Addie Water Systems IRON GENIE1 User manual

IRON GENIE

Chemical Free Iron & Sulfur Reduction

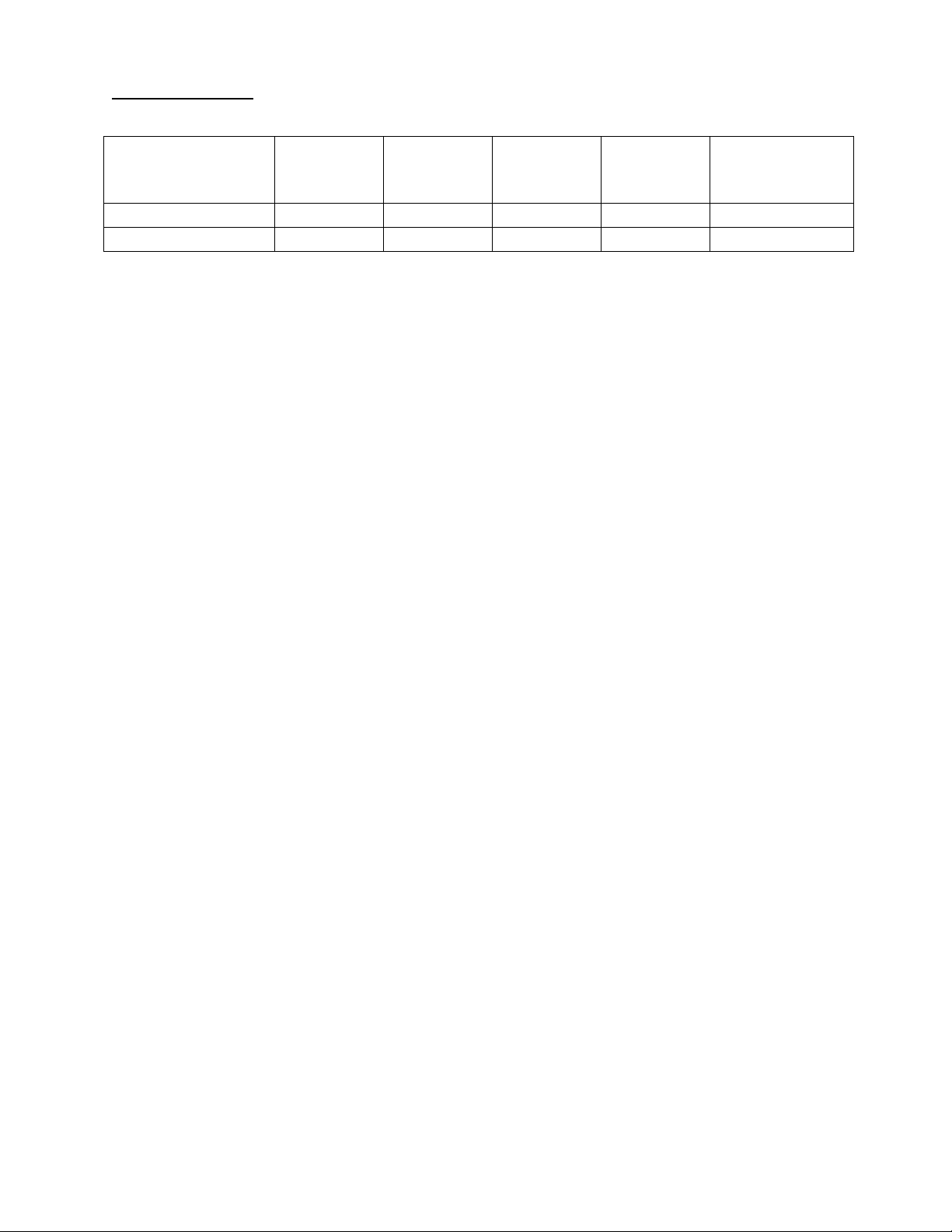

SPECIFICATIONS

MODEL # TANK SIZE

MEDIA

CUBIC FEET

SERVICE *

FLOW RATE

(GPM)

PEAK*

FLOW RATE

(GPM)

BACKWASH RATE

(GPM)

TIG56SXT-SI 10X54 1.0 2.5 3.7 7.0

TIG56SXT-SI-ECM 13X54 2.0 4.5 7.0 11.0

*Peak flow rates are non-continuous for residential use only. Flow rates are substantially higher when ZeoPrep filtering media is used.

Iron Gen e Operat ng & Serv ce Manual

The Iron Genie is an excellent ay to remove iron and sulfur from your ater.

Based on a unique patent-protected (US Patent 5,919,373) process the Iron

Genie removes iron effectively and economically ithout the need for costly

dangerous chemicals, troublesome pumps, or external air injectors.

The Iron Genie can be used henever iron is a problem. Years of field

experience ith the Iron Genie have sho n it ill remove iron in excess of 10

parts per million (PPM) and remain effective in high PH ater.

How Does It Work?

The Iron Genie adds oxygen to the incoming ra ater by passing the ater

through a pressurized air head in the media tank. This ill begin to convert

dissolved elements such as iron or manganese to a physical particle or non-soluble

precipitate. The particles are then captured in the filter media.

