Adec MetOne 1020 Manual

STANDARD OPERATING PROCEDURE

FOR

MetOne Instruments

BETA ATTENUATION MASS (BAM) MONITOR

MODEL 1020

Alaska Department of Environmental Conservation

Division of Air Quality

410 Willoughby Avenue Suite 303

P.O. Box 111800

Juneau, Alaska 99801-1800

Date: Revision 1

August 27, 2009

Met One BAM 1020 SOP page 2 of 53

Acknowledgement

The Alaska Department of Environmental Conservation Division of Air Quality wants to thank

the State of California, Air Resources Board (CARB) for providing a template for this Standard

of Operating Procedures. The main body of text was taken from the CARB Air Monitoring

Quality Assurance, Monitoring and Laboratory Division’s SOP, dated May 2001 and altered and

amended to fit the State of Alaska’s needs.

Met One BAM 1020 SOP page 3 of 53

Table of Contents

Acknowledgement ____________________________________________________________ 2

Table of Contents_____________________________________________________________ 3

List of Figure ________________________________________________________________ 4

1GENERAL INFORMATION _______________________________________________ 5

1.1 Introduction: ______________________________________________________________ 5

1.2 Principle of Operation: ______________________________________________________ 5

1.3 Safety Precautions: _________________________________________________________ 5

1.4 Interferences/Limitations: ___________________________________________________ 5

2INSTALLATION PROCEDURE ____________________________________________ 6

2.1 List of Tools/Supplies:_______________________________________________________ 6

2.2 Physical Inspection _________________________________________________________ 7

2.3 Siting: ____________________________________________________________________ 7

2.4 Installing BAM-1020 Central Unit: ____________________________________________ 8

2.5 Drilling Inlet Tube Hole:_____________________________________________________ 8

2.6 Attaching Inlet Support Hardware: ___________________________________________ 9

2.7 Tape Loading______________________________________________________________ 9

2.8 Pump Connection:_________________________________________________________ 10

2.9 Outside Temperature (OT) Connection:_______________________________________ 10

3INSTALLATION PROCEDURE ___________________________________________ 10

3.1 Configure BAM-1020:______________________________________________________ 10

4START SAMPLING _____________________________________________________ 12

5ROUTINE SERVICE CHECKS____________________________________________ 12

5.1 General Information _______________________________________________________ 12

5.2 Daily Checks______________________________________________________________ 12

5.3 Weekly Checks____________________________________________________________ 13

5.4 Biweekly Checks __________________________________________________________ 13

5.5 Monthly Checks___________________________________________________________ 13

5.6 Quarterly Checks__________________________________________________________ 13

5.7 Semiannual Checks ________________________________________________________ 13

6MAINTENANCE PROCEDURES__________________________________________ 16

6.1 General Information _______________________________________________________ 16

6.2 Sampler Maintenance ______________________________________________________ 16

6.3 PM2.5 Sharp Cut Cyclone (SCC) Maintenance__________________________________ 16

Met One BAM 1020 SOP page 4 of 53

6. PM10 Inlet Maintenance_______________________________________________________ 16

7TROUBLESHOOTING___________________________________________________ 16

7.1 General Information _______________________________________________________ 16

8Acceptance Test Procedures _______________________________________________ 17

8.1 General Information and Acceptance Test Log _________________________________ 17

8.2 Physical Inspection ________________________________________________________ 17

8.3 Operational Checks________________________________________________________ 17

8.4 Perform Operational Checks: _______________________________________________ 18

9Calibration Procedures ___________________________________________________ 19

9.1 Background and General Information ________________________________________ 19

9.1.1 Introduction____________________________________________________________ 19

9.1.2 Overview ______________________________________________________________ 19

9.1.3 Apparatus for BAM-1020 Calibration ______________________________________ 19

9.1.4 General Information_______________________________ Error! Bookmark not defined.

9.2 Calibrations ______________________________________________________________ 20

9.2.1 Calibration Transfer Standards and Equipment:_________________________________ 20

9.2.3 Temperature Sensor Calibration (OT): ________________________________________ 20

9.2.4 Barometric Pressure Sensor Calibration: ______________________________________ 21

9.2.5 Volumetric Flow Rate Calibration ___________________________________________ 21

9.3 BAM-1020 Verification Procedures___________________________________________ 22

9.3.1 Flow Rate Verification:____________________________________________________ 22

9.3.2 Temperature Sensor Verification ____________________________________________ 23

9.3.3 Barometric Pressure Verification:____________________________________________ 24

9.3.4 Clock/Timer Verification:__________________________________________________ 24

10 Data Validation

10.1 BAM 1020 Data Validation Proceedure

1111.0 BAM 1020 FEM

Tech Notes

Tech note # 1 – BAM Removal

Tech note # 2 – Calibration Procedure

Tech note # 3 – Temperature Sensor Installation

Tech note # 4 – Filter Motion

Tech note # 5 – BAM Pump Manual

Tech note # 6 – Verifying External Data Logger

Tech note # 7 – Data down loads

List of Figure

Met One BAM 1020 SOP page 5 of 53

1 GENERAL INFORMATION

1.1 Introduction:

The purpose of this Standard Operating Procedure (SOP) is to document the Met One Beta

Attenuation Mass Monitor, model 1020 (BAM-1020) procedures used by the State of Alaska

Department of Environmental Conservation (ADEC). The goal of this SOP is twofold; to

formalize BAM-1020 installation, configuration and operation procedures in order to ensure

comparability among all BAM-1020 data, and to describe information and modifications to the

Met One BAM-1020 Operation Manual necessary to successfully integrate the BAM-1020 into

the ADEC air monitoring network. The Met One Instrument's BAM-1020 Operation Manual

contains a significant source of information pertinent to the operation, maintenance and understanding

of this instrument. This manual is frequently referenced throughout this SOP and should be included

as an appendix for this document. For the purposes of this SOP, the BAM 1020-9800 Rev E was used.

