Adixen ATH 2300 M User manual

This manual suits for next models

1

Table of contents

Other Adixen Water Pump manuals

Popular Water Pump manuals by other brands

Edwards

Edwards EH500T4 T3 Series instruction manual

White Knight

White Knight PSD08 owner's manual

AirCom

AirCom AST24 instruction manual

Pentair

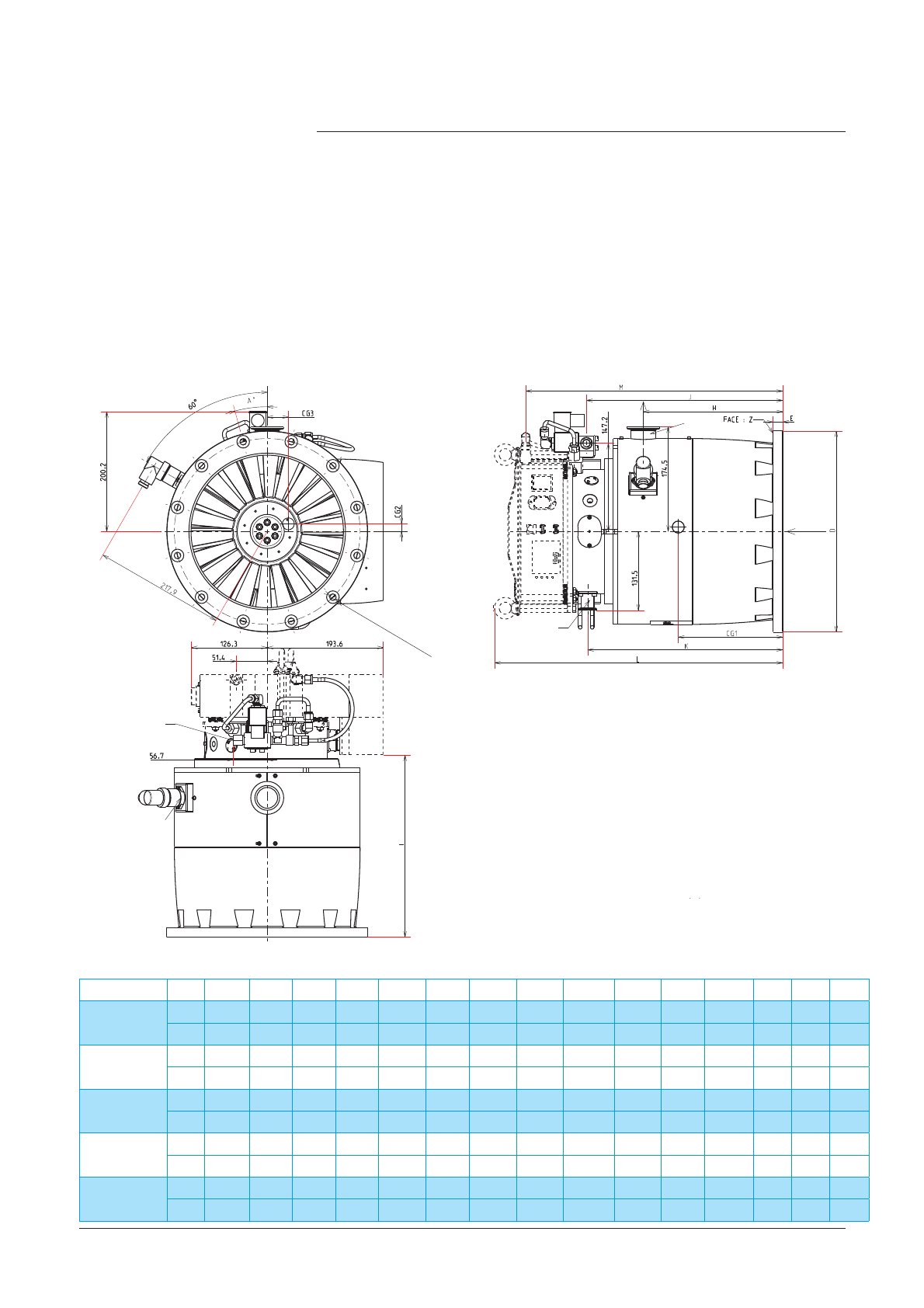

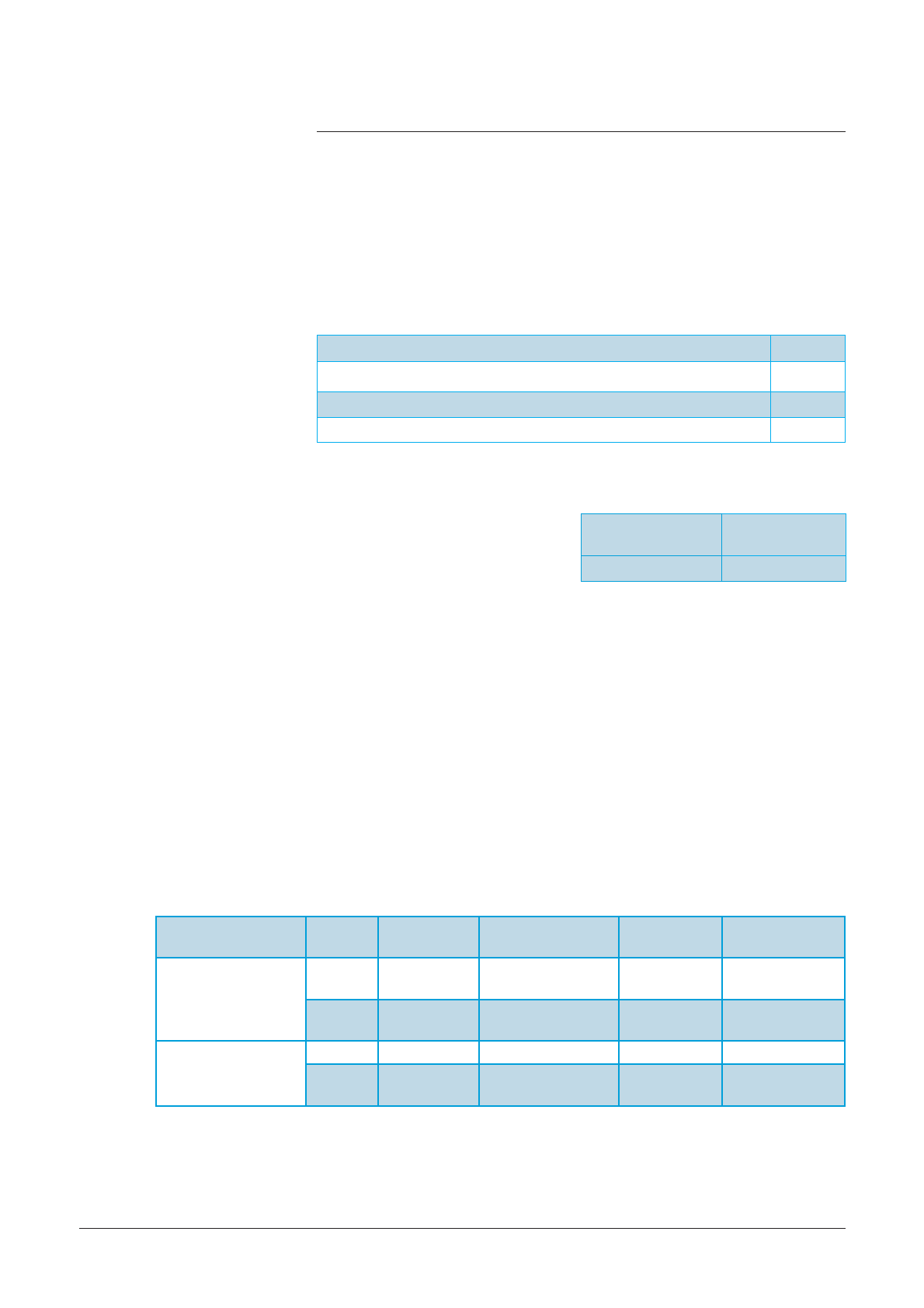

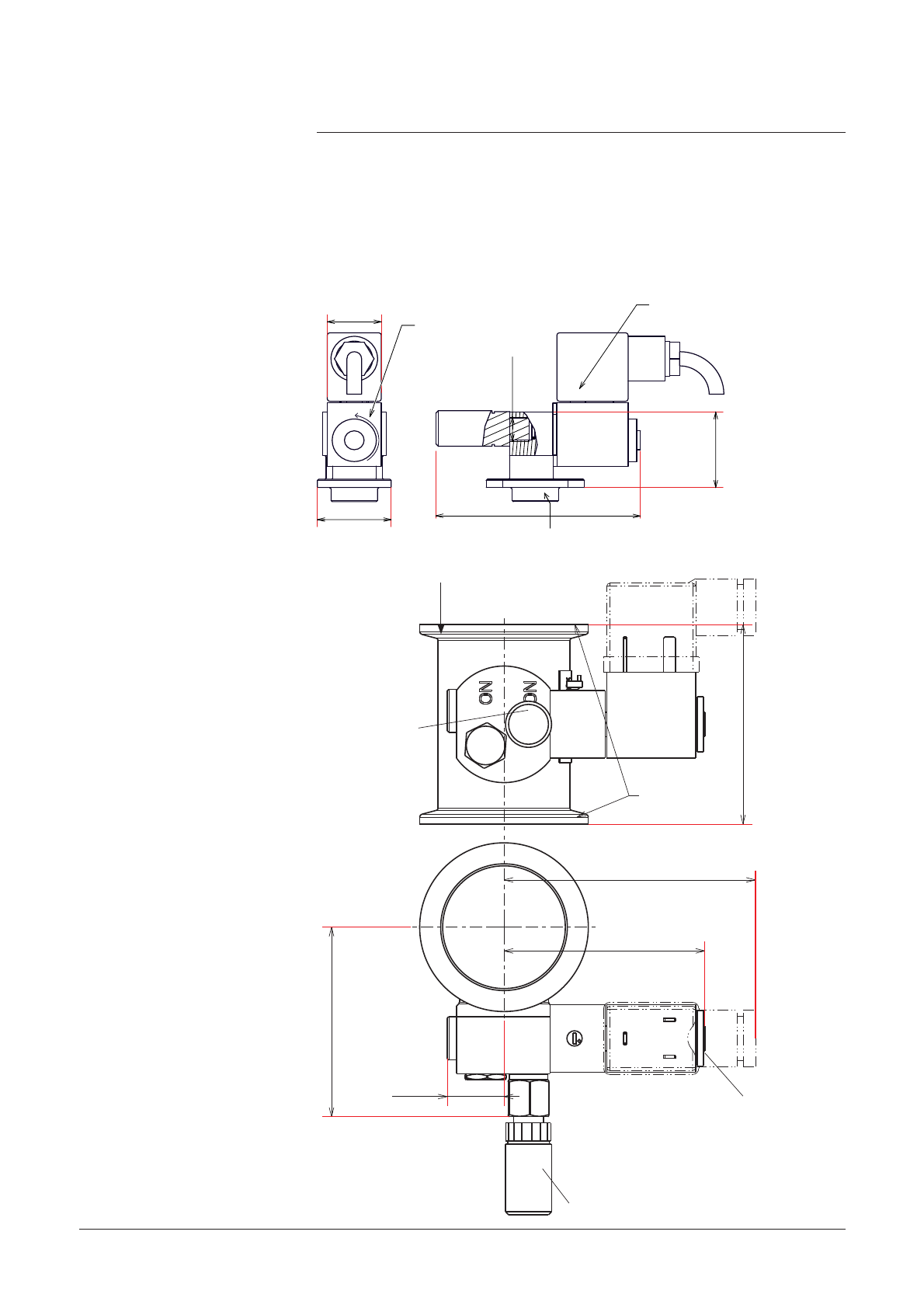

Pentair Berkeley 10VT Series Installation, operation and maintenance manual

Samson

Samson TRUCK MASTER 1700 instruction manual

salmson

salmson LRLA Installation and starting instructions

Giant

Giant P426HHP Operating instructions/ repair and service manual

Gasboy

Gasboy SERIES 9800Q Diagnostic manual

Zoeller

Zoeller FM2102 owner's manual

Calpeda

Calpeda GM 10 operating instructions

Druck

Druck UNIK 5 00 Series instruction manual

Xylem

Xylem Flygt 2075 Installation, operation and maintenance manual

Graco

Graco Merkur A Series Repair and parts

BSC

BSC GVD8-Single phase instruction manual

TriboServ

TriboServ FlexxPump4 D OIL Series Supplementary sheet

GORMAN-RUPP

GORMAN-RUPP 10 SERIES Installation, operation and maintenance manual

Bosch

Bosch GardenPump 18 Original instructions

Pentair

Pentair HYDROMATIC HPS3SC Installation & operation manual