Adixen ACS 2000 User manual

ACS 2000

Single-channel Controller

User’s Manual

Réalization/Publication: Alcatel Vacuum Technology France - User’s Manual - Ed 03 - Date : 09/2010 - Part Number:113161 *113161*

Alcatel Vacuum Technology, as part of the

Alcatel-Lucent Group, has been supplying

vacuum pumps, helium and hydrogen leak

detection systems, plasma sensors, vacuum

measurement for several years.

Thanks to its complete range of products, the

company has become an essential player

in multiple applications : instrumentation,

Research & Development, industry and

semiconductors.

Alcatel Vacuum Technology has launched

Adixen, its new brand name, in recognition

of the company’s international standing in

vacuum position.

With both ISO 9001 and 14001 certifications,

the French company is an acknowlegded

expert in service and support, and Adixen

products have the highest quality and

environmental standards.

Gb 03420 - Edition 01 - August 2007

With 45 years of experience, AVT today has a

worldwide presence, through its international network

that includes a whole host of experienced subsidiaries,

distributors and agents.

The first step was the founding of Alcatel Vacuum

Products (Hingham- MA) in the United States, thirty

years ago, reinforced today by 2 others US subsidiaries

in Fremont (CA) and Tempe (AZ).

In Europe, AVTF-France headquarters and its

subsidiaries, Alcatel Hochvakuumtechnik (Germany),

Alcatel Vacuum Technology UK (Scotland), Alcatel

Vacuum Technology Benelux (Netherlands), Alcatel

Vacuum Systems (Italy) and more recently Adixen

Sensistor AB in Sweden (in 2007) form the foundation

for the European partner network.

In Asia, our presence started in 1993 with Alcatel Vacuum

Technology (Japan), and has been strengthened with

Alcatel Vacuum Technology Korea (in 1995), Alcatel

Vacuum Technology Taiwan (in 2001), Alcatel Vacuum

Technology Singapore, Alcatel Vacuum Technology

Shanghai (China) (in 2004)

This organization is rounded off by more than 40

representatives based in a variety of continents.

Thus, whatever the circumstances, the users of Adixen

products can always rely on quick support of our

specialists in Vacuum Technology.

GB 03432 - Edition 02 - 03 - October 09

1/2

ACS 2000 Single-channel controller

Welcome

The ACS 2000 is a single-channel controller designed to work with the

following gauges:

- PIRANI gauge: AP 2004 - APN 2004

- Combined PIRANI/Cold cathode gauge: ACC 2009

- Combined CRYSTAL/Hot cathode gauge: AHC 2010

- Capacitive gauges: ASD 200X series, ARD 200X series

Dear customer,

You have just acquired an

Adixen ACS 2000 controller.

We thank you for your

purchase and are proud to

be able to count you among

our customers.

Alcatel Vacuum Technology

has acquired a wast wealth

of experience in the design

of controllers over the year.

To guarantee optimum

performance and full

satisfaction in using this

equipment, please take the

necessary time to become

familiar with this manual

before carrying out any

operation, especially the

section covering installation

and commissioning,

before installing or operating

this controller.

2/2

ACS 2000 Single-channel controller

GB 03432 - Edition 03 - October 09

This product meets all the essential requirements contained in

European directives and standards, as listed in the Declaration of

Conformity shown in Appendix 9 of this manual. These Directives are

amended by Directive 93/68/EEC (CE mark).

Copyright/Intellectual property:

The use of Adixen products are subject to copyright and

intellectual property rights in force in any jurisdiction.

All rights reserved, including copying this document in whole

or any part without prior written authorization from Alcatel

Vacuum Technology France.

Specifications and information are subject to change without

notice by Alcatel Vacuum Technology France.

