Adixen ATP 2300 M User manual

Operating Instructions

Operating Instructions

Translated from original version

Translated from original version

ATP 2300 M

Turbopumps

EN

EN

GB 02914 - Edition 05 - 03/2013

1/2

ATP 2300 M - Turbopump

Welcome

APPLICATIONS:

Semiconductor applications

Plasma etching, Ion implantation, Sputtering,

Plasma deposition.

Others Applications

Electron microscopes, Surface analysis,

Research and development, High energy physics,

Space simulation, Accelerators, Coating.

ADVANTAGES:

High pumping speed for light gases - High throughput - Quiet

and clean vacuum - Corrosion proof - High MTBF - Minimum size,

volume and weight - Smart and compact electronic controller -

Reliability - Maintenance free - Battery free - Easy integration.

Dear Customer,

You have just purchased

an adixen Magnetically

turbopump.

We would like to thank you

and are proud to count you

as one of our customers.

This product has benefited

from adixen Vacuum

Products many years of

experience in the field of

Turbopump design.

In order to ensure the best

possible performance of

the equipment and your

complete satisfaction in

using it, we advise you to

read this manual carefully

before any intervention

on your pump and to pay

particular attention to the

equipment installation and

start-up section.

This operating instruction manual includes only the instructions to connect

the pump to the equipment. Refer to the controller operating instructions

to power and use the pump (chapter B, C and D).

This pumping component is designed to gererate vacuum by pumping on

gases, but no liquids neither solids. It is dedicated for running in industrial

environments.

The integrator of this component must provide all operator safety measures

mainly against hot surfaces.

This pumping component must not operate in an area with risk of

explosion. Consult us to study a solution.

adixen Vacuum Products - Operating Instructions - ATP 2300 M

2/2

ATP 2300 M - Turbopumps

GB 02914 - Edition 05 - 03/2013

Copyright/Intellectual property:

The use of adixen products are subject to copyright

and intellectual property rights in force in any

jurisdiction.

All rights reserved, including copying this document in

whole or any part without prior written authorization

from adixen Vacuum Products.

Specifications and information are subject to change

without notice by adixen Vacuum Products.

This product complies with the requirements of European Directives, listed

in the Declaration of Conformity contained in sheet G100 of the controller

operating instructions.

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02915 - Edition 06 - 03/2013

