ADCMT 12701A User manual

©2009 ADC CORPORATION First printing February 28, 2009

All rights reserved. Printed in Japan

12701A

Test Fixture

OPERATION MANUAL

Manual Number FOE-00000045A00

12701ATest Fixture Operation Manual

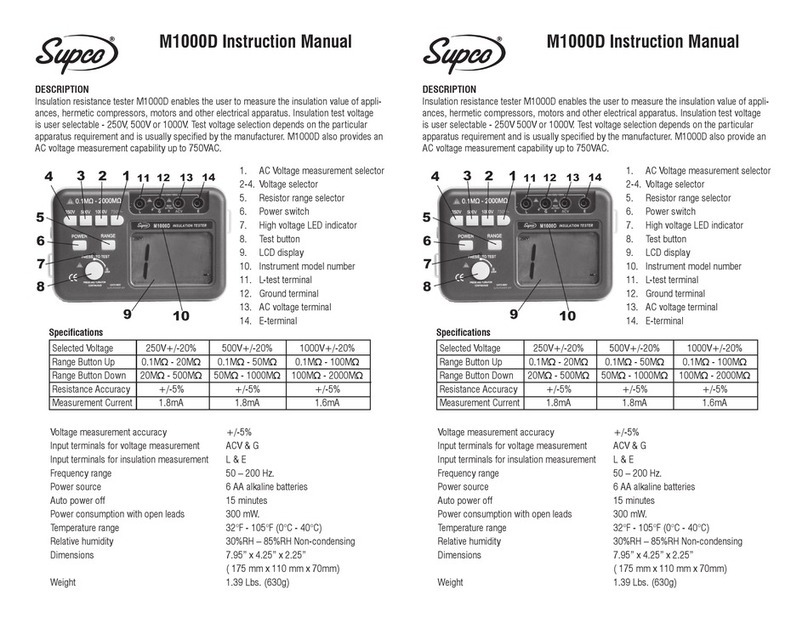

Precautions for Handling 12701A

To operate the 12701A correctly and safety, please observe the following instructions. Note that ADC Cor-

poration bears absolutely no responsibility for the result of operations caused due to incorrect or inappro-

priate use of this instrument.

Please observe the following instructions to prevent danger such as electric shock:

(1) Always use the safety mechanism of the 12701A that allows and stops voltage application by opening

and closing the cover. (Connect the LID SIGNAL of the 12701A and the INTERLOCK or LID SIG-

NAL of the measuring instrument using a cable.

(2) Ground the 12701Abefore use.

(3) Do not touch the test box while voltage is being applied.

When the HI OUTPUT of the 6245, 6246 (Bch), 6242 or 6244 and the FORCE/SENSE 1 to 8 on the

rear panel of the 12701A are connected, and the relay terminal DG 1 to 8 and the TEST BOX GUARD

are connected, the test box and DG will become the same potential, and the maximum voltage of the

HI OUTPUT may occur on the test box.

(4) When placing or removing DUT, check chat no voltage applied to the 12701A.

(5) Close the cover during measurement to perform accurate measurement.

The cover has a shielded, light-shielded and safety structure.

(6) Watch out for vibration to perform accurate measurement.

The vibration of a cable or fixture during low current (1 pA or lower) measurement may cause varia-

tion in measured values.

(7) Check that the voltage or current applied to the 12701A is within the maximum input voltage or cur-

rent range.

Note that the operating temperature range varies depending on the maximum input current.

(8) Use the test box A04509with the average current value for a second of 1 A or less. The maximum in-

put current value for DC is 1 A. For pulse, the average current value for a second that is obtained by

the following formula should be 1A or less.

Average current = Input current value (up to 20 A peak) × Pulse width / Pulse cycle

e.g. When the input current value is 20 A and the pulse cycle is 1 s, the pulse width should be 50 ms

or less. When the input current value is 20 A and the pulse cycle is 10 ms, the pulse width should

be 0.5 ms or less.

(9) When connecting a measuring instrument with the 12701A

zFor how to handle the measuring instrument, refer to its operation manuals.

zGround the measuring instrument before use.

zWhen using the R8340 or 8340A as measuring instrument, short-circuit the LO and the GND.

Preface*

12701ATest Fixture Operation Manual

Preface

This manual describes the functions of the 12701A test fixture, how to set up and how to measure.