Eventually ater passing through the Iron Genie depletes the oxygen and the unit

needs regeneration.

During regeneration process the iron is back ashed out of the filter media and

the oxygen is replenished from atmosphere and then shifts back into service.

INSTALLATION

The Iron Genie ill normally be installed:

After: Supply line to outside faucets

Any Neutralizers

Before: A Water Softener

Any Taste or Odor Filters

SYSTEM INSTALL AND START-UP

1. The Iron Genie ill normally be installed after supply lines to the

outside(unless there is a reason to keep outside faucets iron-free) and after

neutralizing filter if needed(Calcite, Corosex)

2. All plumbing should be done in accordance ith local plumbing codes.

3. Run piping from drain connection to an approved drain, follo ing all local

codes. Secure the drain line! If distance is greater than 10’ increase to 1”

drain line.

4. On the bypass, place in bypass position indicated by small pointer on

handle. Turn on main ater supply.

5. SLOWLY place the bypass in service position and let ater flo into the

mineral tank.

6. Open the nearest cold ater faucet and allo ater to run until the air is

purged from plumbing lines and discoloration is gone. Note: It is normal for

aerated ater to appear effervescent.

7. Plug po er cord into electrical outlet. Be certain the outlet has continuous

electrical po er.

8. The display ill light and sho a time

9. Use the up or do n arro s on the display to set the current time of day

10. Leave the unit in the service position. It is not necessary to run the unit

through the different cycle positions

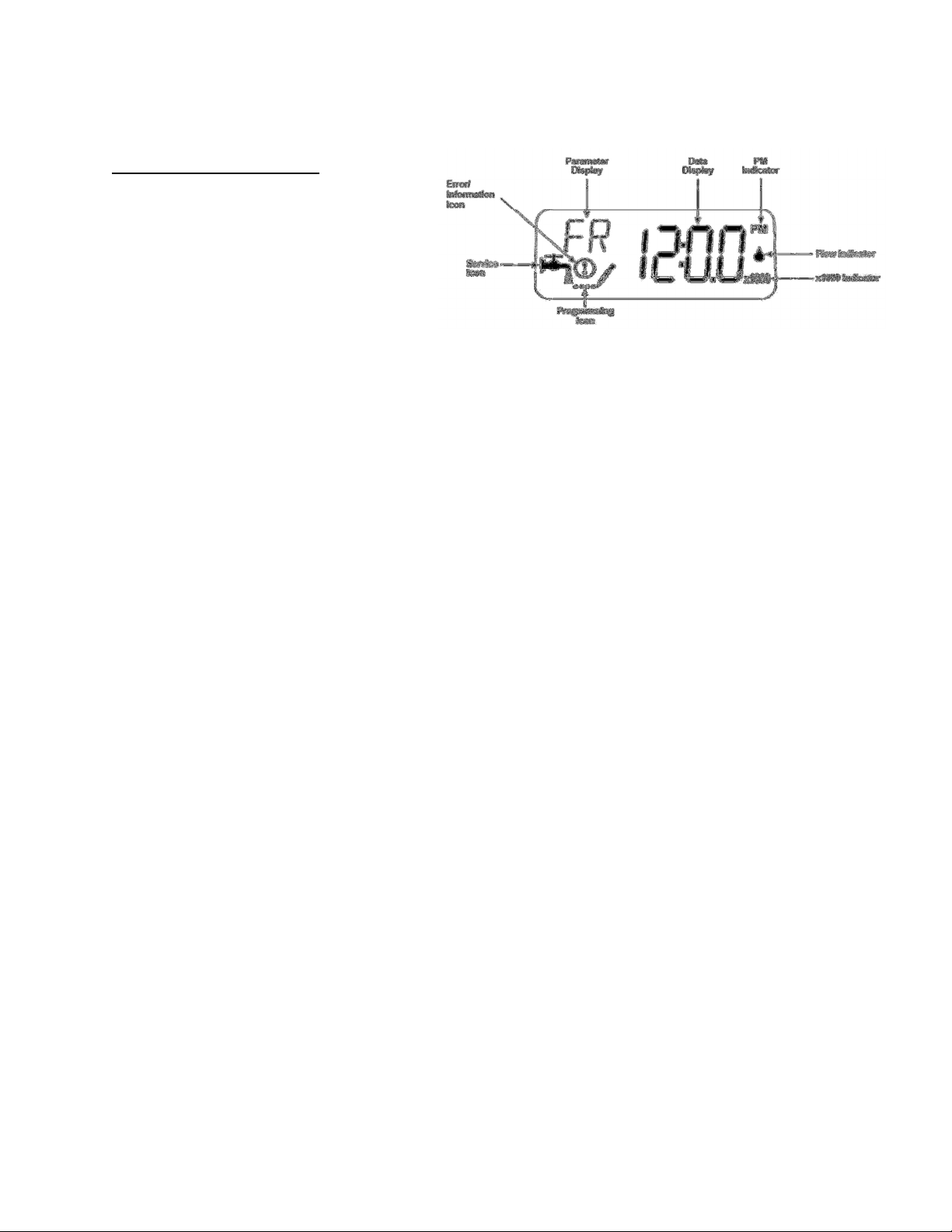

SETTING THE CONTROL

The Iron Genie uses the Fleck

model SXT po er head to manage

the regeneration process.