GB 03431 - Edition 02 - September 07

1/1

General contents

User’s Manual

ACS 2000 Controller

MANUAL REFERENCE: 113161

EDITION : 03 - September 2010

English original version

Chapter A Commissioning

- General safety recommendations

- Unpacking and storing the controller

- Installation

- Quick commissioning procedure

Chapter B Product description

- Overview of the single-channel controller

- Navigation controls

Chapter C Settings

- Overview

- Configuring the gauges

- Set point management

- General settings for the ACS 2000

Chapter D Test mode

- Access to test mode

- Software version checking

- Analog/Digital converter test

- Controller display test

- Memory tests

- Controller interface tests

Chapter E RS232 mode

- Introduction

- List of commands

- Detailed description of RS232 command

Chapter F Appendices

- Appendix 1: Technical characteristics

- Appendix 2: Dimensions

- Appendix 3: Rack Installation

- Appendix 4: Cable and connector details

- Appendix 5: Factory settings

- Appendix 6: Error messages

- Appendix 7: Accessories

- Appendix 8: Conversion of measuring units

- Appendix 9: Declaration of conformity

- Appendix 10: Detailed example of navigation

Commissioning

ACS 2000 User’s Manual

Detailed contents

A

GB 03433 - Edition Edition 03 - October 09

1/9

General safety recommendations 2/9

Unpacking and storing the controller 5/9

- Unpacking

- Storing the controller

- Decontamination - Product recycling

Installation 6/9

- Assembly, installation

- Table mounting

- Rack mounting

- Power connections

Quick commissioning procedure 7/9

- Bringing the ACS 2000 on line

- Start-up screen

- Measurement screen and display

- Warning or error message

- Shutting down

2/9

GB 03433 - Edition 03 - October 09

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

General safety rules

This controller is designed to be completely safe to use.

Nonetheless, there are certain risks that cannot be eliminated. Such

risks are indicated throughout this manual by the following warning

messages:

This type of warning is used to indicate a potential risk that can cause

significant damage to equipment and/or installations if instructions are not

followed.

This type of warning is used to indicate a potential risk that can cause

minor injury if instructions are not followed.

This type of warning is used to indicate a potential risk that can cause

serious injury or death if instructions are not followed.

This type of warning is used to indicate an imminent risk that can cause

serious injury or death if instructions are not followed.

Warning symbols used in

this manual

GB 03433 - Edition Edition 03 - October 09

3/9

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

General safety rules

The EMC performance of this product is obtained only if the installation is

carried out in compliance with the applicable EMC rules. In particular, in

environments liable to emit strong EM disturbances, you must

- use shielded cables and connections for the interfaces

- protect the power line by a shielding from the power source to within

3 metres of the power input to the product.

The enclosure is designed to ensure normal safety conditions in its normal

operating environment (in a rack). When used on a table, or when

handling the enclosure make sure no objects are introduced into the

ventilation holes and that these holes are not blocked.

When switching off equipment containing condensers charged at more

than 60 VDC or 25 VAC, take all necessary precautions to protect against

contact with the pins on the connectors (single phase motors, equipment

with mains filter, frequency inverter, monitor, etc.)

Before switching on the power to this controller, the user must be familiar

with this manual and must follow the safety instructions herein.

• The Controllers must be connected to an electrical installation fitted

with a type TT earthed socket in compliance with ruling 88-1056 of 14th

November, 1988 (for French regulation).

• Our products are designed to meet all CEE regulations in effect. Any

modifications by the user are liable to break compliance with regulations

and jeopardise the EMC (Electromagnetic Compatibility) performance

and product safety. The manufacturer renounces all responsibility for the

consequences of any such intervention.

Safety instructions for the

installation

4/9

GB 03433 - Edition 03 - October 09

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

General safety rules

This symbol on the controller body indicates that certain internal

components are under voltage and can cause electric shock if touched. This

symbol recommends that the controller be disconnected from the mains

before any work is carried out on it or that the circuit breaker be correctly

identified and locked.

This symbol on the controller body indicates a potential risk that could

cause significant damage to the equipment and/or installations if

instructions are not followed.

Qualification of personnel Jobs described in this document may be carried out only by staff

possessing the appropriate technical training and necessary experience or

having been trained to this end by the product owner.

The manufacturer’s responsibility is lifted and the guarantee voided if

the owner or a third party

• fails to observe the instructions in this document,

• uses this product in a way that is not consistent with the

manufacturer’s intended use,

• modifies this product in any way whatsoever,

• uses the product with accessories not listed in the product

documentation.

