ADOR RK3000 User manual

RK3000

High Frequency Power Supply

Microprocessor Transformer Control

for Electrostatic Precipitators

ADOR POWERTRON LIMITED

RAMNAGAR COMPLEX,

PLOT NO 51, D-II BLOCK,

MIDC, CHINCHWAD,

PUNE 411019

INDIA

Version 1.02

DRG NO: 5003-0004-13-06/1

RK3000 High Frequency Power Supply

Operating Manual

Page 2 of 73

TABLE OF CONTENTS

INTRODUCTION:MAXIMUM FLEXIBILITY WITH MINIMUM EMISSIONS.......................................................5

CHAPTER 1 COMPONENTS AND CONFIGURATIONS ...............................................................................6

Major System Components................................................................................................................................................6

Keypad and Display Unit........................................................................................................................................6

Control Unit .............................................................................................................................................................7

Control Communications Cable.............................................................................................................................8

Current Transformer..............................................................................................................................................8

Potential Transformer.............................................................................................................................................9

Secondary Signal Conditioning Resistors..............................................................................................................9

QUICK START CHART.................................................................................................................................... 10

For One-to One System Configuration................................................................................................................ 10

QUICK START CHART.................................................................................................................................... 11

For One-to-Many System Configuration............................................................................................................. 11

CHAPTER 2 OPERATING PARAMETERS AND FEATURES.................................................................... 12

DEFINITIONS OF PROGRAMMABLE PARAMETERS...............................................................................12

Average Readings.................................................................................................................................................. 13

Coordination System ............................................................................................................................................. 13

Definition of Control Responses........................................................................................................................... 13

Display ID............................................................................................................................................................... 13

Energy Management (Mgt) Setup (Optional Feature)....................................................................................... 13

External Alarm/Trip ............................................................................................................................................. 13

External Alarm Message Text ..............................................................................................................................14

Max Set Size........................................................................................................................................................... 14

Pedestal Rate.......................................................................................................................................................... 14

Phase Back ............................................................................................................................................................. 14

Power Down Rapping............................................................................................................................................14

Pre-Spark Readings............................................................................................................................................... 14

Primary Current Limit .........................................................................................................................................14

Primary Voltage Limit.......................................................................................................................................... 14

Process Sense.......................................................................................................................................................... 14

Quench Mode......................................................................................................................................................... 15

Quench Time.......................................................................................................................................................... 15

Ramp Rate.............................................................................................................................................................. 15

Rapping System Set-up ......................................................................................................................................... 15

Re-initialize............................................................................................................................................................. 15

Relay Timers.......................................................................................................................................................... 15

Conduction Display ...............................................................................................................................................15

Secondary Current Limit...................................................................................................................................... 16

Secondary Voltage Limit....................................................................................................................................... 16

Spark and Arc Control Response......................................................................................................................... 16

Spark Rate Control ...............................................................................................................................................16

Spark Sensitivity.................................................................................................................................................... 16

Soft Arc................................................................................................................................................................... 16

Software Version.................................................................................................................................................... 16

Under Voltage Trip –Primary / Secondary ........................................................................................................ 16

Under Voltage Timer.............................................................................................................................................16

DEFINITION OF NON-PROGRAMMABLE FEATURES.............................................................................. 17

Arc Numerical Display..........................................................................................................................................17

RK3000 High Frequency Power Supply

Operating Manual

Page 3 of 73

Automatic Display Calibration............................................................................................................................. 17

IGBT Firing Delay................................................................................................................................................. 17

Soft Start................................................................................................................................................................. 17

Spark Indicator and Numerical Display.............................................................................................................. 17

True RMS Primary Voltage and Current Displays............................................................................................ 17

Manual Control...................................................................................................................................................... 17

Non-Volatile Memory............................................................................................................................................ 17

Watt Meter.............................................................................................................................................................17

CHAPTER 3 DIGITAL DISPLAY.................................................................................................................. 18

Device Selection Screen.........................................................................................................................................18

Device Status Screen..............................................................................................................................................18

Electrical Reading Screen ..................................................................................................................................... 18

Prompt Screen........................................................................................................................................................19

Parameter Screen ..................................................................................................................................................19

Alarm Summary Screen........................................................................................................................................ 19

CHAPTER 4 KEYPAD DESCRIPTION ........................................................................................................ 21

CHAPTER 5 PROGRAMMING INSTRUCTIONS........................................................................................ 24

Viewing Parameters...............................................................................................................................................24

Security Programming Code Entry .....................................................................................................................24

ID Set-Up................................................................................................................................................................ 25

Coordination System ............................................................................................................................................. 26

Programming Discrete Key Parameters.........................................................................................................................27

Limits key............................................................................................................................................................... 27

RAMP.....................................................................................................................................................................29

PHASE BACK ....................................................................................................................................................... 29

PED......................................................................................................................................................................... 29

QUENCH................................................................................................................................................................ 30

PROMPT................................................................................................................................................................ 30

Clear Alarm............................................................................................................................................................ 30

Programming “Prompt Key” Parameters......................................................................................................................31

PROMPT Key........................................................................................................................................................ 31

Average Readings.................................................................................................................................................. 31

Pre-Spark Readings............................................................................................................................................... 32

Conduction Display ...............................................................................................................................................33

Spark Rate Control ............................................................................................................................................... 33

Quench Mode......................................................................................................................................................... 34

Process Sense.......................................................................................................................................................... 35

Reinitialize Interface Unit..................................................................................................................................... 35

Reinitialize Keyboard and Display Unit .............................................................................................................. 36

Software Version.................................................................................................................................................... 37

Max Set Size........................................................................................................................................................... 37

External Alarm Trip.............................................................................................................................................. 39

External Alarm Message Text ..............................................................................................................................40

Under Voltage Setup..............................................................................................................................................42

Energy Mgt Setup..................................................................................................................................................43

Wet Precipitator Wash Down System.................................................................................................................. 44

Power Down Rapping............................................................................................................................................44

