Newport 300 Series User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Model 300 Series

Temperature Controllers

OPERATING

MANUAL

DISPLAYSTATUS

POWER ANALOG OUTPUT MODE OUTPUT

10kΩ/V (100µA)

100kΩ/V (10µA)

100°C/V (335/590)

HEAT

COOL

PRESET

SENSOR

CURRENT

LIMIT

R/T ITE ON

ERROR

LIMITING

LIMIT SET

KΩ

°C

Amp

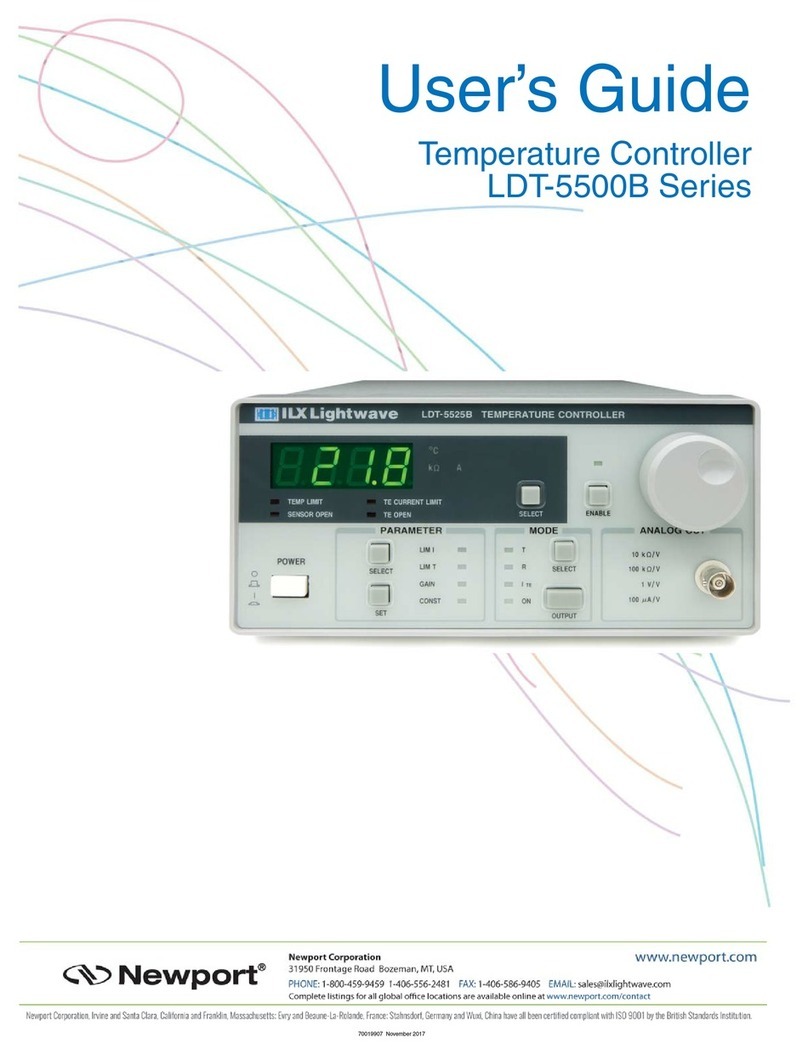

MODEL 325 TEMPERATURE CONTROLLER

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 300 Series Temperature Controllers

Operating Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii

Warranty

Newport Corporation warrants this product to be free from defects in

material and workmanship for a period of 1 year from the date of shipment.

If found to be defective during the warranty period, the product will either

be repaired or replaced at Newport’s option.

To exercise this warranty, write or call your local Newport representative,

or contact Newport headquarters in Irvine, California. You will be given

prompt assistance and return instructions. Send the instrument, transpor-

tation prepaid, to the indicated service facility. Repairs will be made and

the instrument returned, transportation prepaid. Repaired products are

warranted for the balance of the original warranty period, or at least 90

days.