Responsibility and guarantee

This product’s safety and performance can not be guaranteed unless it is

used in compliance with this manual.

GB 03433 - Edition Edition 03 - October 09

5/9

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

Unpacking and storing the controller

Unpacking

This product was manufactured in a clean environment and packaged

carefully to maintain this cleanliness, we advise you not to unpack the

controller until it is at its place of installation.

Remove the equipment manually from its package (weight 1.3 kg).

The electrical cables (power cable and gauge connection cables) are

shipped in a separate package (see appendix 7).

Take care in unpacking the equipment and keep its all of the packaging.

Make sure there is no shipping damage. If any such damage is noted, take

the necessary measures with the carrier and notify the manufacturer if

necessary.

In all cases we advise you to keep the packaging (recyclable material) in

case the controller needs to be shipped again, or must be stored for a long

time.

Storing the controller

The controller can be stored in its original packaging at temperature of

–20°C to +60°C.

Decontamination and

product recycling

In compliance with Directive 2002/96/CE concerning the handling

of electrical and electronic equipment waste and Directive

2002/9/CE concerning restrictions on hazardous substances, Adixen

products that have reached the end of their service life must be

returned to the manufacturer for decontamination and reuse.

The manufacturer’s obligation to recover such equipment applies

only to complete items of equipment that have been neither modified

nor retrofitted and have used only spare parts from Alcatel Vacuum

Technology sold by Alcatel Vacuum Technology and including all their

assemblies and sub-assemblies.

This obligation does not include the cost of transporting the product

to a reprocessing centre, nor the cost of the service which will be

invoiced on to the customer.

For all equipment returned to an Alcatel service center, the safety

questionnaire at the end of manual (or available online at www.

adixen.com) must be filled in and sent to the service center in

advance.

6/9

GB 03433 - Edition 03 - October 09

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

Installation

Table mounting

The controller can be placed on a table or mounted in a rack.

Assembly, installation

Ventilation

Rack mounting See appendix 3

Locate the appliance in a way that ensures good air circulation and avoids

direct exposure to the sun.

Controller ventilation

Internal components can deteriorate through overheating if there is

inadequate ventilation. DO not block the ventilation holes.

Electric shock hazard.

Before connecting the gauges, set the power switch to the «0» (off)

position. Always connect the gauges before switching on power to the

controller.

The supply voltage to the unit must be between 100 and 240 VAC. Check

the supply voltage and always use adequate cabling. Failure to follow

these instructions can lead to electric shock.

GB 03433 - Edition Edition 03 - October 09

7/9

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

Quick commissioning procedure

Bringing the ACS2000

on line

1 - Place the ACS 2000 controller on a table

2 - Connect the vacuum gauge to the connection at the back of the

controller.

3 - Connect the mains power cable

1

23

4

4 - Set the power switch to the «1» (ON) position.

Products which are not properly connected to ground are a danger to life

in the event of failure.

The controller frame must be connected to earth and an earth wire is

provided for this purposes in the 3-pin power cable (PE).

Always connect the power cable to a socket with a ground.

8/9

GB 03433 - Edition 03 - October 09

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

Quick commissioning procedure

Start-up screen At the start-up and before displaying the measurement screen, the

controller performs:

Restores the parameters that were set before power was turned off, or

adapts the parameters if the gauge has changed.

Measurement screen

and display

The measurement is available if:

- The gauge is properly connected

- The pressure lies within the measuring range of the connected gauge

Exponent

Unit

Measurement readout

E.g., the "AHC" type gauge measures a pressure of 1.2 x 102mbar.

Note From the measurement screen, it’s possible to identify what gauge is

connected by pressing the button Enter.

