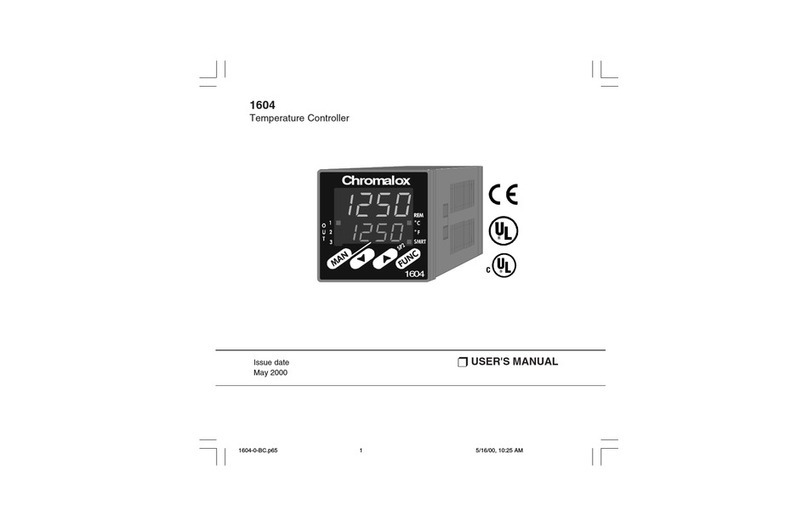

Two Default Setting profiles exist for the 20 Series controllers, which is contingent

upon the Output 1 Selection: SSR Drive or Relay. Many of these settings are found

in Section 7 - Setup Mode. Please see the table below for the default settings for

each profile type:

Output 1: SSR Relay Output 1: SSR Relay

Input Type J T/C Heat Proportional Band 25˚F

Input Units ˚F Hysteresis (deadband) 5˚F

Resolution (Decimal Places) No Decimal Bias (Manual Reset) 25%

Input Scale, Upper Limit 1000 Heat Cycle Time 1 sec

Input Scale, Lower Limit 0 Heat Power Limit 100%

Output 1 Use Heat Output Auto Tune Off

Output 2 Use Alarm 1 Manual Control Off

Output 3 Use (if present) Alarm 2 Setpoint Upper Limit 1000˚F

Alarm 1 Value Off Setpoint Lower Limit 0˚F

Alarm 2 Value Off Setpoint 0˚F

Default Settings Note: The above profiles were established to provide the most ef-

ficient settings for those users with Temperature applications. If one was to execute

a “Reset to Defaults” action, as found in the Display (diSP) Sub-menu, then the

above settings would be replaced with the original factory parameter values. In this

case, please refer to the full manual for procedures to complete the programming.

6. DEFAULT SETTINGS

7. SETUP MODE

The Setup Menu contains commonly used parameter settings. To edit settings found

in the Setup Menu (below), such as Setpoint, one must enter the Setup Menu.

From User Mode: Press and hold down Qand press pfor Setup Mode

S.Loc Setup Mode lock code – default 10.

Once in the Setup Menu, press por qkeys to navigate between parameters, To

edit a parameter, press

Q

. The Parameter name (lower display) flashes when the param-

eter above can be edited. Press por qto change the parameter value (upper display).

To confirm the change, press

Q

within 60 seconds otherwise the change is rejected.

To change a setting not found in the Setup Menu Table, navigate to the Advanced

Configuration Menu: (from User Mode): Press and hold down Qand press q.

A.Loc Advanced Configuration Mode lock code – default 20.

Setup Menu

Screen Name Lower

Display

Upper

Display

Adjustment Range &

Description

Default

Value

Setup mode

lock code S.Loc

Visible when attempting to enter Setup unless,

following a reset with power-down or lock code is

OFF).

Set value (1to 9999) matching the defined lock

code to allow entry to the following screens.