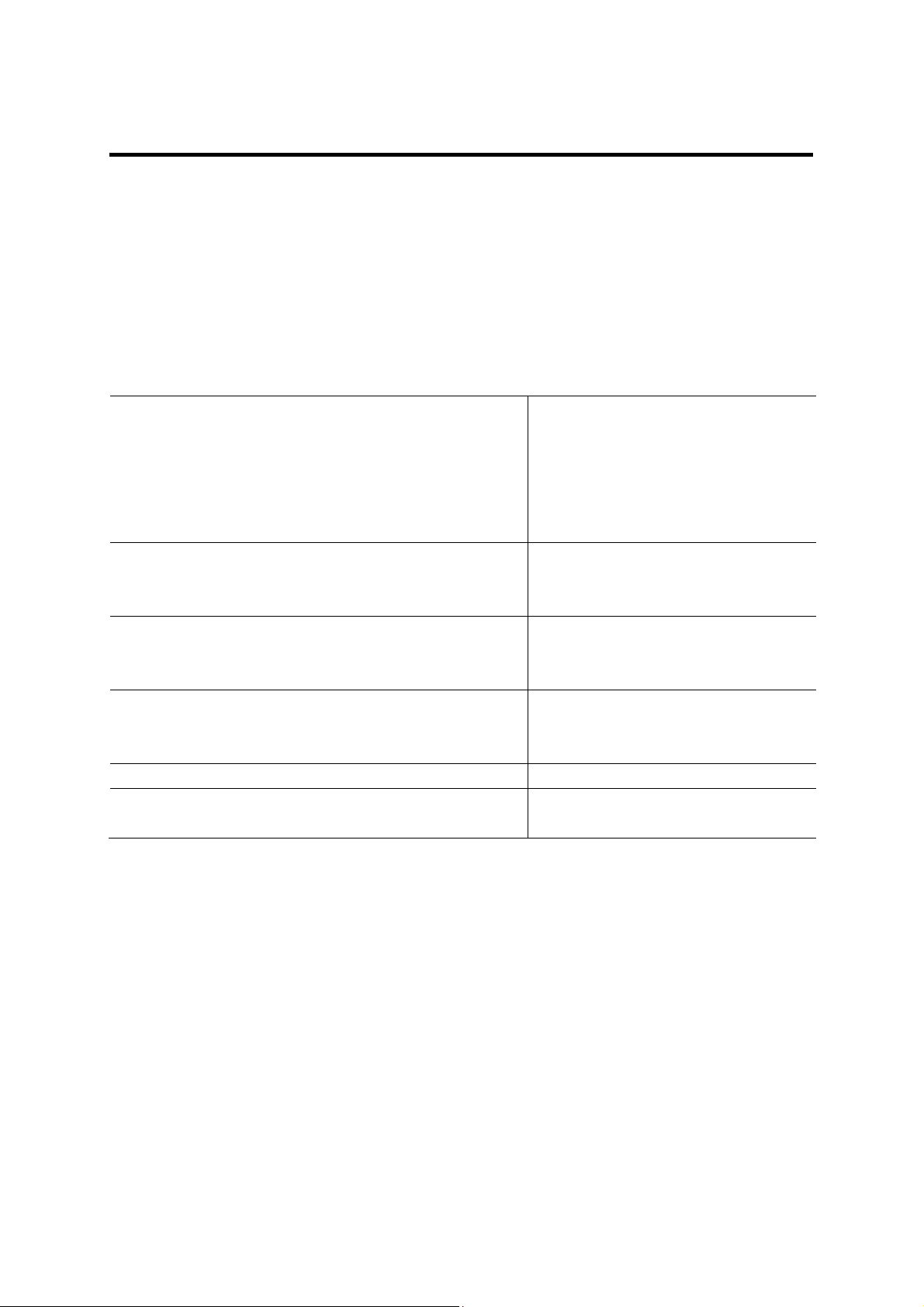

zManual Configuration

This manual consists of the following chapters:

1. Introduction

(1) Product Overview

(2) Supplied Accessories and Optional Accessories

(3) Environmental Conditions

(4) Cleaning, Storage and Transportation of the

Product

Be sure to read through this chapter

before use.

2. Panel Description

(1) Relay Terminals

(2) Rear Panel

Describes the name and function of

each part on the panel.

3. Measurement Examples

(1) Resistance Measurement

(2) Current Measurement

Describes how to use the 12701A.