While in the “Service” position the

display ill alternate bet een time of day and days remaining till regeneration.

The clock uses a standard 12 hour display.

The regeneration cycle is preset to occur at 12:30A.M. every second day. This

timing and frequency of regeneration can be modified as required.

The duration of the regeneration cycle is approximately 50 minutes.

1. Back ash cycle, 10 minute duration. Water flo is reversed inside

the unit to lift and reclassify the filter media rinsing accumulated

iron from the bed.

2. Oxygen refill, 40 minute duration. The unit empties of ater and is

filled ith air. During this cycle ater ill run to drain. There is a

slight delay at the start of the cycle hile the pressure of the air

ithin the tank reaches atmospheric pressure. During this time no

air is dra n into the tank. Once the pressure has equalized, you

ill hear as air is dra n into the unit.

3. The unit returns to the In-Service position. When this happens

ater continues to enter the tank, compressing the air into a

bubble in the top portion of the tank. Air bubble volume ill vary

slightly ith the local conditions.

Untreated ater is available during regeneration cycle.

Should you require the unit to regenerate at a time of day other than 12:30 A.M.

it is important that no other unit, softener or filter, regenerates at the same

time. This ill interfere ith the regeneration process of the Iron Genie.

In condition of high ater usage and/or high levels of iron, the unit may need to

regenerate more frequently than the standard three day cycle. The unit can be

set for every other day regeneration or daily regeneration, as required. Do not

set the regeneration frequency of longer than every three days as this risk

fouling the filter medium and can, over time, render the unit inoperable.

SETTING THE TIME OF DAY

Press and hold the Up or Do n

buttons until the programming icon

replaces the service icon and the

parameter display reads TD.

Adjust the displayed time ith

the Up and Do n buttons.

When the desired time is set,

press the Extra Cycle button to resume

normal operation. The unit ill also

return to normal operation after 5

seconds if no buttons are pressed.

INITIATING A REGENERATION

Press the Extra Cycle

button. The service icon

ill flash to indicate that

regeneration is queued.

To cancel a queued

regeneration press

the Extra Cycle Button.

Regenerate Immed ately

Press and hold the Extra

Cycle button for five

seconds.

IRON GENIE MASTER PROGRAMMING GUIDE

Press the Up or Do n Arro Buttons to enter the Time of Day

Programming Mode, Set the Time of Day Display to 12:01 P.M.

Press the Extra Cycle Button once to exit the Time of Day Programming

Mode.

With the Time of Day Display set to 12:01 P.M., Push and hold the Up

and Do n Arro Buttons for 7 seconds.

Press the Extra Cycle Button once to advance to next parameter.

1.

DF - GAL - US Gallon Display Format

2.

VT - dF1b – Do n flo , Single Back ash

3.

CT - tc - Time Clock Control

4.

NT - 1 - Single Tank System

5.

DO - 3 - Day Override

6.

RT - 12:30 A.M. - Time of Regeneration

7.

BW - 10 - 10 Minute Back ash

8.

BD - 40 - 40 Minute Air Recharge (80 minutes for ECM model)

9.

RR - OFF - Rapid Rinse is Turned Off

10.

