ADF 100 DUO User manual

Owner’s Manual

ADF LINEA 100 DUO

Inbuilt Appliance

Supplied by:

Castworks Pty Ltd

12 Fiveways Boulevard

Keysborough VIC 3173

TESTED IN ACCORDANCE WITH AS/NZS 4012:2014 & AS/NZS 4013:2014

Please read this manual thoroughly before installing and starting your free-standing appliance.

Keep these instructions for future reference

V18062018

2

Index

1. Introduction 03

2. Appliance Layout 05

3. Technical Specifications 06

4. Installation Instructions 09

A. Installation into a Skamol Enclosure Board Construction 09

B. Installation into a Zero Clearance Box and Timber Framing 14

C. Ducting - Convection Air Transfer Ducting 15

D. Decorative Frame Trim 17

5. Flue Installation and Outlet 18

6. Fan 20

7. Installing the bricks and baffles 22

8. Instructions for use 23

9. Maintenance and cleaning 24

10. Troubleshooting 26

11. Warranty 27

12. Data Label 29

3

1. Introduction

Congratulations on your purchase of your new ADF woodfire appliance!

Years of extensive research and dedication to innovation and quality, since 1976, has resulted in these

beautifully designed European appliances, constructed to strict Portuguese and European legislation, and

tested and Certified to the Australian Emissions, Efficiency and Safety standard requirements

guaranteeing excellent performance.

Please read this manual fully to ensure safe and efficient use of your heater and to comply with the

warranty guidelines.

Solid Fuel – Ecological Energy

Through photosynthesis, plants capture energy from the sun and transform it into chemical energy. The

trapped energy, e.g., in the form of wood, pellets, coal are called biomass fuels and can be converted

into various forms: electricity, fuel or heat. Biomass burning causes the release of carbon dioxide into

the atmosphere, but since this compound had previously been absorbed by the plants that originated

the fuel, the CO2 emissions balance is zero, not contributing to the greenhouse effect on the planet.

Firewood is the most environmentally friendly way of producing heat in your home, as it is a fully

renewable resource. The amount of CO2 that is released during the combustion of firewood is not higher

than the amount that would be released from its natural decomposition. Wood ash is a mineral fertilizer

easily absorbed by the environment in a totally ecological way.

4

Firewood – Use

Choosing your wood

All wood types have a different calorific value. You should choose only well-seasoned hard woods.Do

not use logs that are too large.Split round logs so they cannot roll and cause a hazard.

Drying your wood

Whichever firewood is chosen; it must be very dry and seasoned. Unseasoned or green firewood does

not heat as much, because a large part of the energy is consumed in the evaporation of the water and

creosote contained in the wood, which is highly corrosive and will damage the appliance and

consequently it could void your Warranty. In addition, moist firewood produces a large amount of

smoke and little flame, which will foul the appliance, the glass, and the chimney. When raining the

stored wood should be covered and well ventilated. Generally, green wood should be left to “season”

for two years.

Wood to Avoid

Softwoods and low-density wood: This kind of firewood release a lot of heat but burn too quickly and

projects embers and resin that foul the chimney and the interior of your woodstove.These should be

used as Kindling only, for starting your fire.

Do not use:

Wood with varnish, exotic wood, treated/painted timber, agglomerates that can produce toxic fumes

which will damage the appliance. Do not use driftwood or coastal wood with high salt content, it will

quickly damage the heater.