1/2

General contents

ATP 2300 M Operating instructions

MANUAL REFERENCE:112419

EDITION: 06 - June 2013

Translated from original version

Chapter A INTRODUCTION

A 150 - Introduction to the ATP 2300 M

A 200 - Control loop of the pump

A 210 - The pump operating principle

A 400 - Technical characteristics of the pump

A 510 - The accessories of the pump

A 515 - Accessory dimensions

Chapter B START-UP

B 100 - Safety instructions for installation and controller installation

B 201 - Unpacking and storage of the pump

B 300 - Pump connections to an installation

B 310 - Inlet and exhaust connections

B 330 - Nitrogen purge and air inlet valve device connections

B 340 - Water cooling connection

B 401 - Typical electrical wiring diagram

Chapter C OPERATION

C 100 - Safety instructions for product use

Chapter D MAINTENANCE

D 100 - Safety instructions for product removal

D 150 - Maintenance frequency

Chapter E MAINTENANCE INSTRUCTIONS

E 50 - Replacement of the water valve coil

E 100 - Shipping procedure for contaminated pumps

Chapter F MAINTENANCE COMPONENTS

F 000 - Spare parts - Instructions of use

F 100 - First level maintenance parts

Chapter G APPENDIX

G 150 - Pumping curves

G 200 - Service

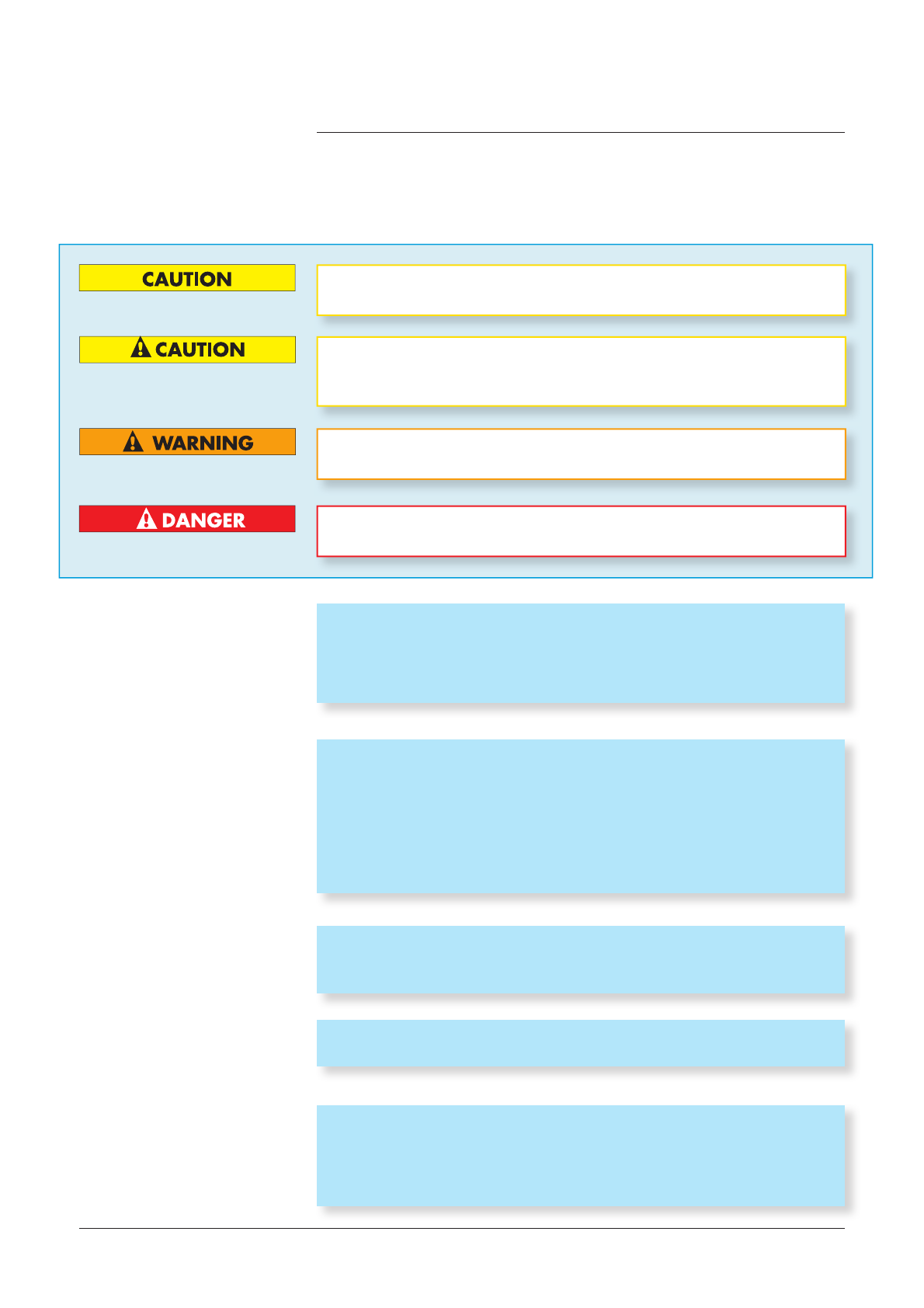

Indicates a potentially hazardous situation which, if not avoided, could

result in property damage.

Indicates a potentially hazardous situation which, if not avoided, could

result in moderate or minor injury. It may also be used to alert against

unsafe practices.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or severe injury.

adixen Vacuum Products - Operating Instructions - ATP 2300 M

2/2

General contents

ATP 2300 M Operating instructions

GB 02915 - Edition 06 - 03/2013

MANUAL REFERENCE:112419

EDITION: 06 - June 2013

Translated from original version

Indicates an imminently hazardous situation that, if not avoided, will

result in death or severe injury (extreme situations).

The performance and operational safety of this product are guaranteed pro-

vided it is used normally in the operating conditions defined in this manual.

It is the customer’s task to:

- train operators to use the product if they do not speak the language the

manual is written in,

- ensure operators know the safe practices to apply when using the

product.

Before switching on the product, study the Operating instructions and make

sure you follow the safety instructions it gives. You can recognise these by

the “Caution”, “Warning” and “Danger” symbols.

Good practice tips and manufacturer’s recommendations are in a blue box.

Symbols, labels Description

Warning : hot surface

Warning : hazardous voltage

Caution : risk of danger. Refer to the operating

instructions before use

ON

OFF

Do not touch when the pump is running

Use of glove is recommended

Moving parts present

Heavy object

Lock the electrical connector before using the

pump and during operation

Purge Purge port

Pump exhaust Exhaust of the pump

Water Water cooling circuit connection

Water max Pr.7 bar/101 psi Max. Cooling water pressure

Direction of rotation of the pump

LOCK

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02916 - Edition 04 - 03/2013

1/1

Introduction

ATP 2300 M Operating instructions

Detailed contents

A

A 150 Introduction to the ATP 2300 M

A 200 Control loop of the pump

- 5 active axis

- Unbalanced force rejection control

A 210 The pump operating principle

- Pumping principle

- The Turbopump in an installation

- The back-up ball bearings

- No maintenance

- Battery free

- Variation of the pump rotational speed

A 400 Technical characteristics of the pump

A 510 The accessories of the pump

- Pump accessories

A 515 Accessory dimensions

- Purge valve (50 sccm) dimensions

- Air inlet valve dimensions

- Water valve dimensions

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02917 - Edition 03 - 03/2013

1/1

A 150

Introduction to the ATP 2300 M

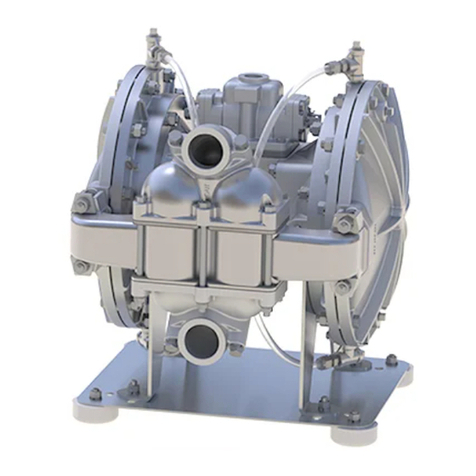

ATP 2300 M

A magnetically

levitated

turbomolecular pump

Five active axes

Rotor position control in 5 directions.

Unbalanced Force Rejection Control

Lowest possible levels of noise and vibration.

Automatic adjustment to any unbalance of the rotor, from very low

speed.

Maintenance free

Inert gas purge

Protect from corrosion the magnetic spindle.

Battery free

In case of a power failure, the pump motor acts like a generator

to transform the rotor energy into electrical power to supply the

controller.

Controllers The ATP 2300 M works with the OBC controller or with the

MAGPOWER controller.

