ADD-A-BATHROOM Pty Ltd. Specifications and details subject to alteration without notice. (c) 2019

No warranty is expressed or implied by the publication or use of this guide. Page 4 of 8

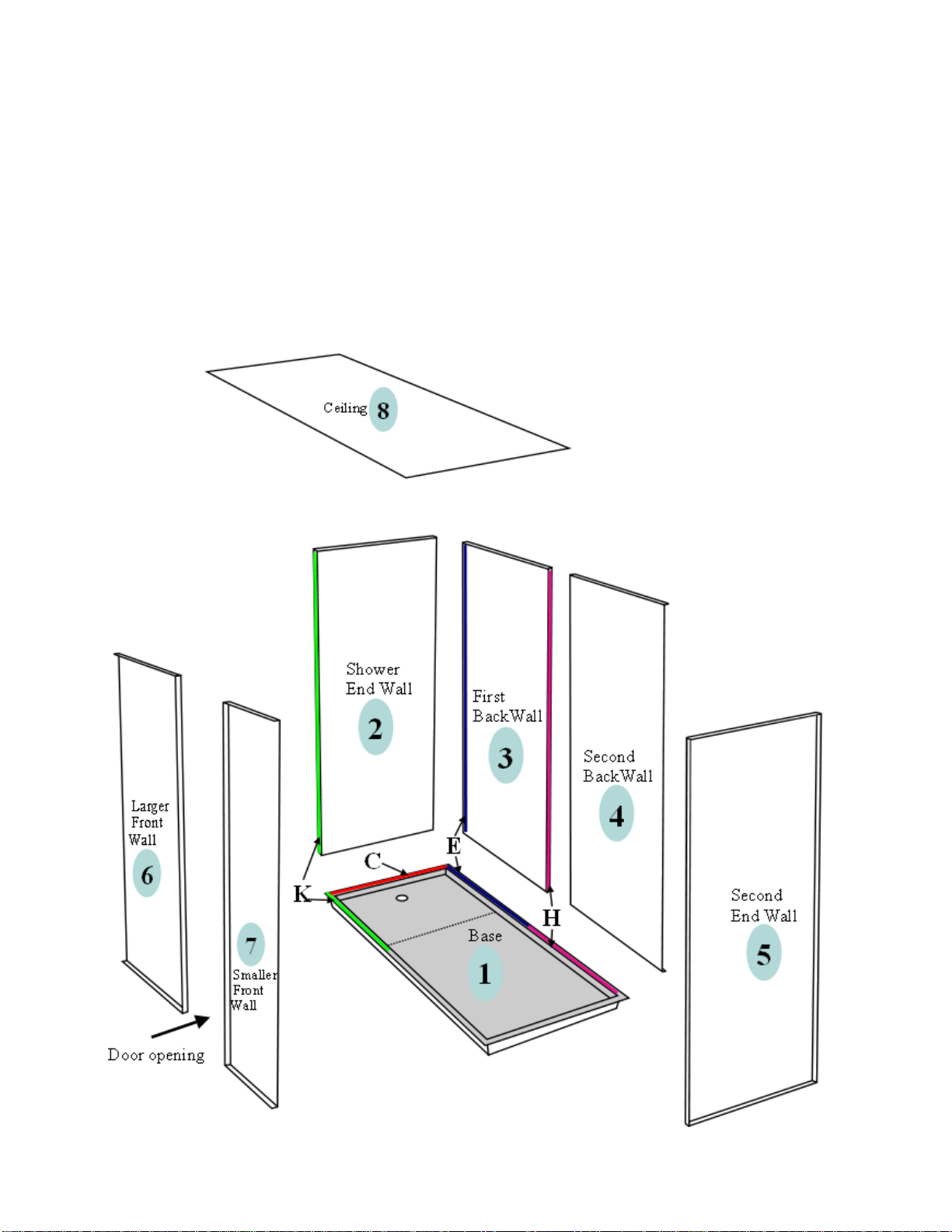

Installation:

(Prior to installation it is important to perform the stipulated ‘dry run’ to ensure correct placement.)

