7

139681_R06 F 500 Oslo 1/20

those that are visible and also include materials that are behind

non-combustible materials.

If you are not sure of the combustible nature of a material, consult

your local fire officials. Contact your local building officials about

restrictions and installation requirements in your area.

Remember: “Fire Resistant” materials are considered combustible;

they are difficult to ignite, but will burn. Also “Fire-rated” sheet

rock is also considered combustible.

Using Shields to Reduce Clearances

Pipe shields: When using listed pipe shields to reduce the connector

clearance to combustibles, it must start 1”(25,4mm) above the

lowest exposed point of the connect pipe and extend vertically

a minimum of 25” (635mm) above the top surface of the stove.

Double wall pipe: Listed double wall pipe is an acceptable

alternative to connector pipe heatshields.

Wall-Mounted Protection: When reducing clearances through the

use of wall mounted protection:

In the U.S. refer to NFPA 211, Standard for Chimneys, Fireplaces,

Vents and Solid Fuel Burning Appliances, for acceptable materials,

proper sizing and construction guidelines.

In Canada, refer to CAN/CSA-B365, Installation Code for Solid-Fuel

Burning Appliances and Equipment, also for acceptable materials,

proper sizing and construction guidelines.

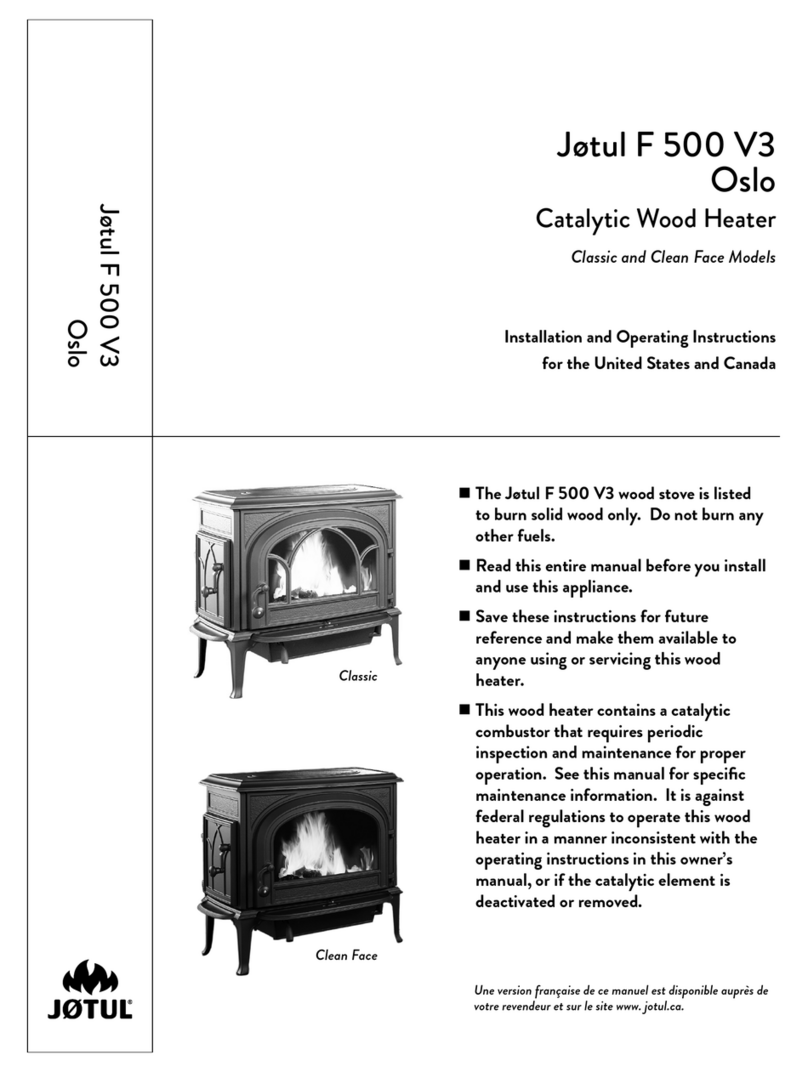

Rear Heatshield: A stove rear heatshield has been specifically

designed for the Jøtul F 500.

