to lift

sign. Otherwise the sign

may fall, causing serious

injury or death.

WARNING

SM1017

Do not lift sign

with more than a

15 degree tilt.

Crush hazard.

WARNING

SM1020

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

4

2Mount signs (continued)

Multiple section sign assembly

NOTE: These instructions only apply to large signs that are shipped from the factory in multiple sections. These

sections must then be assembled into a single sign at the installation site.

Vertical split or horizontal split assembly

Vertical and horizontal split assembly

Lift signs into place and assemble

Left Right Top

Bottom

For a vertically split sign, see “Multiple section

sign, vertical split assembly” on page 16.

For a horizontally split sign, see “Multiple section

sign, horizontal split assembly” on page 18.

Top RightTop Left

Bottom RightBottom Left

For a sign that is split both vertically and

horizontally, see “Multiple section sign, vertical/

horizontal split (sheet 1 of 2)” on page 20.

RECOMMENDED

Lifting bar

NOT RECOMMENDED

See the shop drawings on page 10

for detailed sign mounting

See “Temperature probe mounting”

on page 24 for information on the

optional temperature probe.

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

5

3Connect power

Observe safety precautions

Electrical installation guidelines

• Inspect all internal sign cabling for proper connection and seating.

• All power wiring must be from circuit breaker-protected lines.

• A two-pole disconnect device must be installed in the building wiring for each branch circuit supplying the sign.

• The sign must be properly grounded according to the applicable codes (for example, NEC Article 250 and 600, and IEEE

1100-1999).

• Run separate conduits for signal wires (for example, RS232, RS485) and for power wires. However, fiber optic wire may be

run in the same conduit with power wires.

• This sign should not be connected to a ground fault interrupt (GFI) circuit.

• All electrical connections must be watertight.

• Use minimum 80° C copper wire only.

Utiliser uniquement un fil en cuivre pouvant supporter 80° C minimum.

• Torque terminals to a minimum of 7 in/lbs and a maximum of 10 in/lbs.

Serrer les bornes à 0,79 N/m minimum, mais pas à plus de 1,13 N/m.

Run power to the sign

Use the information from “Determine sign power requirements” on page 2.

NOTE: Make sure two conduits are run to the sign: one for power and the other for communication wires. See

“Connect MASTER UNIT to messaging computer” on page 8.

Ground the sign

The sign must be properly grounded in order to provide the following three types of protection:

• Ground fault protection — The sign must be wired to provide a permanent, low impedance pathway to carry sign ground

fault current. Earth grounding a sign through some type of ground rod bonded to the sign is not sufficient ground fault

protection.

• Lightning strike protection — A sign must be earth grounded either through an existing ground rod or separate ground

rod(s) bonded to the sign. See National Electrical Code (NEC) Article 250.32. A ground lug in the sign’s wireway is provided

for this purpose.

• Electronic equipment protection — A common cause for the failure of sensitive electronic equipment is the presence of

objectionable current on grounding or bonding paths. Likely causes for objectionable current are (1) errors in installation

wiring, (2) improper neutral-to-case bonds, and (3) equipment-grounding conductor used to carry neutral current.

NOTE: Though #3 is permitted by NEC Article 250.32(B)(2), Adaptive does not recommend this wiring method because it

creates a potentially hazardous situation.

Contact with high voltage

may cause death or serious

injury.

Always disconnect power to

unit prior to servicing.

Hazardous voltage.

WARNING

SM1000A

HIGH LEAKAGE

CURRENT.

COURANT DE

FUITE ELEVE.

Earth connection

essential before

connecting

supply.

Raccordement

a la terre

indispensable

avant le

raccordement

au reseau.

AVERTISSEMENT

WARNING

SM1009A

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

6

4Wire signs together (if only 1 sign, skip this)

How are the signs labeled? (select one below)

MASTER / SECONDARY MASTER

MASTER / SLAVE

SECONDARY MASTER UNIT

SERIAL ADDRESS = 2

Sign Wireways (back)

Wireway Terminal Block

Wireway Terminal Block

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

7

TB1 TB2

TB3 TB4

12345

123 12345

1234567

SHIELD

BLACK

RED

SHIELD

BLACK

RED

SHIELD

BLACK

RED

SHIELD

BLACK

RED

MASTER UNIT

SERIAL ADDRESS = 1

SECONDARY MASTER UNIT

SERIAL ADDRESS = 2

Wireway terminal block Wireway terminal block

TB1 TB2

TB3 TB4

12345

123 12345

1234567

(To connect 3 or more signs, go to “MASTER / SECONDARY MASTER sign-to-sign wiring for 3 or more signs” on page 25.)

TB1 TB2

TB3 TB4

12345

123 12345

1234567

MASTER UNIT

SERIAL ADDRESS = 1

SLAVE UNIT

SERIAL ADDRESS = 2

Wireway terminal block Wireway terminal block

TB1 TB2

TB3 TB4

12345

123 12345

1234567

SHIELD

BLACK

RED

SHIELD

BLACK

RED

SHIELD

BLACK

RED

SHIELD

BLACK

RED

SHIELD

BLACK

RED

SHIELD

BLACK

RED

(To connect 3 or more signs, go to “MASTER / SLAVE sign-to-sign wiring for 3 or more signs” on page 25.)