4. Functional Description

(1) Driving Guard Function

(2) Internal Connection

Describes the driving guard function

and the internal connection.

5. Specifications Describes the specifications.

Appendix 1. Test Box (Socket) Describes the sockets to be mounted on

the 12701A.

C-1*

12701ATest Fixture Operation Manual

Table of Contents

1. Introduction.............................................................................................................................1-1

1.1 Product Overview.........................................................................................................................1-1

1.2 Supplied Accessories....................................................................................................................1-2

1.3 Optional Accessories ....................................................................................................................1-3

1.4 Environmental Conditions............................................................................................................1-5

1.5 Cleaning, Storage and Transportation of the Product...................................................................1-6

1.5.1. Cleaning................................................................................................................................1-6

1.5.2. Storage ..................................................................................................................................1-6

1.5.3. Transportation.......................................................................................................................1-6

2. Panel Descriptions................................................................................................................2-1

2.1 Relay Terminals............................................................................................................................2-1

2.2 Rear Panel.....................................................................................................................................2-3

3. Measurement Examples.....................................................................................................3-1

3.1 High Resistance Measurement .....................................................................................................3-1

3.2 Resistance Measurement ..............................................................................................................3-6

3.3 Diode Leak Current Measurement..............................................................................................3-12

3.4 Diode Leak Current Measurement..............................................................................................3-17

4. Functional Description.......................................................................................................4-1

4.1 Driving Guard Function................................................................................................................4-1

4.2 Internal Connection ......................................................................................................................4-3

5. Specifications.........................................................................................................................5-1

5.1 Electrical Specifications ...............................................................................................................5-1

5.2 General Specifications..................................................................................................................5-2

Appendix.........................................................................................................................................A-1

A.1 Test Box (Socket)..................................................................................................................................................A-1

F-1*

12701ATest Fixture Operation Manual

List of Illustrations

No. Title Page

2-1 Relay Terminals …………………………………………………………... 2-1

2-2 Rear Panel …………………………………………………...……………. 2-3

3-1 Connecting the 12701A with the 8340A …………………………………. 3-2

3-2 Installing the Test Box…………………………………………………….. 3-3

3-3 Connecting the Relay Terminals with the Test Box ……………………… 3-4

3-4 12701A and 8340A Connection Diagram ………………………………… 3-5

3-5 Connecting the 12701A with the 6245 …………………………………… 3-7

3-6 Connecting the Relay Terminals with the Test Box ……………………… 3-9

3-7 12701A and 6245 Connection Diagram (4-wire Connection) ……………. 3-10

3-8 Connecting the 12701A with the 6245 …………………………………… 3-13

3-9 Connecting the Relay Terminals with the Test Box ……………………… 3-14

3-10 12701A and 6245 Connection Diagram (2-wire Connection) ……………. 3-15

3-11 Connecting the 12701A with the 8252 …………………………………… 3-17

3-12 Connecting the Relay Terminals and the Test Box ……………………….. 3-19

3-13 12701A and 8252 Connection Diagram ………………………………….. 3-20

4-1 Driving Guard Function …………………………………………………... 4-1

4-2 Block Diagram ……………………………………………………………. 4-3

T-1*

12701ATest Fixture Operation Manual

List of Tables

No. Title Page

1-1 Supplied Accessories ………………………………………………………. 2-1

1-1

12701ATest Fixture Operation Manual

1.1 Product Overview

1. Introduction

This chapter describes the following items:

(1) Product overview

(2) Supplied accessories and optional accessories

(3) Environmental conditions

(4) Cleaning, storage and transportation of the product

1.1 Product Overview

The 12701A is a test head section which connects to a measuring instrument such as an

electrometer (8240/8340A/8252) or DC voltage/current source monitor (6243/6245/6246) to

perform DC characteristics tests of semiconductors and other electronic components.

It allows easy connection of DUTs to a measuring instrument and offers stable measurement

using shield effect, isolation and light shield.

The following features are included:

zDouble guard shielded structure

zShielded cables used as internal connection leads

zLow current measurement down to 10-14 A

zHigh current measurement up to 20 A

zOutputs an open/close signal for safety measurement

zSafety design using a safety socket

zA variety of accessories that accommodate different types of DUTs

1-2

12701ATest Fixture Operation Manual

1.2 Supplied Accessories

1.2 SuppliedAccessories

The following table shows the accessories supplied with the 12701A. If there is any damage or

defect, please contact ADC Corporation or your sales representative. Quote the model name of

the accessory when ordering.

