Addi-Data APCI-8001 User manual

Rev. 12/112018

www.addi-data.com

POSITIONING AND CONTOURING

CONTROL SYSTEM

APCI-8001 AND APCI-8008

OPTIONS MANUAL

CONTENTS 3

1OPMF options print......................................................................................................................................6

1.1Brief description .............................................................................................................................6

1.2Software.........................................................................................................................................6

1.2.1Modified rwmos.elf operating system software.................................................................6

1.2.2PCAP programming ..........................................................................................................7

1.2.2.1rdAin, read analog inputs .................................................................................7

1.2.2.2rddigi, read digital inputs ..................................................................................8

1.2.2.2.1Digi axis qualifier for axis channels 4, 5 and 6 ...................................8

1.2.2.2.2Digi axis qualifier for axis channels 7 and 8 .......................................9

1.2.2.3rddigib, read digital input bit .............................................................................9

1.2.2.4rddigo, read digital outputs...............................................................................9

1.2.2.5rddigob, read digital output bit........................................................................10

1.2.2.6wrdigo, write digital outputs............................................................................10

1.2.2.7wrdigob, write digital output bit.......................................................................10

1.2.3SAP programming...........................................................................................................11

1.2.3.1digi and digo axis qualifiers............................................................................11

1.2.3.2Axis qualifiers ain0 .. ain3...............................................................................11

1.3Hardware......................................................................................................................................11

1.3.1Options print OPMF connection assignments.................................................................12

1.3.1.1Connector X1: 50-pin SUB-D pin connector..................................................12

1.3.1.2Connector X2 FB connector X2 and transformation to SUB-D connector (pin /

socket)............................................................................................................13

1.3.1.3Setpoint value channels.................................................................................14

1.3.1.3.1Setpoint value channel for servo motor axes ...................................14

1.3.1.3.1.1Pin assignment for connector X1, axis channel 4 .....................14

1.3.1.3.1.2Pin assignment for connector X1, axis channel 5 .....................16

1.3.1.3.1.3Pin assignment for connector X1, axis channel 6 .....................16

1.3.1.3.1.4Pin assignment for connector X2, axis channel 7 .....................16

1.3.1.3.1.5Pin assignment for connector X2, axis channel 8 .....................16

1.3.1.3.2Setpoint value channel for stepper motor axes ................................17

1.3.1.3.2.1Pin assignment for connector X1, axis channel 4 .....................17

1.3.1.3.2.2Pin assignment for connector X1, axis channel 5 .....................17

1.3.1.3.2.3Pin assignment for connector X1, axis channel 6 .....................17

1.3.1.3.2.4Pin assignment for connector X2, axis channel 7 .....................17

1.3.1.3.2.5Pin assignment for connector X2, axis channel 8 .....................18

1.3.1.4Pin assignment connector X1, digital inputs..................................................18

1.3.1.5Pin assignment connector X2, digital inputs..................................................18

1.3.1.6Pin assignment connector X1, digital outputs................................................19

1.3.1.7Pin assignment connector X2, digital outputs................................................19

1.3.1.8Pin assignment connector X2, release relay..................................................19

1.3.1.9Pulse acquisition channels.............................................................................20

1.3.1.9.1Incremental encoders with inverted signals (symmetrical circuitry) .20

1.3.1.9.2Incremental encoders without inverted signals (asymmetrical

circuitry).............................................................................................20

1.3.1.9.3Optical decoupling of the pulse acquisition channels.......................21

1.3.1.9.4Pin assignment for the pulse acquisition channels with incremental

encoders ...........................................................................................21

1.3.1.9.4.1Pin assignment X1, channel 4...................................................21

1.3.1.9.4.2Pin assignment X1, channel 5...................................................21

1.3.1.9.4.3Pin assignment X1, channel 6...................................................21

1.3.1.9.4.4Pin assignment X2, channel 7...................................................22

1.3.1.9.4.5Pin assignment X2, channel 8...................................................22

1.3.1.10Pin assignment X2 for the analog input channels..........................................22

1.3.1.10.1Pin assignment for reference voltage outputs ..................................23

4 CONTENTS

1.3.2Connection of the OPMF options (APCI-8008)...............................................................24

1.3.3Component mounting diagram of the OPMF of the APCI-8001, top layer .....................29

1.3.4Component mounting diagram of the OPMF of the APCI-8001, bottom layer ...............30

1.3.5Component mounting diagram of the OPMF of the APCI-8008, top layer .....................31

1.3.6Component mounting diagram of the OPMF of the APCI-8008, bottom layer ...............32

1.3.7OPMF technical data.......................................................................................................33

2OPIBS option..............................................................................................................................................34

2.1Brief description of the INTERBUS master interface...................................................................34

2.2Software.......................................................................................................................................34

2.2.1Modified rwmos.elf operating system software...............................................................34

2.2.2Introduction......................................................................................................................34

2.2.3fwsetup.exe help programme..........................................................................................35

2.2.3.1Interbus page: Configuration..........................................................................35

2.2.3.2Interbus page: SAP........................................................................................36

2.2.3.2.1Explanation of the graphical operating symbols...............................37

2.2.3.2.2Explanation of the SAP Interbus screen text output.........................37

2.2.3.3Interbus page: Diagnostics.............................................................................38

2.2.4Interbus SAP programming.............................................................................................39

2.2.4.1Interbus status information and commands...................................................39

2.2.4.2Proceeding to use the Interbus......................................................................40

2.2.4.3Interbus configuration parameters .................................................................40

2.2.4.4Interbus error handling...................................................................................41

2.2.5Interbus PCAP programming..........................................................................................41

2.2.6Interbus error messages (error codes) ...........................................................................41

2.2.6.1General...........................................................................................................41

