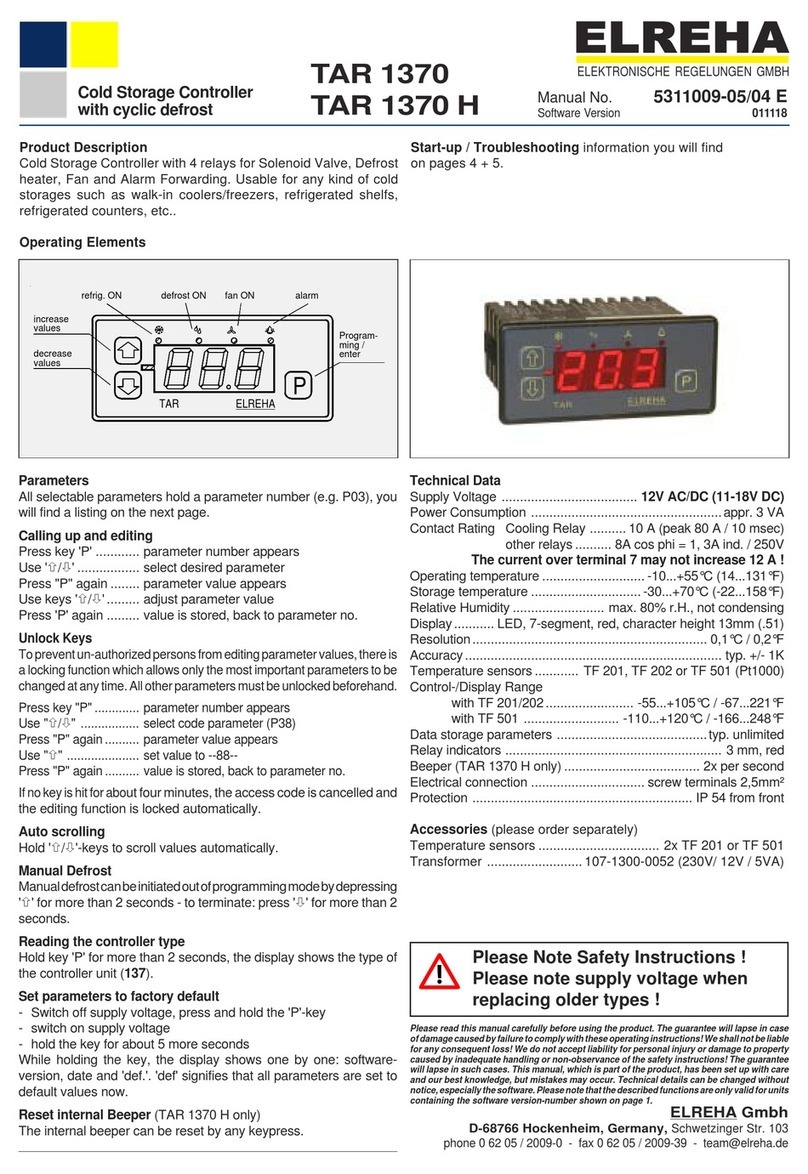

Technical Manual TAR Cold Storage Controller TAR 1380 page 3

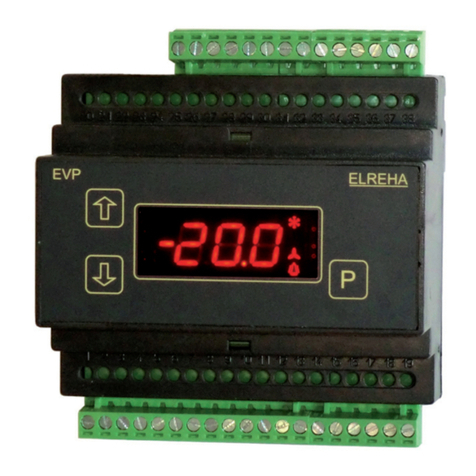

Display & Sensors

All temperature values can be displayed in °C or

°F with a resolution of 0,1K (0,2°F). Parameter

P21 allows toggling between these two display

modes and to change the type of sensor.

TF201, TF 202 (PTC) as well as TF501 (Pt1000)

sensors can be used, but note that this results in

differenttemperatureranges.Ifnotrequired,sen-

sor 2 (Evap. Limit Sensor) can be disabled.

Temperature Control

The controller compares the actual room tempe-

rature (P01) with the control setpoint (P03) and

activatesthecooling relaywhich isable toswitch

solenoid valves or compressors.

The switching hysteresis (differential, P09) is ad-

justableto preventthesystemfromshort cycling.

An idle time (P11) prevents a compressor from

switching ON again immediately.

Setpoint range

P07/P08 limits the setpoint range to prevent the

end-user from entering a critical value.

Switching mode of cooling relay

The switching behavior of the cooling relay

(= cooling mode) is defined by parameter P10.

1= refrigeration

2= heating

2. Setpoint / 'Night'-setpoint / day-night-shift

To economize energy, e.g. at night, the unit can

work with a second setpoint (P04). This setpoint

canbeactivatedby theinternaltime-switch(P05/

P06).

Temperature alarm

Analarmrelay isavailable for warningpurposes.

