Megmeet MC5000 Series User manual

1

IO extension module user quick

reference manual

Thank you for using MC5000 series PLC of Megmeet. Before using the

PLC product, please carefully read this booklet so as to better

understand it, fully use it, and ensure safety.This user manual is to offer

you a quick guide to the design, installation, connection and

maintenance of MC5000 series IO extension module.This quick

reference manual is used for the design, installation, connection and

maintenance of the MC5000 series IO extension module. It is

convenient for users to consult the required information on the spot, as

well as the introduction of the relevant optional accessories, FAQ, etc.,

for easy reference.

This manual for the following members:

MC5000-3232ETN

MC5000-1616ETN

Version 1.3

Revision date Jan 08, 2019

BOM

If you need more detailed product information, please refer to MC5000

series PLC user manual ,MStart programming software user manual

and MC5000 series PLC programming reference manual issued by our

company. Consult the supplier if necessary.

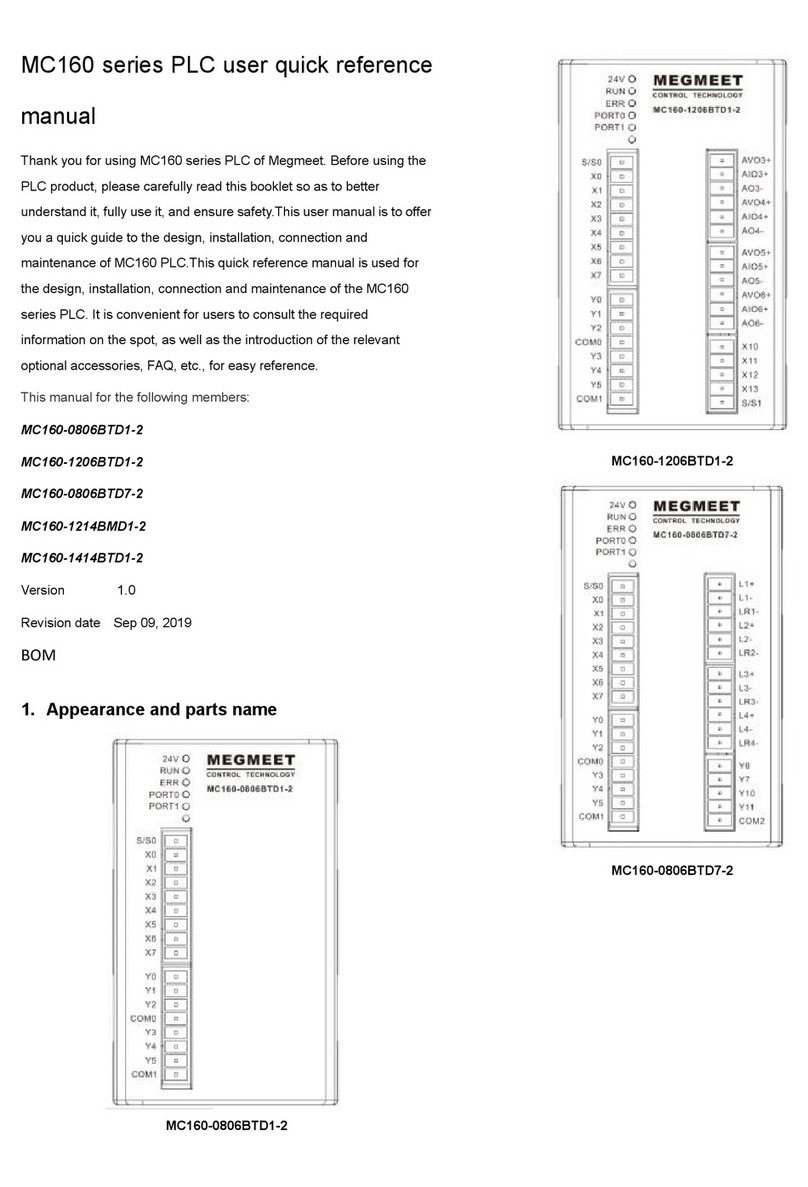

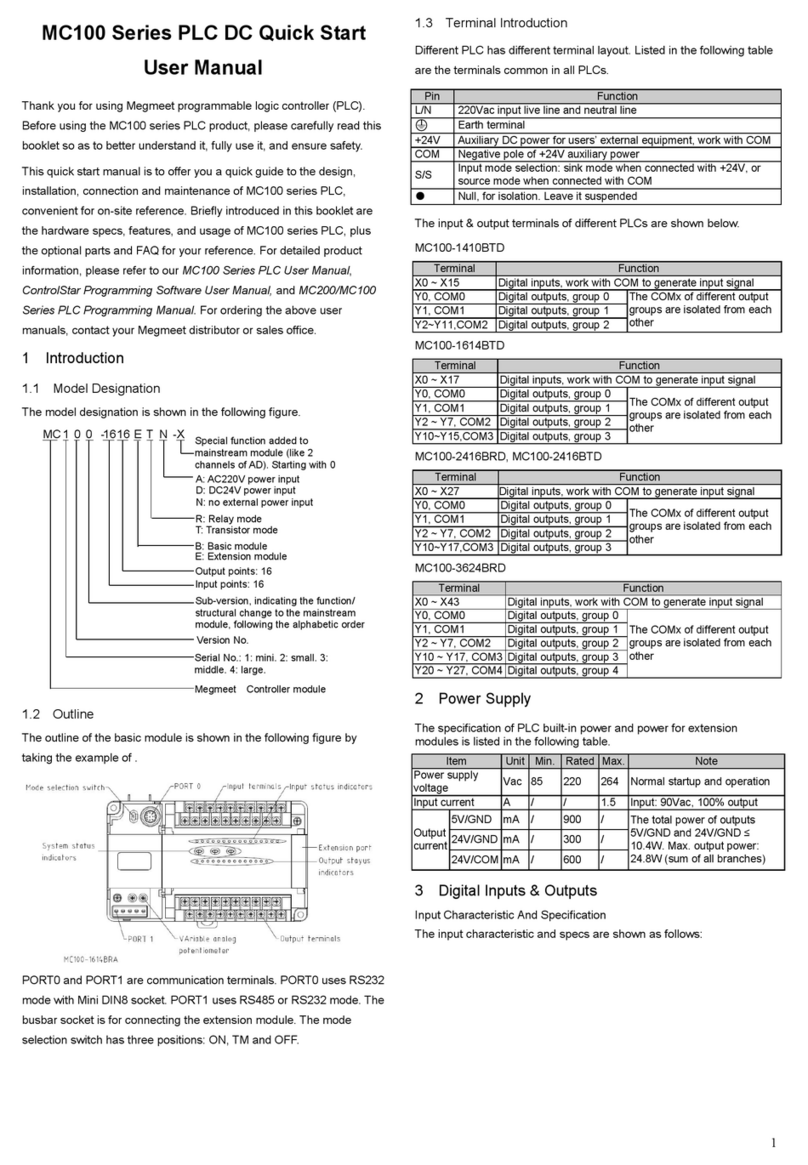

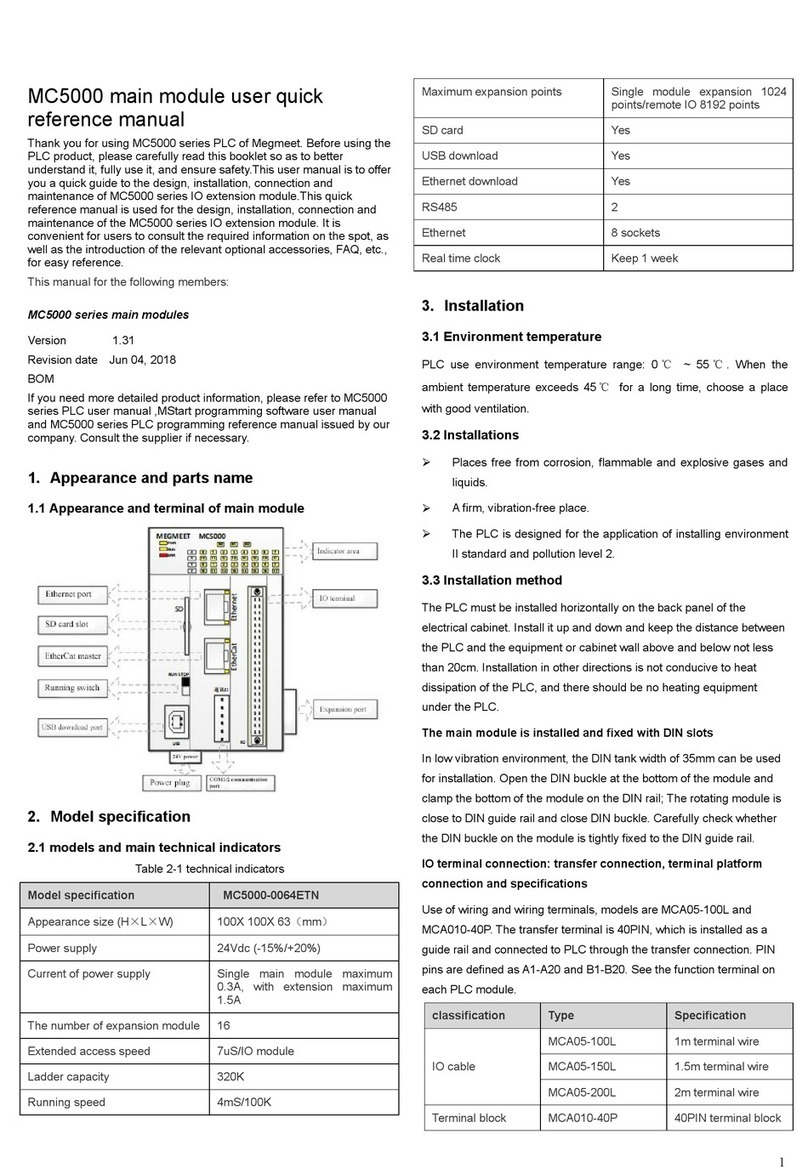

1. Appearance and parts name

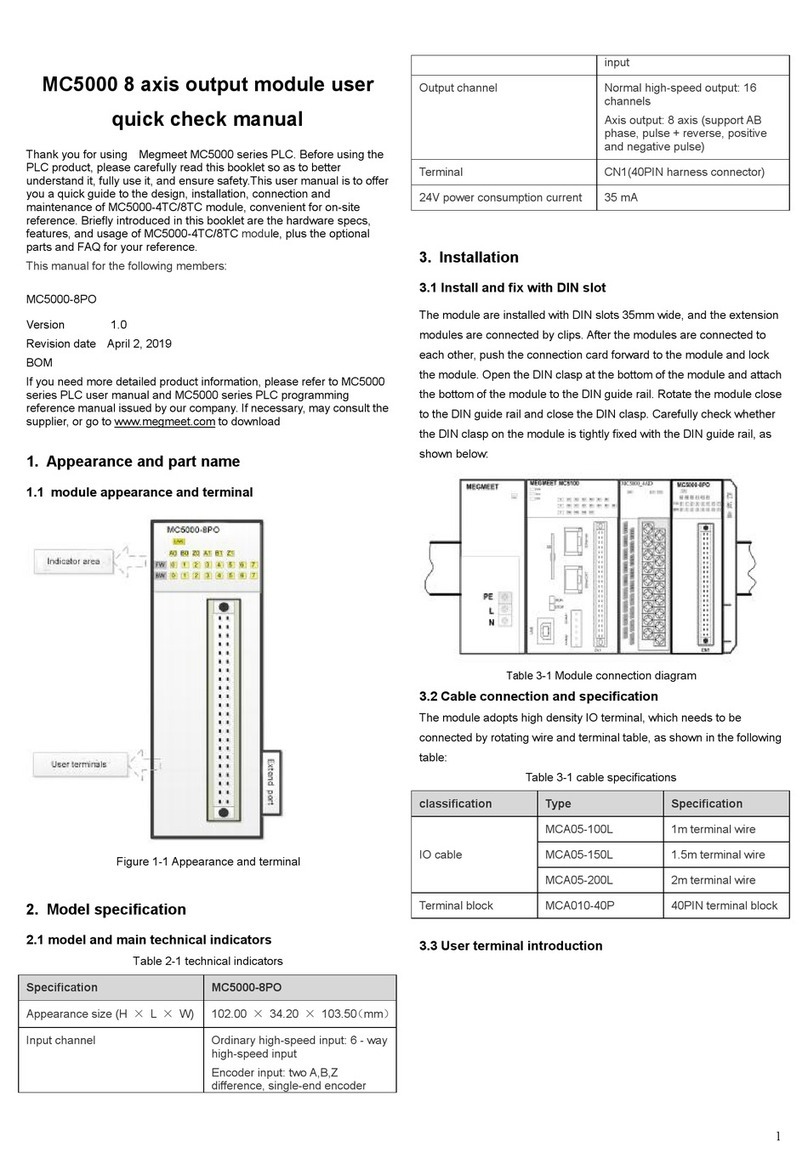

1.1 Appearance and terminal of module

Figure 1-1 Appearance and terminal diagram

2. Model specification

models and main technical indicators

Model specification

MC5000-1616ETN

MC5000-3232ETN

Appearance size (H

×L×W)

100.00 X 100.00 X 43 (mm)

Input points

32

16

Output points

32

16

Connect terminal

CN1

CN1,CN2

24V power

consumption current

40mA

70mA

3. Installation

3.1 Ambient temperature

PLC use environment temperature range: 0℃~ 55℃. When the

ambient temperature exceeds 55℃for a long time, choose a place with

good ventilation.

3.2 Installation occasion

Places free from corrosion, flammable and explosive gases and

liquids.

A firm, vibration-free place.

This PLC is designed for the application of installing environment

II standard and pollution level 2.

3.3 Installation method

The PLC shall be installed horizontally on the back of the electric

cabinet, and the distance between the PLC and the above and below

equipment or cabinet wall shall not be less than 20cm. Other direction

installation is not conducive to PLC heat dissipation, PLC can not have

heating equipment below.

