Adhesive Dispensing 12oz User manual

12oz Size

Barrel Filler

USER GUIDE

Introduction

Thank you for purchasing the 900-120 Syringe Barrel Filling

Station. Our syringe barrel filling systems are built an pre-

assemble using high quality parts to ensure that your time is

spent where it belongs, on pro uctivity. The 900-120 is built to

accept all 12oz (360cc) cartri ges. You can use pre-fille 12oz

supplie cartri ges or empty cartri ges from us. This user

gui e will answer most of the most common questions an

help you to maximise the benefits from your new syringe barrel

filling station.

This version incorporates a precision air regulator, pressure

vessel, a justable stan an all accessories require to achieve

results. Designe for use on a work bench an as part of a

pro uction process, we keep the syringe barrel filling clean,

simple an fast. This is a simple system for setup straight out

of the box.

To achieve maximum performance from A hesive Dispensing

equipment, please rea the instructions carefully.

After completing this gui e, please o not hesitate to contact

the technical team at A hesive Dispensing Lt or contact your

authorise A hesive Dispensing Lt reseller.

Tel. 00 44 845 652 0058

Fax. 00 44 845 652 0059

Table of Contents

………………………………………………………………………………………………………………

Page

Specifications …………………………………………………………………………………………… 4

First Steps ……………………………………………………………………………………………… 5

Setup ……………………………………………………………………………………………………… 6

Reservoir Filling ………………………………………………………………………………………… 8

Component Selection Gui e ……………………………………………………………………… 10

Troubleshooting ………………………………………………………………………………………… 11

Warranty ………………………………………………………………………………………………… 12

Our Pledge

We offer you the assurance that our products will operate and perform to your

satisfaction. Our goal is to provide the highest quality products for use with your

industrial applications.

If for any reason you feel that you are not satisfied with our products, we would be

grateful if you would write or call us.

We strive to develop strong partnerships by delivering cost effective solutions that

provide savings in assembly time and raw materials. So your confidence and trust in

Adhesive Dispensing td is of the utmost importance to us.

Specifications

Capacity: 360cc, 360ml (12oz)

Initiation: Pneumatic Dispenser

Air Input: 0 to 100psi (0 to 6.9 bar)

Pressure Vessel: Anodised Aluminium

Pressure Cap: Cast Aluminium

Base Stand: Steel and Stainless Steel Rod

Weight: 1.2kg (without filled cartridge)

4

First Steps

Step 1:

Unpack the shipping box and use the supplied checklist to make sure all items are

present. If any items are missing, please contact us immediately.

Step 2:

Ensure the area where you are setting up the equipment has access to compressed

air. Air pressure should be between 0 and 100 psi (0 and 6.9 bar). We provide a high

pressure 5 micron filter/ regulator to ensure that the air supply is clean and dry. If

your material requires a higher level of filter, please contact us or source from a

specialist pneumatics supply company. Our filter/ regulator is part TSD800-6FR. A

regulated and constant air pressure must be supplied to our syringe filling station.

Step 3:

Activate your one (1) year no fault warranty by filling in and returning the postage

paid warranty card.

