Adexa ZBS Series User manual

Operation Manual

ZBS Flake Ice Maker Series Commercial

Model: ZBS-20

To ensure use this appliance and your safety,

please read the following instructions completely

before operating this appliance.

8

Circuit Diagram CONTENT

Features ........................................2

Notes Before Operation.........2

Structure......................................4

Operation Procedures............5

Maintenance................................6

Trouble And Shooting............7

Circuit Diagram.........................8

Install the filter..............................8

the operation is opposite with the arrowhead direction in the above

INSTALL THE FILTER

T2

Ice full

sensor

SQ1 SQ2

V2

Purple

M2 M3

Blue

Switch

2 7

≤45

1.The incline angle of the cabinet could

not be over 45° during transportation.

Don't make ice maker upside-down in

case the compressor or refrigerating

system troubles occur.

2.When the i will be used for the first time or ce flaker

reused after let it lie idle for a long time,drainage screw

should be unscrewed and a container should be placed under

it to receive wasted water.The first and second ice making

cycles are just for tube system cleaning, the ice made

should not be taken.After the water drained and drainage

screw is screwed, the normal ice making procedures will

begin and you can take the ice.

Features

Notes before operation

TROUBLE CAUSE REMEDY

Ice f laker does not

work.

1. The voltage is lower

than 187V

2. The ambient

temperature is too low

(lower than 10 )℃

1. Turn off the machine,restart

when the voltage is normal.

2. Try again when the ambient

temperature is over 10℃.

Compressor works,

but no ice was made.

1. Refrigerant leaks.

2. Refrigerating system

blocks.

3.Solenoid valve opens

constantly.

4.Condensing fan does not

work.

5.Hall element has no

interaction.

Compressor does

not work.

1. Water shortage.

2. Ice full.

3. Compressor stops(the

temperature of shell is

too high).

1. Check the water supply

system (water valve and

water supply tube).

2. Take some ice out.

3. Turn off the machine and

restart 1 hour later.

The indicator of

water shortage lights.

1. Water shortage in water

supply system.

2. Water valve damaged.

3. Tap water pressure too low.

The indicator of

trouble lights.

1. There is some ice has not

dropped.

2. The water tank has not

turned to proper position.

1. Check whether the solenoid

valve could be open, if not,

replace with a new one.

2. Check whether the switch(SQ1)

could get information from the

rotation of the eccentric wheel.

Check whether the rotating

motor and eccentric wheel skid

around. Check whether the

motor gear is dammaged when

rotate the eccentric wheel by

hand.

1. Refill the refrigerant and test

leakage.

2. Replace filter for the N2

filling system.

3. Replace the solenoid valve.

4. Check whether the

condensing for works.

5. Check whether the Hall element

is fine and in proper position.

1. Check and make sure the

water supply system is fine,

then restart.

2. Check the water valve.

3. If it is for tap water, the water

pressure should not be lower

than 1Kg/cm .

2

TROUBLE AND SHOOTING

( for reference of users and technicians )

Computerized control , easy operation & high reliability

Stainless steel exterior

Bell shaped clear ice

Self malfunction analysis

If water shortage or something wrong with the water

supply system,the Ice Maker will restart automatically

in 24hours otherwise you will stop the unit and restart

it again.

PU foamed ice storage cabinet ,so it is insulated

well and it could prevent the ice from melting

High Efficiency , low power consumption

Use fresh water to make clear and healthful ice

63

storage container, the ice full indicator on the display panel

will light on and the ice maker will stop automatically;

If there is a water shortage or something wrong with the water

supply system, the water shortage indicator will light on and the

ice maker will stop operation automatically.

6. For the ice use purified water as water source, if the water f laker

shortage indicator light and no ice is made when start the ice

procedure, maybe there is air in the water inlet tube. Unplug f laker

one end connecting water inlet tube and water valve of ice , f laker

then open water inlet switch till there is water and air come from

another end. Then connect the water inlet tube with water valve of

ice quickly.f laker

MAINTENANCE:

1.If the compressor stops for any reasons like water shortage, too

much ice, power off, etc., Don't restart it right away. You can

restart it 5 minutes later to protect compressor.