(refer to corresponding operating instructions).

adixen Vacuum Products - Operating Instructions - ATP 2300 M

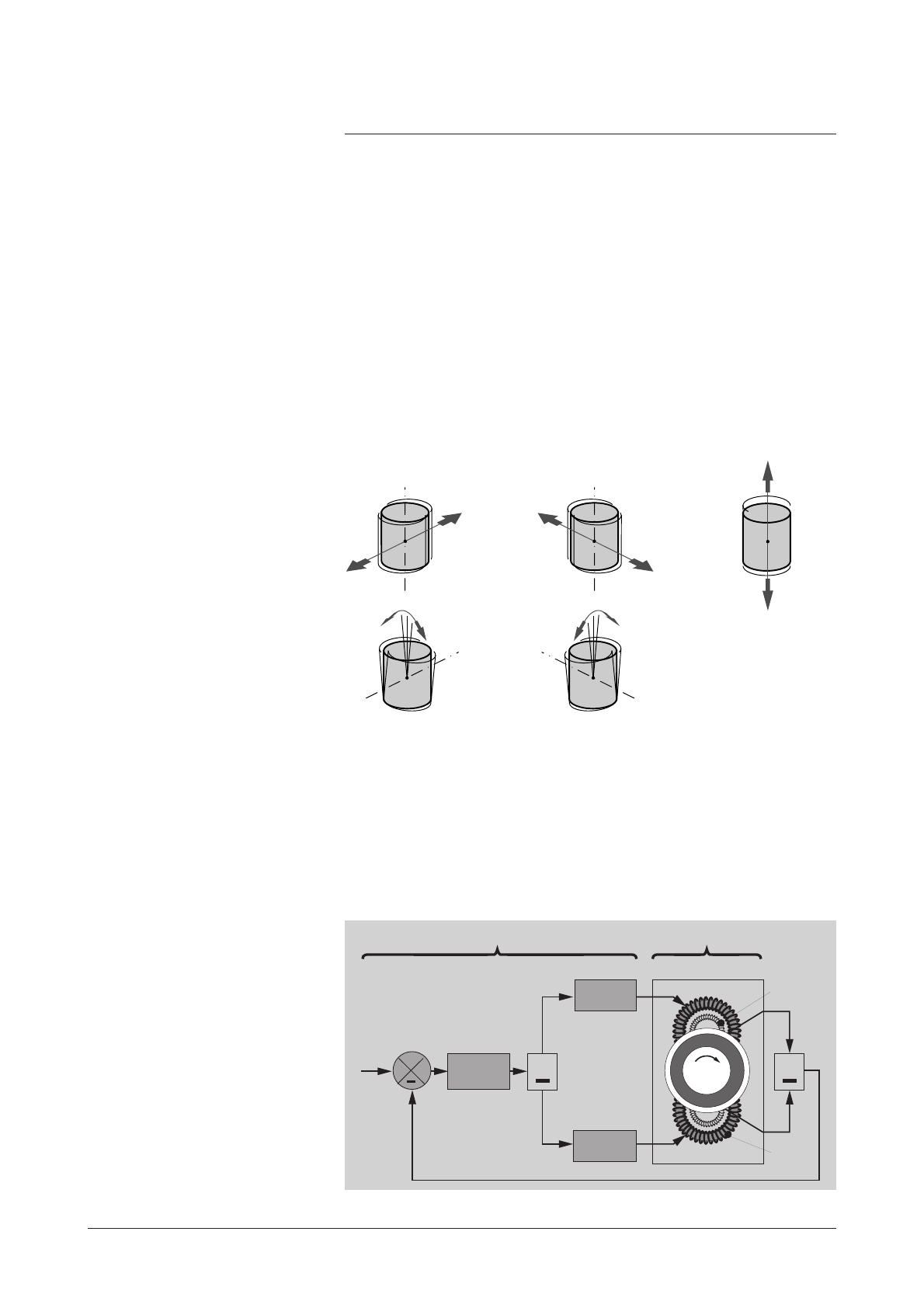

5 active axis The mobile assembly formed by the turbo rotor and the shaft is

known as the rotor. The rotor is driven by the motor and held

in suspension by magnetic fields generated by electromagnets

housed in an active bearing.

The mobile rotor has 5 axes of freedom monitored by 5 active

magnetic bearings.

+

Rotor

Stator

BearingElectronics

Power

amplifiers

Position of

Reference

Position return

Electro-

magnet

+

Correction

+

Position

sensor

Z

X

X

Y

Y

Movements in relation to these axes are monitored by position

sensors. According to the position data recorded, the controller

corrects differences to bring the rotor back to its optimum

position, by varying the current in electromagnets

3 controlled translations (X, Y, Z)

2 controlled tiltings (X, Y)

A 200

Control loop of the pump

1/2

GB 02721 - Edition 04 - Aug 07

adixen Vacuum Products - Operating Instructions - ATP 2300 M

Unbalanced force

rejection control

The unbalanced force rejection control is an electronic

function, that monitors the rotor position, allowing it to rotate

in its own axis of inertia.

Changes in the rotor balance, due to deposit built-up during

the life time of the pump, are automatically compensated by

the unbalanced force rejection control.

It ensures the lowest possible levels of noise and vibration.

Stator geometric axis

Rotor geometric axis

Rotor inertia axis

A 200

Control loop of the pump

2/2

GB 02721 - Edition 04 - Aug 07

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02918 - Edition 03 - 03/2013

1/2

A 210

The pump operating principle

Pumping principle The ATP 2300 M is a multi-staged turbomolecular pump,

recommended for light gases pumping.

The gas molecules of the vacuum system are trapped between the

rotating disks of the rotor and the stationary disks of the stator and

carried to the exhaust of the pump.

* The gas purge provides an excellent protection for corrosive applications and

ensures the rotor cooling.

The turbopump in an

installation

At the pump exhaust, the gases are evacuated to atmosphere by a

roughing pump.

Since the ATPM compression ratio is set by the design, the pumping

performances depend on the primary pump and on the installation.

ATMOSPHERIC

PRESSURE

Primary

pumping

INLET PRESSURE

Secondary

pumping

High vacuum Rough vacuum

Chamber

to be

pumped

Inlet

Magnetic levitated

bearings

Gas purge*

Cooling

Stator

Rotor

Motor

Dry back-up bearings

Exhaust

adixen Vacuum Products - Operating Instructions - ATP 2300 M

2/2

A 210

The pump operating principle

GB 02918 - Edition 03 - 03/2013

The back-up ball

bearings

No maintenance

Battery free

They are dry-lubricated ceramic ball bearings.