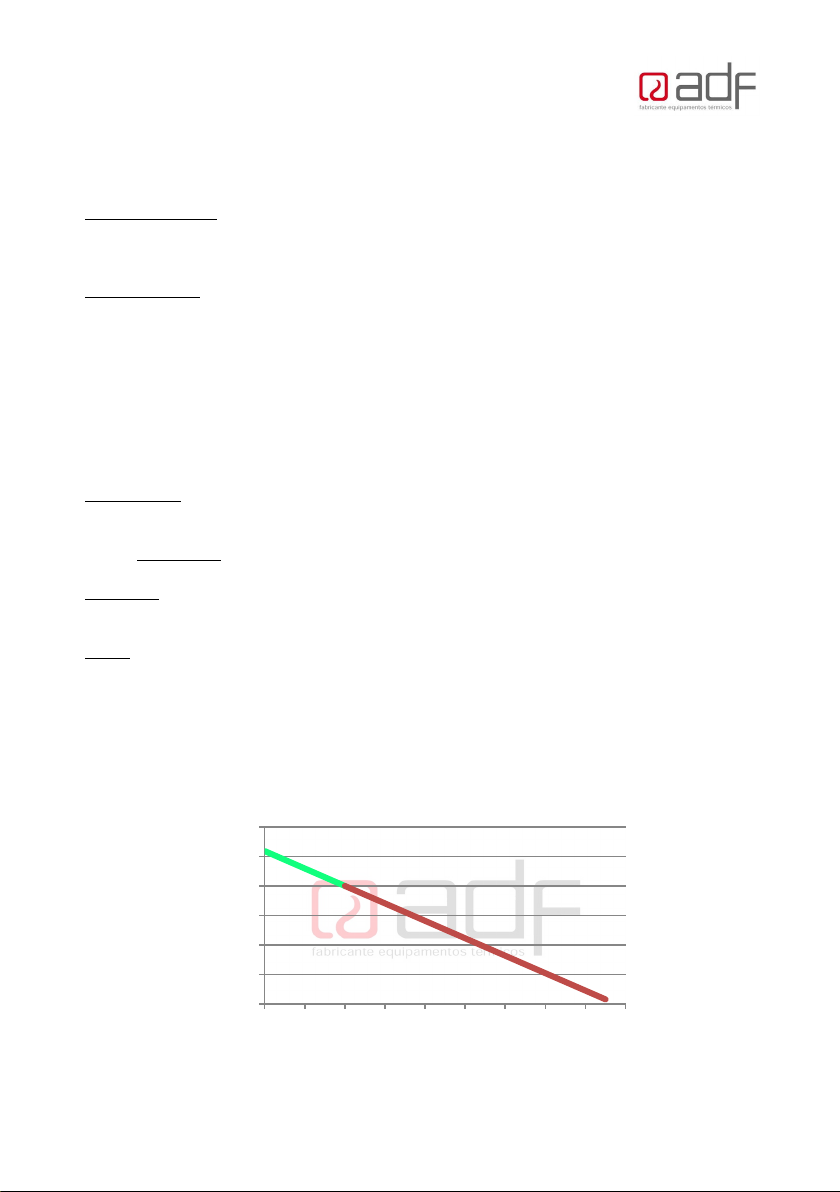

All ADF appliances are designed to burn firewood and firewood only, with less than 20% moisture

content. The use of unseasoned firewood or firewood with moisture or other types of fuel not

recommended will void the warranty.See below, the drier the wood the better heat you get out of it.

0.0

1.0

2.0

3.0

4.0

5.0

6.0

010 20 30 40 50 60 70 80 90

(kWh/kg)

Moisture (%)

Moisture Vs Energy released by firewood

5

2-Appliance Layout

Note: single sided unit shown.

Pos. Designation

1 Door lever, Tool supplied for Door and Air Control

2

Combustion Air control (Use tool):

Open (+) slide to the right

Close (-) slide to the left

3 Vermiculite brick lining

4 Primary convection outlet – comes out each side above both doors.

5 Secondary convection outlet (hot air distribution for ducting) Inbuilt only

6 Smoke Outlet – Flue collar 200mm (or 8” Crimped)

7 Convection inlet

Important:

oPlease read this manual thoroughly before installing and starting yourfree-standing appliance.

oInstallation must be carried out bya licenced and certified installer.

oKeep these instructions for future reference

When Lighting the fire for the first time - use only a

small kindling fire with a minimal amount of wood,

to remove moisture from the brick linings. Then

repeat the process for a longer duration to cure the

paint, without over firing - paint peeling. See full

warnings on page 21.

6

3- Technical Specification

Specifications

TESTED IN ACCORDANCE WITH

AS/NZS 4012:2014 & AS/NZS 4013:2014

Burning Harwood

Unit

ADF

DUO

100

Maximum Avearge Heat Output kW 18.9

Maximum Peak Heat Output kW 20.4

Overall Average Efficiency % 60

Particulate Emission Factor g/kg 1.1

Maximum firewood load kg 10

Minimum clearance distances from combustible materials mm

See page

11.