2.2.6.2Logical errors (F0XXhex)...............................................................................41

2.2.6.3Port errors (F1XX hex)...................................................................................42

2.2.6.4Logical errors in serial communication (F2XX hex) .......................................43

2.2.6.5INTERBUS errors (F3XX hex , F4XX hex).....................................................44

2.2.6.6General error..................................................................................................46

2.3Interbus hardware........................................................................................................................46

2.3.1Connector P1 (Interbus): 9-pin SUB-D connector ..........................................................46

2.3.2OPIBS option technical data...........................................................................................46

3SUB-D connector for release relay, CNC ready relay.............................................................................47

3.1SUB-D adapter from 10-pin FB connector X5 to 9-pin SUB-D connector..................................47

3.2SUB-D adapter from 10-pin FB connector X5 or X2 to 25-pin SUB-D connector (male)...........47

4SUB-D connector for CAN bus.................................................................................................................49

4.1SUB-D adapter from 10-pin FB connector P3 to 9-pin SUB-D connector..................................49

CONTENTS 5

Figures

Figure 2-1: Interbus configuration ................................................................................................................... 35

Figure 2-2: Interbus SAP................................................................................................................................. 36

Figure 2-3: Diagnostics Interbus ..................................................................................................................... 38

Tables

Table 1-1: Bit-coded structure of the digi word for axis channels 4, 5 and 6.................................................... 8

Table 1-2: Bit-coded structure of the digi word for axis channels 7 and 8........................................................ 9

Table 1-3: Pin assignment X1, (SUB-D connector)......................................................................................... 12

Table 1-4: Pin assignment X2, (SUB-D connector)......................................................................................... 13

Table 1-5: Configuration of the incremental encoders for symmetrical and asymmetrical operating modes.20

Table 2-1: Meaning of the symbols on the [Interbus][Configuration] page ..................................................... 36

Table 2-2: Meaning of the symbols on the [Interbus][SAP] page.................................................................... 37

Table 2-3: SAP Interbus screen output........................................................................................................... 37

Table 2-4: Meaning of the symbols on the [Interbus][Diagnostics] page........................................................ 39

Table 2-5: Interbus status information and commands................................................................................... 39

Table 2-6: Interbus features ............................................................................................................................ 40

Table 2-7: Logical errors.................................................................................................................................. 41

Table 2-8: Port errors ...................................................................................................................................... 42

Table 2-9: Logical errors in serial communication........................................................................................... 43

Table 2-10: INTERBUS errors......................................................................................................................... 44

Table 2-11: Result byte ................................................................................................................................... 45

Table 2-12: Pin assignment of the remote bus interface (SUB-D).................................................................. 46

Table 3-1: Pin assignment for relay adapter (SUB-D-09) ............................................................................... 47

Table 3-2: Pin assignment for relay adapter (SUB-D-25) ............................................................................... 48

Table 4-1: CAN bus pin assignment (SUB-D-09)............................................................................................ 49

6 OPTIONS MANUAL

1 OPMF options print

1.1 Brief description

The OPMF options print is used to extend the APCI-8001 / APCI-8008 positioning and contouring control

system. Essentially, it comprises the additional logic for controlling up to five further servo or stepper motor

axes. The device electronics are fully compatible with those of the APCI-8001 / APCI-8008 motherboard.

In addition, the OPMF can also process up to 8 analog input signals with a 12-bit (APCI-8001) or 16-bit

(APCI-8008) resolution. This section describes the technical software and hardware characteristics of the

OPMF.

1.2 Software

The OPMF can be planned and programmed using the standard TOOLSET software for the

APCI-8001 / APCI-8008 (as of software revision V2.5.0). The corresponding additional functions are

described in the following sections, in addition to the description in the programming and referencing manual

[PM] for the APCI-8001 / APCI-8008.

1.2.1 Modified rwmos.elf operating system software

Specific rwmos.elf operating system software is required in some cases so that the additional functions of

the OPMF can be used. The information in the following section must be noted when rigging to a four (five,

six, seven or eight) axis system. In this case, the additional functions for axis channels 4 – 8 are used in the

same manner as for the standard three-axis system.

However, if only individual function modules are available on the OPMF (partial component mounting), these

function modules are accessed with the help of the SAP programming method. A series of new system

parameters are defined for this in rw_SymPas. The example programmes included in the scope of delivery

represent the simple access to this access method.

OPTIONS MANUAL 7

1.2.2 PCAP programming

The next sections describe the individual signals and their connection pins. The corresponding pin

assignments are listed in section 1.3.1.

1.2.2.1 rdAin, read analog inputs

DESCRIPTION: This function provides the current analog value of the channel channel of the an

axis. A maximum of 4 analog input channels are assigned to each axis.

As up to eight channels can be processed, the analog input channels 1 – 4 are

assigned to axis channel 1 and analog input channels 5-8 are assigned to axis

channel 2.

BORLAND DELPHI: function rdAin(an: integer; channel: integer): integer;

C: int rdAin(int an, int channel);

VISUAL BASIC: Function rdAin(ByVal an As Long, ByVal channel As Long) As Long

RETURN VALUE: Analog value as integer.

NOTE: Up to 8 analog values can be processed. There are slight differences in handling

the analog inputs of the different control systems, which has to be considered by

the user where required, especially in case of a system changeover.

APCI-8001: One value (one channel) is refreshed per scan cycle, i.e. with eight

channels, each channel is refreshed every 8 ms, with a pre-defined cycle of 1 ms.

Each channel can be set individually to the following measurement ranges:

0 .. +5 V, 0 .. 10 V, -5 V .. +5 V und –10 V .. 10 V.

