aditec ETA 110 User manual

Temperature Controller ETA 110

_________________________________________________________________________________________________________

_________________________________________________________________________________

04.06.09 page 1

ETA110 V03 Operating manual 04.06.09

The ETA 110 works as a heating- or cooling controller. A second relay can be used as either

an operating, alarm, upper limit or lower limit relay.

The heating control can work in either two point-, XP or interval operation.

The nominal value limit for the temperature can be set by using a code.

When the controller is switched on while the buttons „Plus“ and „Minus“ are pressed

simultaneously, the nominal temperature value is reset to „0“.

The actual temperature is shown in the upper display and the nominal temperature in the lower

display.

As soon as the controller has been connected to the mains it is in operating mode. (Please note:

also see “setting options” under code „100“).

The nominal temperature can be set within the programmed limits by using the „Plus“- and

„Minus“ buttons.

Code entry : press the two buttons on the outer left and right simultaneously, for ca. 3

seconds. The lower display will show „Cod“. Use the „Plus“ and „Minus“ buttons to set the code

numbers (upper display). Confirm the code by pressing the same outer buttons again. To quit

the code, press these two buttons yet again.

Activation or deactivation of the outer left button: Code 100

Upper display shows „StP“.

Choose between „OFF“ (deactivated) and „On“ (activated) by using the arrow

buttons.

Be aware: the following only applies when the button on the outer left has been

activated:

Display –actual

temperature

Display -nominal

temperature

button outer

left

button

outer right

arrow

buttons

plus/minus

1

2

Temperature Controller ETA 110

_________________________________________________________________________________________________________

_________________________________________________________________________________

04.06.09 page 2

- In operating mode, the temperature values can only be changed transiently,

this means that at the next programme start the controller will revert to

working with the value that had originally been entered in programming

mode.

- The code setting can not be changed while the controller is in operation.

Setting function „Relay 1“ heating or cooling: Code 101

Upper display shows „rL1“. Choose between „HEA“ (heating) and „Coo“(cooling)

Choose the setting with the buttons plus/minus

Setting function „Relay 2“ as alarm signal, operation or upper-/lower limit value: Code 102

Upper display shows „rL2“. Choose between “Alr“ (alarm signal), „OPE“

(operation) and „LCo“ (limit comparator)

Choose the setting with the buttons plus/minus

Functions of relays K1 and K2 can be interchanged: Code 105

Upper display: „SrL“ (switch relays). Choose between „on“ (functions are

interchanged) and „off“ (functions are not interchanged). The relay displays in

codes 101 and 102 will be changed accordingly.

Basic setting: „off“

The function of the heating control: Code 111

can be pre-set for example to avoid exceeding the nominal value. There are three

options of how to set the heating control:

2-point controller

When the actual value reaches the nominal value,

the output relay will switch off. The relay will only

switch back on, when the actual value falls below

the nominal value plus the hysteresis.

Xp-controller

While the actual value is within the control range,

the output relay clocks, - here the switch-on interval

depends on the electrical off-set. The control range,

the basic time interval (the sum of switch-on and

switch-off interval) for these clocking intervals, and

a minimum switch-on time can be pre-set. The

minimum switch-on interval cannot be longer than

half the basic time!

Clocking controller

While the actual value is within the control range the

output relay clocks at pre-set switch-on - and off

intervals. The control range and the switch on and

off intervals can be pre-set.

temperature

rel.switch-on interv

100%

50%

control range

temperature

on

Nom. value

hysteresis

T out in sec.

temperature

clocking range in sec.

T on in sec.

Temperature Controller ETA 110

_________________________________________________________________________________________________________

_________________________________________________________________________________

04.06.09 page 3

When selecting a heating controller, there are 3 parameters to choose from. Their significance

is shown in the table below:

Code 111:

Switching type

Parameter 1

Parameter 2

Parameter 3

Type of heating

control

2-point controller

Hysteresis in °C

-

-

Xp controller

Control range in

°C

Basic time

interval in sec.

Min. switch-on time sec.

Clocking

controller

Control range in

°C

Switch-on time

in sec.

Switch-off time in sec.

The factory setting is 2-point controller with a hysteresis of 1°C.

Choose the parameter settings by using the outer button on the right: display shows „HE0“

to „HE3“. Parameter is shown in the upper three-digit display.

„HE0“: choose the switching type : 2-point(„2Pt“), XP („HP“) or interval („Int“)

„HE1“: setting parameter 1

„HE2“: setting parameter 2

„HE3“: setting parameter 3

Setting the upper- and lower limits (limit comparators): Code 113

Display shows „LCo“

Upper display shows difference to the nominal temperature value.

