Adlee Powertronic AS2-N User manual

ADLEEPOWER

INSTRUCTION MANUAL

GENERAL-PURPOSE INVERTER

THANK YOU VERY MUCH FOR YOUR PURCHASE

OF ADLEE INVERTER ASN SERIES.

PLEASE READ THIS INSTRUCTION MANUAL

BEFORE INSTALLATION OF THE INVERTER.

R

PREFACE

This general-purpose inverter made by ADLEE Powertronic., Ltd.

Read this instruction manual throughly before operation.

This manual will be helpful in the installation, parameter setting,

troubleshooting, and daily maintenance of the AC motor drives. To

guarantee safe operation of the equipment, read the following safety

guidelines before connecting power to the AC drives. Keep this oper-

ating manual handy and distribute to all users for reference.

A. General Precaution

1. There are some covers and shields on this inverter.

Make sure all covers and shields are replaced befor operating this

product.

2. This manual may be modified when necessary because of improve-

ment of the product or changes in specification.

3. Contact your ADLEE representative to order a copy of this manual,

if your manual has been damaged or lost.

4. ADLEE is not responsible for any modification of the product made

by the user, since that will void your guarantee.

B. Safety symbols

Symbols which may appear on the manual

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in

death or serious injury to personnel.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury to

personnel and damage to equipment.

- I -

!

CAUTION

Do not install or operate the driver which is damaged or has missing

parts.

Failure to observe this caution may result in personal injury or equip-

ment damage.

- II -

RECEIVING

INSTALLATION

WARNING

Wiring should be performed only by qualified personnel.

Failure to observe this warning can result in an electrical shock or a

fire.

Only commence wiring after verifying that the power supply is turned

OFF.

Failure to observe this warning can result in an electrical shock or a

fire.

Make sure to ground the ground terminal.

Ground resistance : 100 Ohm or less.

Failure to observe this warning can result in an electrical shock or a

fire.

CAUTION

Life the cabinet by the base. When moving the unit, never lift by the

front cover.

Overwise, the mail unit may be dropped causing damage to the unit.

Mount the driver on nonflammable material. (i.e. metal)

Failure to observe this caution can result a fire.

When mounting units in an enclosure, install a fan or other cooling

device to keep the intake air temperature below 45℃ .

Overheating may cause a fire or damage to the unit.

*

*

*

*

!

*

*

*

!

- III -

*

*

*

*

*

!

OPERATION

CAUTION

Verify that the driver rated voltage coincides with the AC power supply

voltage.

Failure to observe this caution can result in personal injury or a fire.

Do not perform a withstand voltage test of the driver.

It may cause semi-conductor elements to be damaged.

To connect a braking resistor, follow in APPENDIX A.

Improper connection may cause the unit damaged or a fire.

Tighten terminal screws.

Failure to observe this caution can result a fire.

Never connect the AC main circuit power supply to output terminals

U,V and W.

The inverter will be damaged and invalidate the guarantee.

*

WARNING

Only turn ON the input power supply after replacing the front cover.

Do not remove the cover while current is flowing.

Failure to observe this warning can result in an electrical shock.

CAUTION

Since it is easy to change. operation speed from low to high speed,

verify the safe working range of the motor and machine before opera-

tion.

Failure to observe this caution can resuit in personal injury and ma-

chine damage.

Do not change signals during operation.

The machine or the inverter may be damaged.

All the constants of the inverter have been preset at the factory.

Do not change the settings unnecessary.

!

*

*

*

- IV -

!

MAINTENANCE AND INSPECTION

WARNING

Only authorized personnel should be permitted to perform maintenance,

inspections or parts replacement.

Failure to observe this warning can result in an electrical shock.

Never touch high-voltage terminals in the driver.

Failure to observe this warning can result in an electrical shock.

Replace all protective covers before powering up the inverter.

To remove the cover, make sure to shut OFF the molded-case circuit

breaker.

Failure to observe this warning can result in an electrical shock.

Perform maintenance or inspection only after verifying that the

CHARGE LED goes OFF, after the mail circuit power supply is

turnned OFF.

The capacitors are still charged and can be dangerous.

CAUTION

The control PC board employs CMOS ICs. Do not touch the CMOS

elements by hand.

They are easily damaged by static electricity.

Do not connect or disconnect wires or connectors while power is ap-

plied to the circuit.