Valid indices for an are 0 and 1, and for channel the values 0..3 are valid. If due to

the equipment version, only 4 analog input channels are available, these are the

first 4 channels. The analog channels have a 12-bit resolution.

APCI-8008: In every scan cycle, all values are refreshed. All channels can be set

only together to the following measurement ranges: 0 .. +5 V, 0 .. 10 V, -5 V .. +5 V

und –10 V .. 10 V.

Valid indices for an are 0 and 1, and for channel the values 0..3 are valid. If due to

the equipment version, only 4 analog input channels are available, these are the

first 2 channels with the first axis and the first 2 channels with the second axis. The

analog channels have a 16-bit resolution.

8 OPTIONS MANUAL

1.2.2.2 rddigi, read digital inputs

DESCRIPTION:This function is used to request the following signal statuses:

yThe current status of the 24 OPMF digital inputs

yThe current status of the zero track (index) signal from the incremental

encoder

yA temporarily stored error in the measurement value acquisition system

yA temporarily stored edge of the zero track (index) signal from the

incremental encoder

yA temporarily stored edge of the hardware latch signal (strobe). If an input

is active, this is indicated with the value 1 for the respective bit. As an

option, all digital inputs can be planned with inversion in the mcfg.exe

TOOLSET programme. It is also possible to plan the required polarity

when using an incremental encoder with an index signal.

You must ensure that the digital inputs are grouped axis-specifically on the OPMF.

BORLAND DELPHI: procedure rddigi(var tsrp:TSRP);

C: void rddigi(struct TSRP far *tsrp);

VISUAL BASIC: Sub rddigi(DTSRP As TSRP)

TSRP COMPONENTS: TSRP[n].digi

n = 3 .. Number of axes-1

RETURN VALUE: The bit-coded return value is in the digi structure or record component and is

constructed as described in the table below.

NOTE: See note PM rddigi()

Digital inputs 17 - 32 (connector X1) are assigned to axis channels 4, 5 and 6.

Digital inputs 33 - 40 (connector X2) are assigned to axis channels 7 and 8.

1.2.2.2.1 Digi axis qualifier for axis channels 4, 5 and 6

The digi register is used to check the status of the digital inputs in the APCI-8001. If the respective inputs are

active, this is displayed with the value 1 at the respective bit position.

Table 1-1: Bit-coded structure of the digi word for axis channels 4, 5 and 6

Bit

No. Function X1/Pin

0 Input 17 9

1 Input 18 10

2 Input 19 11

3 Input 20 12

4 Input 21 13

5 Input 22 14

6 Input 23 15

7 Input 24 16

8 Input 25 42

9 Input 26 43

10 Input 27 44

11 Input 28 45

12 Input 29 46

13 Input 30 and hardware strobe signal for latching the actual position of axis channel 4 47

14 Input 31 and hardware strobe signal for latching the actual position of axis channel 5 48

15 Input 32 and hardware strobe signal for latching the actual position of axis channel 6 49

16 Zero track of the incremental encoder, axis-specific --

OPTIONS MANUAL 9

Bit

No. Function X1/Pin

17 Error of the measurement value acquisition system, axis-specific --

18 Temporarily stored value for the zero track signal of the incremental encoder, axis-

specific --

19 Temporarily stored value of the latch signal (hardware strobe), axis-specific --

20..31 Not assigned, these flags always have the value 0 --

1.2.2.2.2 Digi axis qualifier for axis channels 7 and 8

The digi register is used to check the status of the digital inputs in the APCI-8001. If the respective inputs are

active, this is displayed with the value 1 at the respective bit position.

Table 1-2: Bit-coded structure of the digi word for axis channels 7 and 8

Bit

No. Function X2 / Pin

(SUB-D)

0 Input 33 9

1 Input 34 10

2 Input 35 11

3 Input 36 12

4 Input 37 13

5 Input 38 14

6 Input 39 and hardware strobe signal for latching the actual position of axis channel 7 15

7 Input 40 and hardware strobe signal for latching the actual position of axis channel 8 16

8..15 Not connected

16 Zero track of the incremental encoder, axis-specific --

17 Error of the measurement value acquisition system, axis-specific --

18 Temporarily stored value for the zero track signal of the incremental encoder, axis-

specific --

19 Temporarily stored value of the latch signal (hardware strobe), axis-specific --

20..31 Not assigned, these flags always have the value 0 --

1.2.2.3 rddigib, read digital input bit

DESCRIPTION: This function is used to request the current status of one OPMF digital input and

various other logic signals. The axis number must be specified in the an parameter

(0, 1, … MAXAXIS-1)

Note: Counting for the bit no. starts at 1.

BORLAND DELPHI: function rddigib(an:integer; bitnr:integer):boolean;

C: int rddigib(int an, int bitnr);

VISUAL BASIC: Function rddigib(ByVal an As Long, ByVal bitnr As Long) As Long

RETURN VALUE: The function returns the value 1 or TRUE, provided the corresponding bit no. input

is active.