Flue Diameter mm 200

Recommended Fuel

Burn only Harwood

Moisture ≤ 20%

Electrical Specification – Note optional Fan requires

specific bench requirements and a wall mount control

W

36

V

220-240

Hz

50/60

Fan Settings

Variable speed from 2 to 8

Model

Dimensions (mm)

Width Depth Height Weight

ADF100 DUO 100 Linea (NMV-B) Freestanding

1010

550

565

220kg

7

WARNINGS:

A wood burning heater is, by its nature, an appliance that operates at high temperatures, so it is

necessary to take into account potential risk factors that should be avoided at all costs. Children must

be kept away from any combustion appliance and supervised in the room at all times.

Installation must be carried out by a licenced and certified installer.

The installation must meet the requirements of the manufacturers instructions, AS2918 and the Building

Code of Australia.

The appliance must be installed in such a way as to allow easy maintenance.

Incorrect installation may cause serious damage to the equipment and the safety of people and property.

Before installing your appliance, please ensure the following:

oThe appliance must be installed on a heat resistant surface to 600°C.

oThe floor must be structurally sound, to support the installation weight.

oThe compartment below the heater should not be used to store combustible materials (NM-RS

models).

oReplacement outside air must be supplied to the room with the heater, a minimum equivalent to

half the cross-sectional area of the flue, ie 160cm2 free air.

oFollow the clearances to combustible materials as shown on page 10. Or follow the Zero Clearance

box install.

oYour appliance must be non-permanently installed and easily accessible to ensure general

maintenance (chimney and equipment).

oThe equipment must not be cemented in its enclosure under any circumstances.

Keep these instructions for future reference

WARNINGS:

oREFER TO COMPLIANCE LABEL – DISREGARD ANY CONTRADICTORY FUEL TYPE INFORMATION IN

INSTRUCTION MANUAL

oWARNING: THE APPLIANCE & FLUE SYSTEM SHALL BE INSTALLED IN ACCORDANCE WITH AS/NZS

2918:2001 AND THE APPROPRIATE REQUIREMENTS OF THE RELEVANT BUILDING CODE OR CODES.

oWARNING: APPLIANCES INSTALLED IN ACCORDANCE WITH THIS STANDARD SHALL COMPLY WITH

THE REQUIREMENTS OF AS/NZS 4013:2014 WHERE REQUIRED BY THE REGULATORY AUTHORITY,

I.E. THE APPLIANCE SHALL BE IDENTIFIABLE BY A COMPLIANCE PLATE WITH THE MARKING “TESTED

TO AS/NZS 4013:2014”.

oANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN WRITING BY THE

TESTING AUTHORITY IS CONSIDERED TO BE IN BREACH OF THE APPROVAL GRANTED FOR

COMPLIANCE WITH AS/NZS 4013:2014.

8

WARNINGS:

oCAUTION: MIXING OF APPLIANCE OR FLUE SYSTEM COMPONENTS FROM DIFFERENT SOURCES

OR MODIFYING THE DIMENSIONAL SPECIFICATION OF COMPONENETS MAY RESULT IN

HAZARDOUS CONDITIONS. WHERE SUCH ACTION IS CONSIDERED, THE MANUFACTURER SHOULD

BE CONSULTED INTHE FIRST INSTANCE.

oCAUTION: CRACKED AND BROKEN COMPONENTS, e.g., GLASS PANELS OR CERAMIC TILES,

MAY RENDER THE INSTALLATION UNSAFE.

oWARNING: ANY MODIFICATION OFTHE APPLICANCE THAT HAS NOT BEEN APPROVED IN

WRITING BY THE TESTING AUTHORITY IS CONSIDERED AS BREACHING AS/NZS 4013.

oWARNING: DONOT USE FLAMMABLE LIQUIDS ORAEROSOLS TOSTART ORREKINDLE THE FIRE.

oWARNING: DONOT USE FLAMMABLE LIQUIDS OR AEROSOLS IN THE VICINITY OFTHIS

APPLIANCE WHEN ITIS OPERATING.

oWARNING: DO NOT STORE FUEL WITHIN THE HEATER INSTALLATION CLEARANCES.

oWARNING: WHEN OPERATING THIS APPLIANCE AS AN OPEN FIRE USE A FIRE SCREEN.

oWARNING: OPEN AIR CONTROL (AND DAMPER WHEN FITTED) BEFORE OPENING FIRING DOOR.

oCAUTION: THIS APPLIANCE SHOULD NOT BE OPERATED WITH A CRACKED GLASS.

oTHIS APPLIANCE SHOULD BEMAINTAINED AND OPERATED AT ALL TIMES IN ACCORDANCE

WITH THESE INSTRUCTIONS.

oTHE USE OF SOME TYPES OF PRESERVATIVE-TREATED WOOD AS AFUEL CAN BE HAZARDOUS.

oTHE APPLIANCE OR FLUE SYSTEM SHOULD NOT BEMODIFIED IN ANY WAY WITHOUT THE

WRITTEN APPROVAL OF THE MANUFACTURER.

oBURN ONLY HARDWOOD

oPrior to installation check with your state and local authorities regarding any specific regulations that

may apply.