Rapping System Set-up for Motor Timers (Option)........................................................................................... 45

Spark Sensitivity.................................................................................................................................................... 45

Soft Arc Detection.................................................................................................................................................. 46

Switching to Manual Operation ...........................................................................................................................46

CHAPTER 6 AIR LOAD INSTRUCTIONS ................................................................................................... 48

Pre-Operating Checkout:...................................................................................................................................... 48

RK3000 High Frequency Power Supply

Operating Manual

Page 4 of 73

CHAPTER 8 GAS LOAD ADJUSTMENTS.................................................................................................. 50

Normal Operation.................................................................................................................................................. 50

High –Resistivity Ash Operation......................................................................................................................... 50

Process Upset Operation.......................................................................................................................................50

CHAPTER 9 OPTIMIZING THE RK3000 PRECIPITATOR CONTROL OPERATION................................ 51

CHAPTER 10 DISCUSSION OF TYPICAL CONTROL WAVEFORMS........................................................ 52

Waveform #1, Quench Mode, Arc Only, Pedestal Programmed to 1 Cycle.....................................................52

Waveform #2, Quench Mode, Arc Only, Pedestal Programmed to 5 Cycles ...................................................53

Waveform #3 and #4, Quench Mode, Arcs and Sparks, Pedestal Programmed to 1 and 10 Cycles ..............54

Waveforms #5 and #6, Automatic Parameter Adjustment with Sparking and Arcing................................... 55

Waveform #7, Typical Control Waveform.......................................................................................................... 56

Waveforms #8 and #9, Back Corona Control ..................................................................................................... 57

CHAPTER 11 DESCRIPTION OF INTERFACE UNIT CONNECTIONS, LEDS, AND RELAYS.................. 58

CHAPTER 12 TECHNICAL HELP ................................................................................................................. 59

WARRANTY RETURN AUTHORIZATION................................................................................................... 60

APPENDIX I –WET PRECIPITATOR WASH DOWN SYSTEM (OPTIONAL FEATURE) ............................. 61

Wet Precipitator Wash Down System Timer.................................................................................................................61

APPENDIX II –TIMERS FOR MOTOR OPERATED CLEANING DEVICES (OPTIONAL FEATURE).......... 64

Motor Operated Electrode Cleaning Equipment Timers .............................................................................................64

APPENDIX III –LIST OF ALARM TEXTS ....................................................................................................... 67

TABLE 1 PREPROGRAMMED LEVELS AND OPERATING RANGES............................................... 68

INDEX QUICK REFERENCE .................................................................................................................. 69

RK3000 High Frequency Power Supply

Operating Manual

Page 5 of 73

INTRODUCTION: Maximum Flexibility with Minimum Emissions

Ador’s RK3000 High Frequency transformer-rectifier control is designed specifically for

use on electrostatic precipitators.

An extremely high degree of control flexibility is available through the RK3000’s many

easily programmed operating parameters and automatic features. This flexibility, in turn,

results in maximum precipitator efficiency and minimum outlet emissions.

This manual will define all the pre-programmed and field programmable features of the

RK3000 control, as well as provide a description of the control components. A description

of typical waveforms, and suggestions for optimizing the control’s operation, are also

included.

RK3000 High Frequency Power Supply

Operating Manual

Page 6 of 73

CHAPTER 1 COMPONENTS AND CONFIGURATIONS

Major System Components

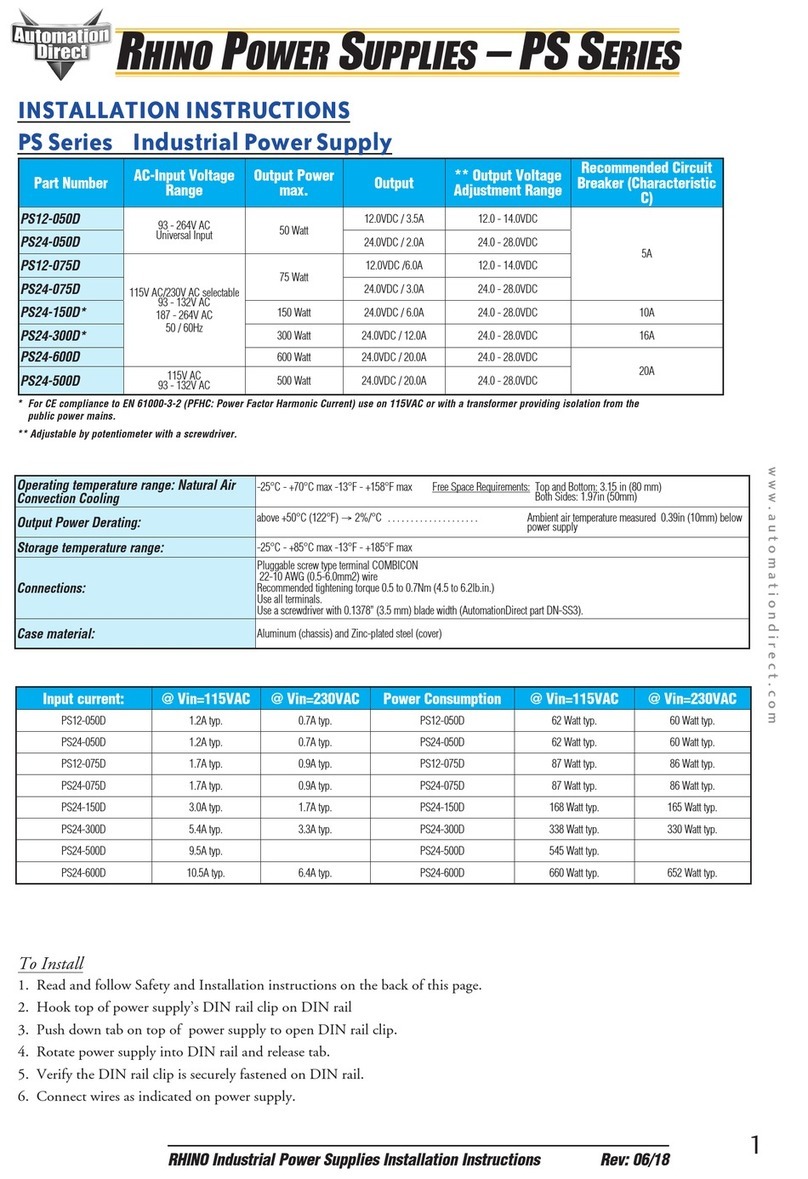

The following descriptions and pictures are presented to familiarize the user with the six

components that make up the RK3000 High Frequency transformer-rectifier control: The

photos shown are typical and may vary slightly from those shown.