Limitation of Warranty

This warranty does not apply to defects resulting from modification or

misuse of any product or part. This warranty also does not apply to fuses.

This warranty is in lieu of all other warranties, expressed or implied,

including any implied warranty of merchantability or fitness for a particular

use. Newport Corporation shall not be liable for any indirect, special, or

consequential damages.

ii

© 1995 Newport Corporation

1791 Deere Ave

Irvine, CA 92606

(949) 863-3144

P/N 21206-01, Rev. B

IN-04952 (10-99)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iii

VP European Operations General Manager-Precision Systems

Zone Industrielle 1791 Deere Avenue

45340 Beaune-la-Rolande, France Irvine, Ca. USA

We declare that the accompanying product, identified with the

"" mark, meets the intent of the Electromagnetic Compatability

Directive, 89/336/EEC and Low Voltage Directive 73/23/EEC.

Compliance was demonstrated to the following specifications:

EN50081-1 EMISSIONS:

Radiated and conducted emissions per EN55011, Group 1,

Class A

EN50082-1 IMMUNITY:

Electrostatic Discharge per IEC 1000-4-2, severity level 3

Radiated Emission Immunity per IEC 1000-4-3, severity level 2

Fast Burst Transients per IEC 1000-4-4, severity level 3

Surge Immunity per IEC 1000 4-5, severity level 3

IEC SAFETY:

Safety requirements for electrical equipment specified in

IEC 1010-1.

Alain Danielo Jeff Cannon

EC DECLARATION OF CONFORMITY

Active Isolation Module Set Series

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

Table of Contents

Warranty ................................................................................................................ii

Figures ...................................................................................................................iv

Safety Precautions ...............................................................................................iv

Section 1 — General Information 1

1.1 Introduction .............................................................................................. 1

1.2 Specifications ............................................................................................ 1

1.3 Accessories ............................................................................................... 3

Section 2 — System Operation 4

2.1 Introduction .............................................................................................. 4

2.2 Front Panel ................................................................................................ 4

2.2.1 AC Power Switch ............................................................................ 5

2.2.2 Analog Output................................................................................. 5

2.2.3 Mode Switch.................................................................................... 5

2.2.4 Output Section ................................................................................ 5

2.2.5 Status ............................................................................................... 5

2.2.6 Display ............................................................................................. 5

2.2.7 Control Knob................................................................................... 6

2.3 Rear Panel.................................................................................................. 7

2.3.1 Analog Interface ............................................................................. 7

2.3.2 Gain Adjust...................................................................................... 9

2.3.3 Sensor Select Switch...................................................................... 9

2.3.4 Output Connector .......................................................................... 9

2.3.5 AC Power Inlet ................................................................................ 9

Section 3 — Principles of Operation 10

3.1 Introduction ............................................................................................ 10

3.2 Thermistors............................................................................................. 10

3.3 Working With IC Sensors .......................................................................11

3.3.1 AD590 SERIES IC SENSORS.......................................................... 11

3.3.2 LM335 SERIES IC SENSORS.......................................................... 11

3.4 Using Thermo-Electric Modules ........................................................... 11

3.5 Mounting Considerations ...................................................................... 13

3.6 Model 300 Series Setup.......................................................................... 13

3.6.1 Rack Mounting Model 300 Series Units ...................................... 13

3.6.2 Model 300 Series Operating Checklist ........................................ 14

Section 4 — Factory Service 16

4.1 Introduction ............................................................................................ 16

4.2 Obtaining Service ................................................................................... 16

Service Form ........................................................................................... 17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

v

Figures

Figure 1 Front panel layout................................................................................ 4

Figure 2 Rear panel layout................................................................................. 7

Figure 3 TE module configuration .................................................................. 12

Figure 4 Mounting arrangement of a TE module,

heat sink and laser diode.................................................................. 13

Figure 5 Gain Adjust Settings .......................................................................... 15

Safety Precautions

CAUTION

Check that all equipment is unplugged before connecting

Check that the selector is set at the position which corresponds to

your mains voltage

All units are factory preset to operate at 180–250 VAC, 50–60 Hz.