10

Input Type

type TC_J

J Thermocouple

TC_J

-328 to 2192˚F

-200 to 1200˚C

-199 to 999.9˚F

-128 to 537.7˚C

TC_h

K Thermocouple

-400 to 2503˚F

-400 to 1200˚C

-199 to 999.9˚F

-128 to 537.7˚C

p100

PT100

-328 to 1472˚F

-400 to 1200˚C

-199 to 999.9˚F

-128 to 537.7˚C

Several additional Thermocouple types are avail-

able, such as B, C, L, N, R, S & T. Please refer to the

full Installation and Operation Manual for details.

0_20 0 - 20 mA DC

0_40 0 - 40 mA DC

Several additional Analog or Linear Input types

are available, such as 0-50, 10-50, 0-5, 1-5, 0-10

and 2-10. Please refer to the full Installation and

Operation Manual for details.

Screen Name Lower

Display

Upper

Display

Adjustment Range &

Description

Default

Value

Input Units Unit F Temperature displayed as °F. F

C Temperature displayed as °C.

Process Display

Resolution decp. 0000 No decimal place 0000

000.0 1 decimal place

Input Scale,

Upper Limit scul

Scale Input Lower Limit +100 display units to

range maximum. (Only visible in Setup Mode when

a DC linear type is selected)

Input max

Lin=1000

Input Scale,

Lower Limit scll

Range minimum to Scale Input Upper Limit -100

display units. (Only visible in Setup Mode when a

DC linear type is selected)

Input min

Linear=0

Output 1

Useage Out1

HEAT Heat Power HEAT

COOL Cool Power

ALI Alarm 1

AL2 Alarm 2

AL12 Alarm 1 or 2

Loop Control Loop Alarm (2x integral time)

Output 2 Usage

Out2 As Output 1 Usage AL1

Output 3 Usage

Out3 As Output 1 Usage AL2

Alarm 1 Adjust

AL_1 Range minimum to range maximum

OFF disables the alarm. Default high alarm

OFF

Alarm 2 Adjust

AL_2 Range minimum to range maximum

OFF disables the alarm. Default low alarm

OFF

Setpoint Adjust SP Target setpoint adjustable between setpoint upper

and lower limits

0

Automatic

Tuning Start /

Stop

tune OFF Use current PID control terms or

manually tune OFF

Pre Start a pre-tune routine

Atsp Start the tune at setpoint

8. MESSAGES & ERROR CODES

Some messages provide useful information about the process, others indicate error,

or problem with the process variable signal or its wiring.

Do not continue with the process until the issue is resolved.

Screen Name Lower

Display

Upper

Display Screen Meaning and Visibility

Alarm Active Normal -AL- One or more alarms are active (alternates with

PV). Optional – _see diSP

Output Latched Normal Ltch One or more output are latched on (alternates

with PV), and no alarm is active

Input Over

Range Normal -HH- Process variable input >5% over-range.

Input Under

Range Normal -LL- Process variable input >5% under-range.

Input Sensor

Break OFF OPEN Break detected in process variable input sensor

or wiring.

Un-calibrated

Input OFF Err Selected input range has not been calibrated.

Manual Power Pxxx Normal Manual power value replaces the setpoint.

Setpoint

Ramping SPr Normal Setpoint ramp is active (alternates with

setpoint)

Control

Disabled OFF Normal Control is disabled, control outputs are off.

Control

Delayed dLy Normal Visible if control delayed by Delayed Start Time

(d_ti)

Automatic

Tuning tune Normal Tuning is active (alternates with setpoint).

Screen Name Lower

Display

Upper

Display Screen Meaning and Visibility

Automatic

Tuning Errors

If the tune fails the display alternates between the tune error code and

the setpoint. Remains visible until tune set to off.

Ter1

Normal

PV is within 5% of setpoint

Ter2 Setpoint is ramping

Ter3 Control is ON/OFF

Ter4 Control is manual

Ter5 Pulse tune not able to run

Ter6 Sensor break

Ter7 Timer running

Ter8 Sensor break

9. SPECIFICATIONS

UNIVERSAL INPUT

Thermocouple Calibration: ±0.25% of full range, ±1LSD (±1°C for Thermocouple CJC).

BS4937, NBS125 & IEC584.