The following is a list and definition of the major control components.

oKeypad and Display Unit

oControl Unit

oInterface Communications Cable

oCurrent Transformer

oPotential Transformer

oSecondary Signal Conditioning Resistors

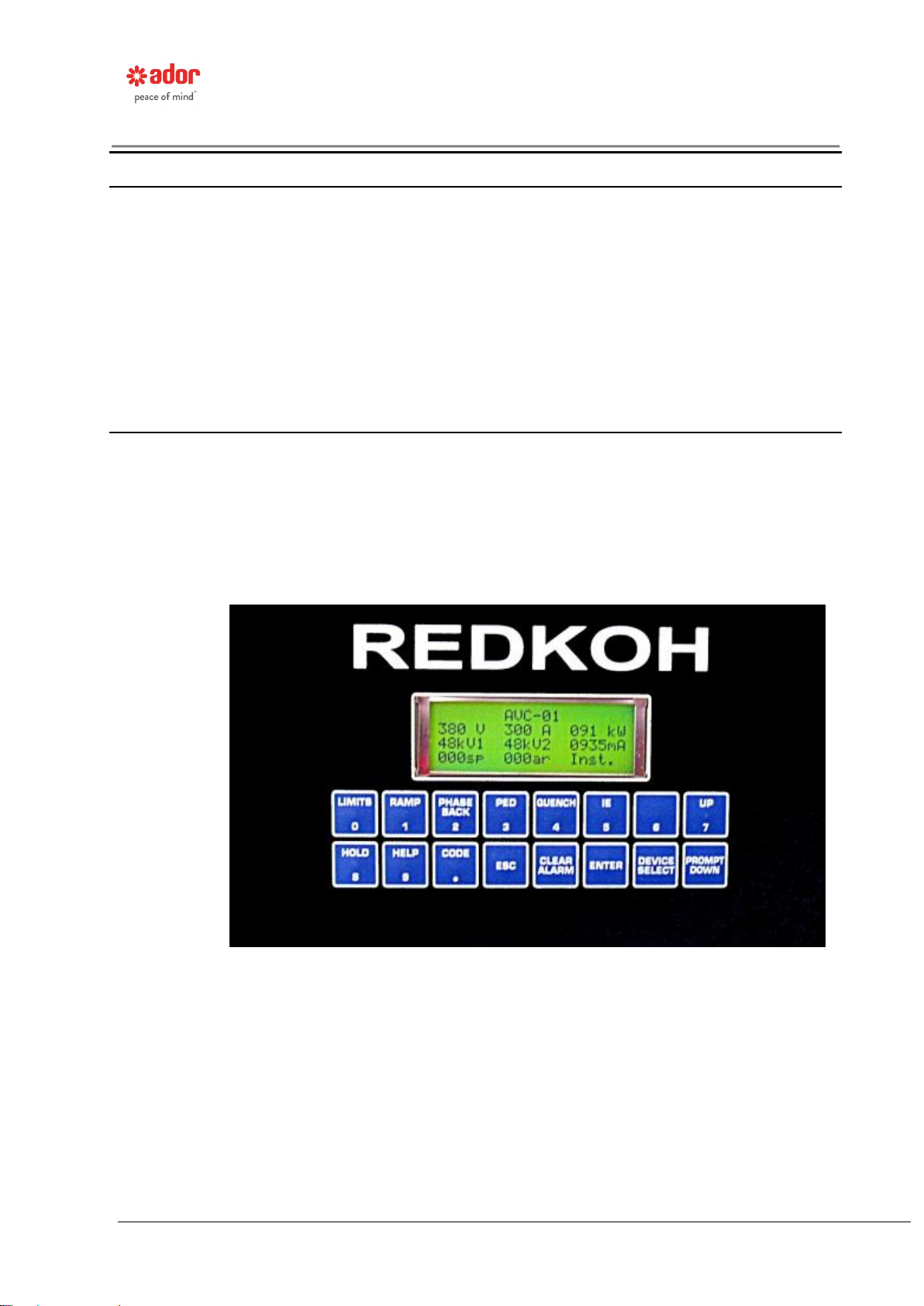

Keypad and Display Unit

The Keypad and Display Unit is the user interface to the various operating modes and

variable parameters of the system. It communicates with one or more Interface Boards.

Electrical readings, programming screens, alarm messages, operating messages, and

communication information, are displayed on the face of this unit. A keyboard, for

programming purposes, is also located on the face of this unit.

Figure 1: Keypad and Display Unit

RK3000 High Frequency Power Supply

Operating Manual

Page 7 of 73

Control Unit

The Control Unit is the interface between the analog and digital signals present in the

control and feedback circuits. The IGBT firing circuit is located on this Unit. It responds

to precipitator operating conditions based on the parameters programmed into the

Keyboard and Display Unit. The switches for setting the Control Unit ID number are

also located on this Unit.

Figure 2: Control Unit

RK3000 High Frequency Power Supply

Operating Manual

Page 8 of 73

Control Communications Cable

This cable is used between the Keypad and Display Unit, and the Control Unit to provide

a communications link for passing data.