Minus sign in front of the number: lower limit

Plus sign in front of the number: upper limit

Setting and activating the 3 levels heating: Code 119

The graded 3-level heating has a nominal temperature value and two difference

values. These difference values for the temperature are entered under code 119.

Once the graded heating is activated, you are restricted to entering only the 2-

point behaviour with hysteresis under Code 111 and under Code 101 only the

heating „HEAt“.

If the actual temperature is above the nominal temperature value, both relays are

inactive. Within the first temperature window d1 (see diagram) relay 1 is

energised, within the second temperature window d2, relay2 is energised and

below the second temperature window both relays are energised.

Example graded heating

T in °C

Rel 1&2 off

Temp.-nom.v.

d1 Rel 1 on 10°C

d2 Rel 2 on 10°C

Rel 1& 2 on

After the code entry „SSH“ (select step heat) will appear in the upper display and

„On“ or. „OFF“ respectively. Use the „Plus“ button to select „On“ (enabled), use

the „Minus“ button to select „OFF“ (disabled).

30

50

40

Temperature Controller ETA 110

_________________________________________________________________________________________________________

_________________________________________________________________________________

04.06.09 page 4

Use the buttons „outer right“ to set the difference values. Display shows „d1“ or

„d2“. Now make your entry, in a range from 0 to 100°C, using the arrow buttons.

Setting the upper temperature limit: Code 302

Display shows „HIG“

Range from 30°C to 400°C

Software version is shown (for a few seconds): Code 678

(e.g. Uer 10.0)

Digital offset adjustment: Code 777

The temperature sensor is shown in the upper left display „1“ or „2“.

Use the outer left button - „2“ has no meaning.

The actual current temperature is shown in the lower display. The upper left

display shows the value of the hundreds.

Make the offset adjustment by using the „Plus“ and „Minus“ buttons

Load default factory setting: Code 993

(display “InI“)

Load by using the outer left button

Standard default settings are:

-Code 100 „left outer“ button not active (OFF)

-Code 101 : heating

-Code 102 : upper-/lower limit (Limit comparators)