NOTE: See rddigi() section [1.2.2.2] and Note PHB rddigib() section [1.2.2.3]

1.2.2.4 rddigo, read digital outputs

See wrdigo in section [1.22.6]

10 OPTIONS MANUAL

1.2.2.5 rddigob, read digital output bit

See wrdigob in section [1.2.2.7]

1.2.2.6 wrdigo, write digital outputs

DESCRIPTION: This register can be used to set the digital outputs of the OPMF. You must ensure

that the digital outputs are grouped axis-specifically on the OPMF. If you wish to

set an output, set the respective bit. The bit-coded structure of the digo status word

can be taken from the following table:

Table: Bit-coded structure of the digo word for axis channels 4, 5 and 6

Bit No. Function Connector X1 / PIN

0 Output 9 26

1 Output 10 27

2 Output 11 28

3 Output 12 29

4 Output 13 30

5 Output 14 31

6 Output 15 32

7 Output 16 33

8..31 Not assigned --

Table: Bit-coded structure of the digo word for axis channels 7 and 8

Bit No. Function Connector X2 / PIN (SUB-D)

0 Output 17 26

1 Output 18 27

2 Output 19 28

3 Output 20 29

4..31 Not assigned --

BORLAND DELPHI: procedure wrdigo(var tsrp:TSRP);

C: void wrdigo(struct TSRP far *tsrp);

VISUAL BASIC: Sub wrdigo(DTSRP As TSRP)

TSRP COMPONENTS: TSRP[n].digo

1.2.2.7 wrdigob, write digital output bit

DESCRIPTION: This function is used to set or reset one OPMF digital output. The axis number

must be specified in the an parameter (3, … MAXAXIS-1) The output is reset with

the value 0 or FALSE.

Note: Counting for the bit no. starts at 1.

BORLAND DELPHI: procedure wrdigob(an:integer; bitnr:integer; value: boolean);

C: wrdigob(int an, int bitnr, int value);

VISUAL BASIC: Sub wrdigob(ByVal an As Long, ByVal bitnr As Long, ByVal value As Long)

NOTE PCAP command wrdigo()

OPTIONS MANUAL 11

1.2.3 SAP programming

1.2.3.1 digi and digo axis qualifiers

For the functionality of the digi and digo axis qualifiers for PCAP commands rddigi() and rddigo(), see

sections [1.2.2.2] and [1.2.2.4] respectively.

1.2.3.2 Axis qualifiers ain0 .. ain3

Axis qualifiers ain0 to ain3 are used to read in the analog input channels. The axis qualifiers are assigned to

axis channels 1 and 2. This means that up to 8 analog inputs can be processed. The input information is

returned as integer type.

OPMF of the APCI-8001: The value range is specified as values from -2048 to +2047, based on the AD

converter 12-bit word width, including signs. The voltage level for this measurement value depends on the

input voltage range of the respective A/D channel. This is usually -5 to +5 V. However, measurement ranges

from -10 to +10 V, 0 to 5 V or 0 to 10 V can also be processed. Each input channel can be set individually to

one of the above-mentioned measurement ranges. If only 4 input channels are fitted, these are accessed

under the 4 channels of the first axis. For this, inputs AIN1 to AIN4 are wired.

OPMF of the APCI-8001: The value range is specified as values from -32768 to +32767, based on the AD

converter 16-bit word width, including signs. The voltage level for this measurement value depends on the

input voltage range of the respective A/D channel. This is usually -10 to +10 V. However, measurement

ranges from -5 to +5 V can also be processed. All input channels can be set only together to one of the

above-mentioned measurement ranges. If only 4 input channels are fitted, these are accessed under the 2

channels each of the first two axes. For this, inputs AIN1, AIN2, AIN5 and AIN6 are wired.

1.3 Hardware

The OPMF options print is designed as a daughter board for the APCI-8001 / APCI-8008 motherboard. Both

modules are assembled in the factory with plug and screwed connections. The control system requires one

or two PC slots for mechanical reasons, depending on the configuration, but electrically only one PCI slot is

required.

Depending on the level of configuration, the peripheral electronics are connected to the OPMF via a 50-pin

SUB-D connector (X1) and a 60-pin SUB-D connector (X2). There is a cable loom with a board holder and

integrated 50-pin SUB-D connector for the 60-pin FB connector X2 of the OPMF. This board holder can be

installed in a free PC slot adjacent to the control system. In the maximum configuration (8 axes), up to three

50-pin SUB-D connectors can be used.

All the following pin descriptions refer to these 50-pin SUB-D connectors.

12 OPTIONS MANUAL

1.3.1 Options print OPMF connection assignments

1.3.1.1 Connector X1: 50-pin SUB-D pin connector

Table 1-3: Pin assignment X1, (SUB-D connector)

Pin Name Group

1 SERVO4 / PULSE4+ Setpoint value 4/stepper 4

2 AGND4 / PULSE4- Setpoint value 4/stepper 4

3 CHA4+ / CLKSSI4+ Actual value 4

4 CHA4- / CLKSSI4- Actual value 4

5 CHB4+ / DATSSI4+ Actual value 4

6 CHB4- / DATSSI4- Actual value 4

7 NDX4+ / SIGN4+ Actual value 4/stepper 4

8 NDX4- / SIGN4- Actual value 4/stepper 4

9 I17

10 I18

11 I19

12 I20

13 I21

14 I22

15 I23

16 I24

Digital inputs 17-24 (24V)

Assignment to axis channel 4, 5 and 6

17 + 24V Power supply for the digital outputs 24V, if digital outputs are being used, this

voltage must be supplied externally.

Should be connected with APCI-8001 motherboard connector X1, pin 17.

18 SERVO5 / PULSE5+ Setpoint value 5/stepper 5

19 AGND5 / PULSE5- Setpoint value 5/stepper 5

20 CHA5+ / CLKSSI5+ Actual value 5

21 CHA5- / CLKSSI5- Actual value 5

22 CHB5+ / DATSSI5+ Actual value 5

23 CHB5- / DATSSI5- Actual value 5

24 NDX5+ / SIGN5+ Actual value 5/stepper 5

25 NDX5- / SIGN5- Actual value 5/stepper 5

26 O9

27 O10

28 O11

29 O12

30 O13

31 O14

32 O15

33 O16

Digital outputs 9.0.16 (24V)

Assignment to axis channel 4, 5 and 6

34 SERVO6 / PULSE6+ Setpoint value 6/stepper 6

35 AGND6 / PULSE6- Setpoint value 6/stepper 6

36 CHA6+ / CLKSSI6+ Actual value 6

37 CHA6- / CLKSSI6- Actual value 6

38 CHB6+ / DATSSI6+ Actual value 6

39 CHB6- / DATSSI6- Actual value 6

40 NDX6+ / SIGN6+ Actual value 6/stepper 6

41 NDX6- / SIGN6- Actual value 6/stepper 6

42 I25

43 I26

44 I27

45 I28

46 I29

47 I30

48 I31

49 I32

Digital inputs 25-32 (24V)

Assignment to axis channel 4, 5 and 6

Faster latch input axis channel 4

Faster latch input axis channel 5

Faster latch input axis channel 6

OPTIONS MANUAL 13

Pin Name Group

50 GND-D Reference potential for all signal sources. These include digital inputs and

outputs and the transmitter actual value.