Figure 3: Control Communications Cable

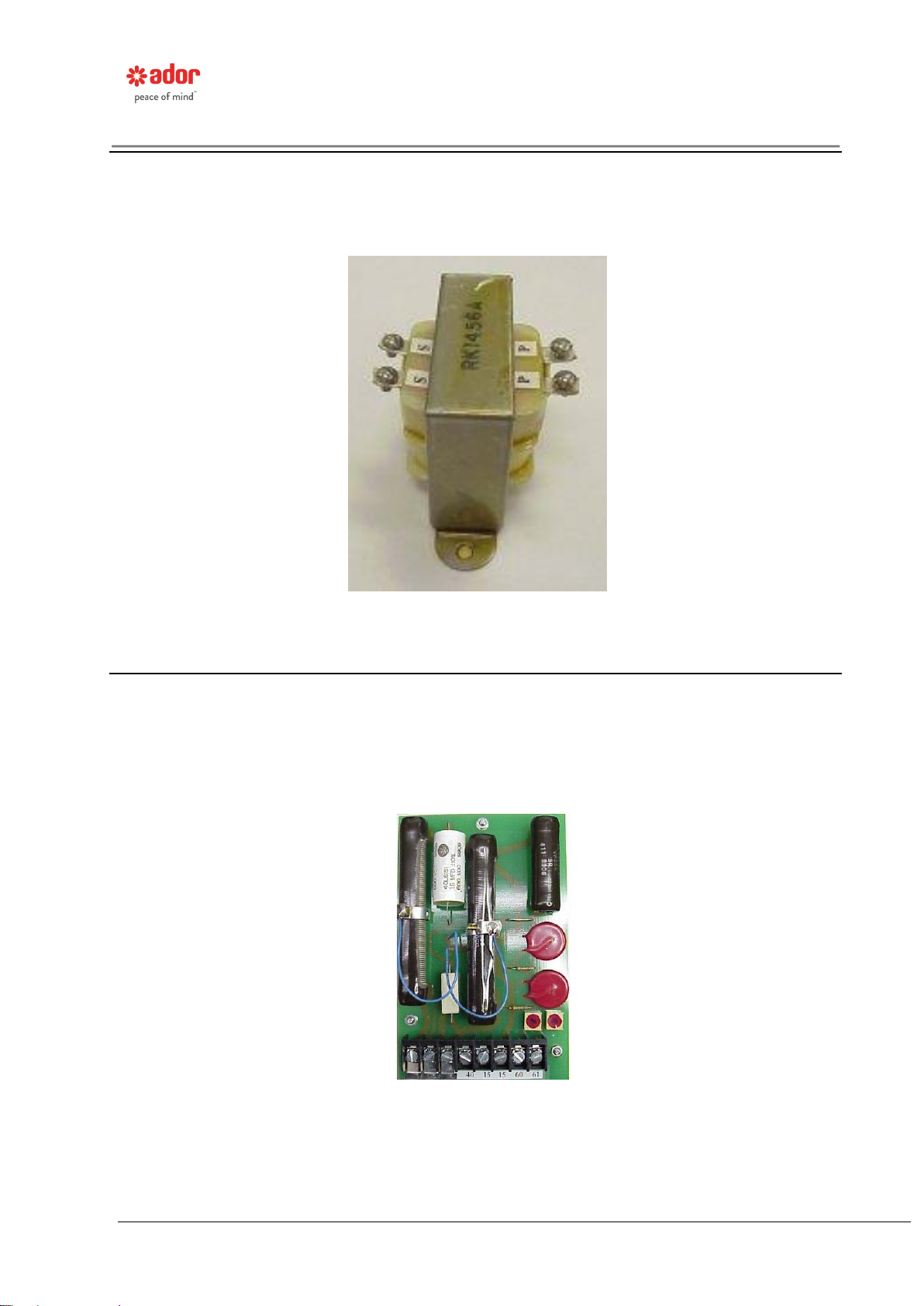

Current Transformer

The Current Transformer (CT) and load resistor combination, when properly set, provides

a 5V signal, at rated current, to the Control Unit. The signal is used for primary current

display and limit.

Figure 4: Current Transformer

RK3000 High Frequency Power Supply

Operating Manual

Page 9 of 73

Potential Transformer

The Potential Transformer (PT) measures the transformer primary voltage and provides a

reference signal to the Control Unit. The PT has a ratio of 600 volts to 20 volts. The

signal is used for primary voltage display and limit.