Exit Master Programming and Return Valve to Service Display

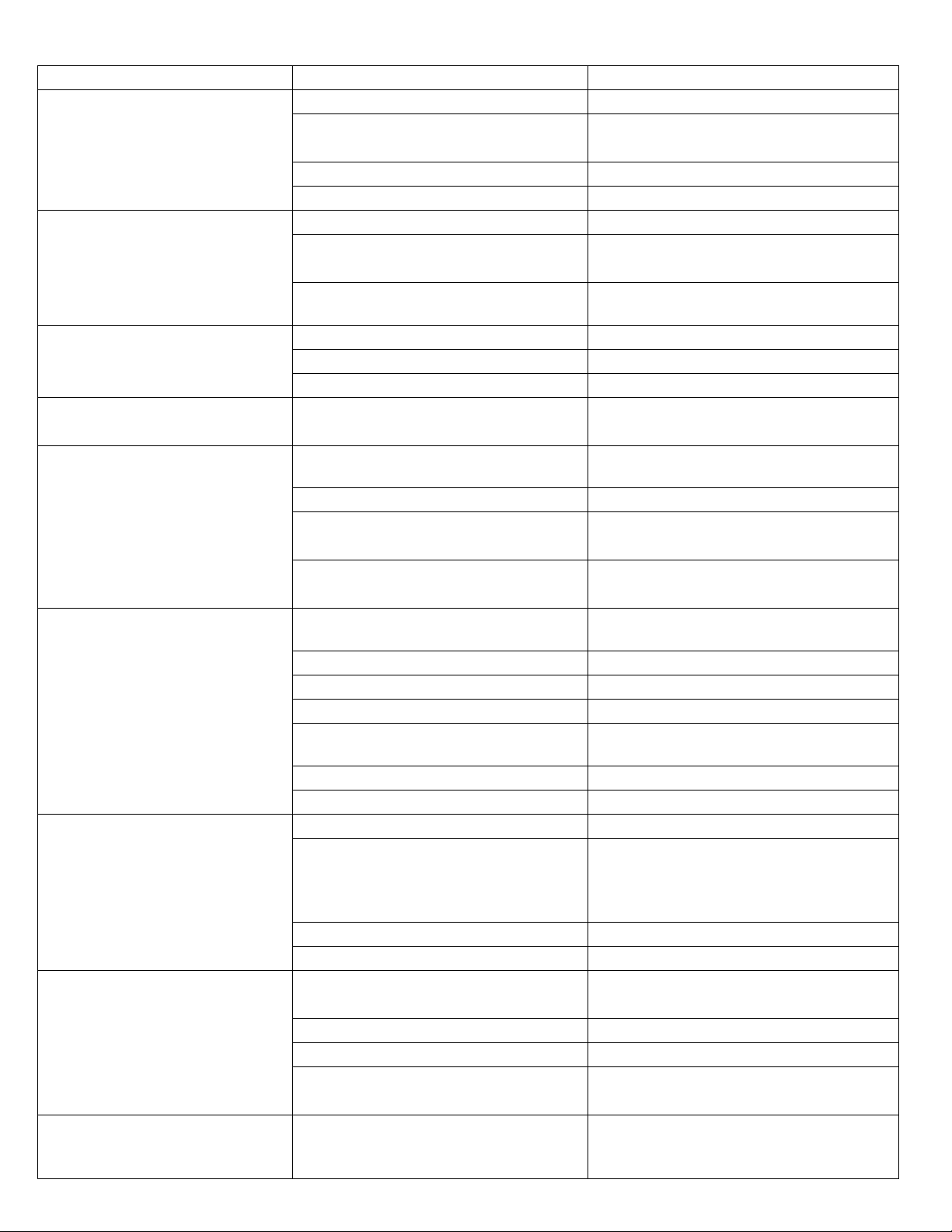

Troubleshoot ng

Problem Possible Cause Solution

No Display on PC Board

No po er at electric outlet Repair outlet or use orking outlet

Control valve Po er Adapter not

plugged into outlet

Plug Po er Adapter into outlet

Defective Po er adapter Replace Po er Adapter

Defective Circuit Board Replace Po er Head Assembly

Circuit Board does not display

correct time of day

Po er Outage Reset time of day

Po er Adapter plugged into electric

outlet controlled by light s itch

Use uninterrupted outlet

Tripped breaker s itch and/or tripped

GFI Reset breaker s itch and/ or GFI s itch

Control valve regenerates at

rong time of day

Po er Outage Reset to correct time of day

Time of day not set correctly Reset to correct time of day

Time of regeneration set incorrectly Reset regeneration time

Time of day flashes on and off

Po er Outage

Press

any button to stop the time of day

from flashing

Unit does not regenerate

Electrical Service to unit is interrupted

Use uninterrupted outlet. Reset time of

day

Po er failure Reset time of day

Not Programmed

Enter Master Programming mode and

verify that the unit is configured properly

Defective Timer

Verify that days advance on main di

s

play.

If not replace Po er Head Assembly

Unit does not dra air in "BD"

cycle

Injector is plugged

Clean or replace injector throat and

nozzle

Injector screen is plugged Clean or replace injector screen

Line to drain is crimped or plugged Replace drain line

Drain line flo control is plugged Clean drain line flo control

Line pressure is too lo

Increase line pressure to

minimum

of 20

psi

Internal control leak Replace seals and spacers

Main drive gear grooved Replace main drive gear

Water to drain continuously

Motor stopped or jammed Replace motor if necessary

Foreign material in control

Remove po er head assembly and

inspect bore. Remove foreign material

and check control in various regeneration

positions

Internal control leak Replace seals and spacers

Main drive gear grooved Replace main drive gear

Air in house line or at faucets

Iron Genie regenerating at same time

as other equipment is regenerating

Reset to correct time of day and verify

regeneration time of all equipment

Worn seals Replace seals and spacers

Distributor O-ring damaged Replace distributor O-ring

Inadequate ater supply to meet

back ash requirements

Verify ater supply and proper flo rate

Control cycles continuously

Misadjusted, broken, or shorted s itch

Determine if s itch or timer is faulty and

replace it, or replace complete po er

head assembly

Troubleshoot ng

Error

Code

Error

Type Cause Reset and Recovery

0

Cam

Sense

Error

The valve drive took

longer than 6 minutes

to advance to the

next regeneration

position.

Unplug the unit and examine the po er

head. Verify that all

cam s itches are connected to the circuit board and

functioning properly. Verify that the motor and drive train

components are in good condition and assembled properly.

Check the valve and verify that the piston travels freely.

Repla

ce /reassemble the various components as necessary.