•Prepare the installation site, ensure the substrate is solid and level, any items that may interfere with the

bathroom have been removed (floor coverings, unwanted power points, skirtings, cornices etc.).

•Have your plumber pre-install the sewer pipe-work and bring in any hot and cold water pipes as required.

•It may be beneficial to also have your electrician pre-install wiring prior to the bathroom’s installation.

•Manoeuvre the assembled bathroom into its desired position and confirm sewer pipe, hot and cold plumbing,

electrical, etc. are all correctly placed and align; relocate the unit or plumbing as necessary and recheck. Ensure

that the bathroom sits level. (The moulded falls in the floor will then allow adequate drainage to the waste).

•Mark the floor around the edge of bathroom (to indicate area required for bedding screed). Remove bathroom.

•Should a window be required, carefully measure and mark its placement on the inside of the bathroom walls,

check, and then drill a 6mm hole in each corner. With a suitable disc (thin carborundum or diamond) attached

to an angle grinder and from inside the bathroom, carefully cut between the holes, along the marked lines.

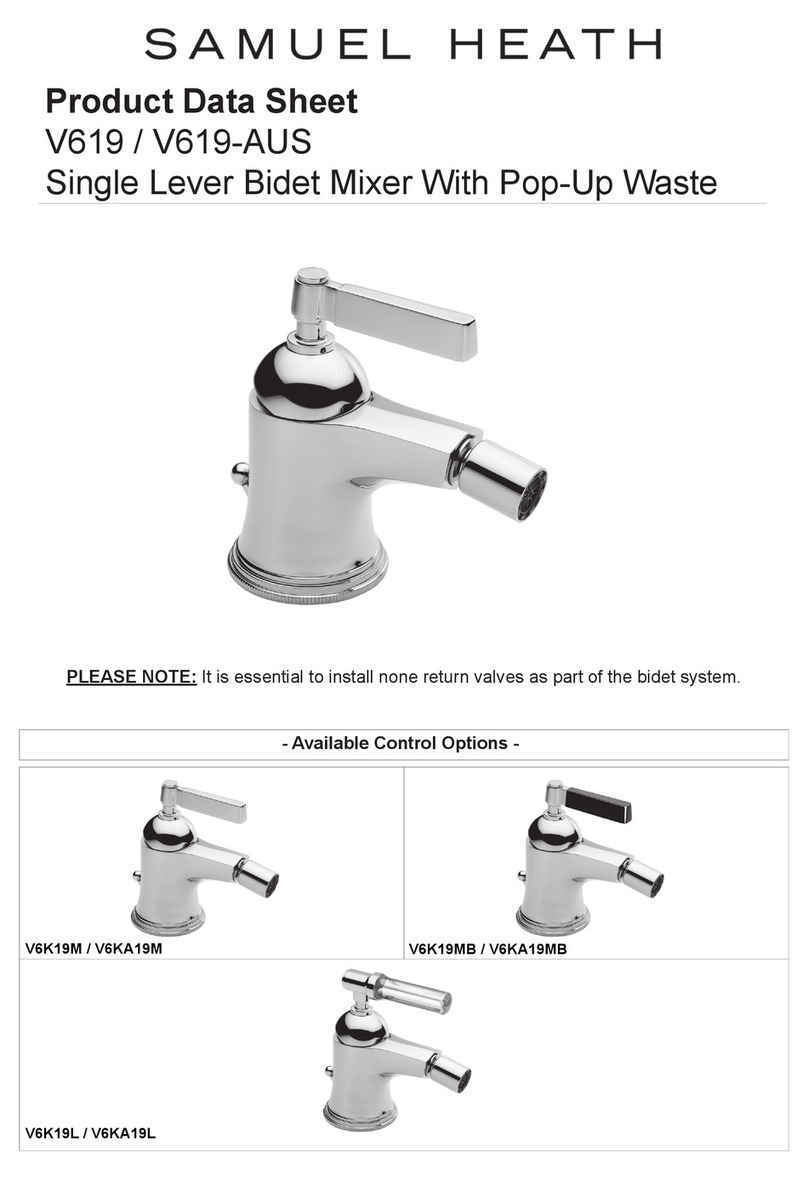

•If your bathroom was purchased with a hot and cold pipe kit, attach this to the factory pre-drilled holes in the

bathroom wall panels. (Note: It is a requirement that pipe kits be re-pressure tested prior to installation.) If

not, have your plumber attach (and pressure test) any required pipes and plumbing fittings. (Internal fittings,