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

8

5Connect MASTER UNIT to messaging computer

What is included with the signs? (select one below)

Converter Box III

(Connected by outdoor wire to MASTER

UNIT. Connected to messaging computer by

cable. Placed next to computer.)

Telephone modem

(One modem connected inside MASTER

UNIT. Another connected to messaging

computer.)

Fiber optic modem

(One fiber optic modem connected inside

MASTER UNIT wireway. Another fiber optic

modemconnected to messaging computer.)

Alpha RF900 wireless transceiver

(A client transceiver connected inside

MASTER UNIT. A server transceiver

connected to messaging computer.)

LANTRONIX

MSS485-T

serial console

shld

txa

txb

rxb

rxa

shld

6vdcreset10BASE-T

power

link

ok

serial

Lantronix MSS485 Ethernet interface

(Connected to MASTER UNIT by outdoor

wire. Also, MSS485 and messaging

computer both connected to Ethernet.)

External connection box

(Connected to MASTER UNIT using

outdoor wire. Placed at base of signs.)

NOTE: GND must be connected to the

White Wire. Blue and White wires may not

be wired as shown.

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

9

Messaging computer

running AlphaNET

software

up to 4000 feet 10 feet

Outdoorcable

(pn7124-0203)

RS232 cable

(pn1088-8634)

ConverterBox III

(pn1088-1111)

Wireway

(see diagram onleft)

AlphaEclipse 3600

MASTER UNIT

Outdoor

cable

TB1 TB2

12345 1234567

RED

BLACK

SHIELD

RS232 cable

Transmitting modem (pn1088-9301)

Receiving modem (pn1088-9301)

(inside signcube)

Each modem needsits

owntelephonenumber.

Messaging computer

running AlphaNET software

AlphaEclipse 3600

MASTER UNIT

Fiberoptic mini-modem (inside wireway) Fiberoptic mini-modem

Messaging computer

running AlphaNET software

up to 2 miles

Fiberoptic cables

(mini-modem connections:RXtoTXandTXtoRX)

RXTX DATA

DB9-to-DB9 cable

DB25-to-DB9 adapter

AlphaEclipse 3600

MASTER UNIT

Messaging computer

running AlphaNET software

Clienttransceiver

(inside signcube)

AlphaEclipse 3600

MASTER UNIT

Alpha RF900

server

transceiver

RS232 cable

(supplied with transceiver)

Messaging computer

running AlphaNET

software

10BASE-T

Ethernet

Lantronix MSS485

(pn1088-4112A)

up to 4000 feet

Outdoorcable

(pn7124-0203)

LANTRONIX

MSS485-T

serial console

6vdcreset10BASE-T

power

link

ok

serial

Wireway

(see diagram onleft)

AlphaEclipse 3600

MASTER UNIT

Outdoor

cable

TB1 TB2

12345 1234567

RED

BLACK

SHIELD

Sign

mounting

pole External connectionbox (see diagram onright)

RS485outdoorcable (pn7124-0203) canbe used

Wireway (see diagram onright)

Wireway terminal block

AlphaEclipse 3600

MASTER UNIT

Outdoorcable

(pn7124-0203)

SHIELD

BLACK

RED

TB3 TB4

123

123

45

RED

BLACK

SHIELD

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

10

Sign mounting (sheet 1)

43

2

3

4

SOCKET HEAD CAP SCREWS.

OPEN WITH 5/32 HEX TOOL

(PROVIDED).

NOTE: DESIGN AND DIMENSIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. SEE SHEET 2 FOR ADDITIONAL NOTES.

22.05 WIREWAY

B

(SEE SHEET 2)

6.34 WIREWAY BOX.

LEFT WIREWAY OPTIONAL.

LOCATION TO BE SPECIFIED

AT TIME OF ORDER.

A

(SEE SHEET 2)

B

B

FRONT VIEW

FRONT ACCESS

TO POWER AND

SERIAL DATA

CONNECTIONS

VIA WIREWAY BOX.

CONTROLLER LOCATED IN SECOND

CUBE FROM WIREWAY IN BOTTOM ROW.

WIREWAY CONDUIT ENTRY

KNOCKOUTS PROVIDED.

DO NOT RUN RS485 POWER

AND DATA CABLE IN THE

SAME CONDUIT. POWER AND

FIBER OPTIC CAN BE RUN

IN THE SAME CONDUIT IF

NECESSARY.

ONE ENCLOSURE CUBE

CONSISTS OF FOUR

DISPLAY MODULES.

RS485 CONNECTOR

SERVICE DOOR ACCESS

(ALLOW 18.5" MINIMUM.

REAR ACCESS IS OPTIONAL.)

1.00

18.5

.79

1.19

6.87

3.00

11.85

TOP VIEW

REAR ACCESS

FRONT ACCESS

4.00

19.7122.05 TYP.

22.05 TYP.

1.18 TYP. .36 TYP.

7.35 TYP. 7.35 TYP.

19.29 TYP.

1.38 TYP.

2.76 TYP.

7.35 TYP. 4.83 TYP.

3.67 TYP.

L2x3x¼, A36 STEEL

PAINTED BLACK

4x¼, A36 STEEL PAINTED

BLACK (BETWEEN EACH

ROW.) DO NOT ATTACH

MOUNTING STRUCTURE TO

THESE MEMBERS.