Plug the unit in and observe its behavior. The

unit should cycle

to the next valve position and stop. If the error re-occurs,

unplug the unit and contact your ater treatment dealer.

1

Cycle

Step

Error

The control

experienced an

unexpected cycle

input

Unplug the unit and examine the po er

head. Verify that all

cam s itches are connected to the circuit board and

functioning properly. Enter Master Programming mode and

verify that the valve type and system type are set correctly

ith regard to the unit itself.

Step the unit through a

manual regeneration and verify that it

functions correctly. If the error re-occurs unplug the unit and

contact you ater treatment dealer.

2

Regen

Failure

The system has not

regenerated for more

than 99 days

Perform a manual regeneration to reset the

error code.

Enter the Master Programming Mode and verify that the unit

is configure properly.

3

Memory

Error

Control board

memory failure

Perform a Master Reset and reconfigure the system via Master

Programming mode. After reconfiguring the system, step the

valve through a manual regeneration. If the error re-occurs

unplug the unit and contact your local ater treatment dealer.

UD

Upper

Drive

Sync

Po er failure install

programming change

Valve ill automatically recover.

Resets

Soft Reset: Press and hold the Extra Cycle and Do n Buttons for 25 seconds hile in normal service mode.

This resets all parameters. Check and verify all parameters in master programming.

Master Reset: Hold the Extra Cycle button hile po ering up the unit. This resets all parameters. Check and

verify all parameters in mater programming

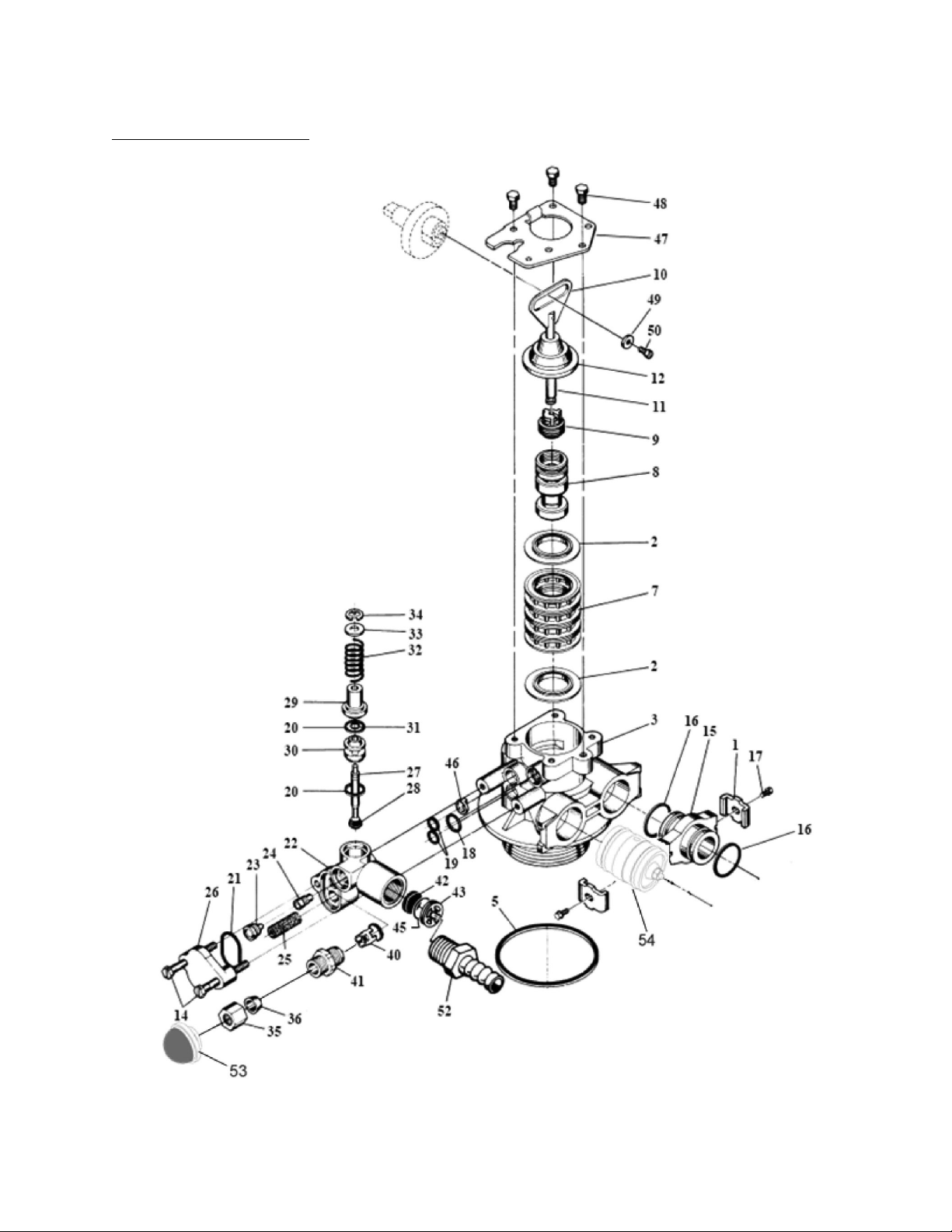

Power Head Assembly

Valve Power Head Asse bly, Continued

Item No. Quant ty Part No. Descr pt on

1

......................1 ..................26001-02 ..............Housing, Control Valve Drive