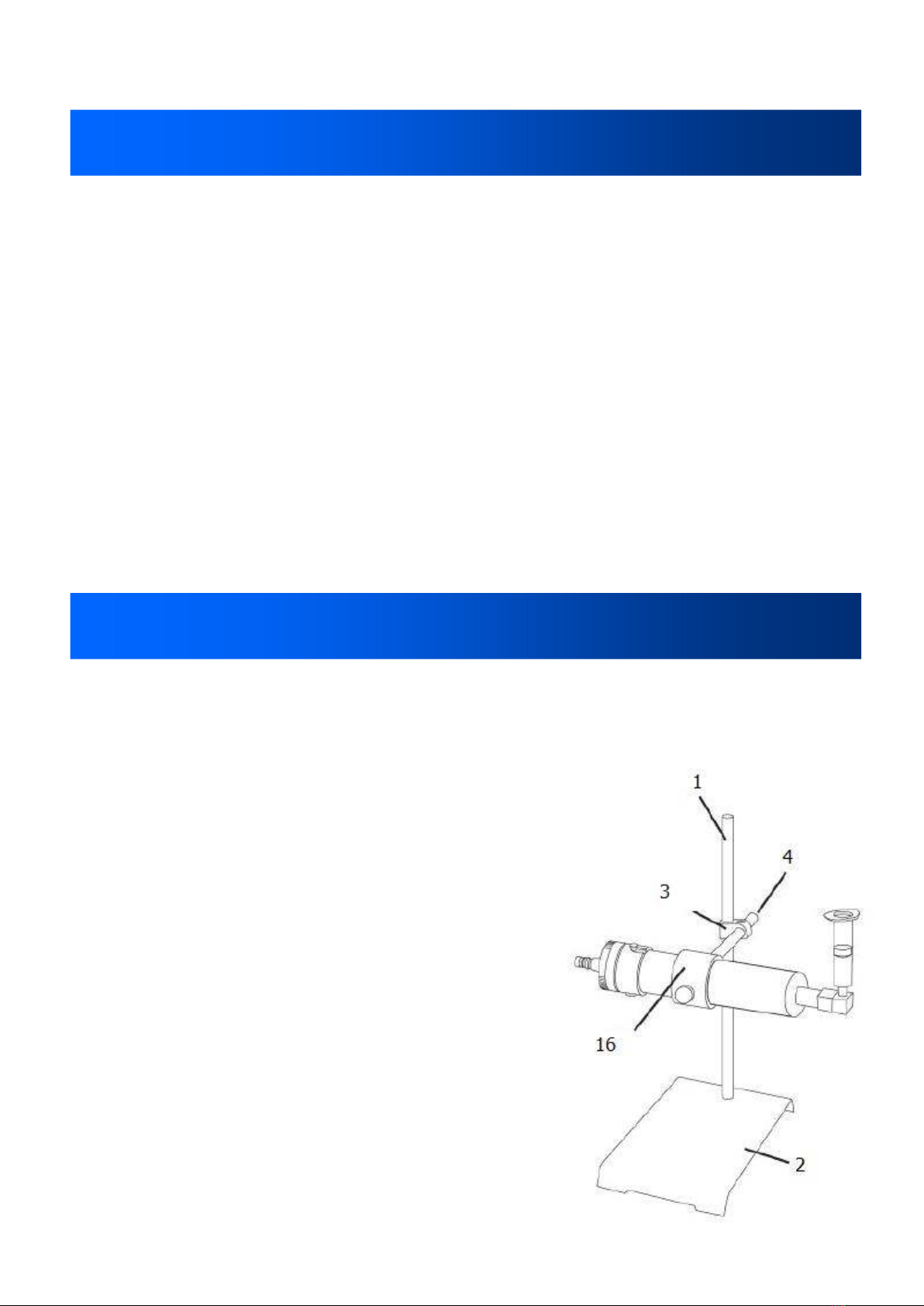

Assemble Stand:

Unpack the shipping box and use the supplied checklist to make sure all items are

present. If any items are missing, please contact us immediately.

Place the stand on a flat surface/ work bench.

Thread the pole (1) into the base (2) by using the

supplied nut. Turn clockwise and tighten.

Slide the rod clamp (3) onto the pole (1) to your

suitable height and tighten the locking nut (4).

Attach cartridge mounting bracket with rod (16) to

the rod clamp (3) and tighten. Position the arm to

hold the reservoir horizontally as pictured.

Review the setup and adjust to the suitable height

for your application.

The base stand and upright rod part number is

918-033-000 and is built specifically to handle the

weight of a filled cartridge. Please ensure all screws

are tight before inserting the filled cartridge.

Setup

5

Setup Continued

Assemble Fluid Reservoir:

ocate the reservoir pressure chamber and remove the cap (5) by turning counter

clockwise.

Insert a 12oz size cartridge reservoir that is pre-filled with your assembly fluid, in the

retainer (7) . Remove the storage cap from the large end of the cartridge.

Re-attach the reservoir chamber cap by aligning the slots in the cap with the slide

bolts (8) on the chamber pushing down and turning clockwise until tight.

Slide the assembled reservoir chamber into the reservoir holder (16). Centre the pres-

sure vessel so the weight is evenly balanced in the holder and tighten the thumb

screw (9) to secure.

Assemble 90 Degree Elbo :

Remove the end cap from the polyethylene cartridge reservoir.

ocate the cartridge adapter (10) and thread it into the polyethylene cartridge reser-

voir by turning clockwise.

ocate the 90-degree elbow (11) and thread it into the cartridge adapter by turning

clockwise. Make sure the open end of the adapter is pointed up when finished.

Assemble Air In Line:

ocate the pressure regulator (15) and air in hose (12). Connect the air pressure reg-

ulator to your air source.

Connect the opposite end of the air input hose (13) to a pneumatic dispenser such as

the TS924 footvalve, TS250 dispenser or TS350 dispenser.

Connect the opposite end of the air input line to the air pressure regulator by insert-

ing the twist lock adapter and turning clockwise. This is also a filter and will ensure

the air supply is clean and dry.

Note: Be certain your plant air is properly filtered and dry. Please use the 5 micron filter

part # TSD800-6F , to guarantee dry filtered air. A regulated and constant air pressure

must be supplied to the reservoir filler.

