Admesy MSE Series User manual

MSE

colorimeter

operating manual

2

Contents

1Introduction.......................................................................................... 3

1.1 MSE............................................................................................. 3

1.2 MSE highlights ............................................................................ 3

1.3 Standards.................................................................................... 4

2Interfaces............................................................................................. 5

2.1 USB interface.............................................................................. 5

2.2 RS232 interface .......................................................................... 5

2.3 Trigger in/out............................................................................... 6

2.4 Power connections...................................................................... 6

3Communications protocol.................................................................... 7

3.1 USB............................................................................................. 7

3.2 RS232 ......................................................................................... 7

4Device drivers...................................................................................... 8

4.1 USB............................................................................................. 8

4.2 RS232 ......................................................................................... 8

5Command set description ................................................................... 9

5.1 Commands.................................................................................. 9

5.2 Command structure..................................................................... 9

5.3 System commands.................................................................... 10

5.4 Configuration commands.......................................................... 10

5.5 White point references ..............................................................12

5.6 Measurement commands..........................................................13

5.7 User EEPROM commands .......................................................14

5.8 Returned results........................................................................ 15

6Measurement example......................................................................16

7Auto-ranging......................................................................................17

7.1 Introduction................................................................................ 17

7.2 How auto-ranging works ........................................................... 17

7.3Auto-range parameters .............................................................18

7.4 Auto-range in practice...............................................................18

7.5 Programming MSE for auto-ranging .........................................20

7.6 Auto-ranging recommendations................................................ 21

8MSE formulas.................................................................................... 22

8.1 Formulas ................................................................................... 22

8.2 XYZ to Yxy conversion.............................................................. 22

8.3 XYZ to CIE 1976 UCS Yu’v’......................................................22

8.4 Flicker calculation......................................................................23

8.5 Additional colour spaces ...........................................................23

9Operating mode................................................................................. 24

10 Typical spectral sensitivity of colorimeter...................................... 24

3

1 Introduction

1.1 MSE

The MSE series colorimeter offers a unique combination of high speed

and accurate colour measurement capabilities packed in a robust jacket.

The MSE colorimeter is available in 10mm spot size and M8 fibre

connector version. The fibre version is available with several optics,

custom optics can be applied on request.

Thanks to its supreme quality, robustness of both hardware and software

and its compact size, the MSE is the ultimate choice for in-line colour

measurement applications. Thanks to its build-in mechanical shutter, dark

measurements are carried out easily and accurately.

The MSE series are predominantly found inline in display production

facilities or the adjacent R&D departments to handle white point

adjustment, uniformity, flicker, reaction time and general colour quality

control.

1.2 MSE highlights

Absolute colour measurement according to human eye (CIE1931)

Colour measurement even at low luminance level

Colour measurement in XYZ, Yxy, Yu’v’

Other colour spaces available via a supplied colour library

Fast colour measurement: 140 measurements/second at

luminance level 200 cd/m²

High speed luminance (Y) function: 22.000 luminance

samples/second

Mechanical shutter for accurate dark level measurement

Trigger in and output for inline applications

USB and RS232 communication interface

USBMTC standard compliant

Windows, Linux and MAC OSX compatible

Directly supported in Labview, Labwindows, Visual Studio via

VISA library. Other programming languages that support VISA can

be used

4

1.3 Standards

The MSE is compliant to the USBTMC standard and can be used in

combination with external provided USBTMC compliant drivers. Currently

it has been tested on Windows, Linux and Apple OSX using NI VISA

(www.ni.com/visa) and using the open source drivers on Linux (i686,

x86_64 and ARM). Refer to the Admesy support site for a more detailed

description and free source code or contact us.

5

2 Interfaces

2.1 USB interface

The USB-B connector is used to connect the MSE to a PC/Laptop. USB

connection is preferred to ensure high speed data transfer of colour

measurements. The MSE uses the USBTMC class protocol and can

therefore be used directly with third party provided VISA compliant libraries

like NI-VISA. The MSE can be used USB powered in case the host

provides enough current. Normally every USB 2.0 host should be able to

drive 500mA. Non powered USB-HUB’s mostly do not supply enough

current. It is therefore recommended to use powered USB-HUB’s only.