Failure to observe this caution can result in personal injury.

*

*

*

*

*

*

OTHERS

WARNING

Never modify the product.

Failure to observe this warning can result in an electrical shock or

personal injury and will invalidate the guarantee.

*

CONTENTS

1. RECEIVING

2. SPECIFICATIONS

3. DIMENSION DRAWINGS

4. INSTALLATION

5. DESCRIPTION OF TERMINALS

6. DIGITAL OPERATION PANEL .

7. FUNCTIONS DESCRIPTION

8. PROTECTIVE FUNCTION

9. PRECAUTIONS

10. TROUBLESHOOTING

11. APPLICATION

12. INVERTER SELECTION

13. APPENDIX

A. Optional braking resistor

B. Terminal wiring diagram

14. REPAIRING AND MAINTENANCE

1

2

4

7

8

17

18

82

86

87

88

92

94

94

95

96

1. RECEIVING

This AS series AC drive has gone through rigorous quality control

tests at the factory before shipment. After receiving the AC drive,

please check for the following :

(1) No damage is found on each product after shipping.

(2) The product is as ordered (check the nameplate, voltage and fre-

quency).

(3) A set of inverter unit and instruction manual is contained in the

package.

For any irregularity, contact the sales shop where you purchased

immediately.

(4) Description of name plate

MODEL : AS 2 - 115 N

N : With current setting

Max Applicable motor(4 pole)

Single Phase :

104 : 0.4KW 107 : 0.75KW 115 : 1.5KW

122 : 2.2KW

3 Phase :

304 : 0.4KW 307 : 0.75KW 315 : 1.5KW

322 : 2.2KW 337 : 3.7KW

AS series

Voltage class :

2 : 220V

4 : 380/440V

1

R

2. SPECIFICATIONS

(1) Single phase input port

2

Model AS2-N

Voltage 1φ220VAC ±10% (TN system)

Model No AS2-104 AS2-107 AS2-115 AS2-122

Input Frequency 50HZ ~ 60HZ ± 10%

Output Voltage 3φ 220VAC

Output Frequency 0.5 ~ 400HZ

Output

Rated current (A) 3 A 4.1 A 8 A 11 A

Capacity (KVA) 1.0 KVA 1.6 KVA 2.7 KVA 3.8 KVA

Largest motor

KW ( 4 poles ) 0.4KW 0.75KW 1.5KW 2.2KW

Control Sine wave pulse width modulation

Braking Regenerative discharge braking

Over current

Capacity 150% of rated current ( 1 minute)