㪧㪩㪦㪞㪄㪈㪉㪊 㪫㪜㪪㪫 㪞㪘㪬㪞 㪜 㩷 㪪㪧 㩷 㪈 㩷 㪉 㪚㪦 㪤㪤

㪤㪜㪘㪪 㪝㪠㪣 㪛㪜㪞㪘㪪 㪟㪭㪄㪛 㪪㪙 㪣 㪱㪜㪩㪦 㪞㪘㪪 㪣㪦㪚㪢 㪘㪣㪤

㪭㫆㫃㫋 㪫㫆㫉㫉

㪧㪸㫄㪹㪸㫉

SP

mbar

12

1 - Display test

2 - Display of the software version

㪧㪩㪦㪞㪄㪈㪉㪊 㪫㪜㪪㪫 㪞㪘㪬㪞㪜 㩷 㪪㪧 㩷 㪈 㩷 㪉 㪚㪦㪤㪤

Software version number

3 - Detection of the gauge type

Type of gauge

GB 03433 - Edition Edition 03 - October 09

9/9

A Commissioning

B Product description

C Settings

D Test mode

E RS232 mode

F Appendices

Quick commissioning procedure

Warning or error

messages

The following warning message comes up when no gauge is

connected.

An error message is displayed when an error is detected at controller

start-up - see Appendix 6 for the error message list.

Shutting down Switch off the ACS 2000 by setting the power switch to the «O» position (or

via the distribution box if rack mounted).

Before switching the ACS 2000 on again, wait at least 10 seconds to allow

it to reset.

Product description

ACS 2000 User’s Manual

Detailed contents

B

GB 03434 - Edition Edition 03 - October 09

1/5

Overview of the single-channel controller 2/5

- Controller concept

- Rear view of controller

- Control panel

- Description of display

Navigation controls 5/5

- Buttons

2/5

GB 03434 - Edition Edition 03 - October 09

A Commissioning

BProduct description

C Settings

D Test mode

E RS232 mode

F Appendices

Overview of the controller

Controller concept The ACS 2000 provides power, control, and pressure display for the

operation of a gauge. It can be controlled by an operator via the front

panel, or externally by a computer via the built-in RS232 link.

Technical and dimensional characteristics Appendices 1 and 2

GB 03434 - Edition Edition 03 - October 09

3/5

A Commissioning

BProduct description

C Settings

D Test mode

E RS232 mode

F Appendices

Overview of the controller

Navigation, selection and

modification buttons

Control panel

Display

Settings

and confirm

parameters

buttons

Rear view of controller RS232 connector

(see Section E and Appendix 4)

Power indicator light

Power switch

Power Connection

Ground connection

(if required)

Connectors for gauges

(see appendix 4)

The ACS 2000 is operated from the front face of the enclosure which

includes touch buttons and a display.

Front face

Rear face

Remote connector

(see appendix 4)

4/5

GB 03434 - Edition Edition 03 - October 09

A Commissioning

BProduct description

C Settings

D Test mode

E RS232 mode

F Appendices

Overview of the controller

Description of display

㪧㪩㪦㪞㪄㪈㪉㪊 㪫㪜㪪㪫 㪞㪘㪬㪞 㪜 㩷 㪪㪧 㩷 㪈 㩷 㪉 㪚㪦 㪤㪤

㪤㪜㪘㪪 㪝㪠㪣 㪛㪜㪞㪘㪪 㪟㪭㪄㪛 㪪㪙 㪣 㪱㪜㪩㪦 㪞㪘㪪 㪣㪦㪚㪢 㪘㪣㪤

㪭㫆㫃㫋 㪫㫆㫉㫉

㪧㪸㫄㪹㪸㫉 Unit

Displayed with gauge type

Program in progress

Display of set point status

Activated function(s) (gauge or controller)

Measured pressure or

No Gauge message (if no gauge) or

Error message: (Errxx) or

Gauge type (*)

(*)

AP = AP 2004 - APN 2004

ACC = ACC 2009

AHC = AHC 2010

AD = ASD 200X - ARD 200X

GB 03434 - Edition Edition 03 - October 09

5/5

A Commissioning

BProduct description

C Settings

D Test mode

E RS232 mode

F Appendices

Navigation controls

You can navigate through the controller settings using the buttons.

Only the buttons are described below. Refer to appendix 10 if you

would like a detailed example of how to navigate.

Buttons

0,5 s

Access to SETTING functions.

Back to previous menu up to DISPLAY screen.

2 s

On a SETTING screen:

Back to DISPLAY screen.

3 s

On the measurement screen:

Access to TEST MODE.