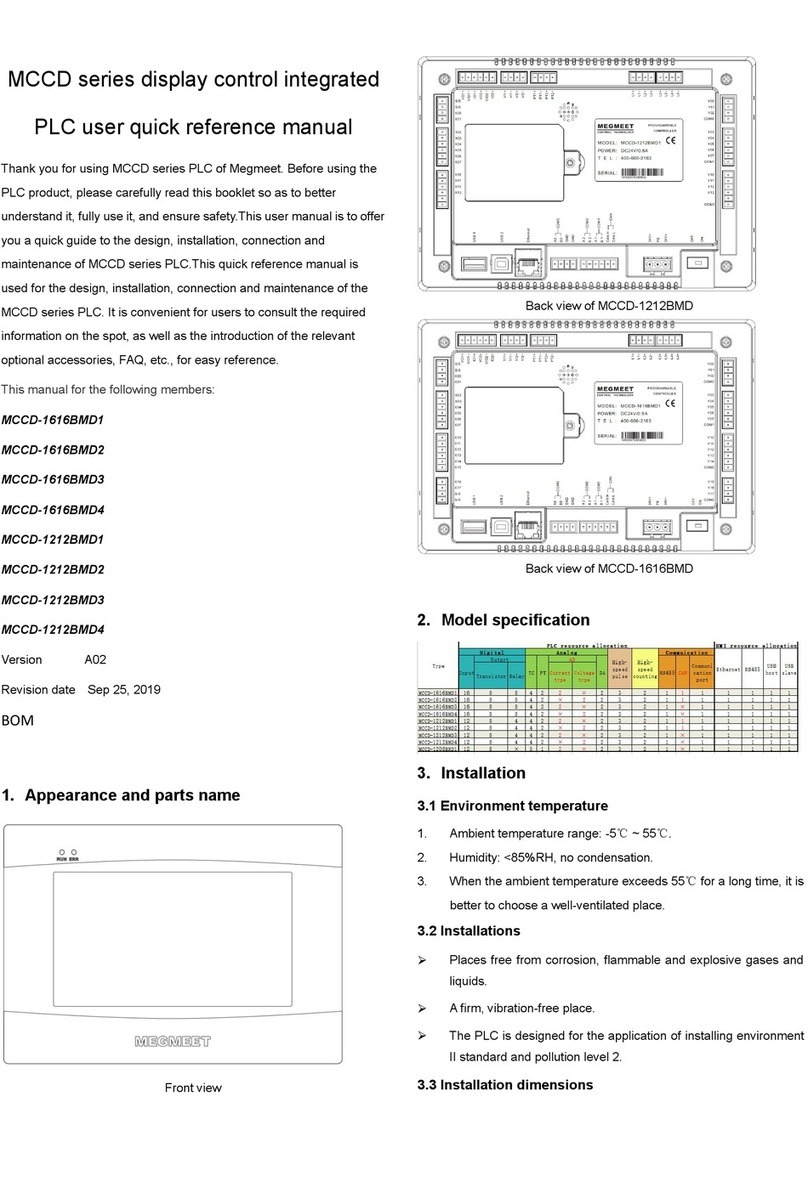

DIN slot installation and fixation

The module are installed with DIN slots 35mm wide, and the extension

modules are connected by clips. After the modules are connected to

each other, push the connection card forward to the module and lock

the module. Open the DIN clasp at the bottom of the module and attach

the bottom of the module to the DIN guide rail. Rotate the module close

to the DIN guide rail and close the DIN clasp. Carefully check whether

the DIN clasp on the module is tightly fixed with the DIN guide rail, as

shown below:

3.4 Cable connect and specification

The module adopts high density IO terminal, which needs to be

connected by rotating wire and terminal table, as shown in the following

table:

Table 3-1 cable specifications

classification

Type

Specification

IO cable

MCA05-100L

1m terminal wire

MCA05-150L

1.5m terminal wire

MCA05-200L

2m terminal wire

Terminal block

MCA010-40P

40PIN terminal block

4. User terminal introduction

The IO terminal of the extended IO module is 40 PIN, and users need

to be equipped with IO wire and IO terminal to use it, so they need to

buy separately. A 40PIN terminal block is adopted, and PIN is defined

as A1-20 and B1-20. The functions are shown in the following table.

2

Module IO Block Wiring terminal

The IO terminal CN1 of MC5000-1616ETN and MC5000-3232ETN is

defined as follows

Function definition

Terminal screen printing

Function definition

X0

B20

A20

X10

X1

B19

A19

X11

X2

B18

A18

X12

X3

B17

A17

X13

X4

B16

A16

X14

X5

B15

A15

X15

X6

B14

A14