(SEE NOTE 5.)

IF REAR DOOR ACCESS IS

NEEDED, MOUNT TO

VERTICAL STRUCTURES IN

THIS AREA ONLY TO AVOID

BLOCKING DOOR. (SEE

NOTE AT LOCATION D-3.)

CRS STEEL FORMED ANGLE

POWDER COAT BLACK

L2x3x¼, A36 STEEL

PAINTED BLACK

BACK VIEW

BOLTS AND NUTS MUST NOT

BE REMOVED OR REPLACED.

(SEE NOTE 3.)

OPTIONAL

CONDUIT

LOCATIONS.

(AS

INDICATED

ON

WIREWAY.)

OPTIONAL FLATHEAD SCREWS

ARE USED WHEN SIGN

SECTIONS ARE CONNECTED

TOGETHER INTO LARGER

SIGN SECTIONS. CONTACT

ADAPTIVE FOR DETAILS.

(SEE PAGE 3.) EXHAUST VENTS TYP.

(SEE NOTE 8.)

INTAKE VENTS TYP.

(SEE NOTE 8.)

21.90 TYP.

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

11

FRONT DISPLAY ACCESS

NOTES:

1) REFER TO INSTALLATION MANUAL FOR POWER AND ADDITIONAL INSTALLATION REQUIREMENTS.

2) THE ONLY SERVICE TOOLS REQUIRED ARE A #2 PHILLIPS SCREWDRIVER, 5/32 HEX TOOL

(PROVIDED), AND A TECHNICIANS SLOTTED BLADE SCREWDRIVER (PROVIDED).

3) REMOVAL OF ANY FASTENERS OR OTHER NOTED PARTS WILL NEGATE THE PRODUCT WARRANTY.

Y

4) ALL FASTENERS ARE METRIC A2 STAINLESS STEEL.

5) USE ONLY TOP AND BOTTOM ANGLE OR VERTICAL ANGLES TO MOUNT SIGN DIRECTLY TO

SUPERSTRUCTURE. ALL INSTALLATIONS, SUPERSTRUCTURE DESIGNS, AND CONNECTIONS MUST

BE DESIGNED/APROVED BY A QUALIFIED STRUCTUAL ENGINEER. CALL ADAPTIVE MICRO SYSTEM

AT 1-800-558-7022 FOR STRUCTURAL ENGINEERING CONSULTANT CONTACT INFORMATION.

6) DUE TO STREGTH LIMITATION OF DISPLAY SUBSTRUCTURE, LARGER SIGNS WILL REQUIRE MULTIPLE

DISPLAY SECTIONS. DISPLAY SECTION SIZE WILL BE OPTIMIZED FOR PRODUCTION YIELD AND MAY

VARY WITH EACH SIGN. (SEE SHEET 3.)

7) DESIGN AND DIMENSIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

8) IF SIGN IS BUILT INTO AN ENCLOSED STRUCTURE, INTAKE AND EXHAUST AIR SHALL BE PROPERLY

VENTED TO PREVENT MIXING AND RECIRCULATION OF EXHAUST AIR WITH THE INTAKE AIR.

REV. DESCRIPTION ECO BY DATE

ARELEASED FOR PRODUCTION PER RFE 1566 -RDM 09/14/04

7840 North 86th Street

Milwaukee, WI 53224 USA

SHT

DOCUMENT NO.

C

SIZE

TITLE

REVISION

APPROVED BY

DESIGNED BY DATE

DATE

SCALE:

DIMENSIONS ARE INCH AND TOLERANCES ARE

AS FOLLOWS UNLESS OTHERWISE SPECIFIED

DATEDRAWN BY

ALPHA ECLIPSE 3600 MECHANICAL DETAILS

11800001-07

1:10 1of5

A

Released

STATUS:

±0.1

±0.02

±0.005

±1°

.X

.XX

.XXX

ANGLES

D

C

B

A

21

1

2

THIS DRAWING IS THE PROPERTY OF ADAPTIVE MICRO SYSTEMS LLC AND SHALL NOT BE DUPLICATED WITHOUT PERMISSION

SSL 9/4/03

SSL 9/4/03

6.68 WIREWAY BOX

11.0

LIGHT

SENSOR

LOCATION

2.5

14.0

1.0

1.5

2.8

3.5±.5

6.00

A

RIGHT SIDE VIEW

OPTIONAL:

DRILL HOLES

FOR POWER

AND DATA

ENTRY HERE.

WARNING!

LIFTING BRACKETS TO BE USED PER

INSTALLATION MANUAL ONLY.

LIFTING BRACKETS TO BE USED TO LIFT SIGN

ONLY. DO NOT LIFT SIGN IF IT IS STILL

ATTACHED TO THE SHIPPING CRATE.

LIFTING BRACKETS DESIGNED FOR

INITIAL INTALLATION ONLY AND

SHOULD BE REMOVED AFTER SIGN

IS INSTALLED.