They are never used in normal operation, since the rotor is not in

contact with the ball bearings.

The back-up ball bearings are only used to protect the pump in

accidental air in-rushes, accidental shocks or power failure.

By design, the pump doesn’t include parts liable to wear and

doesn’t need preventive maintenance. However, the back-up

bearings used in case of accidental shut-downs have to be changed

when the controller indicates it: the percentage of landing time to

be deducted depends on the number of incidents ( D 150).

In case of a power failure, the motor acts like a generator, supplying

enough power for the magnetic bearings.

When the rotation speed is too low, the pump shuts down and

lands on the back-up ball bearings.

The ATPM pump rotation speed can be selected and set between a

minimum speed and the maximum speed.

This makes it possible to optimize pumping characteristics according

to each customer application (for example, high pressure pumping).

A distinction is made between the following speeds:

- reduced speed (STANDBY speed) which can be set between the

low speed value and the nominal speed.

- nominal speed : maximum speed preselected at factory.

Variation of the pump

rotational speed

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02919 - Edition 04 - Mar 13

1/3

A 400

Technical characteristics of the pump

CHARACTERISTICS UNIT ATP 2300 M

Flange (inlet) ISO-K DN 200 DN 250

Flange (exhaust) ISO KF DN 40

Pumping speed*

Ar l/s 1 400 1 900

H2 l/s 1 600 1 700

He l/s 1 750 2 050

N2 l/s 1 450 1 950

Compression rate

Ar > 1 · 108

H2 > 7 · 103

He > 1 · 105

N2 > 1 · 108

Gas throughput (1) (2)

Ar sccm 900

H2 sccm > 3 000

He sccm > 3 000

N2 sccm 2 200

Fore vacuum max. (3)

Ar hPa 1.7

H2 hPa 1.9

He hPa 1.5

N2 hPa 2.1

Inlet vacuum max. (2) Ar hPa 0.011

N2 hPa 0.04

He hPa 0.2

Ultimate pressure (4) hPa < 4 · 10-9

Nominal rotation speed tr/mn (Hz) 31 000 (517)

Standby speed tr/mn (Hz) from 15 000 (250) to nominal

speed 31 000 (517)

Sound pressure level db(A) < 46

Pump protection index IP 42

Controller power supply V 200-240 (50/60) (Hz)

Maximum leakage current (7) mA < 12

Max. start-up supply ** W < 1 000

Power consumption at ultimate pressure W < 130

Max. apparent start-up power ** VA < 1 250

Mounting orientation any

N2 purge flange ISO KF DN16

Integral leak rate hPa l/s < 5·10-8

* Without inlet screen.

** Value could be depend on controller type.

(1) At nominal rotational speed, water temperature = 25 °C (M = cold ; MT = 65 °C).

(2) With a low exhaust pressure, depends on external conditions (water temperature, water flow, ambient temperature).

(not applicable for air cooling version).

(3) With ratio inlet pressure/exhaust pressure >100, max. throughput reduced.

(4) ISO/F flange, better with CFF flange.

adixen Vacuum Products - Operating Instructions - ATP 2300 M

2/3

A 400

Technical characteristics of the pump

GB 02919 - Edition 04 - Mar 13

CHARACTERISTICS UNIT ATP 2300 M

ISO-K DN 200 DN 250

Run-up time up to 90 % of nominal

rotation speed, with exhaust pressure

< 0,1 hPa **

min < 8

Maximum baking temperature °C 120

Recommended purge flow rate sccm 50

Vibration level at nominal speed μm < 0,01

Maximum water line pressure hPa 7·103

Weight of the pump (kg) lb (52) 112

Recommended backing pump adixen ADP / ADS

Cooling water flow rate l/h 60

Water temperature (5) °C 15 < T < 40

Environmental conditions:

- Ambient operating temperature (6) °C 5 < T < 45

- Use of the product Indoor only

- Maximum altitude m/ft 2 000/6 562

- Accept transient over voltages typi-

cally present on the main supply

Catégory II

- Pollution degree applicable 2

- Maximum relative humidity (8) 80 %

Three phase motor characteristics

(max values): **

- Voltage between phases

- Supply frequency

- Phase current

Vrms

Hz

A

36

1033

9.7

(5) Over 25 °C apply a derating on continuous max flow.

(6) Not applicable for air cooling version.

(7) Not all leakage current is necessary evacuated through the earth wire; it depends on the pump earth connect regarding the

equipment to which the pump is connected.

(8) Maximum relative humidity 80 % for temperatures up to 31 °C, decreasing linearly to 50 % relative humidity at 40 °C.