9

4-Installation

Keep these instructions for future reference

All local regulations, including those referring to national standards, must be observed

when installing the appliance.

NOTE: If the heater is supplied with base feet, these are to be removed. Remove the door to avoid

breakage, lay heater on its back, and undo the bolts fixing the feet. Feet are included for transit when

fan installed. If feet are required, ie including fan and using an existing hearth – contact your supplier if

required.

Replacement room air from outside equivalent to 314cm2 must be supplied into the room.

The heater must have its own dedicated flue. The active flue must be 8” for the entire length of the

flue, and always less than 45 degrees from the vertical.

The Flue terminal must meet the minimum height and external clearances for the flue, according to

AS/NZ 2918:2001, see the diagram shown below on page 12.

The ADF DUO Linea 100 was tested with a 200mm (8”) triple skin flue kit in a manner confirming to joint

Australia/New Zealand Standard 2918:2001.

A. INSTALLATION INTO A SKAMOL ENCLOSURE BOARD

CONSTRUCTION

The floor must be structurally sound.

The Hearth must have a heat resistant surface to 600°C, with an insulating thickness of non-

combustible material equivalent to 24mm of cement sheet with thermal resistivity of 0.1m².K/W for

6mm. eg Bellis Board or fibre cement sheet equivalent.

The base of the unit is raised 350mm from the floor protector for the following clearances to apply.

AS2918 default clearances apply for installations directly on the floor (75mm concrete slab suspended

with 25mm air gap below – see AS/NZS2918 3.3.3)

The appliance must be placed on a box 1000mm wide x 400mm high x 470mm deep made from 50mm

Skamol.

A minimum 300mm deep x 1240mm wide x 6mm thick floor protector (Bellis Board or similar cement

sheet) should be used in front and behind the appliance base when installing the appliance (see joint

AS/NZS 2918:2001 3.3.2). The floor protector must extend 300mm in front of both appliance fuel loading

doors and be placed centrally in the 1240mm width. The Thermal conductivity of the floor protector is

0.1m².K/W for 9mm thick sheets.