CENTER OF

GRAVITY

RESERVED

FOR FIBER OPTIC

MODEM OPTION

**DO NOT DRILL IN

THIS AREA**

.25

3.00

DETAIL A

SCALE 1 : 4

DISPLAY DETAIL

SCALE 1:4

5/32 HEX TOOL ACCESS

HOLE. TURN HEX TOOL

(PROVIDED) 180º

COUNTERCLOCKWISE

TO REMOVE 8x8 DISPLAY.

.38 LOUVER

DEPTH

.08 CASE

THICKNESS

SECTION B-B

POLYCARBONATE

DISPLAY LOUVER

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

12

Sign mounting (sheet 2)

NOTCHED CLIP ANGLE

SUGGESTED FOR

LOCATING ONLY. SIGN

MUST BE SECURED IN

POSITION BY ADDITIONAL

WELD, BOLTS, OR RIVETS.

(SEE SHEET 1, NOTE 5.)

A

B

C

D

43

3

4

PYLON/POLE

SUPERSTRUCTURE

SIDE VIEW

(PYLON/POLE DETAIL)

BACKSIDE OPEN

TO MAXIMIZE AIR

FLOW/COOLING.

QTY/SIZE AND FASTENING

MEANS DETERMINED BY

SHEAR AND FLEXURAL

DESIGN CRITERIA.

(SEE SHEET 1, NOTE 5.)

ALLOW SUFFICIENT

AIR GAP FOR

ADEQUATE

AIRFLOW/

COOLING

WALL

SIDE VIEW

(WALL DETAIL)

SIDE HOLES

COVERED WITH

WATER TIGHT

HOLE PLUGS.

(SEE SHEET 1,

NOTE 3.)

TOP VIEW

BACKSIDE OPEN

TO MAXIMIZE AIR

FLOW/COOLING.

B

A

PYLON/POLE

SUPERSTRUCTURE.

(NOT PROVIDED

BY ADAPTIVE.

SEE SHEET 1, NOTE 5.)

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

13

7840 North 86th Street

Milwaukee, WI 53224 USA

SHT

DOCUMENT NO.

C

SIZE

TITLE

REVISION

APPROVED BY

DESIGNED BY DATE

DATE SCALE:

DIMENSIONS ARE INCH AND TOLERANCES ARE

AS FOLLOWS UNLESS OTHERWISE SPECIFIED

DATEDRAWN BY

ALPHA ECLIPSE 3600 MECHANICAL DETAILS

11800001-07

1:12 2of5

A

Released

STATUS:

±0.1

±0.02

±0.005

±1°

.X

.XX

.XXX

ANGLES

D

C

B

A

21

1

2

THIS DRAWING IS THE PROPERTY OF ADAPTIVE MICRO SYSTEMS LLC AND SHALL NOT BE DUPLICATED WITHOUT PERMISSION

SSL 9/4/03

SSL 9/4/03

Model Number Explanati on: SIGN

WEIGHT

SIGN SECTION MODEL NUMBER DIM "A"

(lbs) ¹DIM "B"