1.2 Principle of Operation:

The BAM-1020 measures and records hourly particulate mass concentrations in ambient air. The

unit consists of three basic components; the central unit, the sampling pump and the sampling

inlet hardware. Each component is self-contained and may be easily disconnected for servicing

and replacement.

The BAM-1020 uses beta ray attenuation to calculate collected particle mass concentrations in

units of ug/m3. A14C element (<60 µCi) emits a constant source of high-energy electrons, also

known as beta particles. The beta rays are attenuated as they collide with particles collected on a

filter tape. The decrease in signal detected by the BAM-1020 scintillation counter is inversely

proportional to the mass loading on the filter tape. A more detailed description of the “Principle

of Operation” can be found on page 18 of the BAM 1020 Operation Manual.

1.3 Safety Precautions:

Only properly trained personnel should perform BAM-1020 testing, installation, operation,

maintenance and calibration procedures. As with all monitoring equipment, precautions should be

taken when working around electricity, power tools and on elevated platforms.

The 14C radioactive source should never be dismantled, removed or tampered with. It will never

be necessary for any field personnel to adjust, replace or touch the 14C source. All 14C issues will be

handled by the manufacturer either under warrantee or at ADEC cost. When working close to the 14C

beta source for any length of time, the wearing of long sleeves and laboratory gloves may help reduce

possible exposure to 14C beta rays.

The US EPA Code of Federal Regulations (CFR) allows no more than ten (10) BAM-1020 units

at any one facility at one time. There are NO restrictions or special requirements (such as

licenses or permits) to ship, receive or operate a BAM-1020 monitor within the State of Alaska.

1.4 Interferences/Limitations:

Moisture: The Met One BAM-1020 is a mass analyzer, and therefore any component that is

suspended on the filter tape and attenuates beta rays will subsequently affect the average mass

Met One BAM 1020 SOP page 6 of 53

value for that hour. To date, all ADEC purchased BAM-1020 monitors currently include or are in

the process of being upgraded with an inlet heater kit. This heater kit is crucial for most

applications throughout the State of Alaska. When the BAM-1020 internal relative humidity

sensor detects inlet moisture content > 55% RH, the inlet heater will activate. Heat is applied to the

inlet tube warming the inlet air ~ 3-5 OC above the ambient air temperature. The slight elevation

in temperature prevents inlet air moisture from condensing on the filter tape. The internal inlet

%RH sensor is only used as a triggering device and should not be used or confused with external

%RH data.

Reference Membrane: The reference membrane values generated during each hourly cycle are

instrument drift values, not to be confused with span values. All BAM-1020 monitors purchased

by the ADEC possess a reference membrane. Each ADEC BAM-1020 monitor should be deployed

with a Met One BAM-1020 Operation Manual that is unique to that instrument. Page 80, Appendix

B of the BAM-1020 manual lists the calibration and membrane values specific to the serial number

of the instrument indicated. The density of the reference membrane for any particular BAM-1020 is

listed on the line labeled "ABS", a value typically between 0.800 to 0.850 mg/cm2. Each hour, this

membrane is automatically positioned in the beta path and analyzed for instrument drift. The

analysis of this membrane is integrated and displayed on the BAM-1020 display screen as "LAST

m:" during the following hour. The purpose of the membrane is only to monitor instrument drift

from factory calibrations. The "LAST m:" value should not be used or confused with instrument span

values. The BAM-1020 does not have the capability to analyze or report any span value

information. If a "LAST m:" value differs more than +/- 5% from expected, then the mass data

for that hour should appear flagged with a “D” (Deviant Membrane Density). This would indicate

that the Reference Membrane was out of limits by more than +/- 5%.

2 INSTALLATION PROCEDURE

The BAM-1020 Installation procedure has been separated into the following nine (9) areas. Each

area is described in further detail.

1. List of tools/supplies

2. Physical Inspection.

3. Siting.

4. Installing BAM-1020 Central Unit.

5. Drilling Inlet Tube Hole.

6. Attaching Inlet Support Hardware.

7. Tape Loading.

8. Pump Connection.

9. Outside Temperature (OT) Connection.

2.1 List of Tools/Supplies:

1. Hole saw/bits (1 3/8" and 2 1/4").

2. Weather proof silicone or roof sealant.

3. 2 conductor cable (min. AWG 20 gauge).

4. Tape (i.e. Scotch or masking).

5. 4 lag screws adequate for roof mounting plate.

6. Rack mounting screws.

Met One BAM 1020 SOP page 7 of 53

7. Tools that include drill, screwdriver and socket set.

8. Certified flow standard capable of measuring 16.7 L/min.

9. Certified temperature and pressure standard

2.2 Physical Inspection

Upon receipt of a BAM-1020, inspect equipment and accessories for completeness and for

shipping damage. If shortage or damage is found, immediately notify your supervisor and/or your

agency's shipping department.

NOTE: The BAM-1020 should never be moved unless the two hard foam packing rings (referred

to as donuts) are placed around the transport rollers. Failure to install the donuts can cause

severe damage to the instrument.

List of BAM-1020 Components:

1. BAM-1020 central unit.

2. Vacuum pump.

3. Inlet Tubing.

4. PM10 FRM Inlet.

5. PM2.5 Sharp Cut Cyclone (SCC) Inlet.

6. Pump tubing and wiring.

7. Heater Kit.

8. Inlet Support Brackets.

9. Outside Temperature Sensor.

2.3 Siting:

The BAM monitor has specific physical requirements that should be considered prior to installation.