GND-D must be connected with the mass potential of the external device

electronics.

Should be connected with APCI-8001 motherboard connector X1, pin 50.

1.3.1.2 Connector X2 FB connector X2 and transformation to SUB-D connector (pin / socket)

Table 1-4: Pin assignment X2, (SUB-D connector)

Pin

SUB-D Name Description/comments Pin

FB-60 - X2

1 Relay 1, NC contact 1

2 Relay 2, NC contact 3

3 Relay 3, NC contact 5

4 Relay 4, NC contact 7

5 Relay 5, NC contact 9

6 Relay 1, NO contact, release axis channel 4 2

7 Relay 2, NO contact, release axis channel 5 4

8 Relay 3, NO contact, release axis channel 6 6

9 Relay 4, NO contact, release axis channel 7 8

Relay 5, NO contact, release axis channel 8 10

1 Servo7 / Pulse7+ 11

2 AGND7 / Pulse7- 14

3 CHA7+ / CLKSSI7+ 17

4 CHA7- / CLKSSI7- 20

5 CHB7+ /DATSSI7+ 23

6 CHB7- / DATSSI7- 26

7 NDX7+ / SIGN7+ 29

8 NDX7- / SIGN7-

Axis channel 7

32

9 I33 35

10 I34 38

11 I35 41

12 I36 44

13 I37 47

14 I38 50

15 I39 53

16 I40

Digital inputs 33-40 (24V)

Assignment to axis channels 7 and 8

Faster latch input axis channel 7

Faster latch input axis channel 8 56

17 +24V Power supply for digital outputs

is internally connected with X1-17. 59

18 Servo8/ Pulse8+ 13

19 AGND8 / Pulse8- 16

20 CHA8+ / CLKSSI8+ 19

21 CHA8- / CLKSSI8- 22

22 CHB8+ /DATSSI8+ 25

23 CHB8- / DATSSI8- 28

24 NDX8+ / SIGN8+ 31

25 NDX8- / SIGN8-

Axis channel 8

34

26 O17 37

27 O18 40

28 O19 43

29 O20

Digital outputs 17.20 (24V)

Assignment to axis channels 7 and 8

46

30 RGND1 49

31 AREF1 Reference output group 1 52

32 RGND2 Reference output group 2 55

14 OPTIONS MANUAL

33 AREF2 58

Pin

SUB-D Name Description/comments Pin

FB-60 - X2

34 AIN1+ 12

35 AIN1- 15

36 AIN2+ 18

37 AIN2- 21

38 AIN3+ 24

39 AIN3- 27

40 AIN4+

Analog inputs 1 to 4

Assignment to axis channel 1.

30

41 AIN4- 33

42 AIN5+ 36

43 AIN5- 39

44 AIN6+ 42

45 AIN6- 45

46 AIN7+ 48

47 AIN7- 51

48 AIN8+ 54

49 AIN8-

Analog inputs 5 to 8

Assignment to axis channel 2.

57

50 GND-D Power supply for digital outputs

is internally connected with X1-50. 60

The colour fields highlighted in yellow indicate the pin assignment on the 50-pin SUB-D connector.

An FB8001 connection cable is required for these.

The colour fields highlighted in green indicate the pin assignment on the 9-pin SUB-D connector (see also

section [1.3.1.8]). An FB-8001 connection cable is required for this.

The assignment of the OPMF of the APCI-8001 and the OPMF of the APCI-8008 is identical. With the

analog inputs, the different resolutions should be noted.

1.3.1.3 Setpoint value channels

The OPMF system electronics supports operation of up to five more stepper or servo motor axes. The

required motor system is planned and selected using the mcfg.exe TOOLST programme.

1.3.1.3.1 Setpoint value channel for servo motor axes

The analog output signal is used to control a power amplifier, which is activated as a speed or moment

controller (current amplifier). In the factory, the offset of this setpoint value channel is stored in the non-

volatile flash memory of the APCI-8001 and is taken into consideration by the software during output. The

analog value output is only supported for SERVO planned axes.

1.3.1.3.1.1 Pin assignment for connector X1, axis channel 4

Pin Name Group Description

1 SERVO4 Setpoint

value 4 Analog output signal 4 for controlling a power amplifier (+/-10V, 5mA). This

signal is electrically isolated from the OPMF and has reference potential

AGND4.

2 AGND4 Setpoint

value 4 Reference potential for SERVO4. This potential is electrically isolated from the

OPMF system electronics.

Note: Jumpers J1 and J2 must be bridged in position 2-3, so that the signals listed in the table are available

at connector X1.

OPTIONS MANUAL 15

16 OPTIONS MANUAL

1.3.1.3.1.2 Pin assignment for connector X1, axis channel 5

Pin Name Group Description

18 SERVO5 Setpoint

value 5 Analog output signal 5 for controlling a power amplifier (+/-10V, 5mA). This

signal is electrically isolated from the OPMF and has reference potential

AGND5.