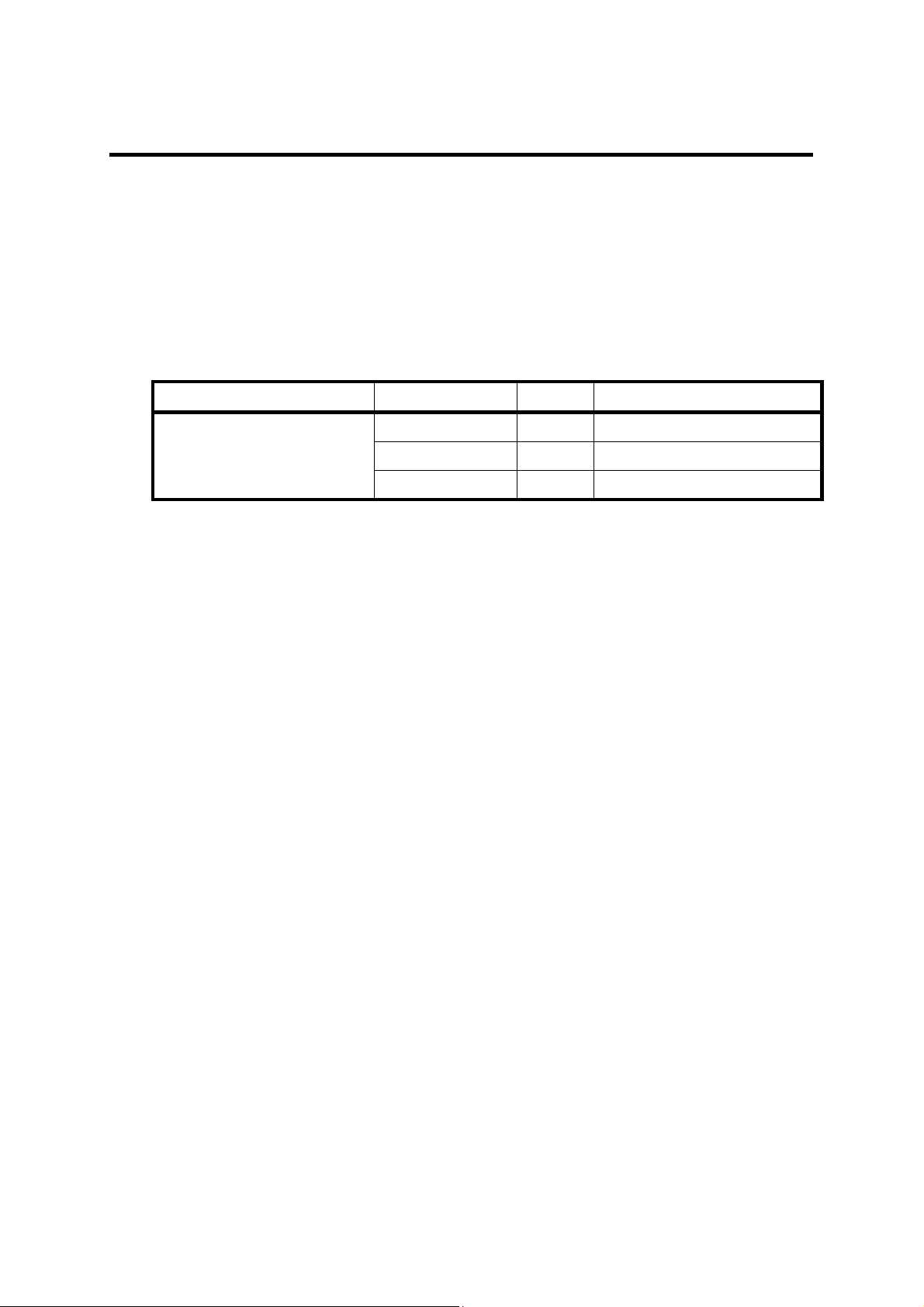

Table 1-1 Supplied Accessories

Name Model Quantity Remarks

Connection lead A01214-20 3 2 dia.-1 dia.

A01215-15 3 2 dia.-2 dia.