(See AC Power Inlet, in Section 2.3.5)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vi

Notes

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

Section 1

General Information

1.1 Introduction

Two controllers, the Model 325 and 350, provide superior temperature

stability and a wide range of power outputs. Each has a fast settling,

hybrid P-I control loop that delivers a low noise, bipolar current output in

three operating modes: 1) constant R (thermistor), 2) constant T (IC

sensors), or 3) constant ITE . A user adjustable ITE current limit setting

unconditionally protects the TE modules from damage by excessive drive

current independent of the operating mode. The Model 300 Series is

compatible with thermistors, and AD590 and LM335 Series IC temperature

sensors. Temperature readings (°C) are displayed when using one of these

IC sensors. Model 325 AN and 350 AN include an Analog Interface allowing

remote instrument control and monitoring of display levels.

1.2 Specifications

Model 325 Model 350

Model 325AN Model 350AN

Output

Output Type Bipolar, constant current source Bipolar, constant current source

Control Loop Type Hybrid P-I Hybrid P-I

Maximum Current ±2.5 Amps ±5 Amps

Compliance Voltage >6 Volts >10 Volts

Available Output Power 15 Watts 50 Watts

Current Limit

Range 0 to 2.5 Amps 0 to 5 Amps

Accuracy ±10 mA ±20 mA

Ripple/Noise (rms) <1 mA <2 mA

Stability

Short Term (10 to 30 min.) 0.005 °C 0.005 °C

Long Term (24 hour period) 0.01 °C 0.01 °C

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

Model 325 Model 350

Model 325AN Model 350AN

Display

Range:

Temperature −50.0 to +150.0°C −50.0 to +150.0°C

Resistance (10 µA) 0.1 kΩto 199.9 kΩ0.1 kΩto 199.9 kΩ

Resistance (100 µA) 0.01 kΩto 19.99 kΩ0.01 kΩto 19.99 kΩ

TE Current −2.50 Amps to +2.50 Amps −5.00 Amps to +5.00 Amps

Resolution:

Temperature 0.1°C 0.1°C

Resistance (10 µA) 100 Ω100 Ω

Resistance (100 µA) 10 Ω10 Ω

TE Current 10 mA 10 mA

Accuracy:

Temperature ±0.2 °C ±0.2 °C

Resistance (10 µA) ±200 Ω±200 Ω

Resistance (100 µA) ±20 Ω±20 Ω

TE Current ±10 mA ±20 mA

Temperature Sensors

Sensor Types Thermistor (NTC 2-wire) AD590 LM335

Temperature Resolution 0.1 °C 0.1 °C 0.1 °C

Temperature Accuracy (at 25°C) 0.2 °C 0.5 °C 3.0 °C

Sensor Bias 10 µA/100 µA +12 Volts 1 mA

General

Input Power 90–125, 180–250 VAC, 50–60 Hz

Chassis Ground 4 mm banana jack

Size, H x W x D 88 x 215 x 280 mm

(3.5" x 8.5" x 11")

Weight

Model 325 & 350 2.9 kg (6.5 lbs.)

Operating Temperature 0°C to +50°C

Storage Temperature −40°C to +70°C

Humidity <90% relative, non-condensing

Connectors

Output 15-pin, D-sub (female)

Analog Output Isolated BNC

Analog Interface

(Model 325AN & 350AN) 15-pin, high density D-sub (female)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

1.3 Accessories

The Model 300 Series Temperature Controllers come with a line cord for

connection to AC power. To order accessories use the following part

numbers:

PART # DESCRIPTION

300-02 Temperature Controller Cable

300-04 Temperature Controller/Mount Cable

300-16 10.0 kΩthermistor (±0.2°C)

300-22 AD592CN IC Sensor

35-RACK Rack Mount Kit

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4

Section 2

System Operation

2.1 Introduction

The Model 300 Series Temperature Controllers have been engineered to

simplify the use of thermoelectric (TE) modules for cooling or heating laser

diodes, IR detectors and other semiconductor devices.

