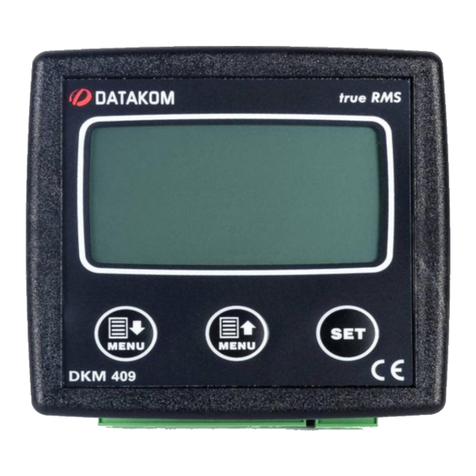

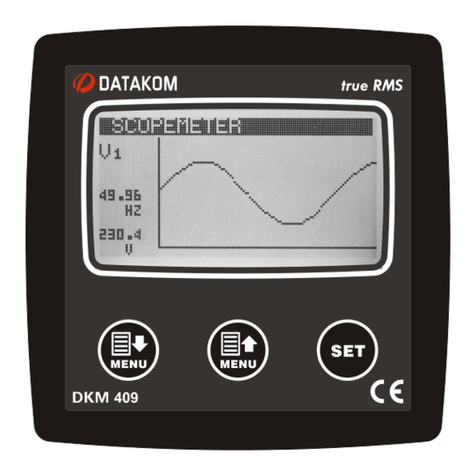

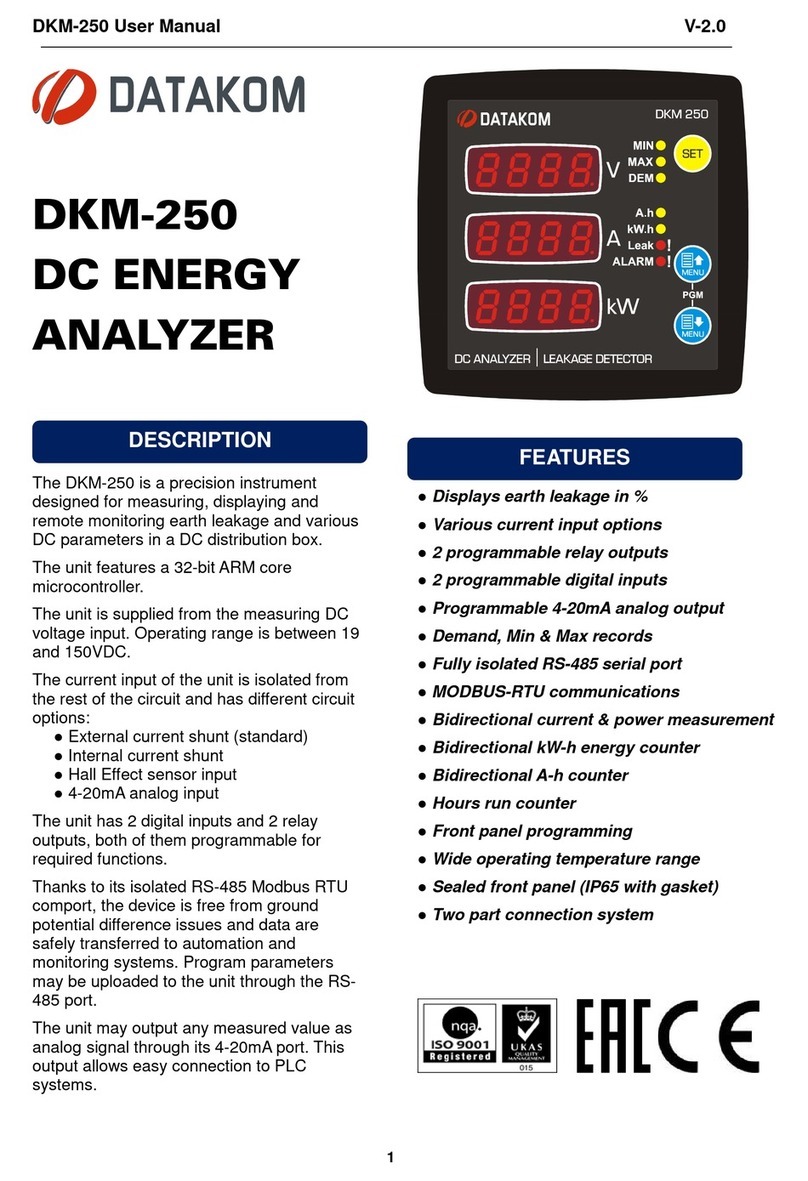

The DKM-409 is a precision instrument

designed for displaying various AC

parameters in 3-phase distribution panels.

The unit has 3 x 4-20mA analog outputs. Any

measurement can be output as analog value.

The unit has 4 digital inputs and 2 relay

outputs with programmable functionality,

selected from a list.

Thanks to its isolated RS-485 Modbus RTU

communication port, the device is free from

ground potential difference issues and

measured parameters are safely transferred

to automation systems.

* Electrical equipment should be installed

only by qualified specialist. No responsibility

is assured by the manufacturer or any of its

subsidiaries for any consequences resulting

from the non-compliance to these

instructions.

* Check the unit for cracks and damages due

to transportation. Do not install damaged

equipment.

* Do not open the unit. There is no

serviceable parts inside.

* Fuses of fast type (FF) with a maximum

rating of 6A must be connected to the power

supply and phase voltage inputs, in close

proximity of the unit.

* Disconnect all power before working on

equipment.

* When the unit is connected to the network

do not touch terminals.

* Short circuit terminals of unused current

transformers.

* Any electrical parameter applied to the

device must be in the range specified in the

user manual.

* Do not try to clean the device with solvent

or the like. Only clean with a dry cloth.

* Verify correct terminal connections before

applying power.

* Only for front panel mounting.

Before installation:

Read the user manual carefully, determine

the correct connection diagram.

Remove all connectors and mounting

brackets from the unit, then pass the unit

through the mounting opening.

Put mounting brackets and tighten. Do not

tighten too much, this can brake the

enclosure.

Make electrical connections with plugs

removed from sockets, then place plugs to

their sockets.

Note that the power supply terminal is

separated from measurement terminals.

Below conditions may damage the device:

Incorrect connections.

Incorrect power supply voltage.

Voltage at measuring terminals beyond

specified range.

Current at measuring terminals beyond

specified range.

Connecting or removing data terminals

when the unit is powered-up.

Overload or short circuit at relay outputs

Voltage applied to digital inputs over

specified range.

High voltage applied to communication port.

Below conditions may cause abnormal

operation:

Power supply voltage below minimum

acceptable level.

Power supply frequency out of specified

limits

Phase order of voltage inputs not correct.

Current transformers not matching related

phases.

Current transformer polarity incorrect.