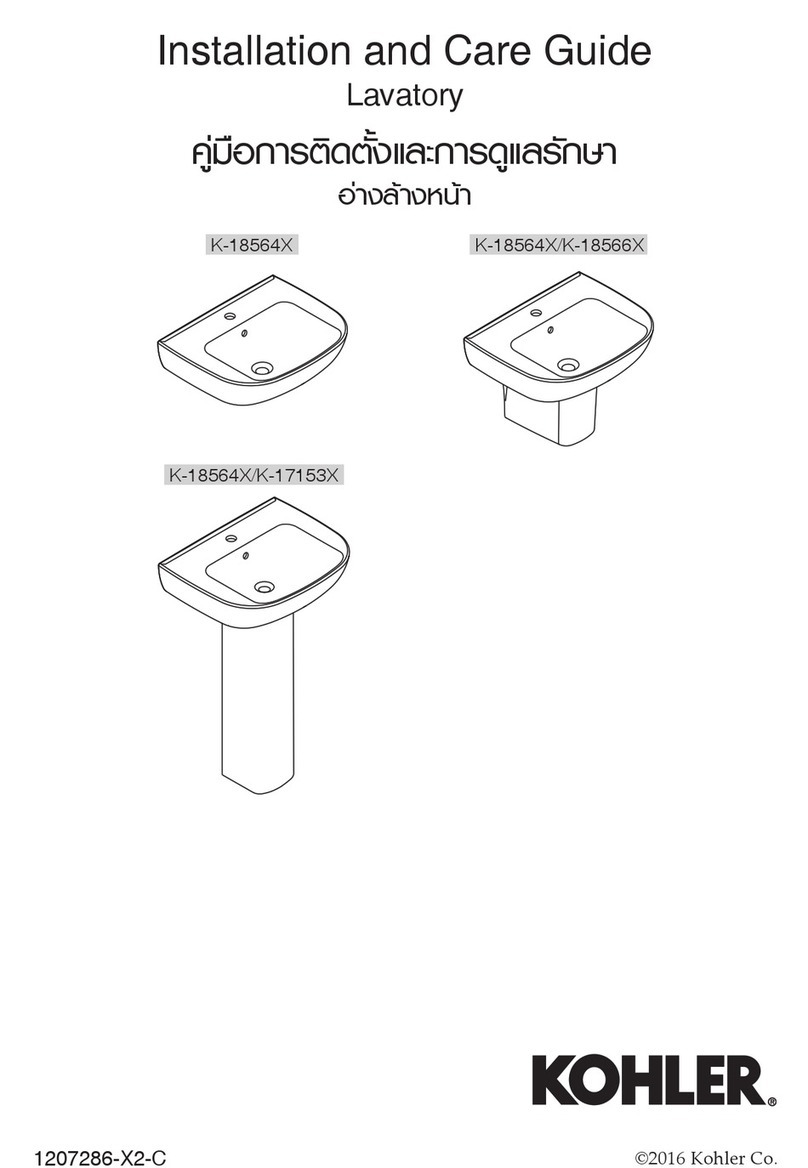

toilet, basin, taps, shower doors, etc. can be installed either at this time or after installation. Note that only

basins with inbuilt overflow protection are to be used.)