2.2 Front Panel

The front panel is outlined with six functional areas and a multi-turn

control knob used to set a stable output value.

DISPLAYSTATUS

POWER ANALOG OUTPUT MODE OUTPUT

10kΩ/V (100µA)

100kΩ/V (10µA)

100°C/V (335/590)

HEAT

COOL

PRESET

SENSOR

CURRENT

LIMIT

R/T ITE ON

ERROR

LIMITING

LIMIT SET

KΩ

°C

Amp

MODEL 325 TEMPERATURE CONTROLLER

Figure 1: Front panel layout

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

2.2.1 AC Power Switch

When the AC power is turned on the unit starts up with the OUTPUT off,

R/T MODE selected, and the display in the PRESET mode.

2.2.2 Analog Output

A BNC connector can be used to monitor the temperature sensor value.

The transfer function of the output is dependent on the sensor type se-

lected. The thermistor current selection values are either 10µA or 100µA

and result in either 100 kΩ/V or 10 kΩ/V respectively. Both IC sensors have

a transfer function of 100°C/V.

2.2.3 Mode Switch

The Model 300 Series can be operated in either 1) constant R (thermistor

resistance), 2) constant T (IC sensors), or 3) constant ITE mode. The R/T

mode is used with temperature sensors and the ITE mode to maintain a

constant output current.

2.2.4 Output Section

Output ON Switch

Pushing this switch allows current flow to the TE module. The output stays

on, as indicated by the green LED above, until the switch is pushed again or

an error condition occurs.

Error Indicator LED

An ERROR condition occurs when there is an open circuit to the TE module

or temperature sensing device. The output current is automatically turned

off. Once the device is replaced or reconnected, pushing the output switch

twice will clear the error indication and restore the output on condition.

Limiting Indicator LED

This LED lights up whenever the output current reaches a user adjustable

threshold, limiting the current flow to the TE module. It usually occurs

during initial startup as the drive circuitry attempts to reach equilibrium.

Limit Set

A small slotted screwdriver is used to access a recessed trimpot to adjust

the unit’s output current limiting level. Toggle the DISPLAY section push-

button to the LIMIT indicator and adjust the readout (in Amps) with a

clockwise rotation to increase the protection level.

2.2.5 Status

The STATUS indicator LEDs show whether the device under temperature

control is being heated or cooled.

2.2.6 Display

A 3 1/2 digit green LED display is located in the top center of the front

panel. It reads in kΩwhen displaying a thermistor resistance value, °C

when displaying an IC sensor temperature, or Amps when in the constant

current ITE mode. Pushing the switch cycles through the display values as

described below. Display modes can be toggled with the output on or off.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6

Preset Display

The PRESET display mode is used to set the appropriate output value using

the rotary control knob before turning the OUTPUT on. Once the control

level is set, the OUTPUT may be turned on and the actual SENSOR or

CURRENT value can be monitored.

Sensor Display

The actual temperature sensor value is monitored in this mode. The value

displayed depends on the sensor being used with °C displayed for IC

sensors and kΩfor thermistors.

Current Display

This readout monitors the actual current level in Amps being supplied to

the TE module. When the OUTPUT is first selected this current value may

be as high as the LIMIT value. As the temperature stabilizes the output

current will decrease.

Limit Display

This value is set by the limit set screw adjustment. See Limit Set, 2.2.4.

Indicator LEDs

To the right of the numeric display are three LEDs which indicate measure-

ment units: 1) resistance in kΩ, 2) temperature in °C, or 3) output current in

Amps.