The BAM-1020 central unit and pump is neither waterproof nor water-resistant and must be

protected from moisture. The BAM-1020 was designed to operate in a temperature-controlled

enclosure between 0 °C and 40 °C, and where the relative humidity is not condensing and does

not exceed 90%. All ADEC BAM-1020 monitors will be deployed inside a weather-proof and

temperature controlled structure.

In general, when choosing the location for BAM-1020 monitor, it may help to consider the

following items:

1. Inlet radius clearance: The BAM-1020 inlet must have a one (1) meter radius free of any

objects that may influence air flow characteristics, including the air flow radius of another

instrument. For example, if a BAM-1020 is to be installed at a station with another BAM-

1020 or a PM2.5 FRM filter sampler, the inlets of each sampler must be no less than two (1)

meters apart from each other. If installing near a PM10 SSI HiVol sampler, then the distance

between the inlets of the BAM-1020 and the HiVol must be no less than three (2) meters.

These distances are Federal EPA requirements (40 CFR Part 58).

2. Inlet height: The height of the inlet should be equal to the height of the federal reference

method filter samplers such as the PM10 head on the PM2.5 FRM or the large round PM10

impactor on the SSI HiVol.

3. Distance between BAM-1020 and station ceiling: A minimum distance of at least eight

(8) inches is required between the top of the BAM-1020 and ceiling. This distance is

necessary to safely accommodate the inlet heater kit and insulation.

Met One BAM 1020 SOP page 8 of 53

4. Heater Kit: The inlet heater kit includes a heater block that slides over the lower end of the

inlet tube (inside the station). When installed, the heater will cover approximately four

(4) inches in length of the inlet tube. The installed heater should be a minimum of two (2)

inches away from any object at either end of the heater, such as the instrument rack or ceiling.

These measurements suggest that the minimum distance between the BAM-1020 central

unit and the ceiling should be NO less than eight (8) inches.

5. Inlet: The straight, vertical inlet tubing of the BAM-1020 limits the placement of the

BAM-1020 central unit. The BAM-1020 inlet tubing is a 1 5/16" OD, 8' long rigid

aluminum tube. The lower end of the inlet tube inserts directly into the top of the BAM-1020

housing, the other end points horizontally upward through all roofing material and above

the roof line. The selected particle size inlet(s) are mounted on the upper end of the inlet

tube. The BAM-1020 FRM PM10 head should be installed so that its height is equal to the

same inlet height of the PM2.5 FRM or HiVol SSI filter sampler heads. In addition, the

sampler inlet must be between 2 meters above the roof line and between 2 to 15 meters above

the ground. Provisions must be made during installation to allow future removal,

maintenance and re-installation of all equipment.

6. Specifications: Specifications for siting a BAM-1020 will mirror the Federal EPA PM2.5

criteria listed in the Code of Federal Regulations (40 CFR, Part 58).

2.4 Installing BAM-1020 Central Unit:

The BAM-1020 can be rack mounted, placed on a table, shelf or other flat surface. As with all

instrumentation installations, the racks, table or fixture must be secure and the overall installation

must protect both the instrument and personnel.

Because the BAM-1020 connector fitting for the inlet tube is located on top of the BAM-1020

central unit, installation of the BAM-1020 does not allow for other instruments to be mounted

above it. However the BAM-1020 is installed, space for the vertical position of the inlet tube must be

taken into account.

2.5 Drilling Inlet Tube Hole:

Applications may vary due to structural and material makeup. Forethought may help alleviate

problems and frustration. After locating a suitable place for the BAM-1020 monitor, the holes for

the BAM inlet tube can be drilled. Protect instruments from falling debris. The inlet support

hardware should include a rooftop mounting plate for stations with a flat roof. The mounting plate

has a circular ridge that protrudes beneath the surface and therefore a 2¼” diameter recess must

be made on top of the roof in order to accommodate the ridge.

Inside station ceiling hole: The hole on the inside of the station should only be large enough to

accommodate the outside diameter of the inlet tube. Use a 1 3/8" diameter hole saw. A plumb

bob can help locate the best position on the ceiling of air monitoring stations. Drill a 1 3/8" hole

vertically through the ceiling directly above the BAM-1020 monitor inlet spout. STOP drilling

when the tip of the guide bit just begins to poke through the top of the roof. The drill bit hole will be

used as a guide when drilling down from above and therefore do NOT drill a 1 3/8" hole all the way

through the roof.

Outside roof top hole: Relocate to the topside of the roof after drilling the 1 3/8" inside ceiling

hole from underneath (remember to only drill until the hole saw bit just pokes through the roof

top). Using the hole created by the guide drill of the 1 3/8” hole saw bit, drill downward with a 2 ¼”

Met One BAM 1020 SOP page 9 of 53

hole saw until the hole is deep enough to accommodate the roof mounting plate.

2.6 Attaching Inlet Support Hardware:

Affix the inlet mounting plate to the top of the roof with plenty of weatherproof sealant and four

adequate lag bolts. Attach the supplied inlet coupler to the mounting plate. Slide the inlet tube

through the coupler, plate, roof and ceiling. From inside the station, gently insert and seat the

bottom end of the inlet tube into the top of the BAM-1020 central unit. Test seal with water. Two

(2) additional lag screws, the two supplied inlet brackets and the single (1) supplied hose clamp

can be used to help support the inlet tube. The inlet(s) can now be attached to the top end of the

inlet tube.

2.7 Tape Loading

Loading the tape must be performed before accessing other BAM-1020 functions. A diagram of

the Filter Tape area can be found on page 33 of the BAM 1020-9800 Rev E Operator Manual.