2

......................2 ..................12473 ....................Scre , Hex Wsh 10-24 x 5/8

3

......................1 ..................19474 ....................Harness, Po er, 56SXT, Elect

4

......................1 ..................13299 ....................Washer, Spring, 3/8

5

......................1 ..................13017 ....................Gear, Idler

6

......................1 ..................23045 ....................Gear, Drive, 6700

7

......................1 ..................13175 ....................Plate, Motor Mounting

8

......................4 ..................13296 ....................Scre , Hex Wsh, 6-20 x 1/2

9

......................1 ..................16944 ....................Motor, Drive, 24V 60 Hz 2 rpm

10

......................2 ..................11384 ....................Scre , Phil, 6-32 x 1/4 Zinc

11

......................1 ..................13168 ....................Cam, Brine Valve, 5600

12

......................1 ..................12037 ....................Washer, Plain, #10 18-8 SS

13

......................1 ..................40214 ....................Scre , Hex Wsh, #6-20 x 3/4

14

......................2 ..................19080 ....................Spring, Compression, 6700

15

......................2 ..................13300 ....................Ball, 1/4” Stainless Steel

16

......................1 ..................42933 ...................Gear, Main Drive, SXT

17

......................1 ..................13547 ....................Strain Relief, Flat Cord

18

......................1 ..................19674 ....................Transformer, 24V, 9.6VA

19

......................1 ..................40338 ....................Cover, Back Drive Housing

20

......................1 ..................19079 ....................Washer, Friction

21

......................1 ..................17438 ....................Cam, 56SXT/6700, Do nflo

22

......................1 ..................15151 ....................Scre , Flat Hd St, 6-20 x 3/4

23

......................2 ..................10218 ....................S itch, Micro

24

......................1 ..................10302 ....................Insulator, Limit S itch

25

......................2 ..................17876 ....................Scre , Phil, Pan, 4-40 x 1 1/8

26A ......................1 ..................61672-0201 ..........Front Panel Assy, 56SXT, Square, Black

26B ......................1 ..................61673-0201 ..........Front Panel Assy, 56SXT, Curved, Black

27.........................2 ..................13898 ....................Scre , Flat Hd, Phil Steel

CONTROL VALVE ASSEMBLY

Control Val e Assembly, Continued

Item No. Quant ty Part No. Descr pt on

1............................2............................13255..........................Adapter Clip

2............................5............................18759..........................Seal, Lo Drive Force

3............................1............................61400-12....................Valve Body Assembly, 1 Dist.

4............................1............................13304..........................O-ring, Distributor Tube, 1

5............................1............................12281..........................O-ring, Top of Tank

7............................4............................14241..........................Spacer

8............................1............................17218-IG....................Piston, Proprietary

9............................1............................10696..........................Piston Pin

10..........................1............................13001-04....................Rod, Piston, 56SXT/6700

11..........................1............................14309..........................Retainer, Piston Rod

12..........................1............................13446-41....................Plug, End, 56SXT/6700, Green

14..........................2............................13315..........................Scre , Injector Mounting

15..........................1............................19228-01....................Adapter Assy,Coupling,5600, /O-ring

16..........................4............................13305..........................O-ring, Adapter Coupling

17..........................2............................13314..........................Scre , Adptr Coupling

18..........................1............................12638..........................O-ring, Drain

19..........................2............................13301..........................O-ring, Injector

20..........................2............................13302..........................O-ring, Brine Spacer

21..........................1............................13303..........................O-ring, Injector Cover

22..........................1............................13163..........................Injector Body

23..........................1............................10913-x......................Injector Nozzle, specify size

24..........................1............................10914-x......................Injector Throat, specify size

25..........................1............................10227..........................Injector Screen

26..........................1............................13166..........................Injector Cover

27..........................1............................13172..........................Brine Valve Stem

28..........................1............................12626..........................Brine Valve Seat

29..........................1............................13165..........................Brine Valve Cap

30..........................1............................13167..........................Brine Valve Spacer

31..........................1............................12550..........................Quad Ring

32..........................1............................11973..........................Spring, Brine Valve

33..........................1............................16098..........................Washer, Brine Valve

34..........................1............................11981-01 ....................Retaining Ring

35..........................1............................10329...........................BLFC Fitting Nut

36..........................1............................10330..........................BLFC Ferrule

40..........................1............................41861..........................Neo Check

41..........................1............................13244..........................BLFC Fitting, 3/8

42..........................1............................12408..........................DLFC Button, specify size

43..........................1............................13173-01....................Retainer, DLFC, Button, /O-ring

46..........................1............................13497..........................Air Disperser

47..........................1............................13546..........................End Plug Retainer

48..........................3............................12112..........................Scre

49..........................1............................13363..........................Washer

50..........................1............................13296..........................Scre