2.2.7 Control Knob

The knob control on the right side of the front panel sets the appropriate

reference value corresponding to either resistance (thermistor), tempera-

ture (IC sensors), or TE current (ITE) to be maintained by the Model 300

Series Temperature Controller.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

2.3 Rear Panel

Figure 2 shows the layout of the rear panel which contains the ANALOG

INTERFACE and OUTPUT connectors, a REMOTE/ LOCAL switch, the

sensor select switch, GAIN ADJUST screw, and the AC power inlet.

ANALOG

INTERFACE

OUTPUT

1,2

3,4

5

6

7

8

TE (+)

TE (–)

TE SHIELD

SENSOR SHIELD

SENSOR (+)

SENSOR (–)

GAIN

ADJUST

REMOTE

LOCAL

115/230, 2A/1A, 60/50 Hz

250V, 3AG, SLO-BLOW

MADE IN U.S.A.

CAUTION: DO NOT REMOVE COVER, REFER SERVICING TO QUALIFIED

PERSONNEL. DISCONNECT INPUT POWER BEFORE REPLACING FUSE

OFF

ON

OFF

ON

SENSOR SELECT

100µA10µA LM335 AD590

OFF

OFF ON

OFF OFF

ON ON

ON 115V

Figure 2: Rear panel layout.

2.3.1 Analog Interface

Model 325AN and 350AN include a Analog Interface card, located at the far

left of the rear panel. A 15-pin, high density, D-sub connector is used for

the input and output lines. Above the connector is the REMOTE/LOCAL

switch used to activate the set-point control line which is disabled in the

LOCAL mode. The status lines are always available whether the REMOTE

or LOCAL mode is selected.

How To Use The Analog Interface

The Analog Interface may be used with chart recorders, X-Y recorders or

can be operated via a computer using a multiple function I/O card such as

the National Instruments LAB-PC data acquisition card. One data acquisi-

tion card will control two Model 300 temperature controller units or one

Model 300 and one Model 500 laser diode driver unit. The Output Set-point

is set using one of the analog outputs from the data acquisition card. Other

TTL signals of the Analog Interface card are controlled by the digital I/O

lines. R/T Monitor data, such as temperature, is then acquired using the

analog input line of the data acquisition card.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8

Analog Interface Connections

Pin # Designation Function

1 ON/OFF TTL momentary low toggles output on/off

2 ENABLE TTL low = remote level control enabled*

3 STATUS TTL low = output on

4 LIMIT TTL low = output limiting

5 ERROR TTL low = output error

6 MODE TTL low = R/T, TTL high = ITE

7 DGND Digital Common for TTL signals

8 EGND Earth Ground for shielding TTL signals

9 LEVEL (+) Input signal for level control (charts below)*

10 LEVEL (−) Input signal DC Common

11 ANALOG OUT DC output voltage for actual R/T (chart below)

12 AGND DC Common for Analog Output

13 - Not Used

14 - Not Used

15 EGND Earth ground for shielding analog signals

* Front panel control knob is bypassed

External Level Input, VDC (Pin 9 With Respect To Pin 10)

R/T MODE

Range Input Voltage Level Corresponding R/T Value

100µA 0 to 2V 0 to 20 kΩ

10µA 0 to 2V 0 to 200 kΩ

AD590 −0.50V to +1.50V −50.0°C to +150°C

LM335 −0.50V to +1.50V −50.0°C to +150°C

ITE MODE

Model Input Voltage Level Output Current Level

325/325AN −250 mV to +250 mV −2.50 A to +2.50 A

350/350AN −500 mV to +500 mV −5.00 A to +5.00 A

Analog Output Level, VDC (Pin 11 With Respect To Pin 12)

R/T or ITE MODE

Range Output Voltage Level Corresponding R/T Value

100µA 0 to 2V 0 to 20 kΩ

10µA 0 to 2V 0 to 200 kΩ

AD590 −0.50V to +1.50V −50.0°C to +150°C

LM335 −0.50V to +1.50V −50.0°C to +150°C

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

2.3.2 Gain Adjust

The GAIN ADJUST varies the overshoot and stability of the control loop

circuitry in order to accommodate different thermal characteristics of

thermistors, the TE module and heatsink, and mounting structures.