19 AGND5 Setpoint

value 5 Reference potential for SERVO5. This potential is electrically isolated from the

OPMF system electronics.

Note: Jumpers J3 and J4 must be bridged in position 2-3, so that the signals listed in the table are available

at connector X1.

1.3.1.3.1.3 Pin assignment for connector X1, axis channel 6

Pin Name Group Description

34 SERVO6 Setpoint

value 6 Analog output signal 6 for controlling a power amplifier (+/-10V, 5mA). This

signal is electrically isolated from the OPMF and has reference potential

AGND6.

35 AGND6 Setpoint

value 6 Reference potential for SERVO6. This potential is electrically isolated from the

OPMF system electronics.

Note: Jumpers J5 and J6 must be bridged in position 2-3, so that the signals listed in the table are available

at connector X1.

1.3.1.3.1.4 Pin assignment for connector X2, axis channel 7

Pin (SUB-D) Name Group Description

1 SERVO7 Setpoint

value 7 Analog output signal 7 for controlling a power amplifier (+/-10V,

5mA). This signal is electrically isolated from the OPMF and has

reference potential AGND7.

2 AGND7 Setpoint

value 7 Reference potential for SERVO7. This potential is electrically isolated

from the OPMF system electronics.

Note: Jumpers J7 and J8 must be bridged in position 2-3, so that the signals listed in the table are available

at connector X2.

1.3.1.3.1.5 Pin assignment for connector X2, axis channel 8

Pin (SUB-D) Name Group Description

18 SERVO8 Setpoint

value 8 Analog output signal 8 for controlling a power amplifier (+/-10V,

5mA). This signal is electrically isolated from the OPMF and has

reference potential AGND8.

19 AGND8 Setpoint

value 8 Reference potential for SERVO8. This potential is electrically isolated

from the OPMF system electronics.

Note: Jumpers J9 and J10 must be bridged in position 2-3, so that the signals listed in the table are available

at connector X2.

OPTIONS MANUAL 17

1.3.1.3.2 Setpoint value channel for stepper motor axes

There are four output signals to control a stepper motor power module. These comprise a pulse signal, a

directional signal, and their inverted signals according to EIA standard RS422. All outputs deliver a typical

output current of –60 mA (max. –150 mA). The maximum pulse frequency of the stepper signals is 10 MHz.

Note: The positive edge of the PULSx+ stepper signal or the negative edge of the PULSx- stepper signal is

crucial for the correct number of steps to be executed.

1.3.1.3.2.1 Pin assignment for connector X1, axis channel 4

Pin Name Group Description

1 PULSE4+ Stepper 4 Pulse signal

2 PULSE4- Stepper 4 Inverted pulse signal

7 SIGN4+ Stepper 4 Directional signal

8 SIGN4- Stepper 4 Inverted directional signal

Note: Jumpers J1 and J2 must be bridged in position 1-2, in order for the above-mentioned signals to be

available at connector X1.

1.3.1.3.2.2 Pin assignment for connector X1, axis channel 5

Pin Name Group Description

18 PULSE5+ Stepper 5 Pulse signal

19 PULSE5- Stepper 5 Inverted pulse signal

24 SIGN5+ Stepper 5 Directional signal

25 SIGN5- Stepper 5 Inverted directional signal

Note: Jumpers J3 and J4 must be bridged in position 1-2, in order for the above-mentioned signals to be

available at connector X1.

1.3.1.3.2.3 Pin assignment for connector X1, axis channel 6

Pin Name Group Description

34 PULSE6+ Stepper 6 Pulse signal

35 PULSE6- Stepper 6 Inverted pulse signal

40 SIGN6+ Stepper 6 Directional signal

41 SIGN6- Stepper 6 Inverted directional signal

Note: Jumpers J5 and J6 must be bridged in position 1-2, in order for the above-mentioned signals to be

available at connector X1.

1.3.1.3.2.4 Pin assignment for connector X2, axis channel 7

Pin (SUB-D) Name Group Description

1 PULSE7+ Stepper 7 Pulse signal

2 PULSE7- Stepper 7 Inverted pulse signal

7 SIGN7+ Stepper 7 Directional signal

8 SIGN7- Stepper 7 Inverted directional signal

Note: Jumpers J7 and J8 must be bridged in position 1-2, in order for the above-mentioned signals to be

available at connector X2.

18 OPTIONS MANUAL

1.3.1.3.2.5 Pin assignment for connector X2, axis channel 8

Pin (SUB-D) Name Group Description

18 PULSE8+ Stepper 8 Pulse signal

19 PULSE8- Stepper 8 Inverted pulse signal

24 SIGN8+ Stepper 8 Directional signal

25 SIGN8- Stepper 8 Inverted directional signal

Note: Jumpers J9 and J10 must be bridged in position 1-2, in order for the above-mentioned signals to be

available at connector X2.

1.3.1.4 Pin assignment connector X1, digital inputs

The basic wiring diagrams for the digital inputs I17..I32 listed below are printed in [CM/section 5.2.7.1].

Pin Name Function

9 I17 Digital input 17

10 I18 Digital input 18

11 I19 Digital input 19

12 I20 Digital input 20

13 I21 Digital input 21

14 I22 Digital input 22

15 I23 Digital input 23

16 I24 Digital input 24

42 I25 Digital input 25

43 I26 Digital input 26

44 I27 Digital input 27

45 I28 Digital input 28

46 I29 Digital input 29

47 I30 Digital input 30 and faster hardware latch input to save the actual position of axis

channel 4

48 I31 Digital input 31 and faster hardware latch input to save the actual position of axis

channel 5

49 I32 Digital input 32 and faster hardware latch input to save the actual position of axis

channel 6

1.3.1.5 Pin assignment connector X2, digital inputs

The basic wiring diagrams for the digital inputs I33..I40 listed below are printed in [CM/section 5.2.7.1].