Acceleration time 0.1 ~ 6000 SEC

Deceleration time 0.1 ~ 6000 SEC

Frequency

setting DigitalUse keyboard for setting and confirm by

Analog By frequency knob / 0~5VDC, 0~10VDC, 4~20mA / RS-485

Display type LED Digits

Cooling Method Self-cooled Self-cooled Air-cooled Air-cooled

Environmental

Enclosure Rating IP20

Protective Class I

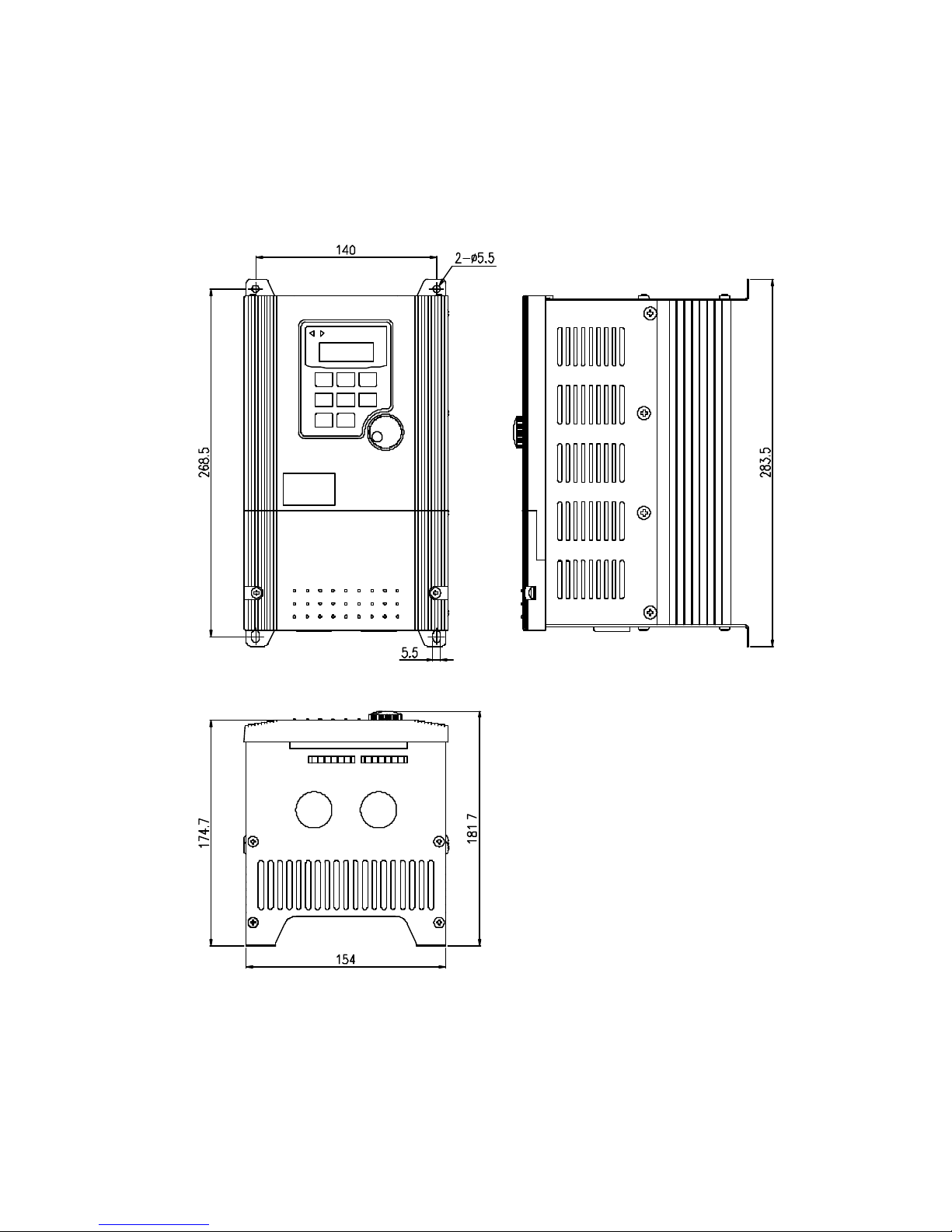

Dimension drawing Fig 1 Fig 1 Fig 2 Fig 2

Weight ( NW . KG ) 1.2KG 1.3KG 1.3KG 1.4KG

(2) 3 Phase input port

3

Model AS2-N AS4-N

Voltage 3φ 220VAC ± 10% (TN system) 3φ 380/440VAC ±10% (TN system)

Model No AS2-304 AS2-307 AS2-315 AS2-322 AS2-337 AS4-307 AS4-315 AS4-322 AS4-337

Input Frequency 50HZ ~ 60HZ ±10%

Output Voltage 3φ 220VAC 3φ 380/440VAC

Output Frequency 0.5 ~ 400HZ

Output

Rated current (A) 3 A 5 A 8 A 11 A 17 A 2.5 A 4 A 6 A 8.5 A

Capacity (KVA) 1.1 KVA 1.9 KVA 3.1 KVA 4.2 KVA 6.5 KVA 1.9 KVA 3.1 KVA 4.2 KVA 6.9 KVA

Largest motor

KW ( 4 poles ) 0.4 KW 0.75 KW 1.5 KW 2.2 KW 3.7 KW 0.75 KW 1.5 KW 2.2 KW 3.7 KW

Control Sine wave pulse width modulation

Braking Regenerative discharge braking

Over current

Capacity 150% of rated current ( 1 minute)

Acceleration time 0.1 ~ 6000 SEC

Deceleration time 0.1 ~ 6000 SEC

Frequency

setting Digital Use keyboard for setting and confirm by

Analog By frequency knob / 0~5VDC, 0~10VDC, 4~20mA / RS-485

Display type LED Digits

Cooling Method Self-cooled Self-cooled Air-cooled Air-cooled Air-cooled Air-cooled Air-cooled Air-cooled Air-cooled