Sections 3.2, 3.3, 3.4 and 3.5 present the details of using TE modules, IC

sensors, thermistors, and how physical mounting arrangements affect the

operation of the Model 300 Series Temperature Controllers. An initial GAIN

value is set at the factory and should be satisfactory for most mounts.

Adjusting the GAIN is described in Section 3.6.2 (i).

2.3.3 Sensor Select Switch

This 2-position DIP switch is used to select the appropriate bias for each

one of the sensor types. The switch position for each sensor is printed on

the rear panel next to the switch.

2.3.4 Output Connector

Connection to the TE module and temperature sensor are made using a 15-

pin, D-sub connector. There are two pins each for the TE+and TE−connec-

tions to provide redundancy and reduce the voltage drop in the cable.

Wire Color

Pin # Connection (300-02 cable)

1 & 2 TE +RED

3 & 4 TE −BLACK

5 TE SHIELD

6 SENSE SHIELD

7 SENSOR +GREEN

8 SENSOR −WHITE

2.3.5 AC Power Inlet

The input voltage setting is indicated in a small window on the face of the

power module. A small screwdriver is needed to flip down the panel once

the AC line cord is removed. Carefully rotate the plastic tumbler so the

proper range is indicated. The fuse is also located behind this panel and

can be pulled out, to be replaced with the appropriate size indicated on the

back panel.

All units are preset at the factory for operation at 180–250 VAC, 50–60 HZ.

The line cord supplied with each unit should be plugged only into a prop-

erly grounded three prong outlet to prevent electrical shock in the event of

an internal short circuit to the metal cabinet.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10

Section 3

Principles of Operation

3.1 Introduction

Three factors must be taken into account when optimizing the operation of

a Model 300 Series Temperature Controller: selection of both the appropri-

ate temperature sensor and TE module heat sink, and the manner in which

they are mounted. Selecting the proper thermistor to cover a specific

temperature range of operation is a simple but important procedure. The

proper TE module must be selected to remove the heat dissipated by the

laser diode or other device. Finally, the arrangement of the TE module and

the heat sink, as well as the heat sink size, are crucial in maximizing the

heat transfer efficiency.

3.2 Thermistors

Model 300 Series Temperature Controllers are designed to operate using a

thermistor as one of the temperature sensing devices. Temperature is

displayed as a resistance (kΩ) corresponding to the temperature of the

thermistor. The actual temperature of the thermistor can be determined from

the manufacturers curves or tables listing temperature vs. resistance. Two

precision current sources, 10µA and 100µA, are used to generate a voltage

across the thermistor and it is this voltage that is read on the front display.

For the 10µA current source the maximum resistance that can be displayed

is 199.9 kΩ, while for the 100µA source the maximum reading is 19.99 kΩ.

The minimum resistance value that can accurately be read is 200 ohms

(100µA current source). These two current values allow a wide range of

temperatures to be controlled by the Model 300 Series Temperature

Controllers. Different ranges of temperatures can be adjusted for by selecting

the proper thermistor value. The following table illustrates this point:

Temperature vs. Thermistor Resistance

Thermistor value @ 25°C 1k 10k 100k

200 kΩ–75°C –37°C –11°C

100 kΩ–66°C –24°C 25°C

20 kΩ–40°C 8°C 65°C

10 kΩ–27°C 25°C 85°C

1 kΩ25°C 93°C >150°C

100 Ω100°C >150°C >150°C

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

Careful thermistor value selection therefore enables control over a wide

temperature range.