Begin by lifting the pinch roller (the pin with the black roller located in the upper front of the

BAM) and locking the roller into position with the latch (located immediately to the left of the pinch

roller). Remove both clear spool caps by unscrewing the black knobs (bottom left and bottom right

spools). Unroll approximately 2-3 feet of tape and slide the roll on to the bottom right spool

(supply spool) of the BAM-1020. Position the supply spool so that as the tape unwinds on the

spool, the roll turns counter clockwise. The tape will 'S' around the two center rollers by feeding

around the left supply tension roller located just above and to the left of the supply spool, then around

the right side of the right end roller located slightly above and to the right of the tension roller. The

tape slides in the slit located between the source and detector, and between the pinch roller and

capstan shaft (the thin metal shaft located just below the pinch roller). 'S' the tape around the left side

of the left end roller (roller on the upper left), around the right side of the take-up tension roller

(just below and to the right), then secure the end of the filter tape onto the take-up spool (located

bottom left) with a small piece of Scotch tape. Wrap the filter tape approximately once around the

take-up spool. The left side tape configuration should be a mirror image of the right side.

Note: The take-up spool core will be removed with the used filter tape each time a new

filter is installed. The spool core that is left when each filter tape role is completely used up

should be moved from the right supply spool area to the left take-up spool area. Do not

connect the filter tape directly to the take-up spool wheel; this will require you to unwind

the complete filter tape the next time it is replaced.

Lift up on the pinch roller (the latch will automatically unlock). Gently lower the pinch roller

until it completely touches the filter tape against the capstan roller. Advance the tape about 10

spaces, then reverse the tape about 5 (this will help position the tape on to the rollers). Advance

the tape by:

1) Press the "TEST" soft key.

2) Using the right arrow key, move the cursor over to ‘TAPE' and press the

"SELECT" soft key.

3) With the up or down arrow keys, adjust the number on the 'FEED:' line until '10

MORE WINDOWS' is displayed.

Met One BAM 1020 SOP page 10 of 53

4) Press the "FWD" soft key

5) Wait until the 'X:' display reads '10 WINDOW (S)'

6) With the up or down arrow keys, adjust the number on the 'FEED:' line until '5

MORE WINDOWS' is displayed.

7) Press the "BKWD" soft key.

8) Visually check tape for binding, tears or other obvious problems. Wherever the tape

comes in contact with the rollers, the entire width of the tape should be on the

roller with a little bit of the roller's edge showing.

9) Press the "EXIT" soft key. The BAM-1020 tape is now loaded and adjusted.

2.8 Pump Connection:

The pump connects to the BAM-1020 with the supplied clear vacuum tube and 2-lead wire.

Pump wiring: Attach one end of the supplied 2-lead wire to the two inside terminals on the pump,

and the other end to the terminals on the rear of the BAM unit labeled 'PUMP CONTROL'.

Pump tubing: Insert one end of the supplied clear tubing to the only flow 'inlet' connector of the

pump, and the other end of the tubing to the only tube connector located to the lower rear of the

BAM unit. Push in each end of the tubing all the way, then pull back slightly to ensure a good seal.

The tubing should remain at least 6 feet in length to help reduce any possible flow fluctuations caused

by the pump.

2.9 Outside Temperature (OT) Connection:

All ADEC deployed BAM-1020 monitors will be configured for volumetric flow control. This

will require the installation of the supplied OT sensor. The BAM-1020 OT sensor must be

calibrated prior to the BAM-1020 monitor flow calibration.

Connect the four (4) OT thermister cable wires to the black input blocks on the back of the BAM 1020.

This temperature sensor must be attached to the terminal marked “Chan 6”. The yellow wire

connects to the screw marked “Sig”, the black/white wire connects to “Com”, the red wire

connects to “Power” and the Green wire connects to “ID”. A diagram of these connections can

be found on page 15 of the BAM 1020-9800 Rev E Operator Manual. The tables used to describe

the terminal connections can be found in appendix F, figure 61.

3 INSTALLATION PROCEDURE

3.1 Configure BAM-1020:

Each BAM-1020 is calibrated at the factory and possesses unique calibration settings. The

correct settings for each individual BAM-1020 are located in Appendix B of the BAM-1020

Operation Manual.

After making changes, it is always important to exit out to the main menu and return back to check if

the changes were saved. If changes in the configuration have not been saved, the cause is often

Met One BAM 1020 SOP page 11 of 53

due to a configuration parameter that is out of the BAM-1020 operating range or a value that is

significantly different than the current operating conditions.

When configuring or calibrating the BAM-1020, it is important to exit out to the main menu

before proceeding to the next parameter. This will ensure that each change has been saved and that

the BAM-1020 has updated to its new configuration or set point. The BAM-1020 is in the main

menu when the bottom of the display shows the words "SETUP", "OPERATE", "TEST" and

"TAPE".

Clock Set: To set the clock:

1. Press the "SETUP" soft key.

2. Ensure that the cursor is in the word 'CLOCK and press the "SELECT" soft key.

3. Use the cursor arrows to adjust the BAM-1020 date and time.

4. Press the "SAVE" soft key.

5. Press the "EXIT" soft key.

6. Confirm BAM-1020 date and time display in main menu.

Early Cycle Mode: There are two different configurations for the BAM-1020 analog output; the

'Standard' mode and the 'Early' cycle mode.

Note: This is a setup of the BAM analog output so this should work for all data loggers.

If a BAM 1020 is to be connected to an external data logger, the “Early” cycle mode must be

used. This is done so that the data logger will capture BAM-1020 data within the correct hour. To

configure the BAM-1020 to "EARLY' cycle mode:

1. Press the "SETUP" soft key.

2. Use the arrow keys to move the cursor to the word “INTERFACE” and press the

"SELECT" soft key.