¹

3600 - 64 x 16 R/A/RGB AlphaEclipse 3600 -32x16 R/A/RGB 100 50.43 22.05

AlphaEclipse 3600 -48x16 R/A/RGB 150 72.48 22.05

AlphaEclipse 3600 -64x16 R/A/RGB 200 94.53 22.05

AlphaEclipse 3600 -80x16 R/A/RGB 250 116.58 22.05

AlphaEclipse 3600 -96x16 R/A/RGB 300 138.62 22.05

AlphaEclipse 3600 -112x16 R/A/RGB 350 160.67 22.05

AlphaEclipse 3600 -128x16 R/A/RGB 400 182.72 22.05

AlphaEclipse 3600 -144x16 R/A/RGB 450 204.76 22.05

AlphaEclipse 3600 -160x16 R/A/RGB 500 226.81 22.05

AlphaEclipse 3600 -176x16 R/A/RGB 550 248.86 22.05

AlphaEclipse 3600 -32x32 R/A/RGB 200 50.43 44.09

AlphaEclipse 3600 -48x32 R/A/RGB 300 72.48 44.09

AlphaEclipse 3600 -64x32 R/A/RGB 400 94.53 44.09

AlphaEclipse 3600 -80x32 R/A/RGB 500 116.58 44.09

AlphaEclipse 3600 -96x32 R/A/RGB 600 138.62 44.09

AlphaEclipse 3600 -112x32 R/A/RGB 700 160.67 44.09

AlphaEclipse 3600 -128x32 R/A/RGB 800 182.72 44.09

AlphaEclipse 3600 -144x32 R/A/RGB 900 204.76 44.09

AlphaEclipse 3600 -160x32 R/A/RGB 1000 226.81 44.09

AlphaEclipse 3600 -176x32 R/A/RGB 1100 248.86 44.09

AlphaEclipse 3600 -32x48 R/A/RGB 300 50.43 66.14

AlphaEclipse 3600 -48x48 R/A/RGB 450 72.48 66.14

AlphaEclipse 3600 -64x48 R/A/RGB 600 94.53 66.14

AlphaEclipse 3600 -80x48 R/A/RGB 750 116.58 66.14

AlphaEclipse 3600 -96x48 R/A/RGB 900 138.62 66.14

AlphaEclipse 3600 -112x48 R/A/RGB 1050 160.67 66.14

AlphaEclipse 3600 -128x48 R/A/RGB 1200 182.72 66.14

AlphaEclipse 3600 -144x48 R/A/RGB 1350 204.76 66.14

AlphaEclipse 3600 -160x48 R/A/RGB 1500 226.81 66.14

AlphaEclipse 3600 -176x48 R/A/RGB 1650 248.86 66.14

AlphaEclipse 3600 -32x64 R/A/RGB 400 50.43 88.19

AlphaEclipse 3600 -48x64 R/A/RGB 600 72.48 88.19

AlphaEclipse 3600 -64x64 R/A/RGB 800 94.53 88.19

AlphaEclipse 3600 -80x64 R/A/RGB 1000 116.58 88.19

AlphaEclipse 3600 -96x64 R/A/RGB 1200 138.62 88.19

AlphaEclipse 3600 -112x64 R/A/RGB 1400 160.67 88.19

AlphaEclipse 3600 -128x64 R/A/RGB 1600 182.72 88.19

AlphaEclipse 3600 -144x64 R/A/RGB 1800 204.76 88.19

AlphaEclipse 3600 -160x64 R/A/RGB 2000 226.81 88.19

AlphaEclipse 3600 -176x64 R/A/RGB 2200 248.86 88.19

AlphaEclipse 3600 -32x80 R/A/RGB 500 50.43 110.24

AlphaEclipse 3600 -48x80 R/A/RGB 750 72.48 110.24

AlphaEclipse 3600 -64x80 R/A/RGB 1000 94.53 110.24

AlphaEclipse 3600 -80x80 R/A/RGB 1250 116.58 110.24

AlphaEclipse 3600 -96x80 R/A/RGB 1500 138.62 110.24

AlphaEclipse 3600 -112x80 R/A/RGB 1750 160.67 110.24

AlphaEclipse 3600 -128x80 R/A/RGB 2000 182.72 110.24

AlphaEclipse 3600 -144x80 R/A/RGB 2250 204.76 110.24

AlphaEclipse 3600 -160x80 R/A/RGB 2500 226.81 110.24

AlphaEclipse 3600 -176x80 R/A/RGB 2750 248.86 110.24

Width (Pixel Columns)

x Height (Pixel Rows)

Series Designation

Red/Amber/RGB lamp

Notes:

1) Table represents standard single sign

sections only. Dimensions include either Left

or Right mounted wireway. Location to be

specified at time of order. See note 2 for signs

exceeding table values.

2) Contact Adaptive for information about

multiple sign sections which are available up

to 256x128.

3) All dimensions ±.50" ¹

4) Weight ±10%

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

14

Sign mounting (sheet 3)

NOTE: DESIGN AND DIMENSIONS ARE SUBJECT TO CHANGE. SEE SHEET 2 FOR ADDITIONAL NOTES.

A

B

C

D

43

3

4

2 X 2 SIGN SECTIONS SHOWN FOR ILLUSTRATION ONLY.

(MULTIPLE SIGN SECTIONS ARE REQUIRED FOR NON-STANDARD

SIZES ONLY. SEE SHEET 2 FOR STANDARD SIZES.)

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

15

7840 North 86th Street

Milwaukee, WI 53224 USA

SHT

DOCUMENT NO.

C

SIZE

TITLE

REVISION

APPROVED BY

DESIGNED BY DATE

DATE SCALE:

DIMENSIONS ARE INCH AND TOLERANCES ARE

AS FOLLOWS UNLESS OTHERWISE SPECIFIED

DATEDRAWN BY

ALPHA ECLIPSE 3600 MECHANICAL DETAILS

11800001-07

1:10 3of5

A

Released

STATUS:

±0.1

±0.02

±0.005

±1°

.X

.XX

.XXX

ANGLES

D

C

B

A

21

1

2

THIS DRAWING IS THE PROPERTY OF ADAPTIVE MICRO SYSTEMS LLC AND SHALL NOT BE DUPLICATED WITHOUT PERMISSION

SSL 9/4/03

SSL 9/4/03

BOLT TOGETHER FOR ALIGNMENT USING HOLES PROVIDED.

BOLTS MUST BE USED FOR ALIGNMENT ONLY

AND NOT AS A STRUCTURAL JOINT. (SEE SHEET 1, NOTE 5.)

GROMMET DETAIL

SCALE 1:2

IINSTALL GROMMETS (PROVIDED) BETWEEN SIGN SECTIONS.

ALL DATA AND POWER CABLES MUST BE ROUTED THROUGH

THE GROMMETS. POWER AND DATA CABLES MUST BE ROUTED

THROUGH SEPARATE HOLES. POWER AND FIBER OPTIC CAN BE

ROUTED THROUGH THE SAME HOLE IF NECESSARY.

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

16

Multiple section sign, vertical split assembly

NOTES:

1) REFER TO WIRING DOCUMENTATION

11800000-04, -05, -09, AND -22

FOR PCB CONNECTION DETAILS.

2) AC WIRING IS SPECIFIEC FOR EACH

"SPLIT SECTION" SIGN. REFER TO

THAT SIGNS'S AC WIRING DRAWING

(SEE WORK ORDER).