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02919 - Edition 04 - Mar 13

3/3

A 400

Technical characteristics of the pump

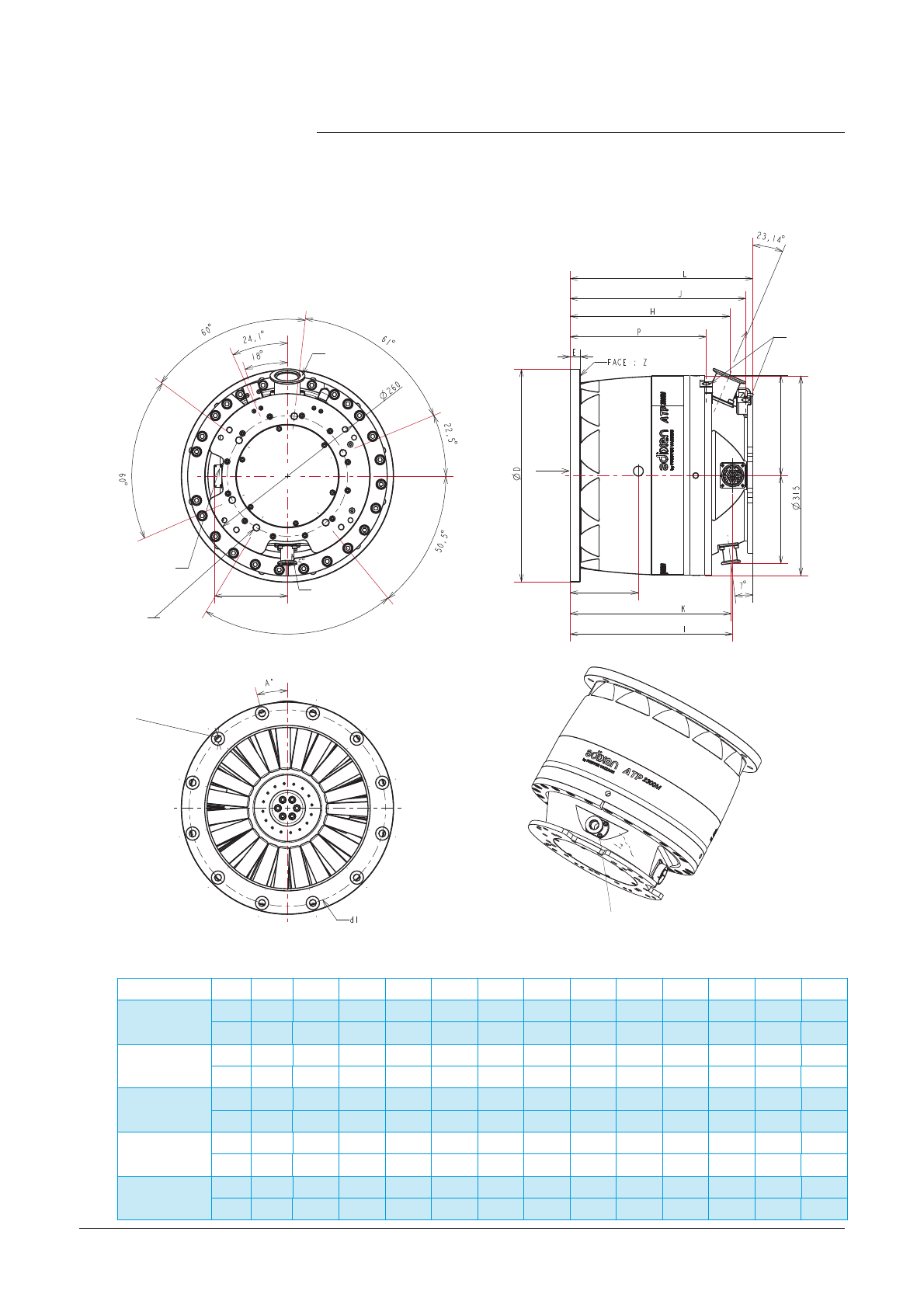

Dimensions

Inlet flange E H I J K L P D d1 d2 N A° CG

DN 250 ISO-F

mm 16,00 253,30 257,90 278,20 255,60 289,20 215,20 335,00 310,00 11,00 12,00 15° 133,70

inch 0.63 9.97 10.15 10.95 10.06 11.39 8.47 13.19 12.20 0.43 12 15° 5.26

DN 250 ISO-K

mm 12,00 253,30 257,90 278,20 255,60 289,20 215,20 290 - - - - 145,50

inch 0.47 9.97 10.15 10.95 10.06 11.39 8.47 11.42 - - - -5.73

DN 250 CF-F

mm 26,00 297,30 301,90 322,20 299,60 333,20 259,20 306,00 284,00 8,50 32,00 5,625° 170,60

inch 1.02 11.7 11.89 13.08 11.79 13.12 10.20 12.05 11.18 0.33 32 5.625° 6.72

DN 200 ISO-F

mm 16,00 314,30 317,90 339,20 316,60 350,20 276,20 285 260,00 11,00 12,00 15° 178,50

inch 0.63 12.37 12.52 13.35 12.46 13.79 10.87 11.22 10.23 0.43 12 15° 7.03

DN 200 ISO-K

mm 12,00 314,30 317,90 339,20 316,60 350,20 276,20 240 - - - - 187,60

inch 0.47 12.37 12.52 13.35 12.46 13.79 10.87 9.45 - - - -7.39

Dimensions

Electrical power

Supply

6 Holes M10-6H along190

Depth max. = 29

Depth min. = 25

N2 purge

DN 16 ISO KF

Exhaust

DN 40 ISO KF

Inlet/Outlet water

1/4 NPT female

Out

115,5 / (4.55)

IN

138,6 / (5.45) 158.4 / (6.23)

Gravity center

(12.4)

(10.24)

Esquidistant along d1

N holes d2

Use one of the 4 screws of the purge port

to connect a fonctionanal earth

Diam.maxi. of the eyelet: 10.5 mm

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02992 - Edition 05 - 03/2013