A01228-15 3 2x2 dia.-1 dia. coaxial cable

1-3

12701ATest Fixture Operation Manual

1.3 Optional Accessories

1.3 OptionalAccessories

(1) Test boxes

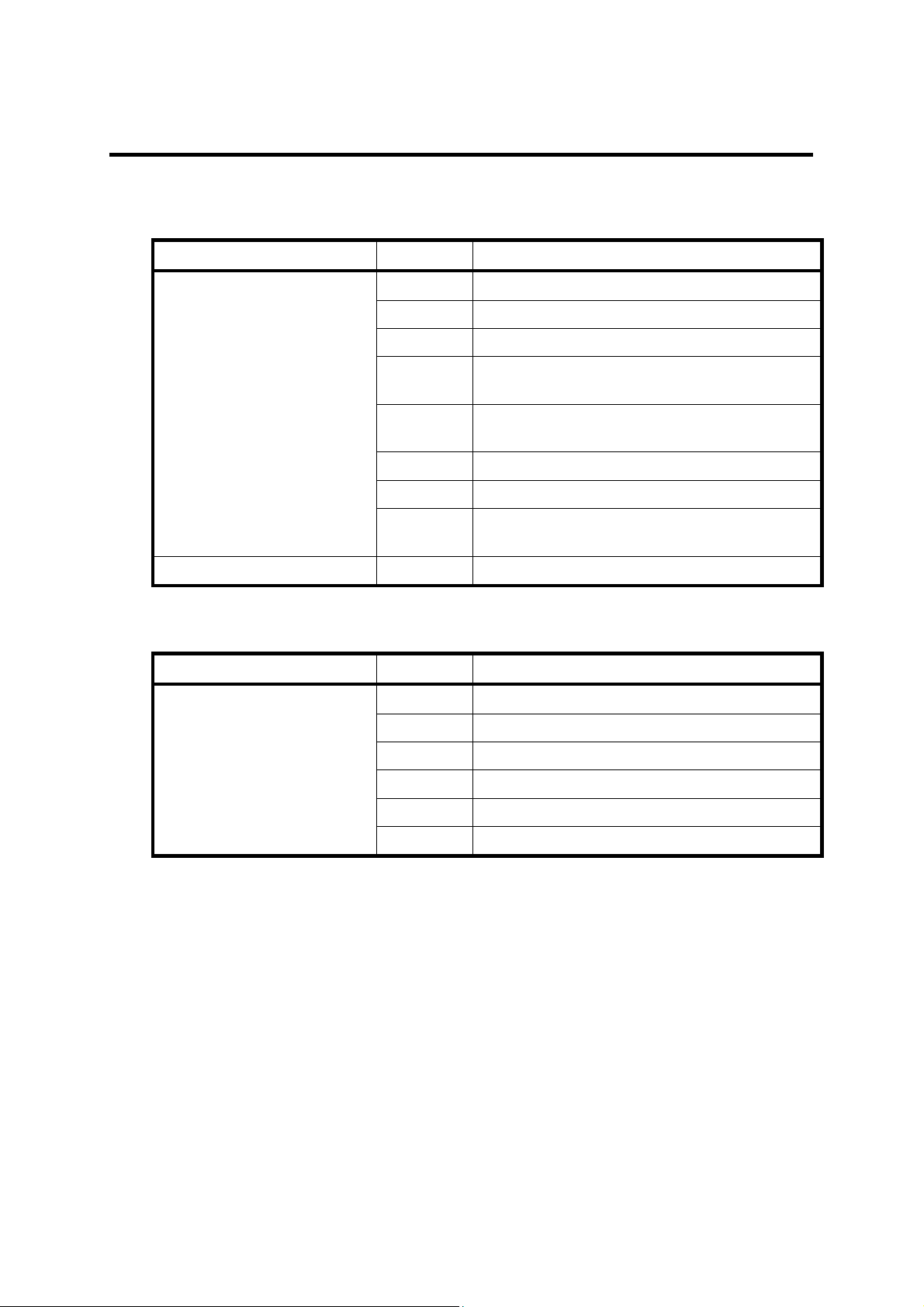

Name Model Remarks

Diode test box A04501 Axial lead-type measurement socket

Applicable to diodes and resistors

Insulating board A04506 Teflon board

Teflon area: 140 x 90 mm

Power transistor test box A04509 TO package 3-pin socket

Applicable to power devices

1-4

12701ATest Fixture Operation Manual

1.3 Optional Accessories

(2) Connection leads and mini hook

Name Model Remarks

Connection lead A01214-20 2 dia.-1 dia. connection lead

A01215-15 2 dia.-2 dia. connection lead

A01216-15 1 dia.-1 dia. connection lead

A01217-25 2 dia.-mini socket connection lead

(with mini hook)