6

Typical Setup

This system is designed to work with a manual or timed dispenser for ON/

OFF control. Fittings are supplied to connect to most dispensers.

7

Syrin e Fillin

Pressurise the reservoir pressure chamber (15) by turning the

knob on your air dispenser pressure regulator clockwise. Adjust

to a pressure that is appropriate to the fluid you are filling.

Some common settings are as follows:

5psi for low viscosity fluids

80psi for high viscosity fluids.

Caution: Over pressurising the reservoir pressure chamber may

cause the empty syringe reservoir to fill very rapidly with the

possibility of fluid overflow. To avoid this start with a relatively

low pressure setting and test. If nothing happens increase the

pressure in small increments and repeat testing until you

optimise your fill time.

ocate an empty syringe barrel and the matching wiper piston

and insert the piston to the bottom of the barrel.

Attach the empty reservoir to the 90-degree elbow by turning

clockwise.

Press the foot pedal on your dispenser until material starts to

flow and the piston moves up the barrel toward the top. Release

the foot pedal when the piston is approx 3/4 up the syringe

barrel. Enough space needs to be left so an air adapter can be

attached without touching the piston.

Remove the filled syringe by turning anti clockwise, attach a tip

cap to the dispensing end and an end cap to the top end.

Repeat steps 1 to 7 for your next syringe barrel.

Plastic pistons work best with most materials. If the piston is

not pushed down to the bottom of the syringe, an air pocket will

appear.

All fittings and components are silicone free plastics so will not

contaminate materials being used.

Insert piston to

the bottom of

the barrel.

Twist on the

barrel to the

elbow fitting.

8

Dispense Component Selection Guide

Available in: Clear for regular

fluids; Black for visible light

cure fluids; Amber for UV

cure fluids. Each package

contains same amount of

barrels and pistons.

Size Clear UV Opaque Quanty

Amber Black Per Pack

Syringe Barrels and

Pistons

Syringe Barrel

Reservoirs Only

Available in: Clear for regular

fluids; Black for visible light

cure fluids; Amber for UV

cure fluids. Supplied in sealed

packs.

Size Clear UV Opaque Quanty

Amber Black Per Pack

Syringe Wiper Pistons

Only

Available in: White for general

purpose; Blue for improved

control over most fluids; Red

for very thick pastes. Supplied

in sealed packs.

Size White Red Blue Quanty

Per Pack

Cartridge Reservoir

Kits

Size Part

Syringe Sealing Caps

End Cap

Size Part Qty

Tip Cap

White Black Orange

9

Dispense Component Selection Guide

Cartridge Reservoir

Each cartridge system comes with an air cap and retainer

Part # Part Size A B

918-032-000 Retainer 12oz 16-3/4” 1-3/4”

918-001-004 Cap 12oz Part of above dimensions

Accessories

Each cartridge system comes with an air cap and retainer

Part # Description

TSD931-7 uer ock Adapter White 1/4” NPT

TSD931-7C uer ock Adapter Clear 1/4” NPT

TSD931-28A 90-Degree Elbow Fitting Female Clear PP

TSD931-28N 90-Degree Elbow Fitting Female White Nylon

TSD800-6FR 5 Micron Filter Regulator 0-100psi

918-000-002 Air Hose 5ft ong with Quick Connectors

534 1/4” Female Fitting Quick Connect for Cap

918-001-007 Replacement Air Cap Rubber Gasket

TSD931-28P Metal Plug Cap for Elbow Fitting

TN00DKIT Tip Kit Assortment 145 Tips

10

Troubleshootin

Problem Possible Solution

No Fluid Flo Check that air supply is properly connected.

Check air in from mains supply and air feed from

dispenser to syringe filling system.

Air pressure is too low. Gradually increase the air

pressure until fluid flows.

Air Pressure Leaking Check all connections to make sure they are

secure.

Add some Teflon tape thread to the air connection

to assist in sealing.

Fluid Leaking From Adapter Tighten all seals.

Add some Teflon tape thread to the fluid

connection threads to assist in sealing.

Fill Time Too Slo Increase air pressure.

If you require any further assistance with this product, please call us on Free Phone

0800 094 9058 or +44 (0) 845 652 0058.

Or email us at [email protected].

11

Warranty

One Year Limited Warranty

12

Table of contents

Popular Water Dispenser manuals by other brands

IBC Water

IBC Water AST0715MP-960 Installation & operating instructions

Lancaster Water Treatment

Lancaster Water Treatment X FACTOR LX15 Series Installation, operating and service manual

Elkay

Elkay EMABF8 Series Installation & use manual

Oasis

Oasis Osmosis Home installation manual

Monarch Water

Monarch Water ULTIMATE MINI AQUA HE install guide

Haier

Haier HLM-109B instruction manual