-Code 111: 2-point, 1°C hysteresis

-Code 113: 0°C

-Code 119: OFF

-Code 302: 400°C

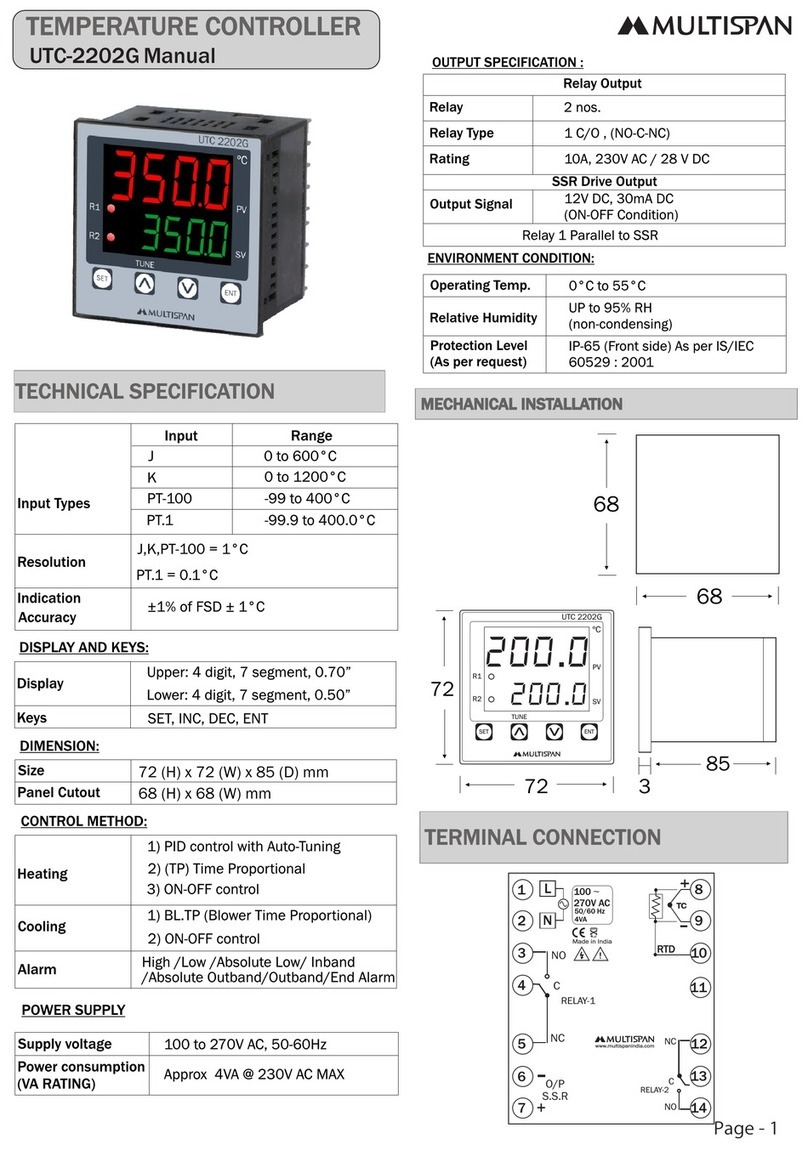

Connection diagram:

Error messages:

Malfunctions of the temperature sensor are shown in the display for the actual temperature:

„EEE“ means sensor break

„- - - „ means short circuit in the sensor

ETA 110

230V AC

PE L1 N

04

03

02

01

08

07

06

05

12

11

10

09

14

13

K1: heating or cooling

K2: upper-/lower value,

operation or signal

chamber

Pt100

K2

K1

Temperature Controller ETA 110

_________________________________________________________________________________________________________

_________________________________________________________________________________

04.06.09 page 5

Safety instructions

To avoid any danger of electrocution, the housing must never be removed nor opened at the back. There

are no parts inside that can be serviced by the user himself. Leave the servicing to the experts! To avoid

a fire or electrocution the appliance must not get wet nor be exposed to rain.

1. Advice: Read all safety instructions and all items in the user manual, before using the controller for the

first time! Keep the safety instructions and the user manual in a safe place in case you need to refer back

to it at a later date!

2. Installation instructions: Always make sure that the appliance is installed by an authorized and

experienced specialist. Please follow the specific safety instructions as well as the VDE guidelines during

installation. The appliance should only be fitted in an approved and specifically designed waterproof

switching cabinet (metal housing) and should only be used for the purpose it was designed for and within

the limits of its technical data.

We recommend that any down-streamed inductors with RC elements should be checked for

interference. These are available on the retail market (e.g. Siemens 3 RT1916).

3. Analogue in- and outputs: To the in- and outputs (4-20mA / 0-10V and Pt100) do not apply separate

source voltage.

4. Sensor leads: The leads for the sensors should be run separately from any voltage carrying

leads, this also includes control wires carrying separate source voltage. It is vitally important that

the sensor leads have a metal shielding and that this shielding is connected to the sensor

housing itself.

5. Relay outputs: The relay outputs are potential free and the maximal load of 250V AC and 4A must not

overshoot.

6. Water and humidity: Never use the unprotected appliance near water, e.g. near a bath tub, water

basin, sink, washing machine, a damp cellar or near a swimming pool. The appliance is only waterproof

on the front (IP67). The back and side panels must not come into contact with water.

7. Ventilation: The appliance must have sufficient ventilation, the ventilation slits in the housing must

never be covered up, or blocked by objects that may have been inserted into the slits.

8. The effects of heat: Keep the appliance away from heat sources, like radiators, heating conduits,

ovens, and other elements that may radiate heat.

9. Energy sources: The appliance should only be connected to the power sources that are specified in

the service manual or on the appliance housing itself.

10. Cleaning: When cleaning the appliance, keep to the recommendations given by the manufacturer.

11. Appliance not in use: When you know the appliance is not going to be used for a longer period of

time, it should be disconnected from the mains.

12. Contaminants: You have to be extremely careful that neither liquids nor foreign objects can get into

the appliance through the openings in the housing. If objects or liquids have contaminated the inside of

the appliance, it has to be disconnected and sent in to the manufacturer immediately.

13. Servicing after damage: The appliance may only be serviced by a qualified specialist. The user

should only do the servicing tasks he is meant to do according to the service manual. For servicing that

exceed his authority, he should always contract a specialist.

14. Please note: Never make any technical alterations to the appliances, unless they were

specifically approved by aditec GmbH. Unauthorized alterations will invalidate your warranty.