PT100 Calibration: ±0.25% of full range, ±1LSD. BS1904 & DIN43760

(0.00385Ω/Ω/°C).

DC Calibration: ±0.2% of full range, ±1LSD.

Sampling Rate: 4 per second.

Impedance: >10MW resistive, except DC mA (5Ω) and V (47kΩ).

Sensor Break Detection: Thermocouple, RTD, 4 to 20mA, 2 to 10V and 1 to 5V ranges

only. Control outputs turn off.

Isolation:

Isolated from all outputs (except SSR driver) by at least

BASIC isolation. Universal input must not be connected to

operator accessible circuits if relay outputs are connected to a

hazardous voltage source. Supplementary insulation or input

grounding would then be required. Isolated from Mains Power

Input by basic isolation.

OUTPUTS

RELAYS (OPTIONAL)

Contacts: SPST Form A relay; current capacity 2A at 250VAC.

Lifetime: >150,000 operations at rated voltage/current, resistive load.

Isolation: Basic Isolation from universal input and SSR outputs.

SSR Drivers (OPTIONAL)

Drive Capability: SSR drive voltage >10V at 20mA

Isolation: Not isolated from universal input or other SSR driver outputs.

SERIAL COMMUNICATIONS (OPTIONAL)

Physical: RS485, at 1200, 2400, 4800, 9600, 19200 or 38400 bps.

Protocols: Modbus RTU.

Isolation: Basic safety isolation from Universal input and SSR.

Basic safety isolation to Mains and Relay Circuits.

OPERATING CONDITIONS

Usage For indoor use only, mounted in suitable enclosure

Ambient Temperature: 0°C to 55°C (Operating), –20°C to 80°C (Storage).

Relative Humidity: 20% to 95% non-condensing.

Altitude <2000m

Supply Voltage and

Power:

100 to 240VAC ±10%, 50/60Hz, 7.5VA (for mains powered

versions), or 24VAC +10/-15% 50/60Hz 7.5VA or 24VDC +10/-

15% 5W (for low voltage versions).

ENVIRONMENTAL

Standards: CE, UL, cUL

EMI: Complies with EN61326 (Susceptibility and Emissions).

Safety Considerations: Complies with EN61010-1

Front Panel Sealing: Front to IP65 when correctly mounted, Rear of panel to IP20.

PHYSICAL

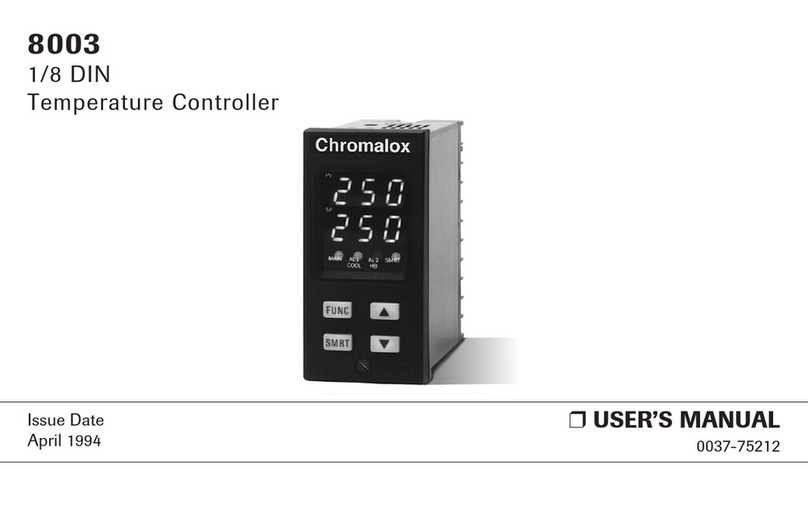

Front Bezel Size: 1/16 Din = 48 x 48 mm, 1/8 Din = 48 x 96 mm

Depth Behind Panel: 67mm with sealing gasket fitted.

Weight: 0.20kg maximum

PK529

0037-75555

August 2015

© 2015 Chromalox, Inc.