X16

X7

B13

A13

X17

SS

B12

A12

SS

/

B11

A11

/

/

B1

A10

/

Y0

B9

A9

Y10

Y1

B8

A8

Y11

Y2

B7

A7

Y12

Y3

B6

A6

Y13

Y4

B5

A5

Y14

Y5

B4

A4

Y15

Y6

B3

A3

Y16

Y7

B2

A2

Y17

COM1

B1

A1

COM1

16-channels X input:X0~X17(SS common port)

16-channels Y output:Y0~Y17(COM1 common port)

The IO terminal CN2 of MC5000-3232ETN is defined as follows

Function definition

Terminal screen printing

Function definition

X20

B20

A20

X30

X21

B19

A19

X31

X22

B18

A18

X32

X23

B17

A17

X33

X24

B16

A16

X34

X25

B15

A15

X35

X26

B14

A14

X36

X27

B13

A13

X37

SS

B12

A12

SS

/

B11

A11

/

/

B1

A10

/

Y20

B9

A9

Y30

Y21

B8

A8

Y31

Y22

B7

A7

Y32

Y23

B6

A6

Y33

Y24

B5

A5

Y34

Y25

B4

A4

Y35

Y26

B3

A3

Y36

Y27

B2

A2

Y37

COM2

B1

A1

COM2

16-channels X input:X20~X37(SS common port)

16-channels Y output:Y20~Y37(COM1 common port)

5. Switching characteristics of input and output

5.1General input X0~X37

X0~X37, command port is SS

Filtering time can be set by input software (adjustable 0 ~ 64ms).

Item

Input

Input impedance

3.3KΩ

Input current

6.5mA

ON voltage/current

18V

OFF voltage/current

4V

The SS terminal on the PLC terminal row is used to select the signal

input mode, which can be set as the source input mode or the leakage

input mode. Connect the S/S terminal with +24V or the positive terminal

providing 24Vdc power externally, that is, set it as leaky input mode,

which can be connected to the NPN sensor. Figure 7-1 shows the

internal equivalent circuit and external wiring of the leaky input mode.