Environmental

Enclosure Rating IP20

Protective Class I

Dimension drawing Fig 1 Fig 1 Fig 2 Fig 2 Fig 3 Fig 2 Fig 2 Fig 2 Fig 3

Weight ( NW . KG ) 1.2 KG 1.3 KG 1.3 KG 1.4 KG 4.2 KG 1.3 KG 1.3 KG 1.4 KG 4.0 KG

3. DIMENSION DRAWINGS

Fig 1

Unit : mm

4

Fig 2

Unit : mm

5

Fig 3

Unit : mm

6

4. INSTALLATION

7

AIR FLOW

4 cm

6 cm

5 cm

6 cm

5 cm

Temperature -10 ~+45 (14 ~113 )℃ ℃ ℉ ℉

Relative Humidity <90%, No condensation allowed

Installation Site Altiude <1000M

Pollution Degree 2

Inadequate environment around installation site and installation surface

can result in damaged to the inverter.

Before operating the ASN series inverter, please check the following

points :

Avoid high temperature, high humidity, easy-to-dew ambient enviro-

nment. Do not expose to dust or dirt, corrosive gas, and coolantmist,

and direct sunlight. Place the unit in a well-ventilated room.

Avoid a place subjected to substantial vibration.

When installing the unit within the cabinet. Please pay attention to

ventilation and limit the ambient temperature in between -10℃~

45℃. (14℉~113℉)

Use a nonflammable material, such a steel sheet on the wall for

installation. (The rear side will generate heat)

Install th unit always vertically with a marginal spacing around.

(1)

(2)

(3)

(4)

(5)