CUT ALONG

CENTER LINE

REMOVE

BACKING

DETAIL A

SCALE2:1

WIRE ID

AC

DTURBO

SECURE GROUND WITH

SCREW (61820017A) AND

WASHER (61230641).

SECURE CABLE TO INSIDE

WALL OF DISPLAY CUBE WITH

A TIE WRAP PAD (63101056)

AND A TIE WRAP (63100008).

REV. DES

C

A

B

C

D

RELEASED FOR PRODUC

T

A

43

2

3

4

DB25

FROM Ca

DB25

67010014A LOCTITE

SHOULD NOT COME

IN CONTACT WITH PLASTIC!

FROM Cb

DETAIL C

SCALE 1 : 6

THREAD HARDWARE, SCREW

(61820017A) AND WASHER

(61230641), FOR GROUND

CABLE. GROUND CABLE TO

BE CONNECTED IN FIELD.

H1

H2

Cb Ca

L1

SEE DETAIL A

Cb Ca

L1

H1

H2

SECURE EACH SET OF CABLES TO INSIDE WALL

OF DISPLAY CUBE WITH A TIE WRAP PAD (63101056)

AND A TIE WRAP (63100008). USE A TOTAL OF TWO

PADS AND TWO WRAPS TOTAL PER CUBE.

63020756 SPACER

FOLD OVER

ALONG

DASHED LINE

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

17

DETAIL B

SCALE 1 : 3

INSERT 2 GROMMETS

(63120013) PER SIGN ROW

INTO DOCUMENT BAG

WIRE ID

AC

DTURBO

7840 North 86th Street

Milwaukee, WI 53224 USA

SHT

DOCUMENT NO.

C

SIZE

TITLE

REVISION

APPROVED BY

DRAWN BY

12/2/03

REV. DESCRIPTION BY DATE

DATE

DATE SCALE:

DIMENSIONS ARE INCH AND TOLERANCES

SSL

ECO

DATE

CHECKED BY

ARE AS FOLLOWS UNLESS OTHERWISE SPECIFIED

P1180, MULTI-SECTION, VERTICAL SPLIT ASSEMBLY

11800000-15

1:8 1of1

A+

Released

STATUS:

±0.1

±0.02

±0.005

±1°

.X

.XX

.XXX

ANGLES

D

C

B

A

12/2/03

SSL

RELEASED FOR PRODUCTION

A

21

1

2

THIS DRAWING IS THE PROPERTY OF ADAPTIVE MICRO SYSTEMS LLC AND SHALL NOT BE DUPLICATED WITHOUT PERMISSION

CENTER LABEL 98118028 OVER

OPEN HOLES ON BOTH UNITS.

SEE DETAIL D.

DO NOT PREP SURFACE.

INSTALL PRIOR TO CRATING,

AFTER TESTING. FOR ALL CUBES. DETAIL D

SECTION

LOCATION

98118029. LABELED

RIGHTORLEFT.

FOR LINE 1 ONLY.

98008881, 98008882,

OR 98008883. SEE BOR.

L1

L1

63120007

Name Module

No. Name Wire No. Color Length Module

No. Na me

LxCb PCB1-P2 71120304 N/A 24" LxCb H1

AP-TB1-B1 BLK

AP-TB1-B2 WHT

AP-TB1-B3 GRN

LxCa PCB1-P1 71120302 N/A 62" LxCa H1

LxCb PCB2-P8 71240901 N/A 40" LxCb H2

LxCa PCB2-P7 71240901 N/A 40" LxCa H2

Ground LxCa GND2 71120116 N/A 13" LxCa H2

Name Module

No. Name Wire No. Color Length Module

No. Na me

LxCa PCB1-P1 71120304 N/A 24" LxCa H1

AP-TB1-A1 BLK

AP-TB1-A2 WHT

AP-TB1-A3 GRN

LxCb PCB1-P2 71120302 N/A 62" LxCb H1

LxCb PCB2-P8 71240901 N/A 40" LxCb H2

LxCa PCB2-P7 71240901 N/A 40" LxCa H2

Ground LxCa GND2 71120116 N/A 13" LxCa H2

SPLIT SECTION WIRING

Between Ca & Cb (Left Wireway)

From Via To

H1

LxCb H1

Dturbo

Between Ca & Cb (Right Wireway)

AC LxCb 71120301 50"

Dturbo

From Via To

AC LxCa 71120301 50" LxCa

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

18

Multiple section sign, horizontal split assembly

NOTES:

1) REFER TO WIRING DOCUMENTATION 11800000-04, -05, AND -09

FOR PCB CONNECTION DETAILS.

2) AC WIRING IS SPECIFIEC FOR EACH "SPLIT SECTION" SIGN. REFER

TO THAT SIGNS'S AC WIRING DRAWING (SEE WORK ORDER).

C4

DETAIL C

SCALE 1: 2

DETAIL D

SCALE 1: 8

REV.

A

B

C

D

REL

E

A

43

3

4

98118029

LABELED TOP

OR BOTTOM

98008881,

98008882, OR

98008883

SEE BOR

CENTER LABEL

98118028 OVER OPEN HOLES.

SEE DETAIL D. DO NOT PREP

SURFACE. INSTALL PRIOR TO

CRATING AFTER TESTING.