3. The word 'EARLY' should be displayed to the immediate right of 'Cycle Mode:'.

4. If the word 'STANDARD" is displayed, press the up arrow key once. The

word 'EARLY' should appear.

5. Change 'STANDARD' to 'CYCLE' by pressing the down arrow key once.

6. Press the "SAVE" soft key.

7. Press the "EXIT" soft key.

8. Confirm 'EARLY' cycle mode configuration by performing steps 1 through 3.

Volumetric flow mode configuration:

There are two different configurations for flow; 'METERED' and 'VOLUMETRIC (the

calibration process is different for each mode). For Federal Reference Method (FRM) PM2.5 filter

Met One BAM 1020 SOP page 12 of 53

comparability, all BAM-1020 monitors purchased by the ADEC have been configured for

'VOLUMETRIC’ flow control. To check the BAM-1020 for correct 'VOLUMETRIC’ flow control

configuration:

1. Press the "SETUP" soft key.

2. Use the arrow keys to move the cursor over the word 'Calibrate' and press "SELECT".

3. The word 'VOLUMETRIC’ should be displayed to the immediate right of 'FLOW

TYPE'.

4. If the word 'METERED' is displayed, use the down arrow key to change the word

'METERED' to ‘VOLUMETRIC’.

5. Press the "SAVE" soft key.

6. Press the "EXIT" soft key.

7. Confirm ‘VOLUMETRIC’ flow control configuration by performing steps 1 through 3.

4 START SAMPLING

To start sampling:

1. From the main menu, press the "OPERATE" soft key.

2. Press the "NORMAL" soft key. The BAM-1020 may take up to two (2) minutes before

sampling. Tape movement will occur approximately four (4) minutes before the beginning

of the next collection cycle.

Note: If the sampler is not left in the Normal Operate mode it may interfere with the remote

communication process.

3. Download the System configuration.

a. Check and insure the date is correct

b. Check and insure the time is correct (within 10 sec of NIST)

c. Check and insure the ABS number is correct for the BAM being used.

Note: This information should be kept as part of the permanent record for the site.

5 ROUTINE SERVICE CHECKS

5.1 General Information

Perform the following checks on the BAM-1020 at the intervals specified in the service schedule.

The checks may be performed more frequently but should be performed at least at the prescribed

intervals. Document all results and maintenance activities. Use the BAM 1020 Monthly QC Check

Form to document required monthly BAM flow rate verifications.

5.2 Daily Checks

Review station data logger values for correct operation of the BAM-1020.

Met One BAM 1020 SOP page 13 of 53

5.3 Weekly Checks

Check the BAM-1020 filter tape. One roll of filter tape should last approximately

2 months. Replace when necessary.

5.4 Biweekly Checks

Download data records and error records directly from the BAM. This data should be used to

verify the data collection via modem or other communications methods.

Note: This may need to be done on a more frequent basis. The BAM will only store the last

100 errors.

5.5 Monthly Checks

Perform a BAM-1020 inlet flow check to ensure the sampler flow rate is operating at 16.7 liters

per minute.

For PM10 the flow rate criteria is:

≤± 10%

∆

(design flow) and

≤± 7%

∆

of NIST traceable flow standard value.

For PM2.5 the flow rate criteria is:

≤± 5%

∆

(design flow) and

≤± 4%

∆

of NIST traceable flow standard value.

5.6 Quarterly Checks

1. Clean the sharp cut cyclone inlet.

2. Clean the FRM PM10 inlet.

3. Make copies of all pertinent log sheets and log books for data validation and quarterly reports.

4. Download data files and error records.

5.7 Semiannual Checks

Perform semi-annual verification/calibration of the external ambient temperature sensor, internal

pressure sensor and volumetric flow controller.

Met One BAM 1020 SOP page 14 of 53

Network Agency: Station Location:

Contractor: Site Name:

Date: Time:

Auditor: Observer:

SAMPLER INFORMATION

Sampler:

PM

10

Continuous monitor

Manufacturer:

Met One M/N: BAM 1020 w/inline heater S/N:

PM

10

Inlet Impaction

Audit Device Manufacturer: M/N: S/N:

certified by: cert date: exp. date: Device certified for temperature, pressure & flow measurements

Sampler Data

Flow Ambient Flow Rate Accuracy Design

QC Temp. Ambient Pressure ∆H

2

OFlow Rate Amb. Temp. Amb. Press. Amb. Temp. Amb. Press. (S-QC)/ (QC -16.7)/

Device

(

o

C) (mbHg) (mmHg) (inches) Q

a

(L/min) Q

a

(L/min) Inlet (

o

C) (mmHg) (

o

C) (mmHg)

QC*100

16.7*100

Sampler

Leak Check

ID (L/min) Date Date Date

Flow Check

QC % ∆= [(Q

a

,BAM - Q

a

,orifice)/Q

a

,orifice]*100 QC % ∆≤± 7%

QC (Data Validation) %∆= [(Q

a

,sampler - Q

a

,orifice)/Q

a

,orifice]*100

QC % ∆≤ ± 10%

Design Condition % ∆= [(Q

a

, BAM - 16.7)/16.7]*100 Design Condition % ∆≤± 10 %

Temperature Check

QC ∆= BAM Temperature (ambient) - QC Check Std. temperature (ambient) QC ∆≤± 4

o

C

Pressure Check QC ∆= BAM Pressure - QC Check Std. Pressure QC ∆ ≤± 10 mmHg.