2.2 RS232 interface

RS232 is provided to connect the MSE colorimeter to any host that doesn't

provide USB or for which no USBTMC drivers exist. Using RS232, the

high speed options of the colorimeter are still available, only transfer of

data to the host is reduced in speed. It is recommended to use USB in

case the high speed sampling options are needed.

Baud

rate

Data bits

Parity

Stop bits

Flow

control

Termination

character

115200¹

8

None

1

None

LF=’\n’

Table 1 RS 232 port configuration.

1 Baud rate can be changed.

In both USB and RS232 modes, USB is still active but when only USB is

used, it is recommended to set it to USB mode so that the MSE responds

in the fastest possible way to commands. The operating mode must be

selected via the Admesy Colorimeter PC application.

Fig 1 MSE RS232 connection.

Fig 2 Rear side mini-DIN-6 pin connector.

6

2.3 Trigger in/out

The MSE has two trigger connections. One trigger output and one trigger

input (SMA connectors). The MSE can be triggered when it is operating in

USB or RS232 mode. When triggering is enabled, the trigger output line

will be set to a high level once the measurement has finished and the

measurement result is available. It will stay at a high level until the next

command is carried out, but has a minimum high level of 50μs. A trigger

will carry out the last send command and send the result to the host via an

interrupt endpoint on the USB bus. The colorimeter main application

allows external triggering in the data-logging tab. Supplied code examples

show how to use this feature in an application. The trigger output line is

used to indicate that the measurement is ready. Trigger signals should

comply to the following timing.

Fig 3 Trigger-in timing.

Trigger pulses arriving faster than the MSE can measure will be ignored,

but it may slowdown overall performance. Trigger pulses should not arrive

faster than the measurement takes to complete. The best way is to use the

trigger output to make sure measurement was finished. The trigger out

port provides a continuous high signal when the device is in use. Its signal

turns low when the device is not executing any commands.

2.4 Power connections

The MSE should be connected to USB with enough supply or using a 9V

DC power supply to the RS232 connector. When using RS232 the

colorimeter needs to be powered via an external adapter. This can be

done through the mini-DIN connector as illustrated in the RS232

connections. The unit shall be powered by a 9V DC voltage or via a

standard USB PC-port, reinforced separated from Mains, with a limited

energy of < 150VA and < 8A.

Connection

Min.

Voltage

Typ.

voltage

Max.

voltage

Max

current

USB powered

4.75 V

5.00 V

5.25 V

225mA

DC powered

8.50 V

9.00 V

15.00 V

225mA

Table 2 Power supply levels.

7

3 Communications protocol

3.1 USB

The MSE colorimeter can be connected to any USB host. The colorimeter

is a USBTMC compliant device which is a standard USB class device and

device drivers for this class are available for most popular operating

systems (also embedded). This makes the MSE colorimeter directly

usable in popular programming languages like NI's Labview and

Labwindows but als C++, Visual basic, C#, Java etc. The MSE colorimeter

has two interfaces build in, which require a different device driver to be

used.

Admesy bootloader

(USB RAW device driver Vendor ID : 0x23CF, Product ID 0x0E92)

MSE colorimeter

(USBTMC device driver Vendor ID : 0x23CF, Product ID 0x0EA0)

When the MSE colorimeter is connected to the host, it will start the MSE

colorimeter firmware. As soon as the firmware is idle to receive

commands, the Power LED goes to the on state. The Admesy bootloader

is a RAW USB device and in order to use this device in Windows, a driver

must be installed which is supplied by Admesy. Besides upgrading to new

firmware, it is also allowed to downgrade firmware in case this is required.

Note that older firmware also may require the use of older software

libraries and/or executable versions of software. The MSE colorimeter is

USBTMC compliant and can be used with libraries that contain a USBTMC

compliant driver like NI-VISA. The MSE colorimeter is a USB 2.0 Full

speed device. In case a USB host is detected, it is assumed that the MSE

colorimeter operates only via USB.