Figure 5: Potential Transformer

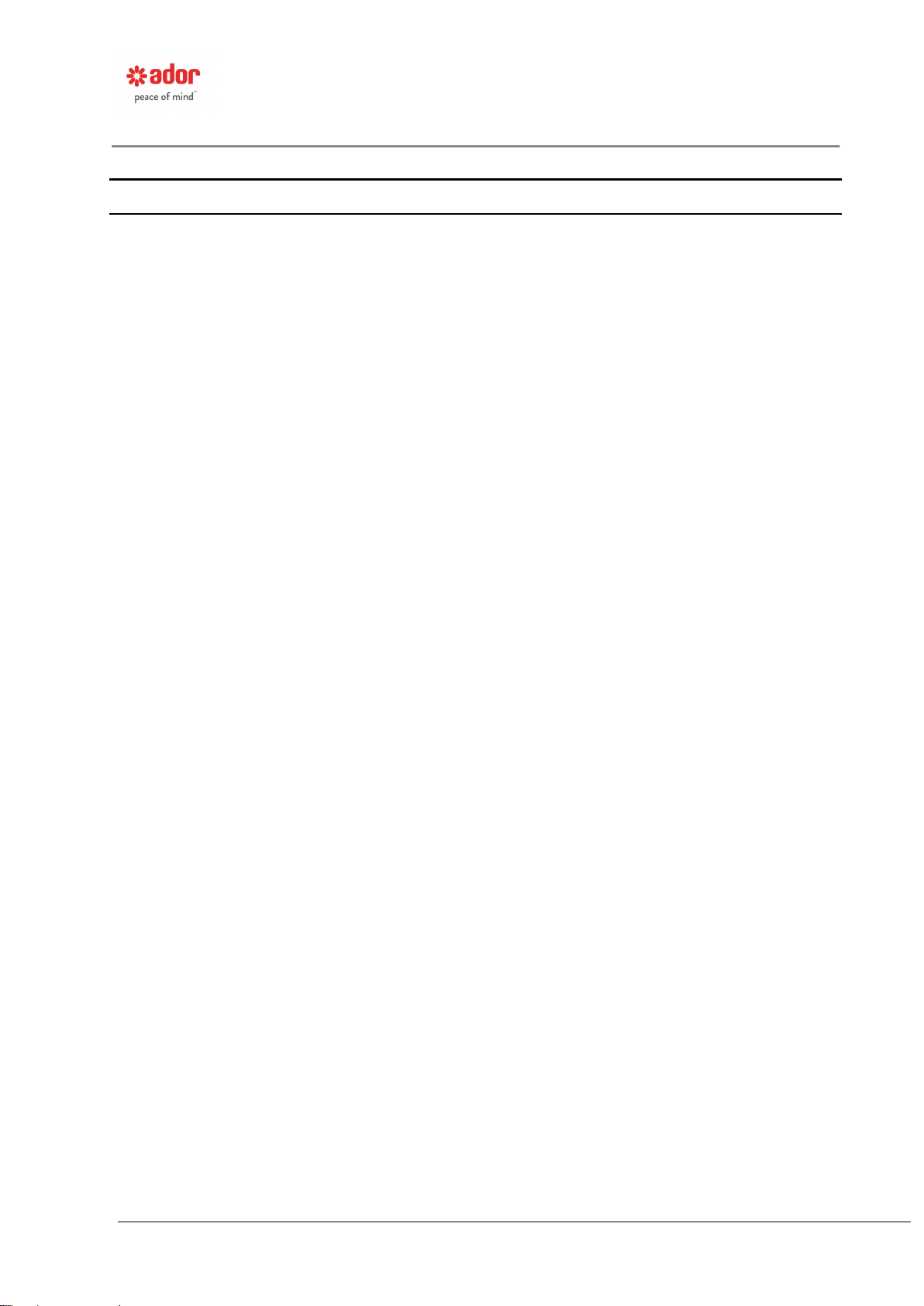

Secondary Signal Conditioning Resistors

Signal conditioning resistors are provided for both the secondary current and secondary

voltage reference signals. Their values will vary depending on the transformer-rectifier

rating. See schematic diagrams for proper values. These signals are sent to the Control

Unit for secondary voltage and current display and limits, as well as spark pickup. Full

scale is represented by a 5V signal.

Figure 6: Secondary Signal Conditioning Resistors

RK3000 High Frequency Power Supply

Operating Manual

Page 10 of 73

QUICK START CHART

For One-to One System Configuration

(See page 24)

A one-to-one system configuration is defined as a system where there is

one Keypad and Display Unit, and one Control Unit physically installed

on each control cabinet. If you have more than one Keypad and Display

Unit associated with more than one Control Unit see the Quick Start Chat

for a One-to Many Configuration (next page).

Not all parameters and operating modes need to be programmed in order

to get the control(s) up and running. To get started quickly, for each

control cabinet, follow the instructions in the order that they appear

below.

1. Enter the Programming security code (page 24).

2. Program the Max Set Size (page 41).

3. Program the Limits (page 27).

The other parameters and operating modes have default values, based

on typical precipitator operation. They will allow the control and

precipitator to operate, but at less than optimum efficiency. All default

values should be reprogrammed, as needed, to optimize the precipitator

efficiency and minimize outlet emissions.

At this point all the control IDs and Names will be the same. Reprogram

the control ID set-up (page 25) to give each TR control a unique name, if

desired.

RK3000 High Frequency Power Supply

Operating Manual

Page 11 of 73

QUICK START CHART

For One-to-Many System Configuration

(See page 24)

A one-to-many system configuration is defined as a system where there

is one or more Keypad and Display Units communicating with one or

more Control Units, regardless of location. If you have only one Keypad

and Display Unit associated with only one Control Unit see the chart for

the One-to-One configuration.

Not all parameters and operating modes need to be programmed in order

to get the control(s) up and running. To get started quickly follow the

instructions in the order that they appear below. This must be done

for each Keypad and Display Unit and each Control Unit (control

cabinet), as applicable.

1. Enter the security code (page 26).

2. Follow the ID set-up on page 25.

3. Program the Max Set Size (page 37).

4. Program the Limits (page 27).

The other parameters and operating modes have default values, based

on typical precipitator operation. They will allow the control and

precipitator to operate, but at less than optimum efficiency. All default

values should be reprogrammed, as needed, to optimize the precipitator

efficiency and minimize outlet emissions.

RK3000 High Frequency Power Supply

Operating Manual

Page 12 of 73

CHAPTER 2 OPERATING PARAMETERS AND FEATURES

The following is a list of the operating parameters and features incorporated in the

RK3000 control. This list is followed by definitions (broken into programmable and non-

programmable groups), and later in this manual, detailed instruction on how the

parameters are programmed.

Arc Numerical Display

Automatic Display Calibration

Average Readings

Coordination System

Display ID

Energy Management Setup

External Alarm/Trip

External Alarm Message Text

Instantaneous Kilowatt Display

Manual Control

Message Display

Nonvolatile Memory

Pedestal Rate

Phase Back

Power Down Rapping

Pre-Spark Readings

Primary Current Limit

Primary Voltage Limit

Process Sense

Quench Mode

Quench Time

Ramp Rate

Rapper System Set-up

Reinitialize Control Unit

Reinitialize Keypad and Display Unit

Relay Timers

Conduction Display

Secondary Current Limit

Secondary Voltage Limit

Separate Spark and Arc Control Responses

Soft Start

Soft Arc Detection

Spark Numerical Display

Spark Sensitivity

Spark Rate Control

Efficiency Display

True RMS Primary Voltage & Current Display

Under Voltage Time Delay

Under Voltage Trip –Primary

Under Voltage Trip –Secondary

DEFINITIONS OF PROGRAMMABLE PARAMETERS

The following definitions explain the programmable parameters available in the

microprocessor transformer-rectifier control. Programming instructions are presented

later in this manual. All programmable parameter values are entered into control memory

through a 16-key, sealed membrane, dual-function keypad located on the control panel

door (see page 21).