Pin (SUB-D) Name Function

9 I33 Digital input 33

10 I34 Digital input 34

11 I35 Digital input 35

12 I36 Digital input 36

13 I37 Digital input 37

14 I38 Digital input 38

15 I39 Digital input 39 and faster hardware latch input to save the actual position of

axis channel 7

16 I40 Digital input 40 and faster hardware latch input to save the actual position of

axis channel 8

OPTIONS MANUAL 19

1.3.1.6 Pin assignment connector X1, digital outputs

The basic wiring diagrams for the digital outputs O9..O16 listed below are printed in [CM/section 5.2.8.1].

Pin Name Function

26 O9 Digital output 9

27 O10 Digital output 10

28 O11 Digital output 11

29 O12 Digital output 12

30 O13 Digital output 13

31 O14 Digital output 14

32 O15 Digital output 15

33 O16 Digital output 16

1.3.1.7 Pin assignment connector X2, digital outputs

The basic wiring diagrams for the digital outputs O17..O20 listed below are printed in [CM/section 5.2.8.1].

Pin (SUB-D) Name Function

26 O17 Digital output 17

27 O18 Digital output 18

28 O19 Digital output 19

29 O20 Digital output 20

1.3.1.8 Pin assignment connector X2, release relay

At connector X2, relay points are provided for the amplifier releases. These are ‘normally open’ contacts.

The relay is switched off after the PC is switched on, after a reset action or after an error occurs.

The release relay is activated for the respective selected axis channel by using the cl() command for PCAP

and the CL() command for SAP.

Note: Depending on the configuration level of the OPMF, 1 to 5 relay outputs are available. In order to be

able to use all relay outputs, these connections are made with the relay outputs of the APCI-8001

motherboard on a 25-pin SUB-D connector (see chapter 3.2).

The relay is a semi-conductor relay with a switching-on resistance of max. 25Ohm. The switching capability

is 100mA, the switching voltage max. 60 V.

Pin (SUB-D) Name Function

1 R1-R Relay S1, P contact, release of power amplifier axis channel 4

2 R2-R Relay S2, P contact, release of power amplifier axis channel 5

3 R3-R Relay S3, P contact, release of power amplifier axis channel 6

4 R4-R Relay S4, P contact, release of power amplifier axis channel 7

5 R5-R Relay S5, P contact, release of power amplifier axis channel 8

6 R1-S Relay S1, NO contact, release of power amplifier axis channel 4

7 R2-S Relay S2, NO contact, release of power amplifier axis channel 5

8 R3-S Relay S3, NO contact, release of power amplifier axis channel 6

9 R4-S Relay S4, NO contact, release of power amplifier axis channel 7

R5-S Relay S5, NO contact, release of power amplifier axis channel 8

20 OPTIONS MANUAL

1.3.1.9 Pulse acquisition channels

The OPMF is fitted with up to five pulse acquisition channels, to which various encoder types, such as linear

scales or incremental or absolute encoders can be connected. Two 90° phase-shifted quadrature signals are

processed as input signals, with a maximum pulse frequency of 2.0 MHz (optionally 5 MHz) and TTL

sensors. A zero track (index signal) can also be evaluated. The signal levels acquired by the encoders are

electronically quadrupled and processed internally as floating-point numbers with double accuracy. This

means that the value range for the traverse path is virtually unrestricted.

1.3.1.9.1 Incremental encoders with inverted signals (symmetrical circuitry)

Incremental encoders with symmetrical outputs are particularly suitable for industrial use and are preferred,

as the output signals are available with inverted and non-inverted signal sensors for all tracks. This enables

pulses to be acquired reliably, even in environments that are subject to severe electromagnetic interference.

The evaluation electronics on the OPMF are based on the RS422 standard and form a signal difference

between the inverted and non-inverted input signal. Interference that is linked with transmission lines, can

thus effectively be suppressed.

Important: In the factory, the OPMF is delivered for incremental encoders with symmetrical outputs but can

be configured by the user for asymmetrical encoders (see next table).

1.3.1.9.2 Incremental encoders without inverted signals (asymmetrical circuitry)

It is also possible to process incremental encoders without inverted pulse trains. However, these should only

be used in environments that are not subject to severe electromagnetic interference, e.g. in laboratory

applications. Please also ensure that the encoder cable is only a few metres long, especially for high pulse

frequencies.

Table 1-5: Configuration of the incremental encoders for symmetrical and asymmetrical operating

modes

Axis

channel Signal

source Solder

jumper Asymmetrical Symmetrical

CHA4- J15 (8001)

J15 (8008) Bridged

Do not connect pin 4 / X1 Unbridged

Connect pin 4 / X1

CHB4- J22 (8001)

J16 (8008) Bridged

Do not connect pin 6 / X1 Unbridged

Connect pin 6 / X1

4

NDX4- J23 (8001)

J17 (8008) Bridged

Do not connect pin 8 / X1 Unbridged

Connect pin 8 / X1

CHA5- J14 (8001)

J19 (8008) Bridged

Do not connect pin 21 / X1 Unbridged

Connect pin 21 / X1

CHB5- J20 (8001)

J20 (8008) Bridged

Do not connect pin 23 / X1 Unbridged

Connect pin 23 / X1

5

NDX5- J21 (8001)

J21 (8008) Bridged

Do not connect pin 25 / X1 Unbridged

Connect pin 25 / X1

CHA6- J13 (8001)

J23 (8008) Bridged

Do not connect pin 37 / X1 Unbridged

Connect pin 37 / X1

CHB6- J18 (8001)