3.2 RS232

MSE commands are equal for all interfaces. Note that for high speed

transfers it is best to use USB. When RS232 will be used, the device mode

should be set to RS232. This is done via software and stored in the device

EEPROM memory.

8

4 Device drivers

4.1 USB

The following table shows an overview of USB support on various

operating systems.

OS

NI-VISA

Libusb

Native

kernel

Agilent

USBTMC

Windows XP 2

·

·

Not

available

Not tested¹

Windows

VISTA

·

·

Not

available

Not tested¹

Windows 7

·

·

Not

available

Not tested¹

Windows 8(.1)

·

Not tested¹

Not

available

Not tested¹

Windows 10

·

Not tested¹

Not

available

Not tested¹

Windows CE

·

Not tested¹

Not

available

Not tested¹

Apple OSX

PPC

·

Not tested¹

Not

available

Unknown

Apple OSX

Intel

·

Not tested¹

Not

available

Unknown

Linux i386

(32bit)

·

·

·

·

Linux i386

(64bit)

·

·

·

·

Linux ARM

Not

available

·

·

·

Linux other

Not

available

·

·

·

Table 3 Supported operating systems.

1 Not tested: Available, but not tested by Admesy, 2 Native Kernel: Driver included with OS.

2 Windows XP SP3 is supported: Windows official support has ended as of April 8 2014.

Admesy supports all tested platforms but does not provide standard

applications on all platforms. The matrix is provided to show the possible

platforms for software development. Admesy does however provide

software examples for most of the tested platforms. Most of these

examples can be found on our support web page.

4.2 RS232

When no USB driver is available or the host system does not provide USB,

RS232 can be used as it does not require additional drivers for the MSE.

9

5 Command set description

5.1 Commands

The functions of the MSE can be best described via the following

categories:

System commands

Configuration commands

Measurement commands

User EEPROM commands

The MSE uses SCPI like commands for control and measurement. These

are ASCII based commands and follow specific rules regarding syntax.

Although the MSE uses SCPI like commands, they deviate from the SCPI

standard.

5.2 Command structure

Every command starts with a colon “:”, which identifies the root of the

command tree. Each further keyword is also separated by a colon. In case

parameters need to be specified, the last keyword and parameters are

separated by a single space character. In case more than one parameter

needs to be specified, the parameters need to be separated by a comma.

The command tables show commands in long and short format. The short

format is specified by upper case characters. It is allowed to use long and

short format or a mixed format. Optional keywords are shown between

brackets [...]. Commands are not case sensitive, so it is allowed to use

both or a mix of upper and lower case. The command structure is valid for

all communication interfaces of the MSE. It is recommended to terminate a

command by a newline character “\n”.

Command table

Valid command

syntax examples

Notes

:SENSe: INT 50000

:sens:int 500000

:sense:int 500000

:SENS:INT 500000

:SENSE:INT 500000

Sets the integration

time of the MSE

:MEASure:XYZ

:measure:XYZ 0

:measure:xyz 0

:meas:XYZ 0

:MEASure:XYZ 0

The measure

commands use the

averaging and gain

options

:SAMPle:Y

:sample:Y

:sample:y

:samp:Y

:SAMPle:Y

With the sample

command, the MSE

colorimeter will

perform fast sampling

to its internal memory.

Results are read from

the memory after the

measurement has

been performed

Table 4 Example commands.

10

5.3 System commands

The following commands can be used to control the MSE or read back

information.

Command syntax

Parameters

Purpose

:*CLS

None

Clear status

:*IDN?

None

Identification query

:*RST

None

Reset Command

:*STB?

None

Read Status Byte query

:*TST

None

Self-test query

:*FWD?

None

Firmware date query

:*FWT?

None

Firmware time query

:SYSTem:VERSion?

None

Get system version

information

:SYSTem:ERRor?

None

Retrieve the last occurred

error

:SYSTem:ERRor:NEXT?

None

Retrieve previous errors

Table 5 System commands.