ENTER Validation button

On the measurement screen, display gauge type.

These buttons are used to navigate the menus, select

variables, change the variables.

Settings

ACS 2000 User’s Manual

Detailed contents

C

GB 03435 - Edition Edition 03 - October 09

1/14

Overview 2/14

- Access to settings

- List of available settings

Configuring the gauges 4/14

General settings

- “Gas” correction factor

- Analog gauge output

Specific settings

- AP 2004 - APN 2004 Pirani gauges

- ACC 2009 Combined PIRANI/Cold cathode gauge

- AHC 2010 Combined CRYSTAL/Hot cathode gauge

- ASD 200X - ARD 200X Capacitive gauges

Set point management 9/14

- Display

- Adjustment by gauge type

General settings for the ACS 2000 10/14

- RS232 parameters

- Locking the settings

- Settings for measurements

- Restoring factory default settings

- Available remote Inputs/Outputs

Table of contents

Popular Controllers manuals by other brands

dixell

dixell XR01-02CX Installing and operating instructions

Evco

Evco RICS 4.30 user manual

Aqua Lung

Aqua Lung mikron Technical maintenance manual

IFM

IFM CR7032 Original operating instructions

Geco

Geco G-202-P05 Installation, operating and maintenance manual

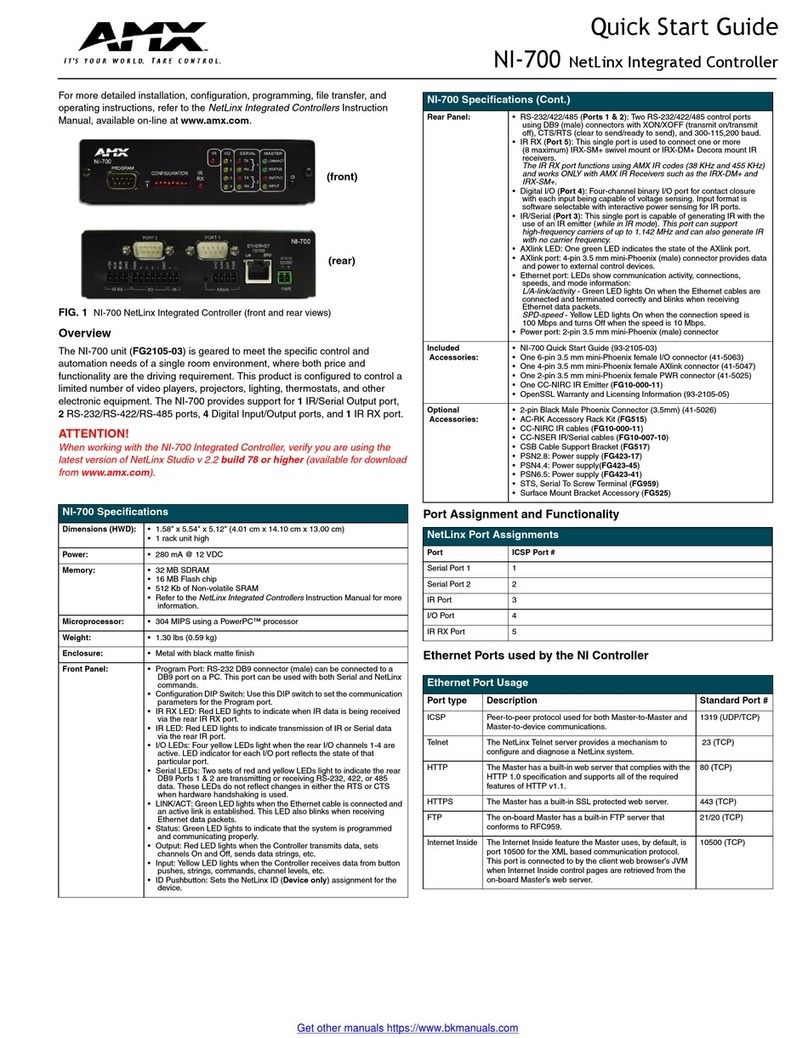

AMX

AMX NetLinx Integrated Controller NI-700 quick start guide