SK00-9663-EI-003-00

IX

Writing setpoint1 setting

value ........................... 31

Writing setpoint2 setting

value ......................... 31

7.5. CHECKSUM......................... 32

7.6. STATUS .......................... 33

SH (Higher status) ......... 33

SL (Lower status) .......... 33

7.7. ASCII CODE TABLE ................. 34

8. ZERO POINT ADJUSTMENT AND ATMOSPHERIC

PRESSURE ADJUSTMENT..................... 35

8.1. ADJUSTING METHOD .................. 35

Zero point adjustment ...... 35

Atmospheric pressure

adjustment ......................... 35

8.2. CHECKING THE COMPLETION OF ADJUSTMENT . 36

8.3. ADJUSTMENT CLEAR .................. 36

8.4. MEMORY FUNCTION ................... 36

9. OUTPUT (MEASURED OUTPUT VOLTAGE

COMPATIBILITY).......................... 37

9.1. SW1 SERIES COMPATIBILITY............ 37

9.2. SP1 COMPATIBILITY ................. 38

9.3. OTHER COMPATIBILITY ................ 39

PSG compatibility .......... 39

APG compatibility .......... 40

9.4. I/O CONNECTOR ANALOG OUTPUT TYPE SP1,

PSG, APG.............................. 41

10. SENSOR REPLACEMENT ............... 42

10.1. TOOLS ......................... 42

10.2. REMOVAL OF SENSOR ............... 42

10.3. MOUNTING THE SENSOR.............. 42

10.4. LEAK TEST...................... 42

10.5. ADJUSTMENT AFTER REPLACEMENT OF SENSOR42

11. HOW TO USE UL-MOBI ............... 43

11.1. FUNCTION....................... 43

11.2. WINDOWS VERSION UL-MOBI ......... 44

Usage environment ........ 44

Download/install ..........45

How to use ................45

11.3. ANDROID VERSION UL-MOBI ..........50

Usage environment .........50

Download/install ..........50

How to use ................50

11.4. STATUS COMMENT..................56

12. TROUBLESHOOTING ...................57

12.1. TROUBLESHOOTING ..................57

12.2. CONFIRMATION OF FILAMENT AND TEMPERATURE

SENSOR DISCONNECTION ......................63

12.3. INSULATION BETWEEN THE SENSOR PIN AND

CASE ..............................63

13. TECHNICAL REPORT ..................64

13.1. GAS SPECIE/HUMIDITY DEPENDENCE......64

13.2. ZERO POINT ADJUSTMENT AND ATMOSPHERIC

PRESSURE ADJUSTMENT .......................65

13.3. SCHEDULED ADJUSTMENT ..............65

14. WARRANTY ..........................67

15. EC DECLARATION OF CONFORMITY ......69

16. UK DECLARATION OF CONFORMITY ......70

17. CERTIFICATE OF DECONTAMINATION ....71

18. DRAWINGS ..........................72

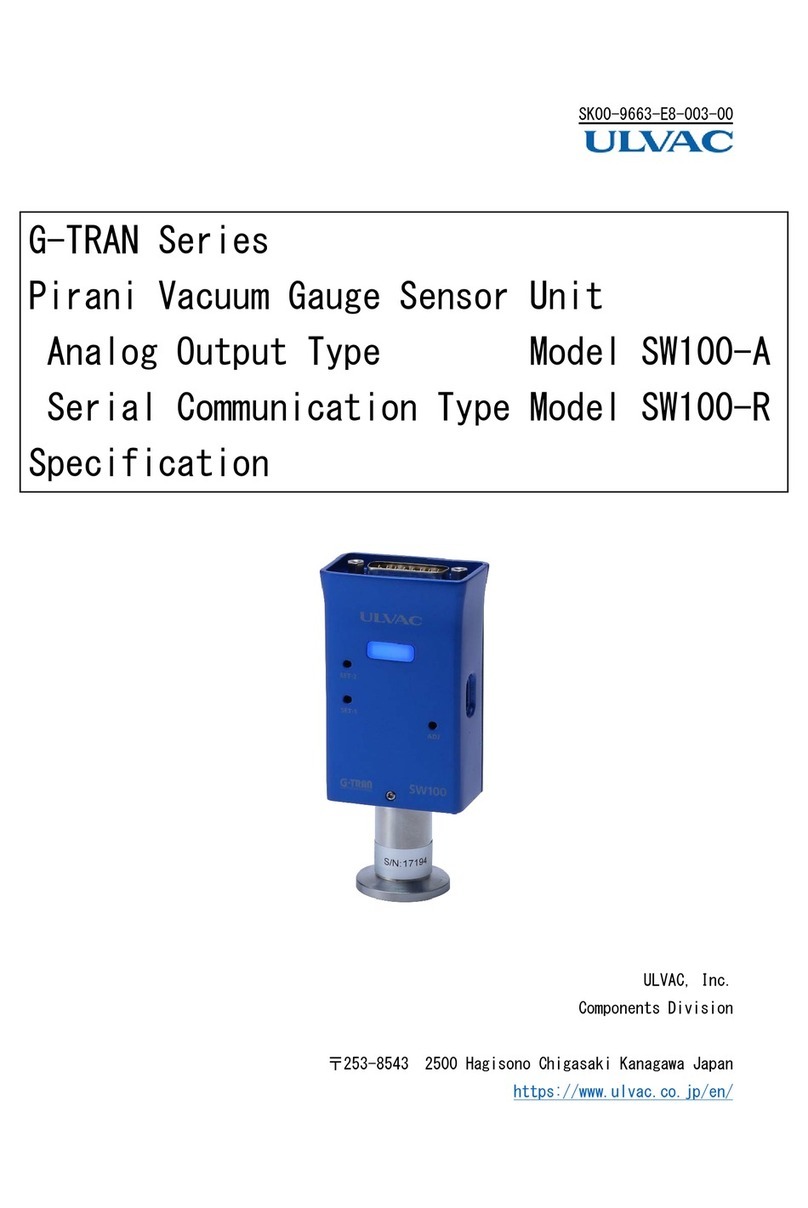

18.1. SW100-A/R DIMENSIONS............72

18.2. SENSOR DIMENSIONS ................73

18.3. DISPLAY UNIT CABLE ...............74