52..........................1............................13308..........................Drain Hose Barb

53..........................1............................19856..........................Inlet Screen

54..........................1............................300-038WW ..............Plastic Inlet Check Valve

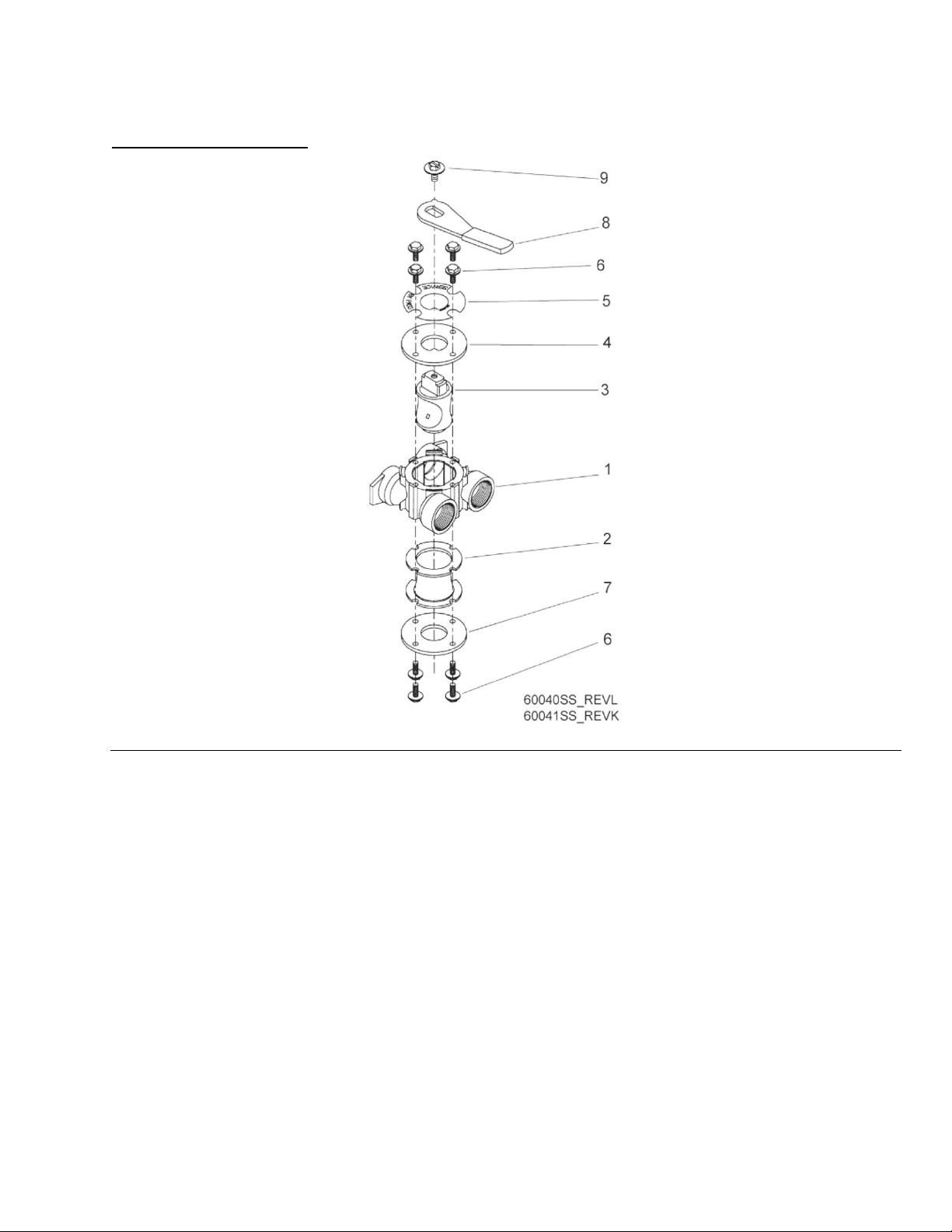

BYPASS VALVE ASSEMBLY

Item No. Quant ty Part No. Descr pt on

1

......................1 ......................17290 ....................Bypass Valve Body, 3/4”

........................1 ......................13399 ....................Bypass Valve Body, 1”

2

......................1 ......................14105 ....................Seal, Bypass

3

......................1 ......................11972 ....................Plug, Bypass

4

......................1 ......................11978 ....................Side Cover

5

......................1 ......................13604-01 ..............Label

6

......................8 ......................15727 ....................Scre

7

......................1 ......................11986 ....................Side Cover

8

......................1 ......................11979 ....................Lever, Bypass

9

......................1 ......................11989 ....................Scre , Hex Head, ¼-14

RECOMMENDED IRON FILTER SERVICE KIT

13001-04 Piston Rod Assembly

13446-41 End Plug Assembly, Green

60125-02 Seal and Spacer Kit, Lo Drive Force

10913-2 Injector Nozzle #2, Blue

10914-2 Injector Throat #2, Blue

10227 Screen

42933 Main Drive Gear

60032 Brine Valve

13302 O-ring, Brine Valve

IOK Injector Body O-Ring Kit

Service Instructions

Power Head Replacement

1. Unplug Po er Head from electrical outlet.

2. Remove the Po er Head back cover.

3. Remove black scre and silver asher at drive yoke on piston rod.

4. Remove 2 silver timer mounting scre s.

5. Lift off entire Po er Head assembly.

6. Put ne Po er Head on top of control valve. Be sure drive pin on main gear engages slot in drive

yoke.