Temperature Controller ETA 110

_________________________________________________________________________________________________________

_________________________________________________________________________________

04.06.09 page 6

For any questions, orders and repairs please contact our customer service team at the address below:

Measurment & control

Process controls

Hardware development

Software development

Specialized electronics

Food-Technology

Process-Visualization

aditec gmbh

Talweg 17

D-74254 Offenau

Tel.:+49(0)7136-96122-0

Fax:+49(0)7136-96122-20

www.aditec.net

aditec

CONTROLS for

FOODTECHNOLOGY

Table of contents

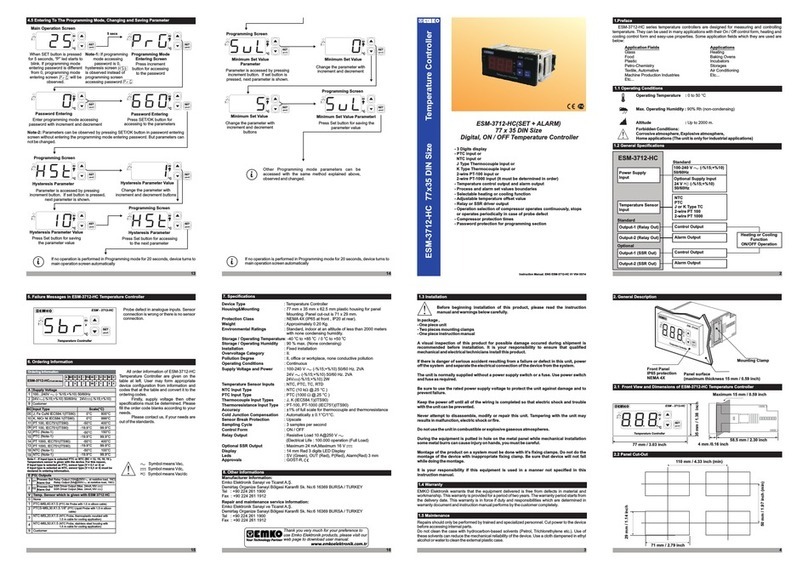

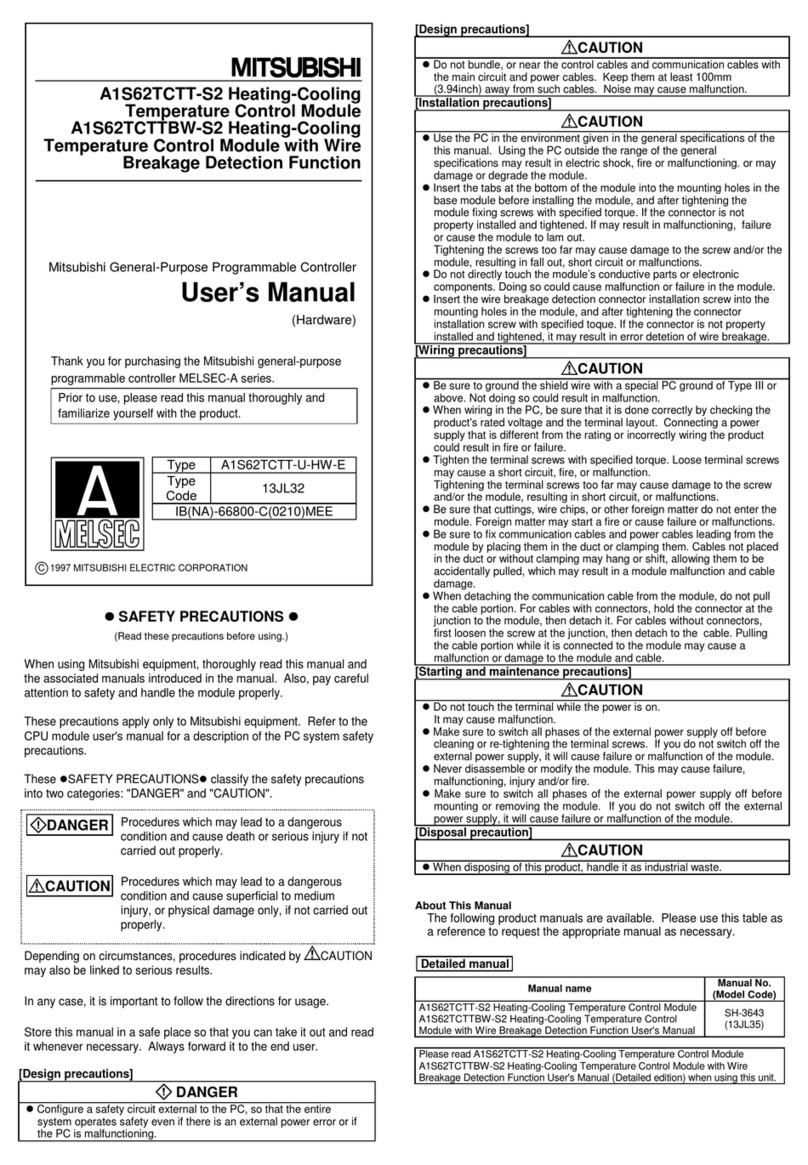