Rear heatshield part # 154332.

No other heat shield may be used.

See pages 17-18 for complete clearance requirements and

diagrams.

Notice

Accessories for wood stoves for clearance reduction have been

developed by many manufacturers. If not following the methods

of the installation codes, be sure that any accessory you choose

has been tested by an independent laboratory and carries the

laboratory’s testing mark. Follow all of the manufacturer’s

instructions.

Always contact your local building inspector or fire officials

about restriction and requirements in your area. Your local

officials have final authority for installation approval.

4.3 Alcove Installation

The Jøtul F 500 can be installed in an alcove situation provided:

See figures 9 and 10.

1. The stove must be installed with listed double walled pipe.

2. In a protected alcove installation both side walls and rear wall

must be protected per NFPA 211 or CAN/CSA-B365. The wall

protection must be elevated 1”(24,5mm) from the floor and

at least 1” (24,5mm)off the combustible wall to allow for an

air-flow.

3. The height of the wall protection including the bottom air

space must be 48”(1219mm).

4. The bottom heatshield is required in all Alcove installations.

See page 15 for installation instructions.

5. Hearth protection material must consist of:

a) a UL/ULC listed Type II Thermal Floor Protector or,

b) material having a minimum r value of 1.6 (see appendix a).

6. Minimum ceiling height in an unprotected installation, off the

top of the stove is 41”(1041 mm). The minimum ceiling height

off the top of the stove in a protected ceiling installation is

15”(380mm).

Use of the left side load door is prohibited in alcove installations.

Install 155840 Side Door Lock kit available from your dealer.

4.5 Mobile Home Installations

The Jøtul F 500 has been approved for use in mobile homes in the

U.S. and Canada, provided:

1. The stove is secured to the floor or the mobile home. Floor

mounting kit #750304. The structural integrity of the mobile

home must be maintained.

2. All chimney components, including chimney sections, supports,

spark arrestor, etc., shall comply with the Standard for Factory-

built Chimneys for Residential Type and Building Heating

Appliances, UL 103 and/or CAN/ULC-S629 Standard for 650°C

Factory-built Chimneys.

3. The chimney shall be attached directly to the stove and extend

at least 3 ft. (0.9m) above the roof. Termination must be at

least 2 ft. (0.6m) above the hightest elevation of any part of

the mobile home within 10 ft. (3m).

4. In order to allow for transportation of the mobile home, the

chimney termination shall be readily removed at or below an

elevation of 13.5 ft. (4.1 m) above ground level and reinstalled

without use of special tools or instructions.

5. A spark arrester must be installed at the termination. The net

free area of the arrester above the chimney outlet must not

be less than four times the net area of the chimney outlet,

and the vertical height of the arrester must not be less than

one-half the diameter of the chimney flue. Openings shall not

permit the passage of a sphere having a diameter larger than

1/2” (12.7 mm), and shall permit the passage of a sphere having

a diameter of 3/8” (9.6 mm).

6. Direct connection of the stove to an outside air source is

required. Use Outside Air Kit 154333. Do not substitute any other

connection method or device. See page 11 for more details. Duct

termination must not be installed at a level that is higher than

the air inlet located at the bottom of the stove.

7. When the chimney exits the mobile home at a location

other than through the roof, and exits at a point 7 ft. (2.1 m)

or less above the ground level, a guard or other method of

enclosing the chimney, must be provided at the point of

exit for a height up to 7 ft. Openings of this chimney guard

shall not permit penetration of a 3/4 in. (19.1 mm) diameter

rod, or contact with the chimney by a 1/2 inch (12.7 mm)

diameter rod inserted through the opening a distance of

4 inches (102 mm).

DO NOT INSTALL THE STOVE IN A BEDROOM OR SLEEPING AREA.

Always consult your local building inspector or fire officials

about restrictions and requirements in your area prior to

installing the stove.