The Status byte can be used to retrieve information about the status of a

command or the system. Return values of the status command can be

seen in the table below.

Code

Description

0

System is idle

1

Data is available

2

Command processed

4

Data in buffer (should not occur)

8

An error occurred Use “:SYSTem:ERRor?”

to get the exact error that occurred

Table 6 Status commands.

Note: The status and error commands should not be used in standard programs. They are

not necessary when programming has been done correctly. They are available in case a

problem occurs during development. The :*RST command is also not necessary in normal

programs. It is advised to use the :SENSe and :CONF commands in case the behaviour of

the MSE needs to be changed to its default settings.

5.4 Configuration commands

Configuration commands are used to set parameters of the MSE

colorimeter that are used by the measurement functions. The settings are

used globally by other measurement functions. The selected white

standard is used for dominant wavelength calculation. The integration time

setting can be varied from 0.1ms to 5s. It is specified in μs. Results from

the MSE colorimeter include a clip and noise indication which indicate

whether the measured light is too bright (clip) or too low (noise). When

clipping is detected, the resulting colour will not be correct and a lower

integration time should be chosen. When noise is detected, a longer

integration time should be chosen, see table 7 on next page.

11

Command syntax

Parameters

Range

Purpose

:SENSe:INT

Int time

100 –

5000000

Set integration time

(μs) of the colorimeter

:SENSe:INT?

None

Returns the current

integration time setting

of the colorimeter

:SENSe:

AVERage

Averaging

1 –200

Set the averaging for

the colorimeter

:SENSe:

AVERAGE?

None

Returns the averaging

setting for the

colorimeter

:SENSe:SBW

Calibration

matrix

“off”

“factory”

“user1”

“user 30”

Set calibration matrix

for the colorimeter

:SENSe:SBW

None

Query selected

calibration matrix

:SENSe:

AUTORANGE

Auto-range

0 –1

Set auto-range mode

:SENSe:

AUTORANGE?

None

Returns current setting

:SENSe:

AUTOPARMS

Frequency

Frames

Adjmin

1 –255

1 –255

1 –50

Set frequency

Set # frames

Percentage level

:SENSe:

AUTOPARMS?

None

Query Auto parameter

values

:SENSe:

SHUTTER

State

0 –1

Set shutter open/close

0 = open, 1 = close

:SENSe:

SHUTTER?

None

Returns shutter state

:SENSe:

REALINT?

None

Returns the real

integration time used

in auto-ranging mode

Command syntax

Parameters

Range

Purpose

:SENSe:

MAXINT

1000 –

5000000

Maximum integration

time. If time is too

short, measuring dark

level may be difficult

:SENSe:

MAXINT?

Query the maximum

integration time

:CONFigure:

MODE

Enum (0, 1)

USB,

USB+RS232

Configure the MSE

mode

:CONFigure:

MODE?

None

0 –1

Returns the current

setting.

:CONFigure:

BAUDRATE

Baudrate

0 –5 (9600 -

230400)

Set RS232 baudrate

:CONFigure:

BAUDRATE?

None

Returns the current

setting

:CONFigure:

TRIG

Trigger

0 –1

Set trigger mode

:CONFigure:

TRIG?

None

Returns the current

setting

:CONFigure:

WHITE

String

A, B, C, D40,

D42, D50,

D55, D65,

D75, D90,

D95, E, F2,

F7, F11

Set reference white

value for Lab/Luv

colour space.

:CONFigure:

WHITE?

None

Query white reference

:CONFigure:

SHUT

State

0 –1

Sets shutter mode in

MSE start-up

conditions

:CONFigure:

SHUT?

0 –1

Returns shutter mode

Table 7 Sense and configuration commands.

12

5.5 White point references

Reference white

X

Y

Z

A

109.85

100.0000

35.58

B

99.07

100.0000

85.22

C

98.07

100.0000

118.22

D40

99.6092

100.0000

60.9432

D42

98.7058

100.0000

65.4253

D50

96.42

100.0000

82.51

D55

95.68

100.0000

92.14

D65

95.04

100.0000

108.88

D75

94.97

100.0000

122.61

D90

95.2270

100.0000

138.5514

D95

95.3315

100.0000

142.9635

E

100.0000

100.0000

100.0000

F2

99.19

100.0000

67.39

F7

95.04

100.0000

108.75

F11

100.96

100.0000

64.35

Table 8 White point references.