Ambient Condition

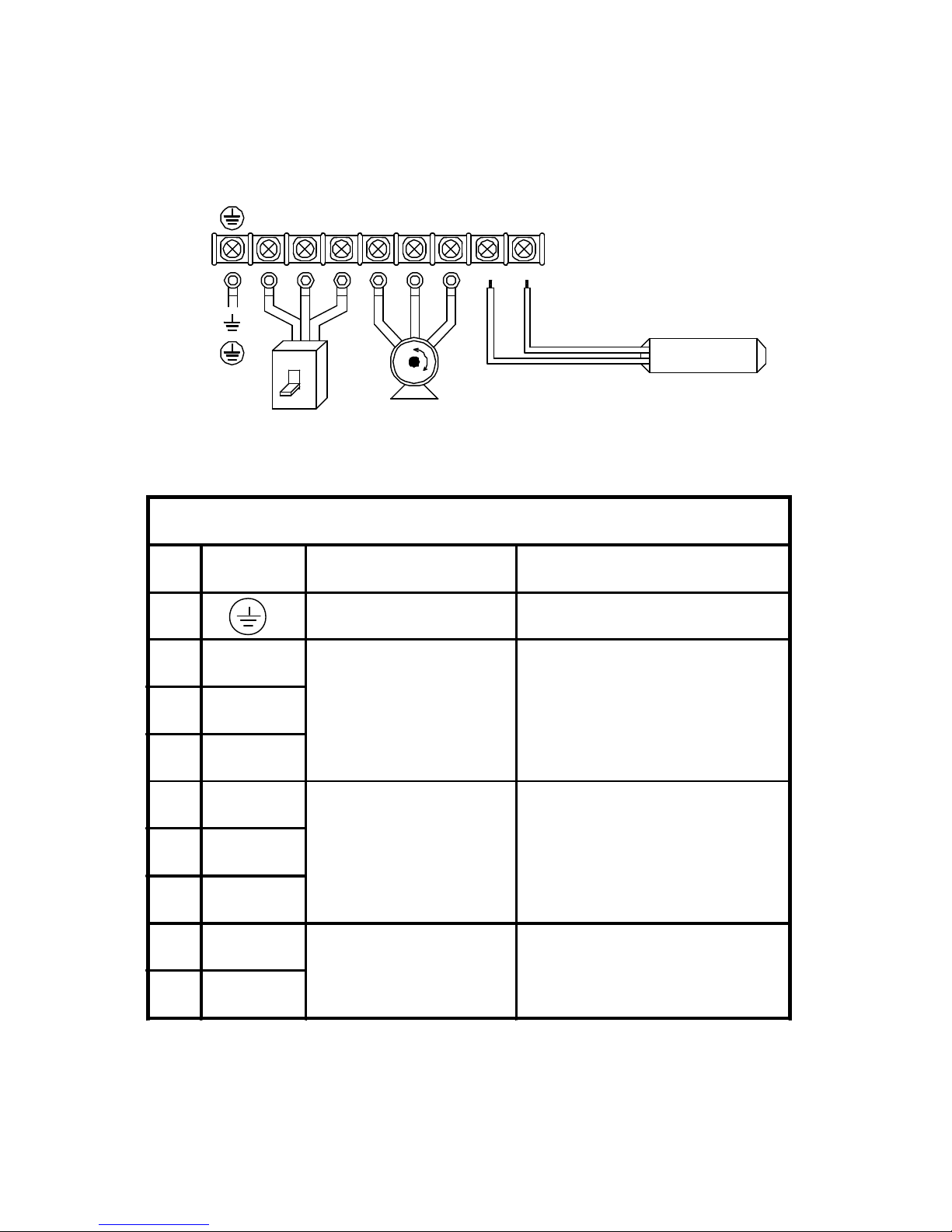

5. DESCRIPTION OF TERMINALS

(1) Main circuit connection diagram

8

L1 L2 L3 U V WPRP

IM

MOTOR

POWER

GROUND

60 80W

External braking resistor

Refer to the appendix A

SOURCE

Ω

Main circuit terminal

No. Symbol Description Terminal name

1Ground Ground(Earth) Terminal

2L1

Connect power supply (L1,L2) Single Phase

(L1,L2,L3) 3 Phase

3L2

4L3

5U

Inverter output Terminals connected

to motor

6V

7W

8P

Dynamic brake

Terminals connected to braking

Resistor, resistance refer to

Appendix A

9PR

9

(2) Control circuit terminal

AS2-104N~122N, AS2-304N~322N, AS4-307N~322N

AS2-337N, AS4-337N

A/B

C

MA/MB

MCFT2CF2REVS+S-10VFA1

COMCOMARRRSTFT1CF1FWD24VMET

ACOM

FA2

2-1 2-2 2-3 2-4 2-5 2-6 2-7 2-8 2-9 2-10 2-11

1-1 1-2 1-3 1-4 1-5 1-6 1-7 1-8 1-9 1-10 1-11

A/BC

MA/MB MC FT2CF2 REVS+ S-

10V FA1 COMCOM

ARR

RST FT1CF1 FWD

24V

MET

ACOM FA2

2-1 2-2 2-3 2-4 2-5 2-6 2-7 2-8 2-9 2-10 2-11

1-1 1-2 1-3 1-4 1-5 1-6 1-7 1-8 1-9 1-10 1-11

10

Symbol Terminal name Description

FWD Forward operation Forward operation / stop terminal

REV Reverse operation Reverse operation / stop terminal

CF1

Multistage speed

terminal

CF2

FT1 Multi function terminal 1 See functions description (CD42)

FT2 Multi function terminal 2 See functions description (CD43)

RST Reset Reset

COM Common terminal Common terminal of control terminals

A / B Alarm output Fault alarm contact

CAlarm output C Fault alarm contact (common)

MT Multi function output terminal

Open collector output 50mA MAX

RUN : Operating indicator

MET : Connect to frequency meter, refer

to CD07 description

ARR : Frequency arrived indicator, refer to

CD55 description

FA1 Free analog terminal 1 See functions description (CD44)

FA2 Free analog terminal 2 See functions description (CD45)

GND Analog common terminal Common terminal of free analog terminals

10V Analog source Power source +10V of analog terminals

MA / MB RUN Relay output RUN Relay contact

MC RUN Relay output RUN Relay contact (common)

S+ RS485 TXD Communication port

S- RS485 RXD Communication port

CF1 CF2 SPEED

OFF OFF SPEED - 1

ON OFF SPEED - 2

OFF ON SPEED - 3

ON ON SPEED - 4

(3) Description of Hardware setting

AS2-104N~122N, AS2-304N~322N, AS4-307N~322N

AS2-337N, AS4-337N

3-1 DIP Switch setting (SW1)

11

FA1

FA2

10V

ACOM

S-

24V

S+

CF1

REV

FWD

CF2

FT1

FT2

RST

MC MA/MB

ARR

C

COM

A/B

COM

S3 S2

S1

J4SW1

SW2

S4

RS485

MET

S+

ACOM

S-

10V

MA/MB

FA2

MC

CF1

C

MET

A/B

RST

CF2

FT1

FT2 REV

FWD

ARR

COM

24V

COM

S3 S2

J4

SW2 SW1

S4

RS485

FA1

S1

Setting FA1 (SW1) Setting FA2 (SW2)