To prevent tampering with the control, a four-digit security programming access code is

required to gain access to the programming mode (see page 24).

RK3000 High Frequency Power Supply

Operating Manual

Page 13 of 73

Average Readings

For situations where the process being controlled is highly erratic or fluctuates a great

deal, the display can be programmed to show average electrical readings over a 5

second time period. This smoothes the display movement and makes it easier to read.

Coordination System

Timer relays are an optional feature of the control system. When timer relays are

supplied, their operation must be coordinated so that, if desired, multiple relays are not

operating at the same time. This only affects systems that are using the relays for

operating motor driven rapping systems or wet precipitator wash down systems.

Definition of Control Responses

A transformer-rectifier will operate at its rated current or voltage levels unless the

microprocessor transformer control circuitry detects a transient. When a transient is

detected, the control automatically takes action to lower the operating levels of voltage

and current.

The types of transients that the control detects are:

Spit –Low current, fast rise time electrical discharge that extinguishes itself

instantaneously. Due to self-extinguishing characteristics, the RK3000 takes no control

action when a spit is detected.

Spark –Low current, relatively slow rise time electrical discharge that persists for one half

cycle or less before extinguishing. The control phases back (reduces) the power for this

condition.

The spark rate that is displayed in the Electrical Reading Screen is a sixty (60) second

rolling average of these spark occurrences.

Arc –High current electrical discharge that persists for great than one-half cycle and

usually requires removal of electrical power before it will extinguish. The control

quenches (turns off) the power for this condition.

The arc rate that is displayed in the Electrical Reading Screen is a sixty (60) second

rolling average of these arc occurrences.

Display ID

In order for information to be properly transferred between the Keypad and Display Unit

and the Control Unit, over the communications system, each Keypad and Display Unit

must have a unique ID number.

Energy Management (Mgt) Setup (Optional Feature)

If your control system is communicating with a Transceiver(communication gateway

between TR, Rapper, and Central controls), and the optional Energy Management

System has been included in the Transceiver, the control can be assigned to one of four

independent energy management systems. And within each energy management system

the control can be assigned to a particular electrical field.

External Alarm/Trip

There are four (4) external alarm inputs (Alarm 1 through Alarm 4) that can be used to

connect normally closed alarm contacts for such things as high TR temperature, high/low

TR oil level, full hopper condition, drag conveyor failure, high O2, or any other condition

where a TR alarm or trip may be desired.

RK3000 High Frequency Power Supply

Operating Manual

Page 14 of 73

External Alarm Message Text

In conjunction with the external alarm inputs, there are preprogrammed tags

(descriptions) that can be assigned to each input. .

Max Set Size

The same microprocessor control components are used regardless of the size of the TR

they are connected to. In order for the control to know what size TR it is connected to,

the TR name plate ratings are field programmed into the control in a programming screen

called Max Set Size.

Pedestal Rate

This feature operates in conjunction with Quench (see quench definition on page 15).

After each Quench, the rate at which the power is reapplied to the precipitator is the

Pedestal Rate. The Pedestal Rate is a programmable parameter (see Preprogrammed

Levels And Operating Ranges, page 68). The rate is the number of cycles to recover

from zero to the equivalent Phase Back level had the arc been a spark. (For a more

detailed description of Pedestal Rate see the Discussion of Typical Control Waveforms on

page 52).

Phase Back

Phase Back is the amount of power reduction that takes place after each spark

occurrence. The amount of Phase Back is programmable (see Preprogrammed Levels

And Operating Ranges, page 68).

Since it is undesirable to operate at high sparking levels, the Phase Back reduces power

in an effort to keep the operating power just below the threshold of sparking. Typically,

fewer sparks result in more uniform power in the precipitator and more stable precipitator

efficiency. (For a more detailed description of Phase Back, see Discussion of Typical

Control Waveforms, page 52).

Power Down Rapping

If the TR controller is communicating with a Microprocessor Rapper Control (MRC-NT)

over a communications loop, or the optional relays and timers are installed on the Control

Unit for controlling motor drives of mechanical rappers, the TR power level can be set for

a value below the automatic level when rappers are energized. Lower power levels make

it easier for the particulate to be released from its collecting surface.

Pre-Spark Readings

The display shows the last set of electrical readings that were taken prior to a spark. It is

used for diagnostic purposes when trying to determine the kV spark over level.

Primary Current Limit

The Primary Current Limit is typically programmed for the nameplate current rating of the

transformer-rectifier being controlled. The Primary Current Limit prevents the

transformer-rectifier primary current from exceeding the programmed value. This limit

can be used to limit operation of the control below the transformer rated current, if

desired.

Primary Voltage Limit

The Primary Voltage Limit is typically programmed for the nameplate current rating of the

transformer-rectifier being controlled. The Primary Voltage Limit prevents the

transformer-rectifier primary current from exceeding the programmed value. This limit

can be used to limit operation of the control below the transformer rate primary voltage, if

desired.

Process Sense

The Process Sense function monitors the time between sparks and arcs. It automatically

overrides the Ramp function if a spark or arc does not occur within a programmable

RK3000 High Frequency Power Supply

Operating Manual

Page 15 of 73

period of time from the last spark or arc occurrence. (For a more detailed description of

Process Sense, see Discussion of Typical Control Waveforms, page 52).

This control feature assures stable and rapid recovery after a process upset has

subsided.

Quench Mode

The Quench Mode is programmable; it can activate the Quench time for “Arcs Only” or for

“Sparks and Arcs”.

With the Quench Mode set to Arcs Only, the detection of a second spark within the Arc

Delay time will cause the Quench Time feature to become active. This is the preferred

operating mode for precipitators collecting ash from the burning of coal.