13

5.6 Measurement commands

Command syntax

Parameters

Range

Purpose

:MEASure:XYZ

None

Measure XYZ

:MEASure:Yxy

None

Measure Y and x,y

colour point

:MEASure:Yuv

None

0/1

Measure Y and u',v'

colour point

:MEASure:Y

None

Measure Y

(luminance)

:SAMPle:XYZ

Samples

0 –4000

Sample XYZ

:SAMPle:Yxy

Samples

0 –4000

Sample Yxy

:SAMPle:Yuv

Samples

0 –4000

Sample Yuv

:SAMPle:Y

Samples

Delay

0 –4000

0 –255

Sample Y

:OVERSAMPle:Y

Samples

0 –4000

Oversample Y

:MEASure:

TEMPerature

None

Measure temperature

of sensor head and

CPU

:MEASure:CCT

None

Measure CCT

:MEASure:

FLICker

Samples

0 –24000

Measure flicker level

(%)

:MEASure:

FLICker:CONtrast

Samples

0 –24000

Measure flicker level

(%)

:MEASure:

OSFLICker

Samples

0 –24000

Measure flicker level

(%)

:MEASure:

OSFLICker:

CONtrast

Samples

0 –24000

Measure flicker level

(%)

Table 9 Measurement commands.

Note: The delay time is set in sample times, meaning a delay of one will skip one sample.

Note: When using high sample amount or long integration times, make sure timeout values in

the application software are set accordingly.

Note: The :SAMPLE functions do not use auto-ranging. They use the fixed integration time.

Since :SAMPLE functions are often used to measure switching signals, auto-ranging is not

useful.

Table 9 shows the measurement commands of the MSE colorimeter.

Regarding colour/luminance measurement, there are two kind of

commands (MEASure/SAMPle). The MEASure commands measure the

requested values using the set averaging and integration time and returns

the result in a single structure of three single precision floating point

values. The SAMPle commands measure the requested parameters using

a sample count and delay time and return an array of data. The array

contains single floating point data. Each sample count equals one

complete structure, for example one XYZ structure of data. The delay time

is set in sample times, meaning a delay of 1 equals skipping 1 sample.

14

5.7 User EEPROM commands

Table 10 shows the commands which can be used to store values in the

user EEPROM space. It is advised to reboot the MSE after writing new

values to the EEPROM.

Command syntax

Parameters

Range

Purpose

:EEPROM:

STARTUP:READ

None

Copies startup

conditions from

EEPROM to internal

variables.

Values can then be

read using

:SENSe:AVERage? for

example

:EEPROM:

STARTUP:WRITE

MSE mode

Integration

time

0 –5

100 –

5000000

Copies internal

variables to EEPROM

and sets mode and

amp factor

:EEPROM:

SBW:READ

User matrix

Index 1

Index 2

0 –29

0 –2

0 –2

Read user calibration

matrix

:EEPROM:

SBW:WRITE

User matrix

Index 1

Index 2

Value

0 –29

0 –2

0 –2

Float

Write user calibration

matrix

:EEPROM:

READ:SN

None

Read serial number

:EEPROM:

READ:SBWNAME

Matrix

number

0 –29

Read name of matrix

:EEPROM:

WRITE:ID

Device ID

1 –255

Device ID can be used

to link to a mechanical

position and read back

in software so the

position is linked with

the measurement data

:EEPROM:

READ:ID

Read device ID

:EEPROM:WRITE

Write all settings to

EEPROM

Table 10 User EEPROM commands.

15

5.8 Returned results

:MEASure command return their result in ASCII formatted floating point as

shown below where X,Y,Z can be substituted for Y,u,v or other colour

spaces.