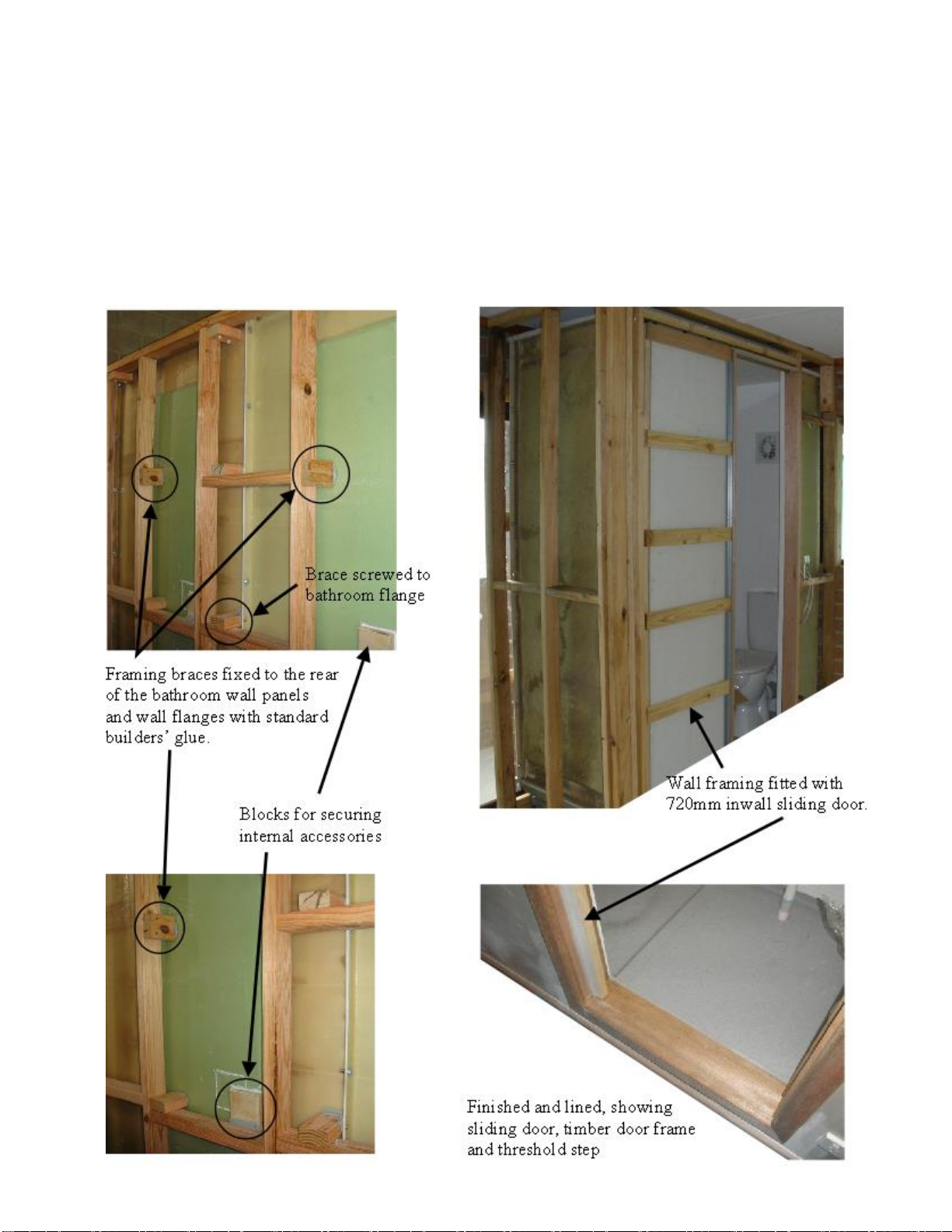

•It is important that any fittings you wish to fit inside your bathroom are securely attached. To this end we

recommend adhering (with standard builders’ glue) blocks of ply (or similar) to the back of the walls of the

bathroom where the fitting (basin, pan, towel rail etc) will be. This provides a firm fixing, and allows for the

fitting to be easily removed and replaced at a later date if required. Where safety grab rails, seats etc are

required to be fitted, contact Add-A-Bathroom as these may require additional measures, specific to the item.

•If your bathroom was purchased with an electrical kit, have this refitted at this time or have your electrician fit

electrical as required.

•The bathroom is now ready for final installation.