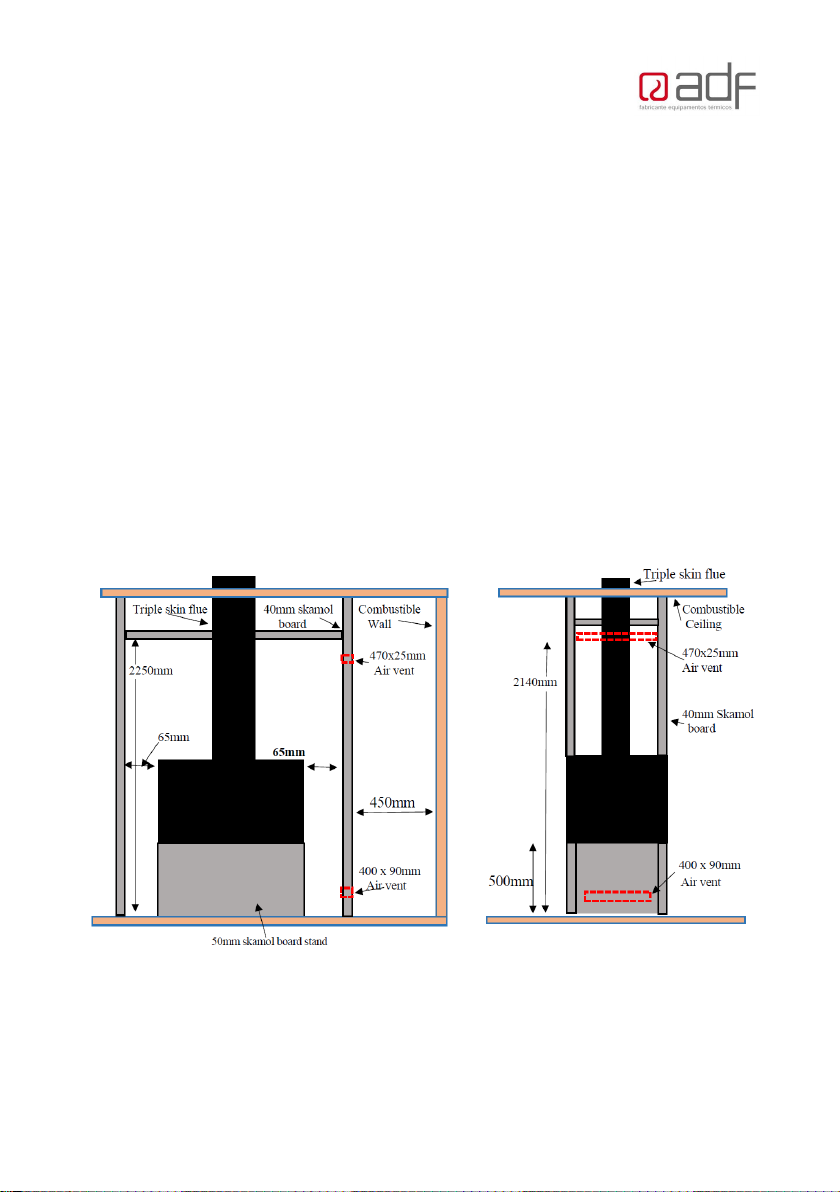

The Enclosure must be made from a minimum of 40mm thick, on all sides. There must be a minimum of