7. Replace black scre and silver asher at drive yoke on piston rod.

8. Replace the 2 silver Po er Head mounting scre s.

9. Plug electrical cord into outlet.

10. Set time of day and cycle the control valve through an immediate regeneration to assure proper

function.

11. Replace the Po er Head back cover.

Injector/Screen Replacement

1. Move the integral stainless steel bypass to the bypass position.

2. Relieve the ater pressure in the Iron Genie by holding do n the Extra Cycle button for 5 seconds.

Once in the “BW” cycle pressure ill be relieved.

3. Push extra cycle button to move control valve to “BD” cycle.

4. Push extra cycle to return the control valve to the service position (time of day on display).

5. Unplug Po er Head from electrical outlet.

6. Remove the t o injector body mounting scre s.

7. Remove injector cap.

8. Remove injector screen.

9. Unscre and remove injector nozzle and throat.

10. Scre in ne injector throat and nozzle.

11. Install ne screen.

12. Insert scre s through injector cap and injector body in to mating holes in the valve body. Tighten

scre s.

13. Return bypass to service position. Water pressure automatically builds in tank.

14. Check for leaks.

15. Plug electrical cord into outlet.

16. Set time of day and cycle the control valve through an immediate regeneration to assure proper

function.

Br ne Valve Replacement

1. Move the integral stainless steel bypass to the bypass position.

2. Relieve the ater pressure in the Iron Genie by holding do n the Extra Cycle button for 5 seconds.

Once in the “BW” cycle pressure ill be relieved.

3. Push extra cycle button to move control valve to “BD” cycle.

4. Push extra cycle to return the control valve to the service position (time of day on display).

5. Unplug Po er Head from electrical outlet.

6. Remove the control valve back cover.

7. Remove black scre and silver asher at drive yoke.

8. Remove 2 silver timer mounting scre s.

9. Lift off entire Po er Head assembly.

10. Remove the t o injector body mounting scre s.

11. Slide the injector body a ay from control valve.

12. Pull brine valve from injector body.

13. Discard o-ring at bottom of brine valve hole in injector body.

14. Install ne o-ring at bottom of brine valve hole in injector body.

15. Press brine valve into brine valve hole in injector body. Be sure shoulder bushing on brine valve is

flush ith injector body.

16. Slide injector body onto control valve.

17. Insert scre s through injector cap and injector body in to mating holes in the valve body. Tighten

scre s.

18. Put Po er Head on top of control valve. Be sure drive pin on main gear engages slot in drive yoke.

19. Replace black scre and silver asher at drive yoke.

20. Replace the 2 silver timer mounting scre s.

21. Return bypass to service position. Water pressure automatically builds in tank.

22. Check for leaks.

23. Plug electrical cord into outlet.

24. Set time of day and cycle the control valve through an immediate regeneration to assure proper

function.

25. Replace the Po er Head back cover.

P ston Rod and End Plug/Seal and Spacer Replacement

1. Move the integral stainless steel bypass to the bypass position.

2. Relieve the ater pressure in the Iron Genie by holding do n the Extra Cycle button for 5

seconds. Once in the “BW” cycle pressure ill be relieved.

3. Push extra cycle button to move control valve to “BD” cycle.

4. Push extra cycle to return the control valve to the service position (time of day on display).

5. Unplug Po er Head from electrical outlet.

6. Remove the control valve back cover.

7. Remove black scre and silver asher at drive yoke on piston rod.

8. Remove t o silver timer mounting scre s.

9. Lift off entire Po er Head assembly.

10. Remove three silver scre s on stainless steel end plug retainer plate.

11. Remove end plug retainer plate.

12. Pull up on end of piston rod yoke until piston is out of valve.

13. Remove five rubber seals and four plastic spacers from valve body.

14. Replace the five rubber seals and four plastic spacers.

15. Take the piston assembly ith the ne piston rod and cap and push piston into valve by means

of the end plug. DO NOT pull up on piston rod.

16. Replace end plug retainer plate

17. Replace three silver scre s on end plug retainer plate.

18. T ist yoke in a clock ise direction to align it ith main drive gear.

19. Put Po er Head on top of control valve. Be sure drive pin on main gear engages slot in drive

yoke.

20. Replace black scre and silver asher at drive yoke.

21. Replace the 2 silver timer mounting scre s.

22. Return bypass to service position. Water pressure automatically builds in tank.

23. Check for leaks.

24. Plug electrical cord into outlet.

25. Set time of day and cycle the control valve through an immediate regeneration to assure proper

function.

26. Replace the Po er Head back cover.

This manual suits for next models

2

Table of contents

Other Addie Water Systems Water System manuals