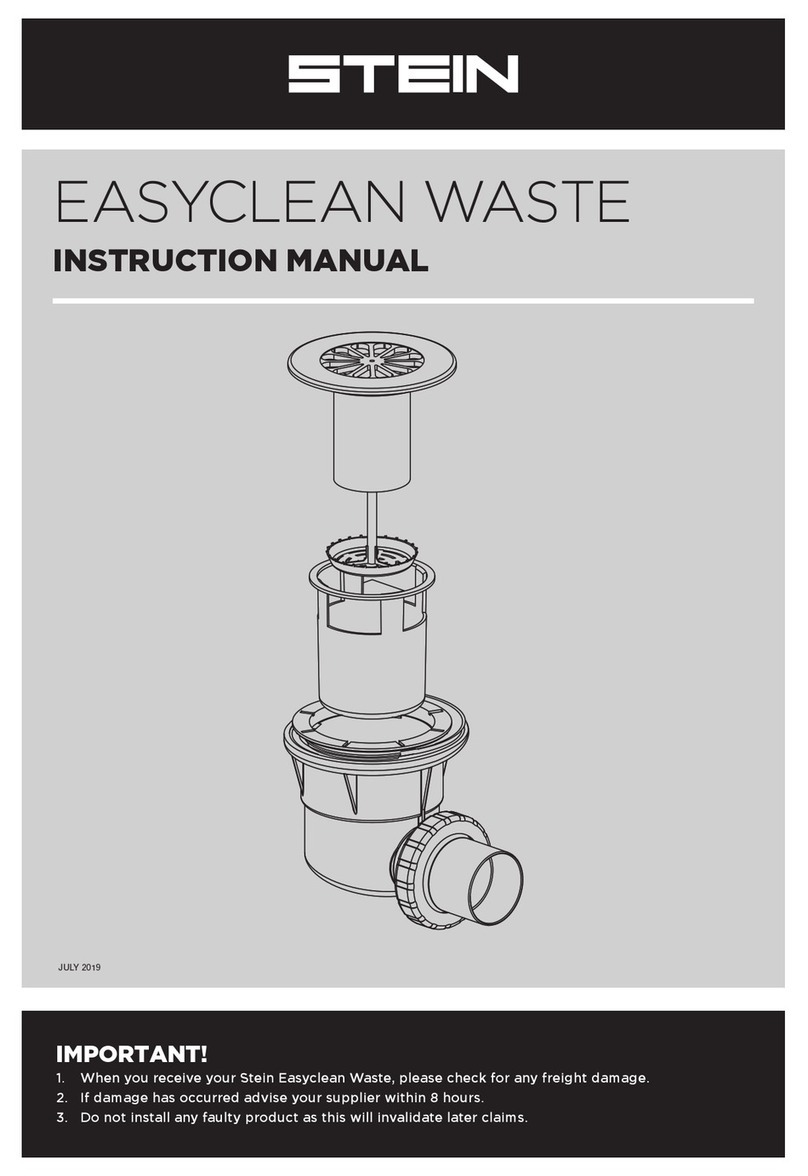

•Lay a thick bed of flexible ceramic waterproof floor tile adhesive (with a 6mm-12mm notched trowel), so as to

cover the entire area of the bathroom base. (Note: It is necessary that the entire base is fully supported by the

slurry; as the bottom of the bathroom will not be a perfect fit with the substrate, it is prudent to provide a thick

over-depth slurry. Any excess will be pushed to the side during installation and not present a problem.)

•Manoeuvre the bathroom into its final position. If it is too awkward to lift into position this can be achieved by

sliding the unit in on lengths of timber battens or conduit. When the unit is in its final position simply pull the

battens out letting the unit settle. Ensure the sewer pipe, hot and cold plumbing, window, etc. are all correctly

aligned. (Note: At this point it is prudent to leave the installation for sufficient time so as to enable the bed to

fully cure, usually overnight.)

•If not previously installed, install toilet, basin, taps and accessories as required. (Note: Ensure any drilled holes

in the shower area have sealant applied prior to installing the fitting so as to prevent any water penetration.)

•Connect floor waste, sewer, hot and cold plumbing.

•If not done previously, have your electrician final fit and test as required.

•Remove protective cardboard.

Your bathroom should now be fully functional, just requiring the installation of the surrounding wall and door.

Please read the relevant section at the end of this guide.

Ensure all slurries, beads, sealants and adhesives are fully set before use, (normally 24 hours).