Popular Temperature Controllers manuals by other brands

Mitsubishi

Mitsubishi A1S62TCTT-S2 user manual

Hubbell

Hubbell GAI-TRONICS TempSense TS100 manual

Clint

Clint floyd FVW Series Instructions for installation, use and maintenance manual

aci

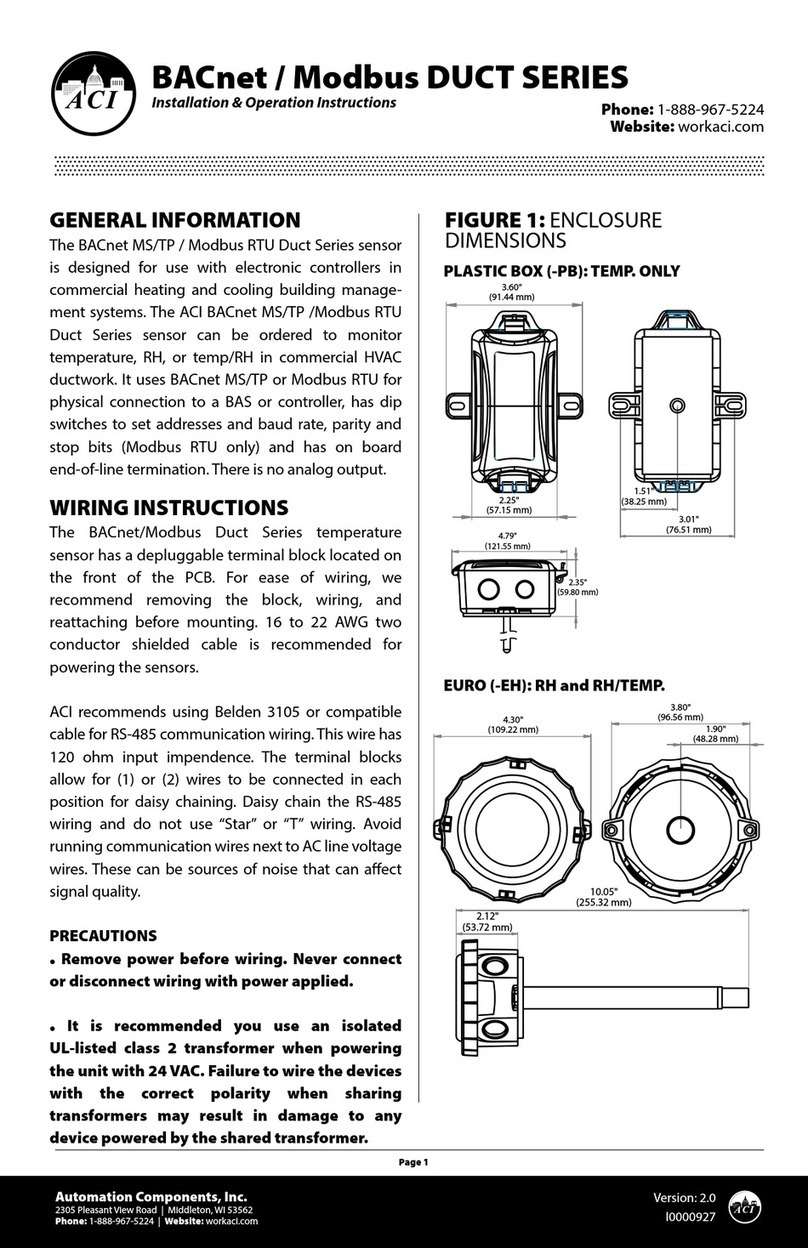

aci BACnet Series Installation & operation instructions

hanshow

hanshow Nebular-T01-N product manual

Qlima

Qlima DD 108 White operating manual

Velleman

Velleman K641LX Assembly guide

Uponor

Uponor UponorControl System Installation and operation manual

Mitsubishi Electric

Mitsubishi Electric PAC-USWHS003-TH-1 Installation instructions manual

Calex

Calex PyroSigma Series Operator's guide

WIKA

WIKA TC47 Series operating instructions

HARRICK

HARRICK ATC-024-1 user manual