2.Check regularly the connectors of the water inlet and outlet tubes

and drain the little surplus water that may occur.

3.If the ice will be unused for long periods of time, pleasef laker

screw off the plastic drainage connector screw on the back of the

ice so as to drain the surplus water in the water groove. Then f laker

screw it on. Wipe the inner liner of the ice storage container with a

clean rag.

4.When plugging or unplugging,

the plug should be held by hand

and the wires should not be

dragged heavily.

5.Please clean the ice and its water supply system for one timef laker

every month. The ice should be unplugged before cleaning.f laker

3.The ice should be placed on flaker

horizontal and structurally sound

ground and away from heat source

and corrosive gas.

At least about 150mm room

should be left around the ice

maker to ensure the fine ventilation.

4. Please adjust the feet when placing the ice maker some where,

otherwise the water level will be effected and so do the ice

shape.Before using the ice for the first time, you should f laker

wait about 12 hours after positioning it in a proper place.

5. The outlet of drainage tube should be lower than cabinet so as to

drain water easily.

6. Voltage range:

187 ~ 242 V

7. The rated capacity of wire should be over 6A, the section area of

2

the wire is 0.75mm . The wire could be consisted by single ply or

multiplies. The rated current of fuse is 5A.

8.The grounding must be good.

>150mm

>150mm

>150mm

242V

187V

220V

45

1.Unpack the package and take out the attached documents and spare

parts such as the water inlet and outlet tubes, ice shovel and gaskets,

etc.

2.Position the ice on a well ventilated place and leave at least f laker

150mm room between the ice maker and the wall. Be sure the ice

is positioned levelly and away from the heat source.f laker

3.Make one end of the φ14 flexible plastic corrugated pipe (supplied

with the machine) connected with the water outlet tube on back of

machine, another pipe end should be placed in a container for

surplus water (prepared by user himself) or in the sewer.

4.Make one end of the water inlet tube (supplied with the machine)

connected with the 3/4″ screw type connector of the water tap so

as to get the drinkable tap water. The water pressure of water supply

2

pipe is 1~8 Kg/cm . The other end of the water inlet tube should be

connected with the screw type connector of water valve on the back

of the ice maker. Be sure to put gaskets (supplied with the machine)

in both ends of the water inlet tube before connecting. If it is an ice

for purified water, a φ14 corrugated pipe (supplied with the f laker

machine) should be used. Connect one end of the pipe with the

purified water supplier (cold water tap or end of water drainage

tube of water dispenser) and another end with water valve

connector on the back of the ice maker. Make sure that the purified

water outlet position is higher than the top of the ice make.

5.Make power connection and press the switch on the panel,the run

indicator light on.Then the maker begins to work. All the procedures:

water inlet ~ ice making ~ice dropping ~ ice storing, are controlled

automatically for ice making continuously. If ice is full in the ice

Structure: Operation Procedures:

7

8

9

5

3

10

1

2

4

6

Operation Panel

Front Panel

Door

Screw of Drainage

Ice Lever Sensor

Ice Storage Container

D I S PL A Y BO A RD

RUN FAULT ICE FULL WATER LOW

Indicator I nstruction

No indicator is on Connect the power for a short time;

In trouble self-correct state

Running i ndicator

is o n.

Ice full indicator

is on.

Ice storage container is full or the

temperature is below 5℃.

Water shortage

indicator is

twinkling every

one second.

No water into the cabinet. But once there

is water, it will operate automatically.

Water shortage

indicator is on.