With the Quench mode set to Sparks and Arcs, the detection of a spark will cause the

Quench time to become active (For a more detailed description of Quench Mode, see the

Discussion of Typical Control Waveforms, page 52.)

Quench Time

When a second spark occurs within the Arc Delay time it is considered an arc and it is

necessary to turn off the power for at least one system cycle to ensure the arc is

extinguished. Turning off power after this second spark is detected is called Quench.

The length of time a Quench occurs is the Quench Time, and its length is programmable

(see Preprogrammed Levels And Operating Ranges, Page 68).

Ramp Rate

The Ramp Rate is the rate at which the precipitator power increases after a Phase Back.

Power recovery starts from the Phase Back level and continues at the Ramp Rate until

either current limit or voltage limit is reached or a spark or arc occurs. The time

programmed for the Ramp Rate is the time it takes the power to increase from the Phase

Back level to pre-spark current level.

The Ramp Rate is field-programmed (see Preprogrammed Levels and Operating Ranges,

page 68) for the lowest opacity operation under normal operating conditions (For a more

detailed description, see Discussion of Typical Control Waveforms, page 52).

Rapping System Set-up

If onboard timers, and relays located on the Control Unit, are being used to operate

motors that drive mechanical rapping systems, this set-up allows the timing and anti-

coincidence parameters to be programmed.

Both the Interval and On-time of the motors as well as groupings for non-simultaneous

operation of the motors can be adjusted.

Re-initialize

Selecting this routine erases the contents of control memory and resets all parameters to

their default values. There are two different re-initialization routines, one for the Control

Unit and one for the Keypad and Display Unit. The control must be reprogrammed after a

re-initialization is requested.

Relay Timers

This control can be configured with up to four on-board relays with normally open

contacts. The on and off times of these relays are set through the keypad. These relays

can be used for controlling motor operated cleaning systems, electric vibrators, air

solenoids, and wet precipitator wash-down systems.

Conduction Display

The control can be programmed to display the IGBT firing percentage. How closely a

control is matched to the actual transformer load is judged by comparing the actual

RK3000 High Frequency Power Supply

Operating Manual

Page 16 of 73

conduction percentage versus the maximum permissible conduction percentage (100%).

The conduction percentage will also be affected by the level of sparking and arcing being

detected.

Secondary Current Limit

The Secondary Current Limit is typically programmed for the nameplate secondary

current rating of the transformer-rectifier being controlled. The Secondary Current Limit

prevents the transformer-rectifier from exceeding the programmed value. This limit can

be used to limit operation of the control below the transformer rated secondary current if

desired.

Secondary Voltage Limit

The Secondary Voltage Limit is typically programmed for the nameplate secondary

current rating of the transformer-rectifier being controlled. The Secondary Current Limit

prevents the transformer-rectifier from exceeding the programmed value. This limit can

be used to limit operation of the control below the transformer rated secondary current if

desired.

Spark and Arc Control Response

The default operating mode is for a spark to initiate a Phase Back, and a second spark

within the Arc Delay time to initiate a Quench. An alternate response of all sparks

initiating a Quench is available.

Spark Rate Control

This mode of operation allows a specific spark rate to be programmed into the control.

The control will then automatically readjust itself to maintain a spark rate equal to the

programmed rate.

Spark Sensitivity

Allows the detection of a spark to be based on a secondary voltage drop rather than a

secondary current increase.

Soft Arc

Where electrical noise, poor electrical grounds, or small signal to noise ratios exist, arc

detection can be performed based on a specific value of secondary voltage increase

simultaneously with a specific value of secondary current decrease.

Software Version

The display can be enabled to show the part number and the version of the software

presently being used in both the Keypad and Display Unit, and the Control Unit.

Physically opening up the control to check these items is no longer necessary.

Under Voltage Trip –Primary / Secondary

If the primary voltage level drops below the programmed Primary Under Voltage Trip

Level, for longer than the number of seconds programmed into the Under Voltage Timer

(see Preprogrammed Levels And Operating Ranges, page 68) and the Primary Current is

more than 20% of its rated value, the control will automatically de-energize. This feature

reduces clinker formation due to full hoppers, increases discharge electrode life by

eliminating energization of slack wires caused by full hoppers, and reduces the chance of

support insulator failure due to tracking.

The same above control function occurs if the under voltage trip is programmed for

Secondary Under Voltage Trip instead of Primary.

Under Voltage Timer

When an under voltage condition is detected (primary or secondary voltage operating

below their under voltage set point level) a delay time can be set to delay the tripping of

RK3000 High Frequency Power Supply

Operating Manual

Page 17 of 73

the control. This time delay allows for a ground condition to clear before the control is de-

energized.

DEFINITION OF NON-PROGRAMMABLE FEATURES

The following are definitions of the non-programmable features that are built into the

RK3000 control.

Arc Numerical Display

The Electrical Reading Screen shows the number of Arcs Per Minute that are occurring.

Automatic Display Calibration

External variable resistors perform the calibration for the control feedback signals. These

resistors are located on the primary current transformer (CT) and on the secondary

current and secondary voltage signal conditioning resistor panel. It is not necessary to

recalibrate any part of the control if replacing a Keypad and Display Unit or a Control Unit.

IGBT Firing Delay

A firing delay of 30 seconds is required for the system to charge the rectifier bank

capacitors. This delay only occurs when the power to the cabinet has been turned off and

then on again (power loss or breaker trip).

Soft Start

When the on/off switch is turned on the conduction of the IGBT is slowly increased, and in

turn the power to the precipitator. This slow power rise eliminates current inrush on the

power feeders and substations.

Spark Indicator and Numerical Display

The Electrical Reading Screen shows the number of Sparks Per Minute that are occurring

as well as a decimal point that flashes each time a spark occurs.

True RMS Primary Voltage and Current Displays

The primary voltage and current are displayed as true RMS values, not average values.