J24 (8008) Bridged

Do not connect pin 39 / X1 Unbridged

Connect pin 39 / X1

6

NDX6- J19 (8001)

J25 (8008) Bridged

Do not connect pin 41 / X1 Unbridged

Connect pin 41 / X1

CHA7- J16 (8001)

J27 (8008) Bridged

Do not connect pin 4 / X2 Unbridged

Connect pin 4 / X2

CHB7- J25 (8001)

J28 (8008) Bridged

Do not connect pin 6 / X2 Unbridged

Connect pin 6 / X2

7

NDX7- J24 (8001)

J29 (8008) Bridged

Do not connect pin 8 / X2 Unbridged

Connect pin 41 / X2

Other manuals for APCI-8001

2

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

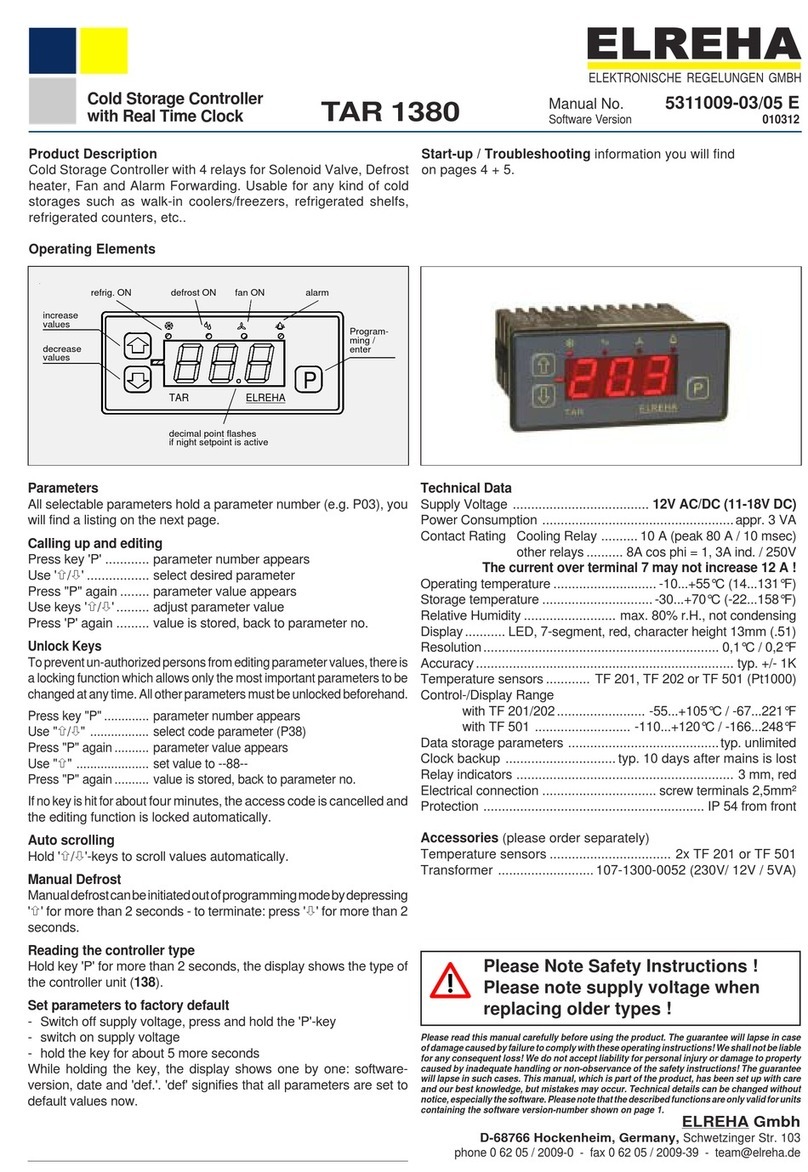

ELREHA

ELREHA TAR 1380 quick start guide

SOMFY

SOMFY animeo WM installation guide

JRT

JRT JHD-1000 Series user manual

Siemens

Siemens RWC32/82 Installation and commissioning guide

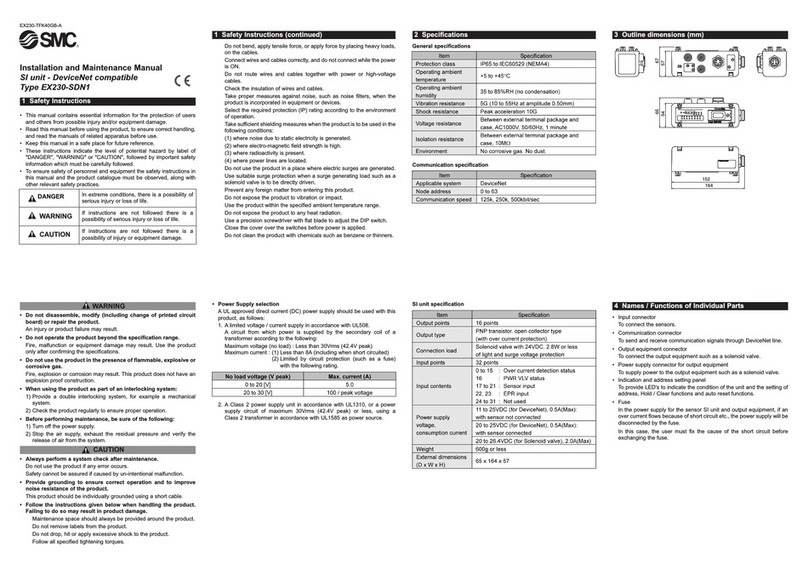

SMC Networks

SMC Networks EX230-SDN1 Installation and maintenance manual

Barnett Engineering

Barnett Engineering ProTalk Plus B1290 operating manual