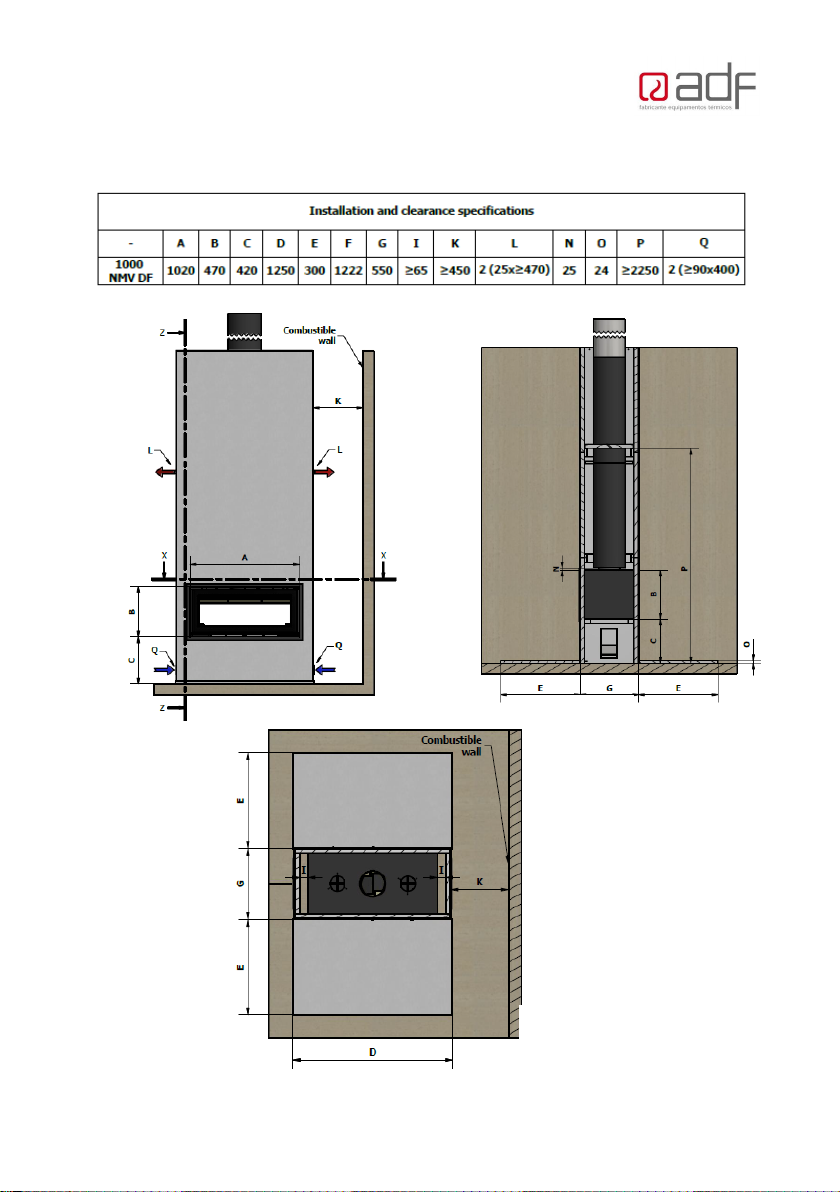

65mm side clearance between the heater and the skamol board. See dimensions below.

10

The appliance and flue were tested at the following clearances:

The side clearance to combustible walls or cabinetry from the Skamol enclosure wall, is 450mm from

the vent outlets.

Aminimum of two air vents must be installed. The top air vent must be 470mm long x 25mm high and

must not be closer than 235mm to the ceiling. The bottom air vent must be a minimum, 400mm long x

90mm high, and must be 60mm from the floor of the enclosure. Combustible material must be a

minimum of 450mm from the side vents. All enclosure joints must be sealed correctly to ensure they do

not allow heat to escape from enclosure.

The combustible ceiling above the Skamol enclosure roof must be no closer than 110mm, a 25mm

clearance must be maintained around the outer casing of the flue in the combustible ceiling. The outer

triple skin where it passes through the Skamol board enclosure must be fully sealed.

The ADF DUO Insert 100 Linea solid fuel appliance installed with a triple skin flue kit conforms to the

requirements of the joint AS/NZS 2918:2018 Standard, Appendix B.

The appliance and Flue Combination must be installed at the following clearances shown below.

Position A – Parallel position – 65mm clearance to Skamol alongside the heater. 450mm clearance to

cabinety on the side of the heater the side inline flush with the door glass

11

Construction of the Skamol Enclosure

Z-Z

X-X

12

The cutting list of the parts required for the build out is shown and listed in table below:

13

STEP 1. STEP 2.

STEP 3. STEP 4.

14

STEP 5. STEP 6.

B. INSTALLATION INTO A ZERO CLEARANCE BOX AND TIMBER

FRAME OUT CONSTRUCTION

See separation instructions included with the Zero clearance box. Contact distributor for an email

electronic copy.

15

C. DUCTING – CONVECTION AIR TRANSFER DUCTING

For the inbuilt models, Ducting can be added to the top of the firebox and transferred to vents either

on side of the Chimney breast via natural convection, or via an air transfer kit with fan to other rooms

(From other supplier). The blanking plates can be opened as below, to direct the convection heat into

the duct, which will also be forced via the heater fan (if fitted).

16

Fit a Ducting collar to the top of the fire box and fit ducting as required (From other supplier).

17

D. DECORATIVE FRAME TRIM

Beading in metal or plastic cannot be used around the firebox opening due to heat. Metal expansion

could crack the Skamol enclosure board or Fibre cement sheet, and plastic will melt.

Ensure there is an expansion gap between the heater box and the fascia material, of 4 or 5mm.

AFrame can be fitted as follows to cover the gap between the heater and the appliance:

The frame has about

25mm of adjustment in

front of the heater.