If the temperature measured by the control sen-

sor exceeds the range set with parameters P32/

P33 a delay timer (P31) starts. After this timer is

rundown,thealarmrelaywillbeactivated. P32is

located relative to setpoint P03, so P32 will be

shifted the same size the setpoint will be shifted.

Ifthe alarmmode P30is setto '4',the alarmrelay

can be reset while the temperature is located

within the alarm range.

If the temperature has left the range, P18 shows

the remaining time until an alarm occurs.

If the temperature comes back to the working

range, the relay will be reset automatically.

war

activated

de-activated

cold

setpoint

hysteresis

Alarm relay operation modes

With parameter P30 you select the alarm relay

mode:

0= Alarm relay active ON

1= Alarm relay active OFF

2/3= no function

4= Alarm relay can be reset while tempera-

ture is located within the alarm range.

Can be used to drive an external klaxon.

5= Continuous ON of alarm relay if control

setpoint 2 is activated. Alarm messages

will be forwarded by alarm-LED only.

Function to switch light by time control.

Real time clock

The TARCold StorageController containsa real

time clock which allows you to initiate four (8 with

AZV) defrost events a day.

The timer has a power backup for about 10 days

in case of power failure.

The clock time can be set with parameters P34

and P35. The defrost times are set with P24 thru

P27in10minuteincrementsina24hour(military)

format. Example: 13.20 = 01:20 p.m.

Switch times can be de-activated by setting to

'oFF'.

The second setpoint switch is made with P05/

P06.

Becausethedisplayhasonlythreedigits,thetime

value comes in the following format:

Defrost

One relay output is able to control a defrost

device.Thereis noneed for externalinterlocking

thedefrostoutputwiththecoolingoutputsincethe

temperature controller is disabled while defrost.

Defrost Initiation

#

by internal timer, four events available

(P24 till P27)

#manually (P37).

ForinformationthereisparameterP15sho-

wing the remaining time of the existing

defrost event until termination by time.

Defrost Modes

With P23 a defrost mode can be selected.

1 = Heater or Airflow Defrost

StartingofdefrosteventswitchesON defrost

relay (i.e heater ON) and switches OFF

the cooling.

2 = Hot Gas Defrost

StartingofdefrosteventswitchesON defrost

relay (i.e. bypass-valve open) and switches

ON cooling relay (i.e. solenoid valve open).

3 = Heater or Free Airflow Defrost + (AZV)

Relay characteristic like = 1.

Addtional generated defrost events.

4 = Hot Gas Defrost + (AZV)

Relay characteristic like = 2.

Addtional generated defrost events.

Manual Defrost

#Parameter P37 allows starting a defrost

cycle with the "!" key, unless the sensor is

setpoint

cold

hysteresis

warm

de-activ.

activated

already above termination temp. or

#While the actual temperature can be read on

display, a defrost event can be initiated by

holding the "!" key for more than 2 sec.

Defrost Termination

#Thermal termination.

Defrosting will be terminated whenever the

evaporatorsensortemperature(P02)exceeds

thetemperaturelimitsetwithparameterP22.

#Termination by (safety) time.

The time set with parameter P28 is the

maximumtimeadefrostcyclecanlastbefore

it is terminated automatically.

#Manual termination.

With parameter P37 you can terminate a

defrost cycle by pressing """ key.

or

While the actual temperature (P01) can be

read on the display, a defrost event can be

terminated by holding """ key for more than

2 seconds.

#If the defrost limit sensor is interrupted, the

defrost event will be stopped immediately.

After the defrost event is terminated, the begin of

the cooling function is delayed by (P29). This

preventsfreezingwaterdropsontheevaporators

surface. P16 showstheremaining timeuntil coo-

ling starts again.

Evaporator Fan Control

Three different modes of fan operation can be

selected with parameter P13.

Fan Modes

1 = Fan runs if compressor output is on.

AfterdefrostingthefanoutputisOFFuntilthe

Fan Delay Time (P14) is run down.

2 = Fan runs continously, except during defrost

and Fan Delay Time (P14) after defrost.

Thermostatic fan delay: The fan stops if the

temperature measured with the evaporator

sensor exceeds P12. If this function is

not desired, P12 can be set to its upper

border to make it inefficient.

3 = Fan runs if the compressor output is on, and

during defrost.

The temporal fan delay must be set to "0".

The end of a defrost cycle

A temporal fan-ON delay is active after a defrost

event (P14).

Athermostaticdelayisalwaysactive,thatmeans

the fan starts only if the temperature measured

withtheevaporator(limit-) sensoris3Kbelowthe

fan operation threshold (P12).

Ifthis functionisnotdesired,P12canbe settoits

upper border to make it inefficient.

While drain time (P29) the fan remains stopped.

(P17) informs about the remaining time until the

fan starts again.

Practical conditions

The fan is always run from the N/O contact

of the fan relay.

If you want to realize a thermostatic delay, select

fan mode 2and adjust setpoint P12.

Ifyouwanttorealizeathermostaticdelayandfree

airdefrost,pleaserealizeaparallel connectionof

fan relay and defrost relay.

Functional Description

3rd Position=

minutes x 10

1st. and 2nd

Position = hours