REMOVE

BACKING

FOLD OVER

ALONG

DASHED LINE

C2 C1

Wy

C3

C1 C2 C3 C4

Wx

TIE WRAP DTURBO TO

ANCHOR, 63100029.

SEE DETAIL A FOR

LABELING.

Wx

Wy

SECURE GROUND WITH

NUT (61620025). SECURE

CABLE TO INSIDE WALL OF

DISPLAY CUBE WITH A TIE

WRAP PAD (63101056)AND

A TIE WRAP (63100008).

THREAD NUT (61620025),

FOR GROUND CABLE.

GROUND CABLE TO

BE CONNECTED IN FIELD.

CUT ALONG

CENTER LINE

DB25

FROM Ca

APPLY LABEL

9800760x

DB25

67010014A LOCTITE SHOULD NOT

COME IN CONTACT WITH PLASTIC!

FROM Cb

APPLY LABEL

9800760x

DETAIL A

SCALE 1: 2

63020756 SPACER

February 14, 2006 Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B)

19

DETAIL C

SCALE 1: 2

DETAIL B

SCALE 1: 8

7840 North 86th Street

Milwaukee, WI 53224 USA

SHT

DOCUMENT NO.

C

SIZE

TITLE

REVISION

APPROVED BY

DRAWN BY

12/2/03

REV. DESCRIPTION BY DATE

DATE

DATE SCALE:

DIMENSIONS ARE INCH AND TOLERANCES

SSL

ECO

DATE

CHECKED BY

ARE AS FOLLOWS UNLESS OTHERWISE SPECIFIED

P1180, MULTI-SECTION, HORIZONTAL SPLIT ASSEMBLY

11800000-16

1:8 1of1

A

Released

STATUS:

±0.1

±0.02

±0.005

±1°

.X

.XX

.XXX

ANGLES

D

C

B

A

12/2/03

SSL

RELEASED FOR PRODUCTION

A

21

1

2

THIS DRAWING IS THE PROPERTY OF ADAPTIVE MICRO SYSTEMS LLC AND SHALL NOT BE DUPLICATED WITHOUT PERMISSION

98118029

LABELED TOP

OR BOTTOM

8

1,

8

2, OR

8

3

R

CENTER LABEL

98118028 OVER OPEN HOLES.

SEE DETAIL D. DO NOT PREP

SURFACE. INSTALL PRIOR TO

CRATING AFTER TESTING.

R

BO TO

0

0029.

O

R

SECURE GROUND WITH

NUT (61620025). SECURE

CABLE TO INSIDE WALL OF

DISPLAY CUBE WITH A TIE

WRAP PAD (63101056)AND

A TIE WRAP (63100008).

THREAD NUT (61620025),

FOR GROUND CABLE.

GROUND CABLE TO

BE CONNECTED IN FIELD.