Time QC Check

QC ∆= Sampler Time - QC Std. Time Time ∆≤± 1 minute

Leak Check ≤ 1.5 liters/minute

Notes:

QC Standards Data

Difference (∆)

Flow Rate % ∆

Sampler - QC Flow Std

ALASKA DEPARTMENT OF ENVIRONMENTAL CONSERVATION

Monthly PM

10 β Attenuation Monitor Flow Rate, Temperature & Pressure QC Check

QUALITY CONTROL (QC) CHECK STANDARDS INFORMATION

QC CHECK RESULTS

Monthly QC Check Criteria

QC Standard Time (AST)

Sampler Time (AST)

∆

hour:minute:second

hour:minute:second

hour:minute:second

Met One BAM 1020 SOP page 15 of 53

Network Agency: Station Location:

Contractor: Site Name:

Date: Time:

Auditor: Observer:

SAMPLER INFORMATION

Sampler:

PM

10

Continuous monitor

Manufacturer:

Met One M/N: BAM 1020 w/inline heater S/N:

PM

10

Inlet Impaction PM

2.5

Inlet: Cyclone

Audit Device Manufacturer: M/N: S/N:

certified by: cert date: exp. date: Device certified for temperature, pressure & flow measurements

Sampler Data

Flow Ambient Flow Rate Accuracy Design

QC Temp. Ambient Pressure ∆H

2

OFlow Rate Amb. Temp. Amb. Press. Amb. Temp. Amb. Press. (S-QC)/ (QC -16.7)/

Device

(

o

C) (mbHg) (mmHg) (inches) Q

a

(L/min) Q

a

(L/min) Inlet (

o

C) (mmHg) (

o

C) (mmHg)

QC*100

16.7*100

Sampler

Leak Check

ID (L/min.) Date Date Date

Flow Check

QC % ∆= [(Q

a

,BAM - Q

a

,orifice)/Q

a

,orifice]*100 QC % ∆≤± 4%

Design Condition % ∆= [(Q

a

, BAM - 16.7)/16.7]*100 Design Condition %∆≤± 5%

Temperature Check

QC ∆= BAM Temperature (ambient) - QC Check Std. temperature (ambient) QC ∆≤± 4

o

C

Pressure Check

QC ∆= BAM Pressure - QC Check Std. Pressure QC ∆ ≤± 10 mmHg.

Time QC Check

QC ∆= Sampler Time - QC Std. Time Time ∆≤± 1 minute

Leak Check ≤ 1.5 liters/minute

Notes:

QCStandards Data

Difference (∆)

Flow Rate %

∆

Sampler - QC Flow Std

ALASKA DEPARTMENT OF ENVIRONMENTAL CONSERVATION

Monthly PM

2.5

β Attenuation Monitor Flow Rate, Temperature & Pressure QC Check

QUALITYCONTROL (QC) CHECK STANDARDS INFORMATION

QC CHECK RESULTS

Monthly QC Check Criteria

QC Standard Time (AST)

Sampler Time (AST)

∆

hour:minute:second

hour:minute:second

hour:minute:second

Met One BAM 1020 SOP page 16 of 53

6 MAINTENANCE PROCEDURES

6.1 General Information

Normal BAM-1020 maintenance requires keeping the BAM-1020 central unit dust free and all

sampler inlets clean.

6.2 Sampler Maintenance

As with all monitoring equipment, the BAM-1020 should be kept clean and dust free. Use a lint

free cloth to remove dust. Remove all inlet filter screens and wash with soap and water.

6.3 PM2.5 Sharp Cut Cyclone (SCC) Maintenance

The PM2.5SCC inlet requires removal from the inlet tube, disassembly and cleaning. The inlet

should be thoroughly cleaned every 3 months. Disassemble the SCC and wipe clean with lint

free cloth. Ensure that all 'O' ring surfaces are in excellent shape, greased and re-installed correctly.

6.4 PM10 Inlet Maintenance

The PM10 inlet requires removal from the inlet tube, disassembly and cleaning. The inlet should

be thoroughly cleaned every 3 months. Disassemble the PM10 inlet and wipe clean with lint free

cloth. Ensure that all 'O' ring surfaces are in excellent shape, greased and re-installed correctly.

6.5 pump rebuild

Please see Tech Note # 5

7 TROUBLESHOOTING

7.1 General Information

A desktop or laptop computer is an important tool when verifying proper data logger acquisition

and troubleshooting. Error codes and BAM-1020 data can be observed and downloaded using the

Microsoft Windows HyperTerminal software program. The HyperTerminal Properties and

Advanced Port Settings are:

1. Properties Screen:

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

2. Advanced Port Settings Screen:

Remove check from "Use FIFO buffers"

Met One BAM 1020 SOP page 17 of 53

Connect the computer port cable to the upper RS232 connector located at the rear of the BAM-

1020. Activate the HyperTerminal program and press the computer's return button three times.

An asterisk (*) should appear. If not, depress the small white and red polarity toggle switch located

next to the RS232 connector on the back of the BAM-1020. Type the letter ‘H’ and a menu will

appear. To download BAM-1020 data to a laptop or desk computer, the 'Capture Text' function of

HyperTerminal can be used.

Should the BAM-1020 fail to operate, refer to section 10.3 of the BAM-1020 operating manual.

This section contains a troubleshooting guide that outlines symptoms, checkpoints, probable

causes and remedies for general problems.

8 Acceptance Test Procedures

8.1 General Information and Acceptance Test Log

The following outlines the acceptance test procedures for the BAM-1020. Before beginning

acceptance testing of the BAM-1020, read the operating manual thoroughly to become familiar with

the theory of operation and hardware of the instrument. Initiate an acceptance test log and an

acceptance test report. Record the dates of the individual tests, problems, and contacts with the

manufacturer, and any other pertinent information on the acceptance test log.

8.2 Physical Inspection

Before the shipping container is opened, check the outside surfaces of the shipping containers for

obvious damage. If there is any damage to the shipping container, notify the people used to ship

the BAM before opening and follow their recommended procedures.