\n

:SAMPle command return all measurement data also in ASCII format,

except the :Sample:Y function. The first three values indicate the delta

time between samples and the clip and noise values.

MEAS command

dt

%f\n

Clip

%f\n

Noise

%f\n

Value1

%f\n

Value2

%f\n

Value3

%f\n

Table 11 Return result MEAS command.

Exceptions to the above are the :MEASure:TEMPerature, :MEAS:Y and

:SAMPle:Y commands.

\n

:SAMPle:Y

returns its data in unsigned integer format.

Sample Y command

dt

%u\n

Clip

%u\n

Noise

%u\n

Value1

%u\n

Value2

%u\n

Value3

%u\n

Table 12 Return result SAMPLE Y command.

:MEAS:Y\n

Note: In RS232 mode the SAMPLE command separate the values using a TAB (\t)

and the last value is terminated using an end of line constant (\n).

16

6 Measurement example

The MSE uses default settings when the device is started. These can be

programmed by the end user so that the device starts with the same

settings each time it is connected.

Although it's possible to program all MSE devices individually in a

production environment to start with equal settings, it is recommended to

set the averaging, integration time and SBW values in the initialization

routine of the host software.

A typical measurement example of XYZ would include the following

commands as shown on the right.

Fig 4 Measurement example.

Action may be performed in a loop

Open device (VISA open, RS232 port init)

Set averaging to 1 sample

Set integration time to 16.666ms

Set calibration matrix to the first user

programmable matrix

Set auto-ranging on

Measures CIE X, Y and Z

Read the result back from device

(VISA/USBTMC read command or RS232 read)

open device

close device

:sens:aver 1

:sens:int 16666

:sens:sbw user1

:sens:autorange 1

:meas:xyz

read result

Close the device

17

7 Auto-ranging

7.1 Introduction

The MSE includes an auto-range function. This function is useful in case

the measured object shows an unknown luminance value. In this case, the

MSE will try to find the optimum setting which is a trade-off between speed

and the stability of the instrument. The auto-ranging function can also be

fine-tuned to reach better stability levels by setting a few parameters.

Auto-ranging can be controlled by 3 parameters.

Frequency : supposed to be frame frequency of the display that is

measured

Frames : The minimum number of frames to measure

Adjmin : The minimum level to adjust to

Adjmin is an important setting which can vary between 1 and 50.

Reasonable results will be achieved when set to 5 regarding the speed

and the stability. If high stability is needed, this setting must be increased

(but it will become slower). If a faster measurement is needed and the

stability level may be lowered a little, the value of adjmin can be

decreased. When the MSE measures in auto-range mode, it can happen

that the found integration time is very low. For example when measuring

white it may be just 5ms. When this happens, the MSE will automatically

increase the averaging so that the total measurement time equals

>= (1/frequency) ·frames.

7.2 How auto-ranging works

The auto-ranging works, by first setting a default integration time. If this

already meets the criteria for a good measurement, the measurement will

be done using that integration time. It should be clear that this is the

fastest because no adjustment will be done. In case the measured result is

either to low or too high (clip), than the MSE will adjust to a better level.

The following graph shows how levels inside the MSE work.

Fig 5 Auto-range levels

When auto-ranging is set, the MSE will accept any level between “Adjmin”

and “Adjmax” as a good signal. The Adjmin level can be set by the user

through a software command, allowing some fine tuning of the stability and

the speed of the instrument.

adjminlevel

adjmaxlevel

clipping

18

7.3 Auto-range parameters

Auto-range controls the following parameters:

Frequency: This setting must be set to the frame frequency of the

measured sample. The range is 1 to 255 Hz. If a sample has a

higher frequency than that, set it such way that 1/frequency covers

multiple frames of the sample.

Frames: The minimum number of frames that should be

measured. It means auto-ranging will have a minimum

measurement time of (1/frequency) ·frames. Example: In case

frequency is 60Hz and frames is 3, the MSE will measure at least

3 frames at an integration time of 16.66ms. This would be equal to

measuring in non-auto-range with a fixed integration time of

16.66ms and averaging of 3.