No water into the cabinet. Reset the

machine when the water source is recovered

DISPLAY BOARD

Item Description Item Description

1

2

3

4

5

6

7

8

9

10

Power Cord

Water inlet

Drainage Tube

Bottom Foot

Ice flaker is Normal

This manual suits for next models

1

Table of contents

Other Adexa Ice Maker manuals

Popular Ice Maker manuals by other brands

Showven

Showven CREEPER ICE PLUS user manual

Follett

Follett Horizon Elite Chewblet 1010 Series installation instructions

Scotsman

Scotsman CSE60 Service manual

KitchenAid

KitchenAid KUID308HPS installation instructions

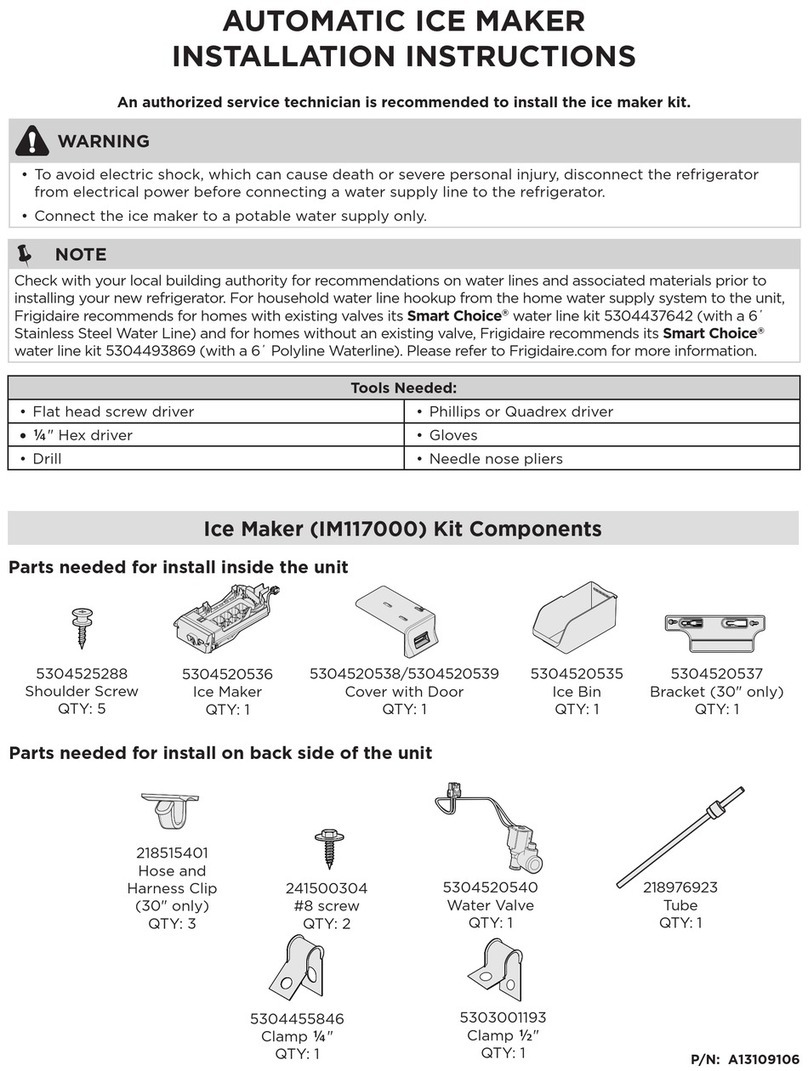

Frigidaire

Frigidaire FFTR1835VS installation instructions

Whynter

Whynter SNO ICE-100S owner's manual

ROWAN ELECTRIC APPLIANCE

ROWAN ELECTRIC APPLIANCE HZB-15NA user manual

U-Line

U-Line UHCR115 User guide & service manual

Hoshizaki

Hoshizaki KM-250BWF Specifications

Cornelius

Cornelius NORDIC ELITE Series owner's manual

Cornelius

Cornelius Remcor 620037007 installation instructions

Viking

Viking FGIM515 installation instructions