18

5 - Flue Installation

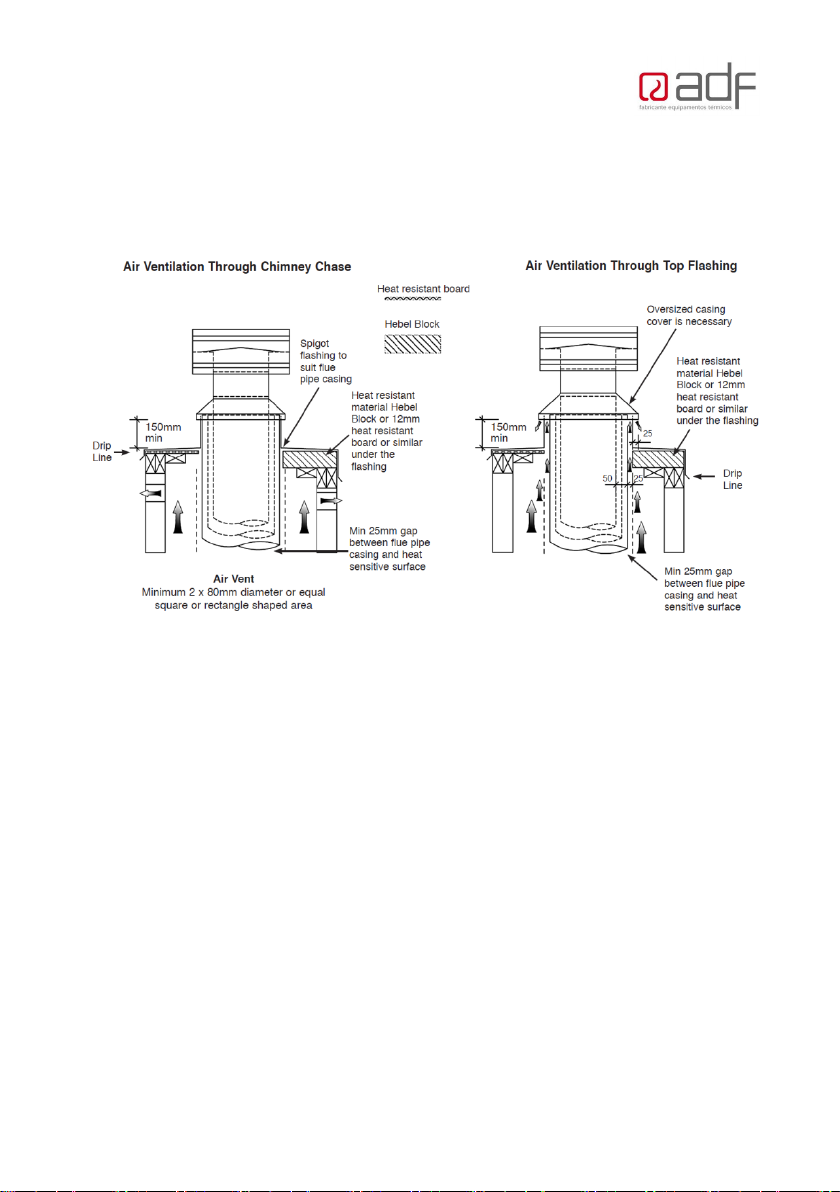

Flue type: Triple skin flue, 200mm/250mm/300mm or8”/10”/12”. The Active 200mm flue must bea

tight fit into the heater collar.

The flue is Triple Skin from teh top of the heater / Zero Clearance

Box.

The heater must have its own dedicated flue. The active flue must be 8” for the entire length of

the flue, and always less than 45 degrees from the vertical.

Replacement room air from outside equivalent to 160cm2 must be supplied into the room.

Flue Outlet Positions

Minimum Flue Height as per AS/NZS 2918:2018

19

NOTE: Flue exit MUST also be as high as any nearby structure within a 6m Radius. ( AS 2918:2018 )

External Requirements

Refer to AS/NZS 2918:2018

Note: All external air vents & ceiling penetrations must be bird & rodent proofed with permanently

fixed screens

20

6 - Fan (for optional inbuilt fan available).

•Must be installed in accordance with AS/NZS 3000.

•Must be installed to the manufacturer’s specifications.

•Power supply must be installed by a licensed electrician.

•If the power cable is damaged, for any reason, do not use. Have the cord replaced

immediately.

•Please follow the fan instructions included with the fan kit.

The fan will need a fan cut out in the bench, and with air supply to each fan below the heater base. A

cable will need to run from the heater to a wall mount controller – the 240V power supply is supplied to

the wall mount controller – see the fan instruction manual for more details.

NOTE: REMOVE THE FEET UNLESS REQUIRED WITH

USING A FAN ON AN EXISTING HEARTH

Warnings

Danger of Electrocution: All electrical work must be carried out by a qualified electrician.

Note: All electrical components should be installed in an airy location away from hot parts

Table of contents

Other ADF Wood Stove manuals

Popular Wood Stove manuals by other brands

RAIS

RAIS attika NEXO 100 GAS installation guide

WoodPro

WoodPro WS-TS-1500 owner's manual

Contura

Contura C 586W installation instructions

Palazzetti

Palazzetti EVA GENERAL INFORMATION - WARNINGS - INSTALLATION - MAINTENANCE

Lopi

Lopi 1250 Republic owner's manual

Panadero

Panadero CAPRI 3V Usage and maintenance instructions