Adjmin: The adjmin parameter is very important. The higher this

level is set, the more stable the measurement becomes, but it also

slows down the measurement if set too high. That means, there is

a trade-off between speed and stability. It mainly affects the lower

grey scale levels. If these levels appear not stable, adjmin needs

to be increased. adjmin is set from 1-50, which means 1-50% of

the adjmax level. The latter one is fixed by Admesy.

Maximum integration time: Although not being part of the auto-

ranging algorithm, this parameter is used when the auto-ranging

result exceeds this setting of integration time. When the grey

scales are low (grey scale 0 for example), the maximum

integration time setting can be used to allow only a maximum

measurement time. Of course this affects stability (longer

measurement is always more stable), but again this is a trade-off

for production environments to save on test time.

7.4 Auto-range in practice

When auto-ranging is set, the measurement settings (integration time and

averaging) are automatically adjusted. This takes a bit of time of course.

An initial measurement is done to determine the final settings of averaging

and integration time, based on the settings of frequency, frames and

adjmin.

The set integration time of the instrument will always be used as the first

value to try. If this setting results in a value between adjmin and adjmax,

no further actions are necessary and the speed is optimal.

When measuring a display we can measure random patterns, but mostly

known patterns are measured. Setting an integration time that is nearly

right, 1/frequency (Hz) is preferred, as it optimizes the speed for adjusting

the auto-ranging settings and thus provides optimal results.

The following chapters show examples of measuring random patterns

(2 cases) and a gamma curve. All cases are compared by setting a fixed

integration time and a feedback of the integration time (useful for gamma

measurement).

Tables 13 and 14 on the next pages show the measurement / integration

time and also show that measurement time is greatly affected by setting

wrong initial values. For this test, a 20” TFT display (standard desktop

LCD) was used with black at 0.2 cd/m² and white at 187 cd/m² and a frame

rate of 60Hz. Settings for auto-ranging are:

Frequency = 60

Frames = 3

Adjmin = 5

19

The test patterns consist of two sets, each containing 24 colours:

Unsaturated set (figure 6)

Saturated set (figure 7)

Fig 6 Unsaturated colours.

Fig 7 Saturated colours.

The results of auto-ranging show a stability level of approximately +-0.001

on color. A higher adjmin level will logically improve this, though it

increases the total measurement time. Note that the wait time after setting

the pattern is 200ms for both tests. This wait time is display dependent.

The following table shows the timing results of measuring all 24 colours

(so, the total time for 24 patterns is shown). This time does not include the

waiting time (200ms) for the pictures to become stable, so this is purely

the real measurement time and communication time of MSE.

Initial integration time

Total measurement time

200

1.8

1.000

1.8

16.666 (1 frame)

1.7

30.000

1.8

50.000

2.8

100.000

5.5

200.000

10.5

Feedback

3.2

Table 13 Unsaturated colours.

The bold values indicate the initial integration time caused clipping. To

adjust down from clipping can take a long time since the MSE cannot tell

what the correct level is that will not clip. This situation should be avoided

as much as possible.

20

Table 14 shows the timing results for the saturated colours. This time does

not include the waiting time for the image to become stable, it is solely the

real measurement and communication time of MSE.

Initial integration time

Total time (seconds)

200

3-10

1.000

2.5-7

16.666 (1 frame)

2.9

30.000

3.2

50.000

5

100.000

6.5

200.000

12

Feedback

8.7

Table 24 Saturated colours.

A similar “clip” situation occurs (bold), but also the extreme low values

(italic) show some issues. Overall, the best timings are around the initial

integration of a single display frame.

7.5 Programming MSE for auto-ranging

MSE has start-up settings. This means that when the MSE is connected to

a PC or pattern generator, it only needs the “:meas:Yxy” command to get

luminance and colour data. All other settings can be saved as preset and

are loaded when the instrument is started. However, it requires the right

settings to be set in advance. This can be done though the Admesy Iliad

application and select DeviceStart-up settingsMSE. These settings

may be optimized per display type. There are a few categories we can

define. Those are shown in the next chapters.