Manual Control

Should the need arise; the control can be operated in the Manual mode. An auto/manual

toggle switch is located on the upper right of the Control Unit (see page 58). When

switched to Manual mode, the message “Manual Mode” will be displayed on the display

status line. When in manual, the control can be operated between 0 and 100% of

conduction by adjusting the Manual bias potentiometer located in the mid right area of the

Control Unit

Non-Volatile Memory

The RK3000 utilizes EEPROM (electronically erasable programmable read only memory)

for storage of all preprogrammed and field-programmed information. EEPROMs do not

require battery backups and are a nonvolatile memory with indefinite storage life.

Watt Meter

The instantaneous power consumption of each TR control is displayed on a continuous

basis on the Electrical Reading screen.

RK3000 High Frequency Power Supply

Operating Manual

Page 18 of 73

CHAPTER 3 DIGITAL DISPLAY

The digital display is an integral part of the Keypad and Display Unit (see page 6) and is

located on the control cabinet front door. All operating and programmable parameters are

viewed on this 4 line by 20-character liquid crystal display (LCD).

There are six (6) individual screen views that are used for programming and display

purposes. These screens are:

Device Selection Screen

When controlling more than one Control Unit on a Display and Keyboard Unit, this screen

shows the Control Unit the display is communicating with and allows choosing a Control

Unit for data display or programming.

This is the opening screen if one Keypad and Display Unit is being used to control more

than one Control Unit or Control Cabinet.

If the Keypad and Display Unit is present on each control cabinet, the opening screen will

be the Device Status Screen.

Using the up and down arrow keys on the keypad, the desired ID number/TR Name is

scrolled in between the arrows. Pressing the ENTER key now will bring up the Device

Status Screen for the chosen ID number.

Device Status Screen

Displays operating conditions of an individual control. Data such as Run/Stop, Alarm

messages, Status messages, etc. are shown here.

This is the opening screen if each control cabinet contains its own Keypad and Display

Unit.

If the Keypad and Display Unit controls more than one control cabinet, this screen comes

up when an ID number is chosen from the Device Selection Screen.

Electrical Reading Screen

Shows the electrical levels of the primary and secondary voltages and currents as well as

spark and arc rates. Instantaneous kW consumption and operating mode are also

shown.

Pressing the ENTER key while in the Devise Status Screen brings up the Electrical

Reading Screen for the same control ID.

Device Selection

> ID 1 RED-01

ID 2 RED-02

ID 3 RED-03

RED-01

Stop. Continuous

Open Contactor

RED-01

205 V 159 A 026 kW

56kV1 00kV2 1874mA

000sp 000ar Inst.

RK3000 High Frequency Power Supply

Operating Manual

Page 19 of 73

The “Mode” area will display various messages (such as Stop, Avg., and Inst. as they

occur –these abbreviations will be explained later in the manual). When in the Stop

mode a decimal point will flash after the “p” to indicate the Keypad and Display unit is

working. The control default operating mode is “Instantaneous” energization. In this

operating mode “Inst.” Will appear in the mode area.

If the control being viewed on the Electrical Reading Screen encounters a Communication

Error alarm, the values for all the readings will reset to zeros and six question marks will

appear in the mode area (see screen below). The control may still be operating normally,

however, the Keypad and Display Unit has no way of knowing the status at the Interface

Board.

Prompt Screen

Displays all the parameters that are available for programming under the PROMPT key.

When the desired parameter appears in the display and the ENTER key is pressed, the

display changes to the Parameter Screen.

TR NAME

Parameter Name

Parameter Screen

Permits programming of the selected parameter, showing valid choices.

Parameter Name

Programming Choices

Alarm Summary Screen

Identifies control names and alarms associated with those controls. The elapse time from

the alarm occurrence in days, hours, minutes, and seconds is also provided. The arrow

keys are used to scroll between multiple alarms on the same control as well as alarms on

other controls.

If no key has been pressed for five minutes, and an alarm occurs, the control will

automatically switch to the Alarm Summary Screen.

Note: If any of the above screens display “Update in Progress” it means the Keypad and

Display Unit has requested data from the Control Unit and it is waiting for the data. This

condition should normally last only a fraction of a second. If this phrase remains on the

screen it may indicate a communications problem between the two units.

The following is a list of the alarm and status message that may appear in the Device

Status Screen. The detailed meaning of each message will be fully explained later in this

manual.

RK3000 High Frequency Power Supply

Operating Manual

Page 20 of 73

Status Messages

Average Readings

-electrical readings are 5 second averaged values

Energy Mgt Mode

-energy management mode active

Manual Mode

-manual mode of operation active

Peak Readings

-electrical readings are peak value

Open Contactor

-control has de-energized the main contactor

Pre-Spark Readings

-electrical readings are pre-Spark values

Stop Mode

-Control is “off”

Power Down Rapping

-reduced KV limit active

Under Voltage

-Under voltage detected and trip may follow

Alarm Messages

See appendix III

Full Hopper

-hopper beneath TR area is full

High O2Trip

-Trip due to high O2in flue gas

High IGBT Temp

-main IGBT heat sink is at an over temperature level

Low T/R Level

-low transformer-rectifier oil level

High T/R Temp

-high transformer-rectifier oil temperature

Communications

Error

-communication error between Keypad and Display

Unit, and Control Unit

MRC Comm. Error

-communication error between the TR control and the

Rapper control when Power Down Rapping is active

Master Fuel Trip

-control de-energized due to master fuel trip\

Memory Clear

-memory has been cleared

Under voltage

-Trip due to under voltage condition

Alarm 1

-User defined alarm/trip

Alarm 2

-User defined alarm/trip

Alarm 3

-User defined alarm/trip

Alarm 4

-User defined alarm/trip

If more than one alarm or status message occurs at the same time, they will be scrolled at

two (2) second intervals in the alarm area of the Device Status Screen. Any number of

alarm or status messages may be present.

NOTE:

Alarms that cause a control to trip require that the ON/OFF switch on the

front of the control cabinet be turned to OFF then ON to reset the control.

The Alarm Clear key must be pressed to clear the alarm from the display

after the cause has been remedied. If the alarm condition is still present,

the control will again trip.

Table of contents