1/2

A 510

The accessories of the pumps

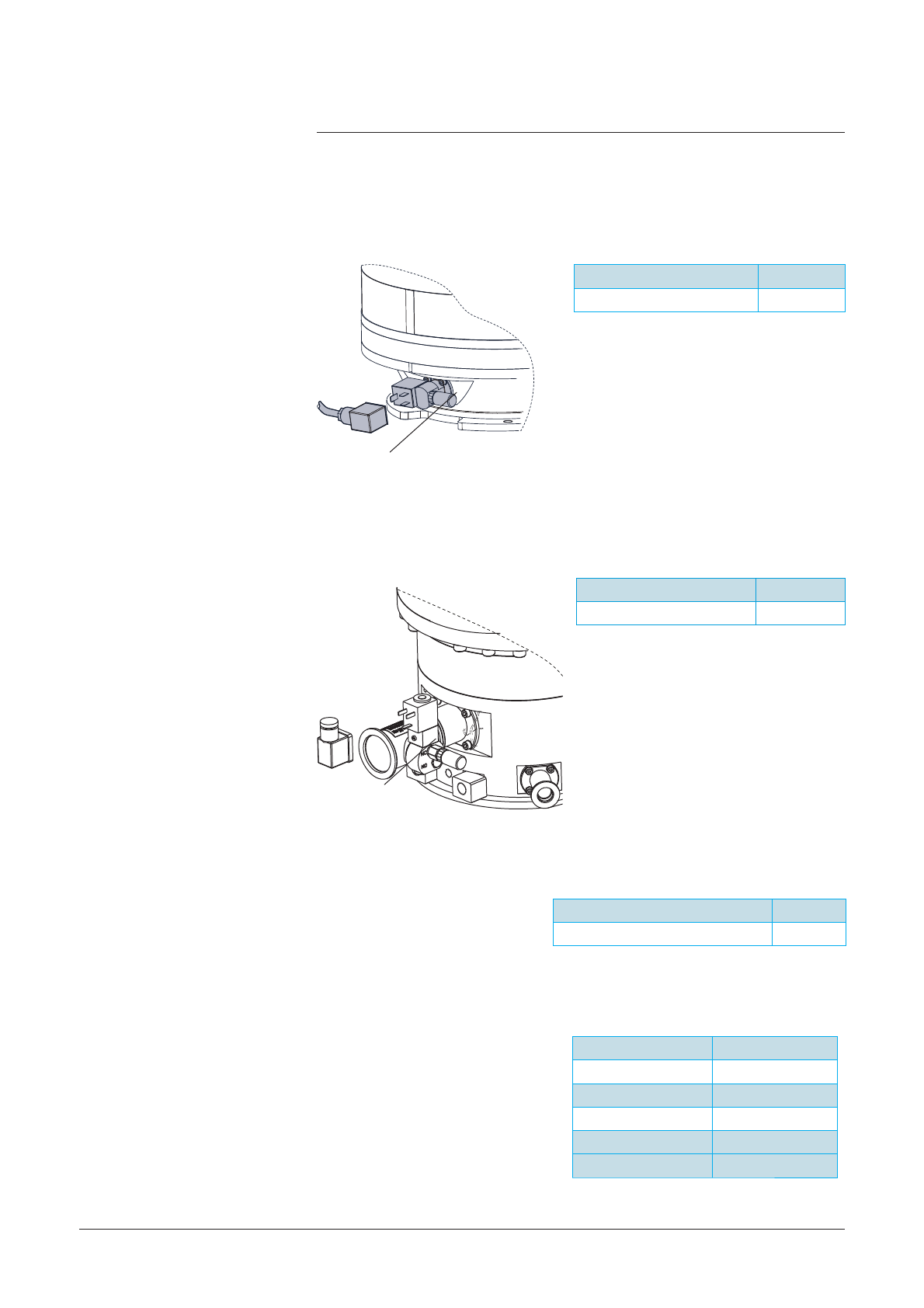

Inlet screen This screen protects the pump against solid particles. It is integrated

into the pump housing.

DN 200 P/N

Convexe filter (S.steel) + clip (mesh size 4.5 mm) 108872

DN 250 P/N

Convexe filter (S.steel) + clip (mesh size 5 mm) 108762

Purge flow reduction

device

This device is used to reduce

the purge gas flow rate in

some processes.

Flow Reduction

device DN 16 * P/N

50 SCCM 066752

Isolation valve

at pump inlet

The secondary isolation valve is used to maintain the vacuum in the

chamber while the pump is reset to atmospheric pressure.

See the manufacturer’s catalog.

* For pumps equipped with purge

valve (see next page).

Pumps model Inlet

size DN

P/N for

ISO F Description P/N for CF-F Description

ATH 1603 M

200 110675

110676S

12 CHC M10x30

12 CHC M10x35 *

250 110675

110676S

12 CHC M10x30

12 CHC M10x35 *

ATH 2303 M

ATH 2300 MT

ATP 2300 M

200 114510 12 stub M10x35 * --

250 110034

110676S

12 CHC M10x30

12 CHC M10x35 * 118690 32 Studs M8x35

Bolt and washer kit

for pump installation

* With centering ring

adixen Vacuum Products - Operating Instructions - ATP 2300 M

2/2

A 510

The accessories of the pumps

GB 02992 - Edition 05 - 03/2013

Dimensions P/N

1 m A462403-010

3.5 m A462403-035

5 m A462403-050

10 m A462403-100

20 m A462403-200

Purge valve * (50 sccm)

(driven by the customer

tool)

Air inlet valve *

Air inlet valve cables

and purge valve cables

(for pumps controlled by

Magpower)

The air inlet valve, powered by the

controller, is installed on the pump

exhaust port. It allows to reduce

the braking time of the pump to

put it at the atmospheric pressure.

It is a NC valve which is activated

when the pump nominal speed is

below 10 000 rpm.

Air inlet valve P/N

24 V DC 114280

Purge valve 50 sccm P/N

24 V DC 111921S

The gas purge provides an

excellent protection of the maglev

bearings for corrosive applications

and ensures the rotor cooling.

The purge of this valve can be

isolated during an air tightness

test.

* Provide a power line compatible with extra low voltage and safety standards

(SELV).