DB25

FROM Ca

A

BEL

x

A

IL A

L

E1:2

63020756 SPACER

Name Module No. Name Wire No. Color Length Module No. Name

L1C2 PCB6-P1 71240901 N/A 40" L1C1 PCB2-P8 98007601

L1C2 PCB6-P2 71241802 N/A 114" L2C1 PCB2-P8 98007602

L1C2 PCB6-P3 71241803 N/A 138" L3C1 PCB2-P8 98007603

L1C2 PCB6-P4 71241805 N/A 162" L4C1 PCB2-P8 98007604

L1C2 PCB6-P5 71241805 N/A 162" L4Wx H3 98007605

L1C2 PCB6-P6 71241805 N/A 162" L4Wx H3 98007606

L1C2 PCB6-P7 71241805 N/A 162" L4Wx H3 98007607

L1C2 PCB6-P8 71241805 N/A 162" L4Wx H3 98007608

L5Wy H3 71240901 N/A 40" L5C1 PCB2-P8 98007605

L5Wy H3 71240902 N/A 90" L6C1 PCB2-P8 98007606

L5Wy H3 71240902 N/A 90" L7C1 PCB2-P8 98007607

L5Wy H3 71241802 N/A 114" L8C1 PCB2-P8 98007608

L1C2 PCB6-P1 71240901 N/A 40" L1C1 PCB2-P8 98007601

L1C2 PCB6-P2 71241802 N/A 114" L2C1 PCB2-P8 98007602

L1C2 PCB6-P3 71241803 N/A 138" L3C1 PCB2-P8 98007603

L1C2 PCB6-P4 71241805 N/A 162" L4C1 PCB2-P8 98007604

L1C2 PCB6-P5 71241805 N/A 162" L4Wx H3 98007605

L1C2 PCB6-P6 71241805 N/A 162" L4Wx H3 98007606

L1C2 PCB6-P7 71241805 N/A 162" L4Wx H3 98007607

L5Wy H3 71240901 N/A 40" L5C1 PCB2-P8 98007605

L5Wy H3 71240902 N/A 90" L6C1 PCB2-P8 98007606

L5Wy H3 71240902 N/A 90" L7C1 PCB2-P8 98007607

L1C2 PCB6-P1 71240901 N/A 40" L1C1 PCB2-P8 98007601

L1C2 PCB6-P2 71241802 N/A 114" L2C1 PCB2-P8 98007602

L1C2 PCB6-P3 71241803 N/A 138" L3C1 PCB2-P8 98007603

L1C2 PCB6-P4 71241803 N/A 138" L3Wx H3 98007604

L1C2 PCB6-P5 71241803 N/A 138" L3Wx H3 98007605

L1C2 PCB6-P6 71241803 N/A 138" L3Wx H3 98007606

L4Wy H3 71240901 N/A 40" L4C1 PCB2-P8 98007604

L4Wy H3 71240902 N/A 90" L5C1 PCB2-P8 98007605

L4Wy H3 71240902 N/A 90" L6C1 PCB2-P8 98007606

Name Module No. Name Wire No. Color Length Module No. Name

L1C2 PCB6-P1 71241810 N/A 52" L1C1 PCB2-P8 98007601

L1C2 PCB6-P2 71240902 N/A 90" L2C1 PCB2-P8 98007602

L1C2 PCB6-P3 71241802 N/A 114" L3C1 PCB2-P8 98007603

L1C2 PCB6-P4 71241803 N/A 138" L4C1 PCB2-P8 98007604

L1C2 PCB6-P5 71241803 N/A 138" L4Wx H3 98007605

L1C2 PCB6-P6 71241803 N/A 138" L4Wx H3 98007606

L1C2 PCB6-P7 71241803 N/A 138" L4Wx H3 98007607

L1C2 PCB6-P8 71241803 N/A 138" L4Wx H3 98007608

L5Wy H3 71240901 N/A 40" L5C1 PCB2-P8 98007605

L5Wy H3 71240902 N/A 90" L6C1 PCB2-P8 98007606

L5Wy H3 71240902 N/A 90" L7C1 PCB2-P8 98007607

L5Wy H3 71241802 N/A 114" L8C1 PCB2-P8 98007608

L1C2 PCB6-P1 71241810 N/A 52" L1C1 PCB2-P8 98007601

L1C2 PCB6-P2 71240902 N/A 90" L2C1 PCB2-P8 98007602

L1C2 PCB6-P3 71241802 N/A 114" L3C1 PCB2-P8 98007603

L1C2 PCB6-P4 71241803 N/A 138" L4C1 PCB2-P8 98007604

L1C2 PCB6-P5 71241803 N/A 138" L4Wx H3 98007605

L1C2 PCB6-P6 71241803 N/A 138" L4Wx H3 98007606

L1C2 PCB6-P7 71241803 N/A 138" L4Wx H3 98007607

L5Wy H3 71240901 N/A 40" L5C1 PCB2-P8 98007605

L5Wy H3 71240902 N/A 90" L6C1 PCB2-P8 98007606

L5Wy H3 71240902 N/A 90" L7C1 PCB2-P8 98007607

L1C2 PCB6-P1 71241810 N/A 52" L1C1 PCB2-P8 98007601

L1C2 PCB6-P2 71240902 N/A 90" L2C1 PCB2-P8 98007602

L1C2 PCB6-P3 71241802 N/A 114" L3C1 PCB2-P8 98007603

L1C2 PCB6-P4 71241803 N/A 138" L3Wx H3 98007604

L1C2 PCB6-P5 71241803 N/A 138" L3Wx H3 98007605

L1C2 PCB6-P6 71241803 N/A 138" L3Wx H3 98007606

L4Wy H3 71240901 N/A 40" L4C1 PCB2-P8 98007604

L4Wy H3 71240902 N/A 90" L5C1 PCB2-P8 98007605

L4Wy H3 71240902 N/A 90" L6C1 PCB2-P8 98007606

Dturbo1(128

pixel total

height)

Dturbo1(112

pixel total

height)

Dturbo1(96

pixel total

height)

1 - NOTE: USE TOTAL SIGN HEIGHT.

From Via To Label (see

Deta il A)

Dturbo1(128

pixel total

height)

Dturbo1(112

pixel total

height)

Dturbo1(96

pixel total

height)

Between Wx & Wy (Left Wireway)

SPLIT SECTION WIRING

Between Wx & Wy (Right Wireway)

From Via To Label (see

Deta il A)

Installer Instructions for AlphaEclipse 3600 Signs (Form no. 9711-8028B) February 14, 2006

20

Multiple section sign, vertical/horizontal split (sheet 1 of 2)

NOTES:

1) REFER TO WIRING DOCUMENTATION 11800000-04, -05, AND -09 FOR PCB CONNECTION DETAILS.

2) AC WIRING IS SPECIFIEC FOR EACH "SPLIT SECTION" SIGN. REFER TO THAT SIGNS'S AC WIRING

DRAWING (SEE WORK ORDER).

WIRE ID

AC

DTURBO

REV.

A

B

C

D

RELEASED F

O

A

43

3

4

H1

H2

Cb Ca

SEE DETAIL A

Wy

Wx

H1

H2

Cb Ca

Wy

SEE DETAIL A

Wx

SEE DETAIL A

H2

H1

Other manuals for AlphaEclipse PureColor 3600

1

Table of contents

Other Adaptive Monitor manuals