The temperature resolution and thermistor sensitivity must also be taken

into account. Thermistors achieve their highest sensitivity at the lower

end of their temperature range. Therefore, the lower the absolute tempera-

ture to be maintained, the lower the resistance value the thermistor should

be. For example, to operate at 0°C a 10k ohm thermistor would be the best

selection while at 100°C a 1k ohm thermistor would be a better selection.

The rule of thumb is to operate the thermistor near the lower end of its

temperature range and use the 100µA current bias. Please contact

Newport’s applications engineers if you have any questions regarding the

selection of the proper thermistor for your application.

3.3 Working With IC Sensors

Two IC temperature sensors may be used with the Model 300 Series Tem-

perature Controllers, the AD590 Series and the LM335 Series. Both come in

several different package types having various accuracy and stability

characteristics. These temperature sensors are easy to use and give a

temperature reading directly in °C on the Model 300 Series display.

3.3.1 AD590 SERIES IC SENSORS

The AD590 Series devices are two-terminal IC temperature sensing devices,

which produce an output current directly proportional to the absolute

temperature at 1µA/°K. The AD590 Series sensor is particularly useful in

remote sensing applications where long cable lengths are used, due to its

high impedance current output. A linear output is displayed in °C on the

Model 300 Series Temperature Controller, which makes it ideally suited for

most temperature sensing applications. The recommended upper operat-

ing limit for AD590 Series devices is 150°C.

3.3.2 LM335 SERIES IC SENSORS

The LM335 Series devices are similar to the AD590 in that they are two

terminal devices and their output is directly proportional to absolute

temperature. Operating like a two terminal zener diode, the LM335 Series

temperature sensors have a breakdown voltage directly proportional to

absolute temperature at +10mV/°K. When using the LM335 Series sensors,

voltage drops resulting from using long cables will introduce inaccuracies

in the temperature display measurement.

3.4 Using Thermo-Electric Modules

Thermo-electric (TE) modules are semiconductor devices that act as heat

pumps when a voltage is applied to them. This effect is called Peltier

cooling or heating. The direction of the current flow determines whether

the TE module is cooling or heating a device such as a laser diode or IR

detector. A TE module consists of a matrix of thermoelectric couples made

of p-type and n-type semiconductor material. A TE module can be fabri-

cated with as few as one couple or with as many as several hundred

couples sandwiched between two ceramic plates. The ceramic plates form

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

12

the top and bottom of the TE module and provide structural integrity as

well as electrical insulation from, and thermal conduction to, the heat sink

and the device being cooled or heated.

Model 300 Series Temperature Controllers are designed to control the rate

and amount of cooling or heating through the use of a feedback loop. The

arrangement of the TE module in the cooling mode is shown in Figure 3.

When a positive DC voltage is applied to the n-type element, electrons pass

from the p-type to the n-type elements and the temperature decreases as

heat is absorbed by the cold side of the TE module. The heat absorbed is

proportional to the amount of current flowing through the TE module and

the number of p-type and n-type elements in the TE module.

+–

P-TYPE N-TYPE

Heat Dissapated To Heat Sink

Current Flow

Cooling Mode

Th (Hot Side)

Tc (Cold Side)

TE + (Pins 1, 2)

TE –(Pins 3, 4)

Heat Absorbed From Device Being Cooled

+–

Figure 3: TE module configuration

It is necessary to remove the heat from the hot side of the TE module. The

amount of heat to be dissipated is equal to the heat pumped from the cold

side plus the input power to the TE module. Although the amount of

cooling is proportional to the current flowing through the TE module, the

power dissipated by Joule heating (input power heating) in the TE module

is proportional to the square of the current. Half of this heat must be

pumped from the cold side of the TE module. When exceeding a maximum

current value (Imax), which is device dependent, the net cooling of the TE

module decreases because Joule heating is increasing at a greater rate than

Peltier cooling. The manufacturer of the TE module will state the maximum

current for each TE module and this current value should not be exceeded.