5.2 Output Y0~Y37

Open collector, COM1/2 end is the common port;

Each channel carries A load of 0.3A

Item

Transistor output port

Loop power supply rated voltage

5~24VDC

Circuit insulation

Optocoupler insulation

Action instructions

The LED lights when the

optocoupler is driven

Leakage current when open

< 0.1mA/24VDC

Mix. load

5mA(5~24VDC)

MAX. output

current

Resistive load

0.3A/point

Inductive load

7.2W/24VDC

ON Response time

<5us/10mA

OFF Response time

Output common port

Y0~Y17/ COM1

Y20~Y37/ COM2

6. Indicator definition

MC5000-1616ETN indicator definition

Indicator

Name

Function

Extended

status indicator

LNK

After the extension module is connected

to the main module successfully, it will

always turn on. In case of

communication failure, it will turn on 1Hz

Input indicator

X0~X17

Each input point corresponds to an

indicator light, numbered in base 8

(starting from 0), and the corresponding

indicator light will be ON when input

contact ON.

Output indicator

Y0~Y17

Each output point corresponds to an

indicator light and is numbered in base 8.

MC5000-3232ETN indicator definition

Indicator

Nam

e

Function

Extended status

indicator

LNK

The extension module will always be on

after successful connection with the main

module, and 1Hz will be on if

communication failure occurs

IO

selection-indicator

input light

IN

On the panel, 0-37 corresponds to 32

indicators indicating the status of X0-37

IO

selection-indicator

input light

OUT

On the panel, 0-37 corresponds to 32

indicators indicating the status of X0-37

IO indicator

0~37

Indicates the status of 32 inputs or

outputs

Note:There are 3 options for IN and OUT functions (User need to

choose from the extension module configuration)

Indicates input only. Lights 0-37 are fixed to indicate the input

state. The IN light is always on.

3

Indicates output only. 0-37 are fixed to indicate the output status.

The OUT light is always on.

Dynamic refresh indication. 0-37 displays 32 input and 32 output

states alternately IN a 4-second cycle. When the input is

displayed, the IN light is on and the output is OUT light.

7. Common problems and solutions

If the LNK light is not on, check whether the connection between

the extension module and the main module is reliable.

If there is an LNK flash, check if the extension clamshell is

fastened.

1. Warranty scope refers to the programmable controller body.

2. The warranty period is 18 months. If the product breaks down or is

damaged during normal use, our company will repair it free of charge.

3. The warranty period starts from the date the product is manufactured.

Machine code is the only basis for judging the warranty period.

Equipment without machine code shall be treated as under warranty.

4. Even within the warranty period, a maintenance fee will be charged

if:

Failure of the machine caused by failure to operate in accordance

with the user's manual.

Damage to machinery caused by fire, flood, abnormal voltage,

etc.

Damage caused when a programmable controller is used for

abnormal functions.

Self-disassemble the programmable controller.

5. The service fee shall be calculated according to the actual cost. If

there is another contract, the contract shall take precedence.

6. If you have any questions, please contact the agent or our company

directly.

SHENZHEN MEGMEET CONTROL TECHNOLOGY CO.,LTD

Add:floor 5, tower B, qinghua information port, langshan road, north

district, science and technology park, nanshan district, shenzhen

Tel:400-6662163

Fax:(+86)0755-26897197

Zip code:518067

Web:www.megmeet.com

This manual suits for next models

2

Other Megmeet Controllers manuals

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MCCD Series Service manual

Megmeet

Megmeet MV820 User manual

Megmeet

Megmeet MC160 PLC Series User manual

Megmeet

Megmeet MC100 Series User manual

Megmeet

Megmeet MC200E Series Manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet L6 Series User manual

Popular Controllers manuals by other brands

Remote Control

Remote Control RCEL005X instructions

Samson

Samson TROVIS 5177 Mounting and operating instructions

Brightlink

Brightlink BL-VW22-4K60-GUI user manual

Xantrex

Xantrex SOLAR CHARGE CONTROLLER 30 owner's guide

Edgewater Networks

Edgewater Networks EdgeMarc 250W Hardware installation guide

Omron

Omron SmartVision MX user guide