Unpack the instrument and check for physical damage. Verify that the sampler is complete and

includes operational manuals, service manuals and all options and parts required by the purchase

order.

Check for correct power cord phasing; standard wiring configuration has the black wire

connected to the brass terminal of the plug, white to the copper terminal, and green to earth

ground.

Complete assembly of any accessory parts required before performing the acceptance test. This

may include the water trap, neck piece, inlet tube, PM 2.5 cyclonic separator, pump, and tubing.

Complete installation of all cables or signal output wiring, following instructions in the

manufacturer's manual.

8.3 Operational Checks

Prior to beginning acceptance procedures, refer to the manufacturer's operating manual for

performance of the operational results.

If the BAM is to be connected to an external datalogger the BAM-Datalogger connections should

be completed before turning on power.

Met One BAM 1020 SOP page 18 of 53

If the BAM analog outputs are going to be used to perform the following tests, connect a strip

chart recorder to the instrument analog output so that variations may be monitored and evaluated.

Recorder charts should be cut into 24-hour segments and labeled at the bottom with the

following:

1. Test Performed

2. Date of Test

3. Manufacturer, Model number and Serial Number of BAM-1020

4. Recorder identification, range, trace color, parameter identification.

Clear and precise notations should be entered on the chart indicating when the tests were started

and ended, pertinent information regarding sample flow, voltages, temperatures, and any unusual

conditions observed. Charts should be attached to the final acceptance reports.

8.4 Perform Operational Checks:

Once the BAM-1020 is completely assembled and meets all of the physical specifications, turn on

the main power switch. The top menu will appear on the display above four "soft" keys. Make

note of PROM version at this time. Following instructions in section 4.7, load the filter tape.

Refer to sections 4 and 5 of the operating manual to become familiar with the proper operation of

each of the four "soft keys". After verification that all switches and controls operate properly,

proceed on with the manual to complete the acceptance testing. Record results and indicate pass or

fail on the acceptance test report data sheet.

Refer to section 4.18 of operation manual (SETUP: INTERFACE). Set cycle mode to "Standard",

Refer to section 8.1 of the operation manual. Set the analog output (Volts out) on rear of

instrument to 1.0 Volt.

Refer to section 4.13 of the operation manual. Use "Setup" mode, select "SAMPLE", Set "Range"

to 0.1mg/m3. The default Password is F1, F2, F3 and F4. Setup "FLOW" to "VOLUMETRIC".

After verifying range can be selected, return to 1.000 mg Full Scale, and click "SAVE".

If applicable, connect the appropriate meteorological sensors or simulator to the rear of the

instrument; refer to section "translator interconnect" BX-964 of the operation manual. The

outside ambient temperature sensor must be connected to Chan 6 for volumetric flow

calibration and test.

Refer to section 4.14 and Appendix B of the operating manual to ensure proper ABS: number is

loaded in memory. Once verified (may have to contact factory), create a typed label in the form

"ABS: nnnn" and affix to the side of the Beta source mounting block, where it will be readily visible

with the display/tape access door open.

Refer to section 4.10 Starting Measurement Cycles and follow steps 1 through 6 to begin

operation. After a few hours of monitoring room air, the chart recorder trace should look similar to

the "standard timing" depicted in section 4.18, fig 25 of the operation manual.

Met One BAM 1020 SOP page 19 of 53

To ensure that the meteorological sensors are "operating", press INST on the Operate Mode

screen. The various sensor outputs should be displayed. Exit to main menu, press "TEST", then

"FLOW”, and proceed to "VOLUMETRIC FLOW CALIBRATION MODE" menu. Ensure

"BAM" and "REFERENCE" temperatures agree with AT (ambient temperature) display.

Check the flow by using a certified mass flow meter (MFM) and Flow Test Adapter with shut-off

petcock. BE SURE PETCOCK IS FULL OPEN BEFORE STARTING FLOW CHECKS. Flow

should be 16.7 VLPM (+/- 0.2 LPM). If necessary convert reference MFM standard flow to

volumetric using room ambient temperature and pressure values. Record standard and volumetric

flows on data sheet. Disconnect flow test tubing from the BAM-1020 inlet. Select TEST: FLOW

screen. Slowly close petcock. Let stabilize for a few minutes, then make a note of leak rate from

BAM FLOW display (< 1.5 LPM). SLOWLY open petcock, and observe that flow returns to set

point before proceeding. Remove test adapters. Allow the BAM-1020 test setup to run

undisturbed for several hours (preferably overnight) before proceeding.

To ensure that the internal Data Logging of the BAM-1020 is operating properly, connect a PC to the

RS232 port at the rear of the instrument. Download the stored data. Data from all of the connected

sensors as well as the concentration should be displayed hourly. If there have been any failures,

such as power fail or a tape break, an error code should be displayed as indicated in section 4.16

page 47 of the operation manual.

9 Calibration Procedures

9.1 Background and General Information

9.1.1 Introduction

The purpose of this section is to outline the Met One Beta Attenuation Mass Monitor, model

1020 (BAM-1020) verification and calibration procedures used by ADEC. The Met One

Instrument's BAM-1020 Operation Manual is an important resource of information for BAM-

1020 calibrations, and therefore the ADEC highly recommends a thorough review of the BAM-

1020 Operation Manual.

9.1.2 Overview

The BAM-1020 requires the calibration of the outside temperature sensor (OT), the internal pressure

sensor and the volumetric flow controller. There are two separate flow configurations for the

BAM; metered flow or volumetric flow.

All BAM-1020 monitors purchased by the ADEC will be configured in the volumetric flow

mode (thus requiring the installation of an OT sensor).

When configuring or calibrating the BAM-1020, a specific instrument password will be required.