The LIMIT SET feature on the Model 300 Series Temperature Controllers

allows you to limit the maximum current flowing through the TE module.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

4

Table of contents

Other Newport Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

J-KEM Scientific

J-KEM Scientific Gemini user manual

Sub-Zero

Sub-Zero SZ-81145 user manual

RKC INSTRUMENT

RKC INSTRUMENT REX-P48 Series Operation manual

alre

alre FTRFB-280 Series manual

Kingspan

Kingspan Temperature differential controller Installation and operating instructions

Saunier Duval

Saunier Duval exacontrol 7 manual

Stahl

Stahl 8146/5051 Series operating instructions

Sorel

Sorel MTDC Installation and operating instructions

STIEBEL ELTRON

STIEBEL ELTRON EASYTRON Connect ERT instructions

Viessmann

Viessmann VITOTROL 100 Operating Instructions for the System User

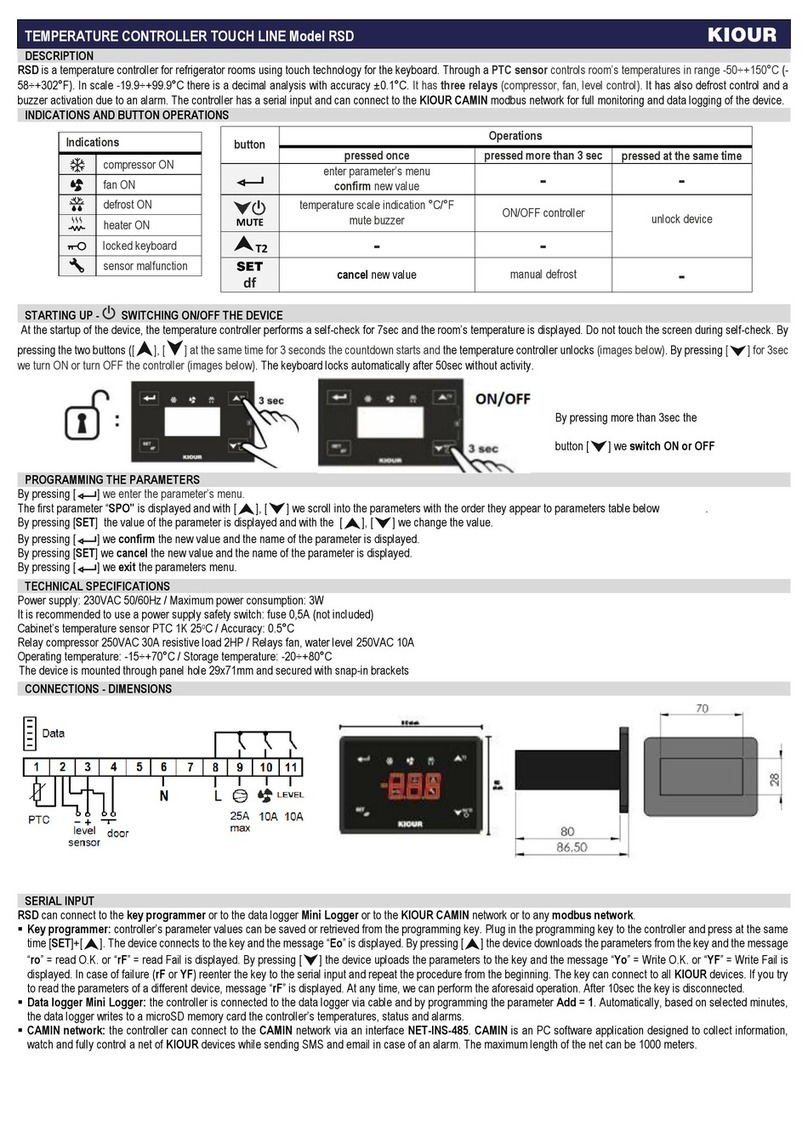

KIOUR

KIOUR RSD quick start guide

Ketotek

Ketotek KT1210W operating manual