A01218-20 1 dia.-mini socket connection lead

(with mini hook)

A01228-15 2x2 dia.-1 dia. coaxial cable connection lead

A01229-15 2x2 dia.-1x2 dia. coaxial cable connection lead

A01287-15 2 dia.-2 dia. connection lead

(for high current up to 10A)

Mini hook A04701-12

(3) Connection cables to a measuring instrument

Name Model Remarks

Connection cable A01009 TRIAX-TRIAX cable

A01036 BNC-BNC cable

A01239 TRIAX-TRIAX cable for high voltage

A01011 TRIAX-BNC conversion cable

A01038 Banana-banana 4-wire shielded cable

A01240 Banana-banana cable with cover

1-5

12701ATest Fixture Operation Manual

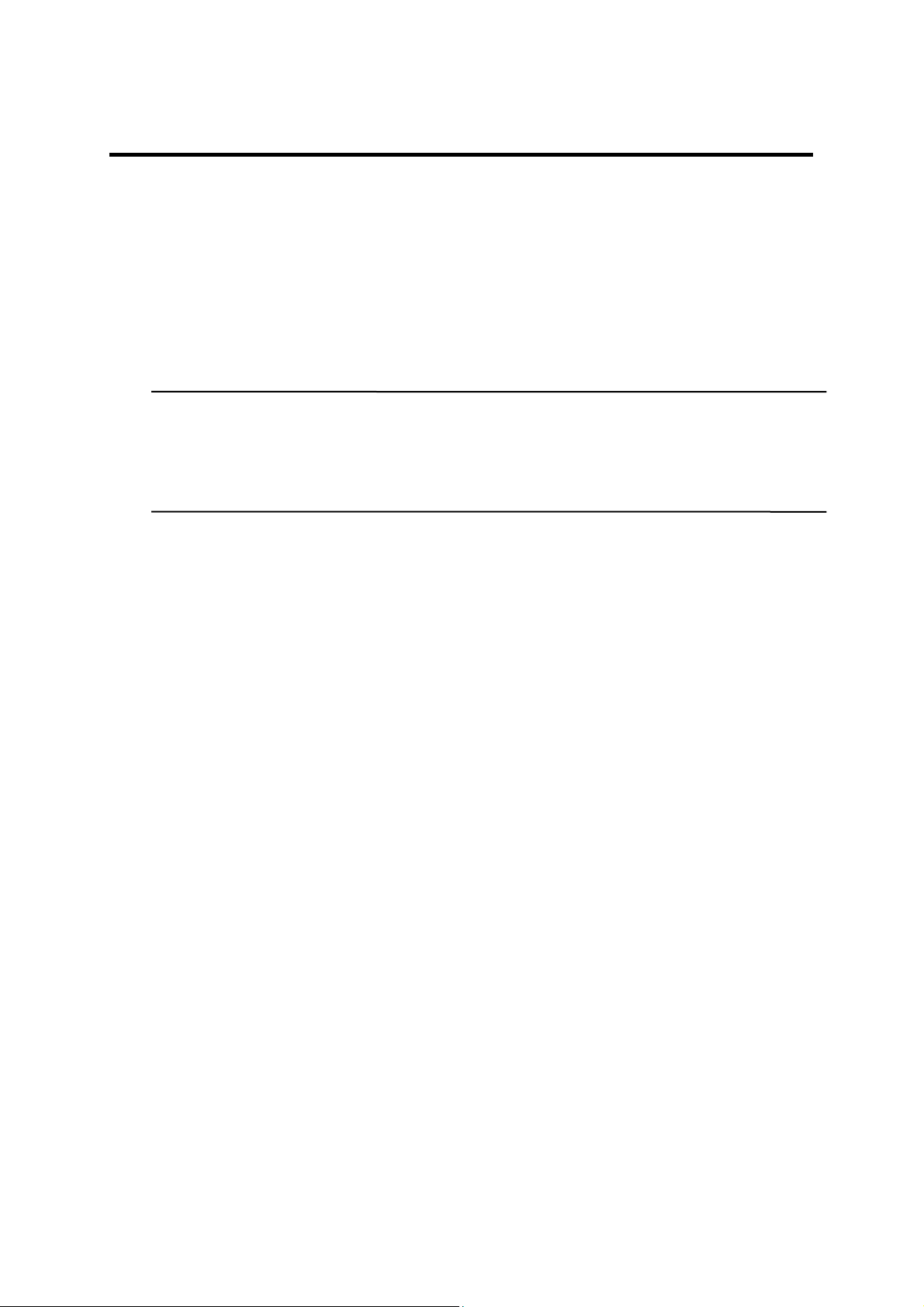

1.4 Environmental Conditions

1.4 Environmental Conditions

Use the 12701A under the following conditions:

zOperating temperature range:

Maximum input current Operating temperature range

0 A to 5 A -20°C to + 75°C

5.1 A to 10 A -20°C to + 70°C

10.1 A to 20 A -20°C to + 65°C

zRelative humidity: 85% or less with no condensation

zAn area free from corrosive gas

zAn area away from direct sunlight

zA dust-free area

zAn area free from vibrations

zA low noise area

1-6

12701ATest Fixture Operation Manual

1.5 Cleaning, Storage and Transportation of the Product

1.5 Cleaning, Storage and Transportation of the Product

1.5.1. Cleaning

Wipe dirt off the 12701A with a soft cloth or small brush as needed. Use the brush when

cleaning around the connectors on the rear panel. When the dirt is hard to remove, use a soft

cloth moistened with a neutral detergent diluted with water.

CAUTION:

1. Do not allow water inside this product

2. Avoid using an organic solvent such as benzene, toluene, xylene or acetone because it

degrades the plastic parts.

3. Avoid using a cleanser.

1.5.2. Storage

Store the 12701A at a temperature ranging from -25°C to + 80°C in an area away from dust

and direct sunlight. When storing it for an extended period (90 days or longer), put the 12701A

in a moisture-proof bag together with desiccants.

1.5.3. Transportation

To transport the 12701A, use the original box that it came in. If the box is not available any

longer, pack it in accordance with the following guidelines.

zPrepare a cardboard box with dimensions that are larger than the external dimensions of

the 12701A by 15 cm or more to allow for cushioning material.

zWrap the 12701A with a protective sheet.

zLine the box with cushioning material to protect all sides of the 12701A.

zClose the box with industrial staples or packing tape.

When sending the 12701A to an ADC CORPORATION sales representative for service or

repairs, attach a label stating the following items.

zCompany name and address

zContact person

zSerial number (on the rear panel)

zType of service required

2-1

12701ATest Fixture Operation Manual

2.1 Relay Terminals

2. Panel Descriptions

This chapter describes the following items.