Display without PWM: This display can be measured using

almost any settings, but the settings may be optimized for high

speed. This means, we can use a short integration time for bright

images (white for example) and decreased the maximum

integration of black to a level that gives stable results and is still

fast. In this case the frequency setting is not critical.

Display with PWM: Since the luminance will show PWM, a

measurement must at least cover 1 full frame. Taking more frames

will result in better stability. In this case the frequency setting is

apparently more critical to get a good stability.

Table of contents

Other Admesy Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Motrona

Motrona AX 346 operating instructions

Keithley

Keithley 2461 Reference manual

Bender

Bender ISOMETER isoHV425 manual

International Light Technologies

International Light Technologies ILT1000 API Manual

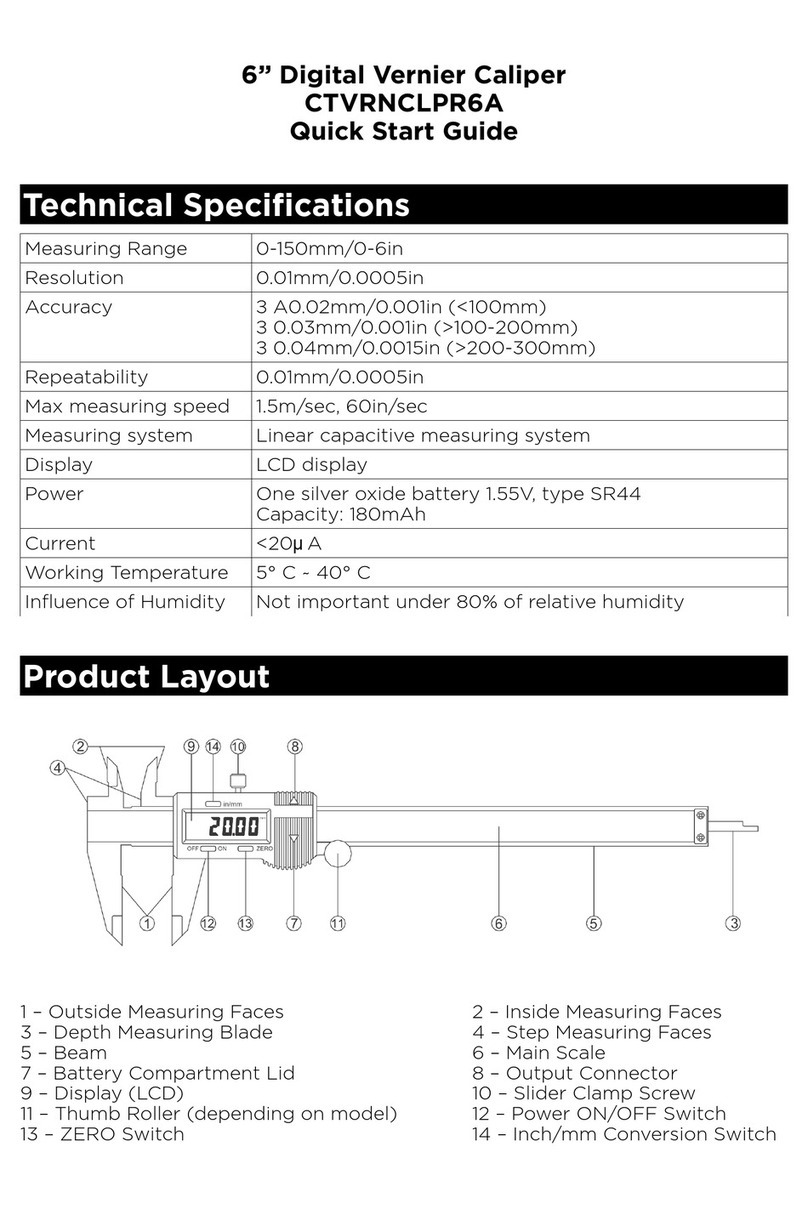

National Metallic

National Metallic CTVRNCLPR6A quick start guide

horiba

horiba D-72 instruction manual