FA1(SW1) : 0 - 10V FA2(SW2) : 0 - 10V

FA1(SW1) : 0 - 5V FA2(SW2) : 0 - 5V

FA1(SW1) : 4 - 20mA FA2(SW2) : 4 - 20mA

Error setting Error setting

3-2 Jumper Setup

1. S1 terminal control structure

1 and 3 short circuit : External terminal NPN(SINK)

structure. (Default value)

2 and 3 short circuit : External terminal PNP(SOURCE)

structure.

2. S2 analog output Relay

1 and 2 short circuit : Fault A. (Default value)

2 and 3 short circuit : Fault B.

3. S3 RUN Relay output

1 and 2 short circuit : Fault A. (Default value)

2 and 3 short circuit : Fault B

4. S4 : VR on panel / VR on F306

1 and 2 short circuit : VR on F306

2 and 3 short circuit : VR on panel

5. RS485 connector

12

1

2

3

1 2 3

12 3

12 3

8765 4321

NO 8 7 6 5 4 3 2 1

Color Black Red Orange Yellow Green Blue Purple Brown

Symbol GND VCC GND A RFA0 BVCC

Connect to F306 or RS485

Symbol Description

VCC Source for F306

BCommunication signal (S-)

RFA0 Analog input for F306

ACommunication signal (S+)

GND Common of F306

※This connector is for both F306 and RS485. Set CD13 for selec-

tion.

13

Main circuit terminals

Wire Wire type Torque

less than AS2(4)N-3HP

Input (L1,L2,L3) / /

Output (U,V,W,P,PR)

14AWG~12AWG

(2.0mm2~3.5mm2)

Stranded copper only

(600V/80 )℃10Kg-cm

(8.68lb-in)

AS2(4)N-5HP

Input (L1,L2,L3) / /

Output (U,V,W,P,PR)

12AWG

(3.5mm2)

Stranded copper only

(600V/80 )℃12Kg-cm

(10.41lb-in)

External control signal

terminals

24AWG~14AWG

(0.5mm2~2.0mm2)

Stranded copper only

(300V/80 )℃5.1kg-cm

(4.42lb-in)

(4) WIRING

4-1 Wiring of main circuit

4-2 Wiring equipments

Select the wiring equipment and wiring size, refer to the table

below.

1. On the input power side, a molded case circuit breaker (MCCB)

to protect inverter primary wiring should be installed.

2. A leakage current breaker threshold of 200mA and above, or of

inverter use is recommended.

3. Use of input side magnetic contactor. An input MC can be used to

prevent an automatic restart after recovery from an external power

loss during remote control operation. However, do not use the MC

reduced reliability.

4. In general, magnetic contactors on the output of the inverter,

Should not be used for motor control. Starting a motor with the

inverter running will cause large surge currents and the inverter

overcurrent protector to trigger.

14

L1

L2

(L3)

E

U

V

W

Filter IM

THRY

MCCB

AS2-Series

Model AS2N AS2-N

Model No 04 07 15 22 37 07 15 22 37

Capacity (KVA) 1.1 1.9 3.1 4.2 6.5 1.9 3.1 4.2 6.5

Current (A) 35811 17 2.5 4 6 8.5

Circuit Breaker

(MCCB) (A) 10 10 15 20 20 10 10 10 15

Electro-Magnetic

Contactor (A) 12 12 12 12 18 12 12 12 12

Thermal relay

RC value (A) 2.4 3.8 6.8 9 15 1.9 3.4 3.8 6.8

This manual suits for next models

14

Table of contents

Other Adlee Powertronic Inverter manuals

Popular Inverter manuals by other brands

Workzone

Workzone PGM6003 product manual

Sunways

Sunways STS 3 KTL Series user manual

Anleaf Technologies

Anleaf Technologies AP300W user guide

Ingeteam

Ingeteam INGECON SUN 3Play 100TL Installation and operation manual

Kessler-Ellis Products

Kessler-Ellis Products 533K.2 Installation and operating manual

SMA

SMA PPM-10 installation manual