(1) Relay terminal

(2) Rear panel

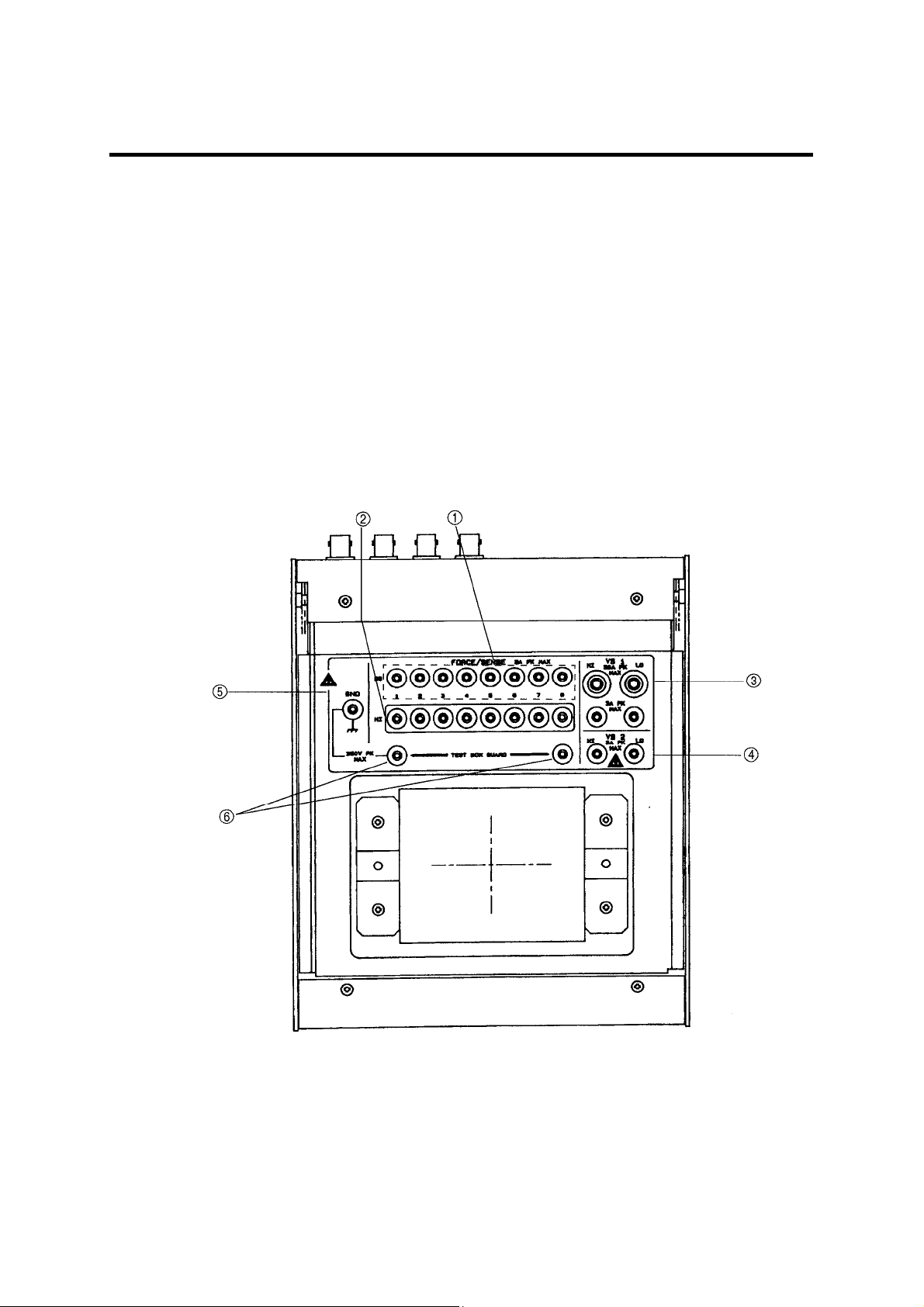

2.1 Relay Terminals

The relay terminals connect to the test box (socket) using the connection leads. The relay

terminals connect with the terminals on the rear panel internally.

Figure 2-1 Relay Terminals

2-2

12701ATest Fixture Operation Manual

2.1 Relay Terminals

1. FORCE/SENSE DG 1 to 8

Connect with the inner shields of the FORCE/SENSE DG 1 to 8 on the rear panel

respectively.

2. FORCE/SENSE HI 1 to 8

Connect with the core wires of the FORCE/SENSE DG 1 to 8 on the rear panel

respectively.

3. VS1 HI and LO

Connect with the VS1 HI and LO on the rear panel respectively. Either 4 dia. or 2 dia.

connection lead can be selected depending on the output current and the test box type.

4. VS2-HI and LO

Connect with the VS2-HI and LO on the rear panel respectively.

5. GND

Connects with the GND on the rear panel. Its potential is equal to those of the outer shields

of the case and the triaxial connectors.

6. TEST BOX GUARD

Connects with the mount of the test box (socket). (See Figure 3-2) Ensure to connect it to

the GND or DG. For how to connect it, refer to Chapter 3, "Measurement Examples."

Applying voltage to the connectors on the rear panel will generate voltage on the

relay terminals equally.

Always disconnect the relay terminals from the test box while applying voltage.

Treat the terminals with great care as follows:

zMaximum 350 V voltage may occur on the FORCE/SENSE DG and HI 1 to 8.

zMaximum 300 V voltage may occur between VS1 HI and LO.

zVS1 HI 4 dia. and 2 dia. are connected. In the same way, VS1 LO 4 dia. and 2

dia. are connected.

zMaximum 1000 V voltage may occur between VS2 HI and LO.

WARNING!

Table of contents

Popular Test Equipment manuals by other brands

Tietzsch

Tietzsch ProfiSafe LSP 4L User instructions

OPTICOM

OPTICOM LCDI-56T - DATASHEET 3 datasheet

Bante Instruments

Bante Instruments PHscan30L instruction manual

SIGLENT

SIGLENT SDS2000X Plus Series quick start

Gardco

Gardco PG-1 user manual

Commercial Electric

Commercial Electric DUALCHECK CE-VD7504GFI Use and care guide