The password can be obtained by contacting the station administrator.

9.1.3 Apparatus for BAM-1020 Calibration

1. NIST-traceable flow transfer standard

2. NIST-traceable temperature meter

3. NIST-traceable pressure meter

4. Tubing

Met One BAM 1020 SOP page 20 of 53

5. Calibration forms or laptop computer

9.1.4 General Information

The calibration of the Met-One BAM Monitor should be performed in the following steps:

1. Ambient temperature sensor calibration/verification.

2. Ambient pressure sensor calibration/verification.

3. Volumetric flow calibration/verification.

Record all calibration information and data.

It is important to exit back to the main menu between each complete calibration parameter. As

with most software driven monitoring equipment, returning to the main menu between

calibrations can be imperative when adjustments are made to specific components that ultimately

impact the calibration and/or operation of the instrument's other components. Exiting out of the

calibration screen and returning to the main menu between calibrating each component allows

the BAM-1020 to completely update any configurations or changes made. Temperature and

pressure changes are especially critical with respect to the BAM-1020's volumetric flow control.

9.2 Calibrations

9.2.1 Calibration Transfer Standards and Equipment:

All calibration transfer standard equipment must possess up-to-date certification. Certified

temperature and pressure sensors are required for both BAM-1020 OT and pressure calibrations.

A certified flow meter or certified fixed orifice device (such as the FTS Streamline) will be

required for flow calibrations.

Allow all AC powered equipment to equilibrate to ambient conditions for a minimum of 1 (one)

hour.

9.2.3 Temperature Sensor Calibration (OT):

The BAM-1020 external OT sensor is calibrated by initiating the BAM-1020 temperature

calibration sequence and entering in a single ambient temperature value. Perform the following

steps to calibrate the BAM-1020 OT sensor:

1. In the BAM-1020 main menu, press the "TEST" soft key.

2. Using the right arrow key, move the cursor over to the word 'FLOW’ and press the

"SELECT" soft key.

3. With the arrow keys, enter the corrected ambient temperature (in °C) on the row to the

right of 'AMBIENT TEMPERATURE', under the column labeled 'REFERENCE'.

4. Press the "ADJUST/SAVE" soft key.

5. Press the "EXIT" soft key.

Table of contents

Popular Measuring Instrument manuals by other brands

Littelfuse Startco

Littelfuse Startco SE-601 manual

KYORITSU

KYORITSU KEW SNAP Series instruction manual

LOVATO ELECTRIC

LOVATO ELECTRIC DMED302 instruction manual

Mitutoyo

Mitutoyo HDM 192 Series Operation manual

Diehl Metering

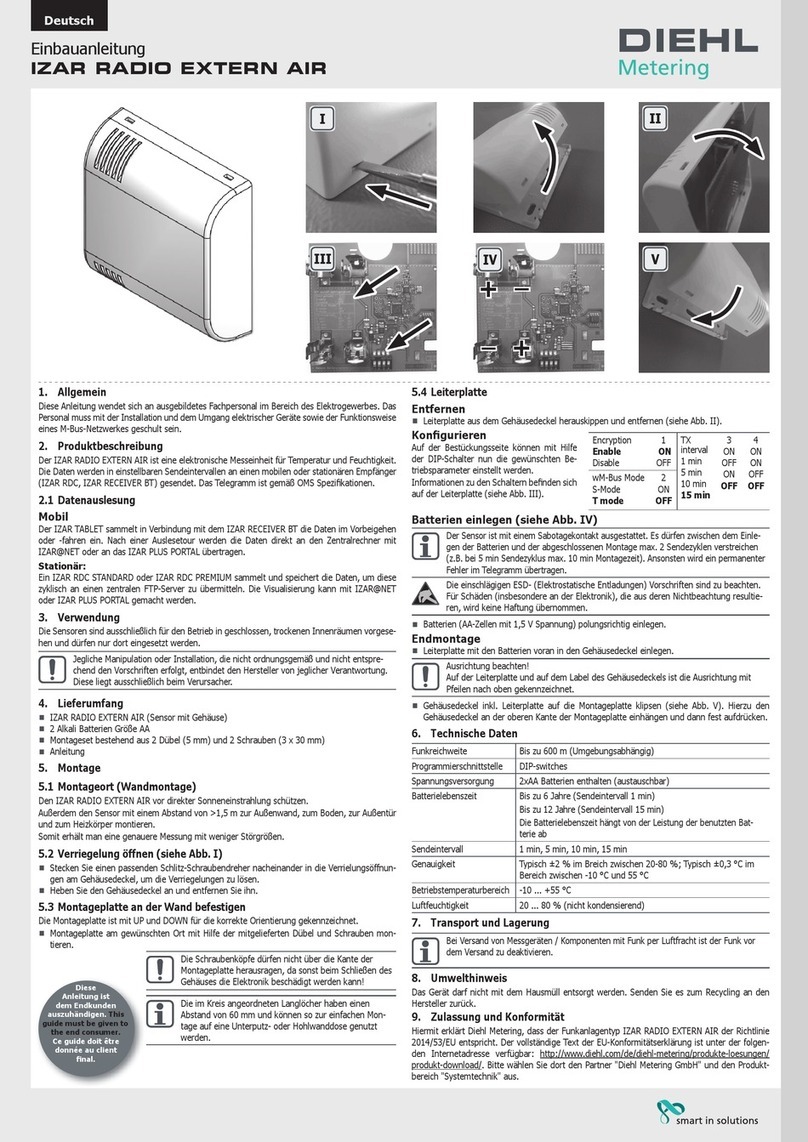

Diehl Metering IZAR RADIO EXTERN AIR installation guide

Timewave

Timewave DM-1 operating manual