Dust filter

Dust filter

Water valve P/N

Water valve 108668

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 04430 - Edition 04 - January 13

1/2

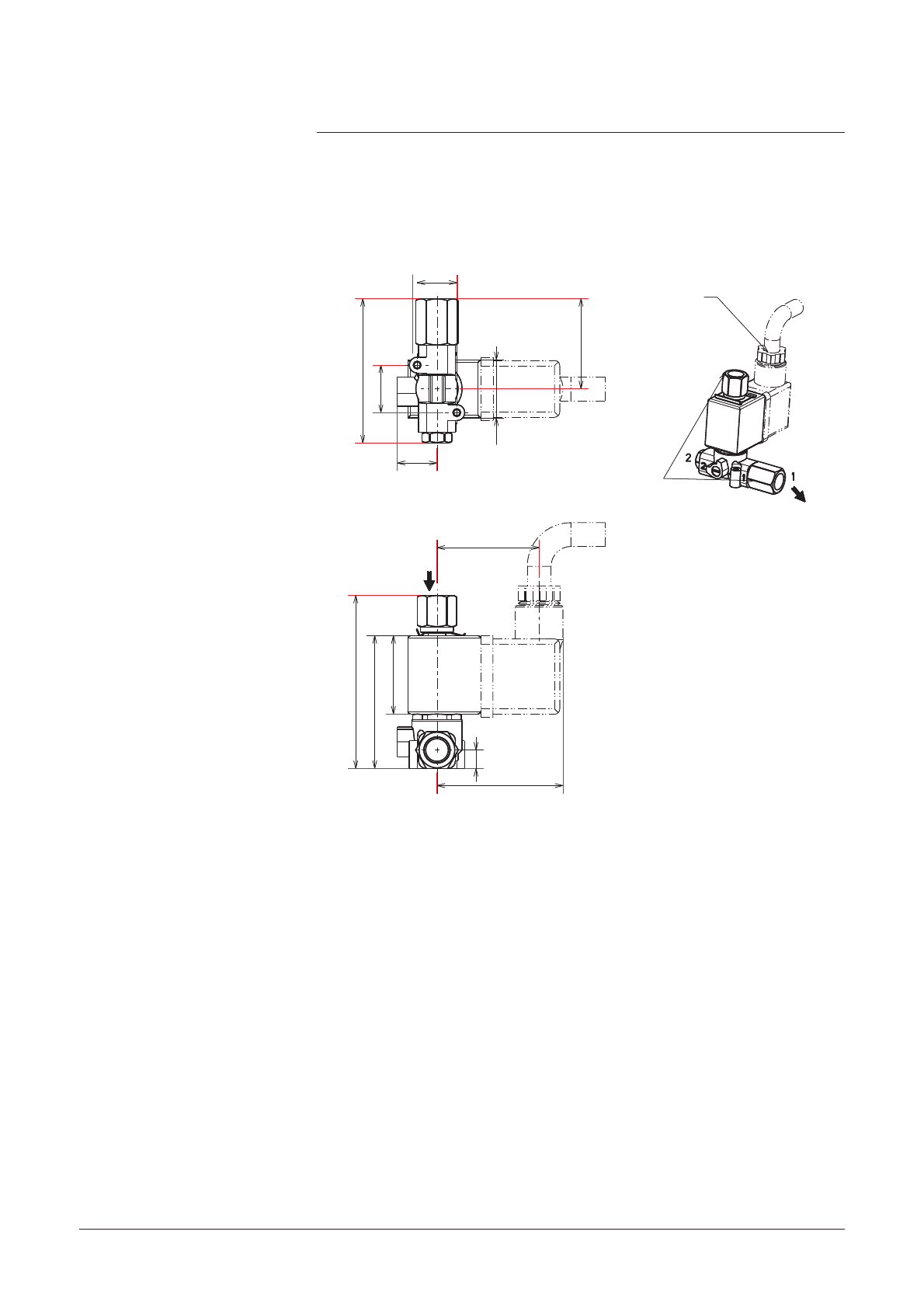

A 515

Accessory dimensions

Purge valve (50 sccm)

dimensions mm (inch)

30 (1.18)

22 (0.86)

83.3 (3.28)

32 (1.26)

1/8 NPT

Can rotate Plug coil

Pump connection

62 (2.44)

82 (3.23)

65,5 (2.58)

18,5 (0.73)

65 (2.56)

1/8NPT female

connector

(air inlet)

DN 40 ISO KF

Pump connection

Connector for coil

(possible to rotate)

1/8 NPT female connector

Dust filter

Air inlet valve

dimensions

mm (inch)

adixen Vacuum Products - Operating Instructions - ATP 2300 M

2/2

A 515

Accessory dimensions

GB 04430 - Edition 04 - January 13

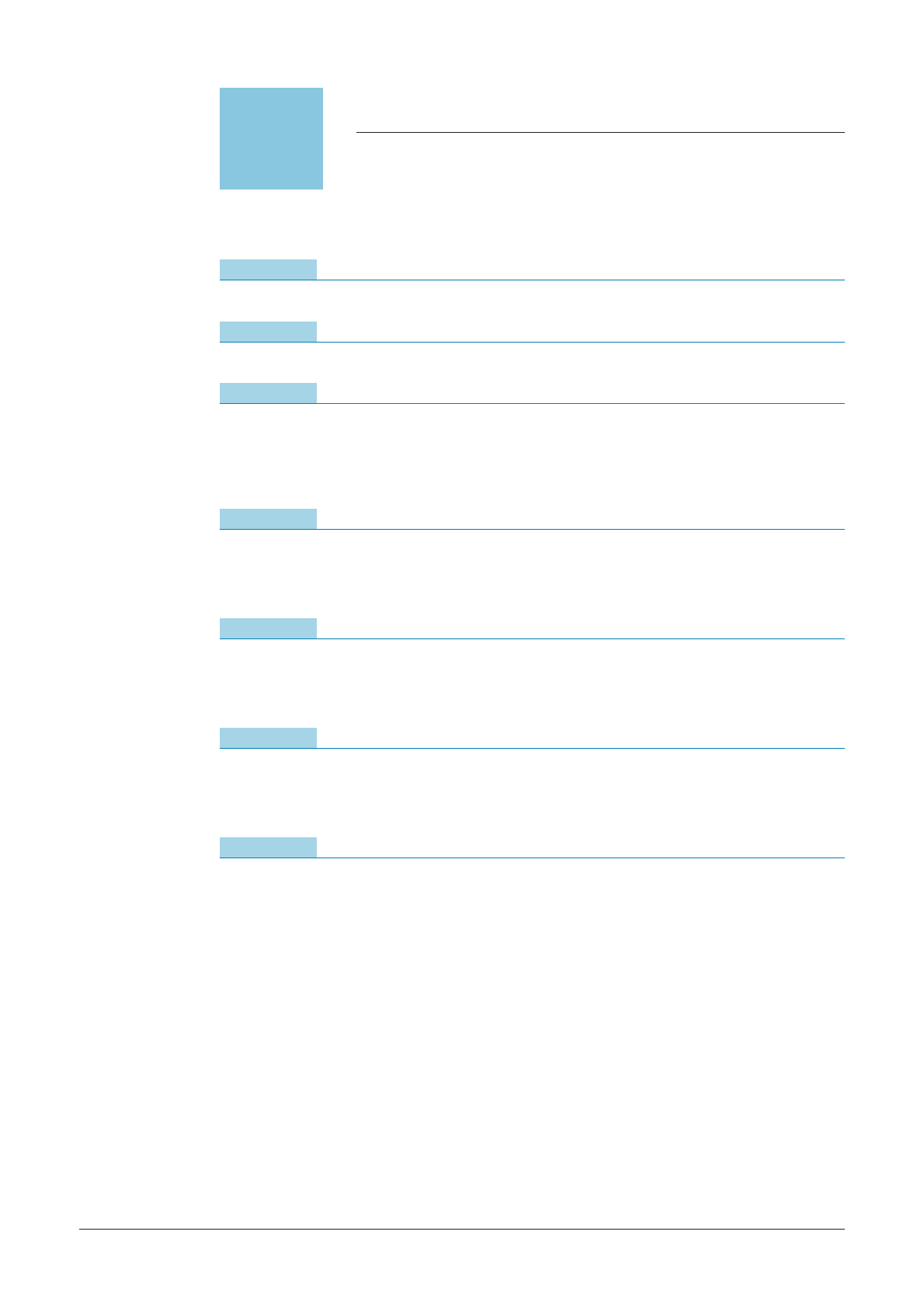

Water valve

dimensions

mm (inch)

Cable water valve

Scale 13/20

Inlet and outlet

1/8 NPT female

(0.86)

(2.15)

(0.59)

54,7

15

15

(0,59)

38,7

(1.88)

(2.58)

(1.52)

65,6

50,3 (1.98)

29,7 (1.17)

47,7

18(0.7)

34,2 (1.34)

(0.28) 22

7

OUT

IN

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 02921 - Edition 04 - 03/2013

1/1

Start-up

ATP 2300 M Operating instructions

Detailed contents

B

B 100 Safety instructions for installation

B 201 Unpacking and storage of the pump

B 300 Pump connections to an installation

- Equipment installation conditions

- Pump connection instructions

- Why securing pump installation

- Worst case Turbo pump crash definitions

B 310 Inlet and exhaust connections

- Vacuum connections

- At inlet

- At exhaust

B 330 Nitrogen purge and air inlet valve device connections

- Characteristics of filtered dry nitrogen supply

- Purge device

- Air inlet valve with purge device

B 340 Water cooling connection

- Characteristics of water cooling

- Standard assembly

- Assembly with a water valve

B 401 Typical electrical wiring diagram

The electrical connections of the pump on the controller are showed on the

contoller operating manual.

adixen Vacuum Products - Operating Instructions - ATP 2300 M

GB 00731 - Edition 14 - Sept. 12

1/6

B 100

Safety instructions for pump and

controller installation

Indicates a potentially hazardous situation which, if not avoided, could

result in moderate or minor injury. It may also be used to alert against

unsafe practices.

Indicates a potentially hazardous situation which, if not avoided, could

result in property damage.

Indicates an imminently hazardous situation that, if not avoided, will result

in death or severe injury (extreme situations).

For emergencies and breakdowns, contact the manager of your local

service center (see addresses on our website).

We took care to provide you with a clean product. To keep it in this

condition, unpack it only in contamination free area and at final place of

use.

The performance and operational safety of this product are guaranteed

provided it is used normally in the operating conditions defined in this

manual.

It is the customer’s task to:

- train operators to use the product if they do not speak the language

the manual is written in,

- ensure operators know the safe practices to apply when using the

product.

Make sure the equipment shows no sign of transport damage. If it has

been damaged, take the necessary steps to record this with the carrier

and inform the manufacturer. In all cases, we recommend keeping the

packaging (reusable materials) for further transport of the equipment or

for prolonged storage.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or severe injury.

Overview

For emergencies

Before switching on the product, study the Operating instructions and

make sure you follow the safety instructions. You can recognise these by

the ‘Caution’, ‘Warning’ and ‘Danger’ symbols.

Good practice tips and manufacturer’s recommendations are in a blue

box.

adixen Vacuum Products - Operating Instructions - ATP 2300 M

Table of contents

Other Adixen Water Pump manuals

Popular Water Pump manuals by other brands

PSG

PSG MOUVEX S6C Installation operation & maintenance

Grundfos

Grundfos Multilift MD Series Installation and operating instructions

Homa

Homa Chromatic Series Original instruction manual

TRITORC

TRITORC BEL-8 Series Operation and maintenance manual

SPERONI

SPERONI CAM 80/PA-HL operating instructions

Graco

Graco FIRE-BALL instructions

Tool Shed

Tool Shed TSPWP manual

Xylem

Xylem GOULDS AC8743 instruction manual

EUROM

EUROM SP400i manual

Pacific hydrostar

Pacific hydrostar 69297 Owner's manual & safety instructions

Amersham Pharmacia Biotech

Amersham Pharmacia Biotech P-910 instructions

Test Equipment Depot

Test Equipment Depot NRP6Di user guide