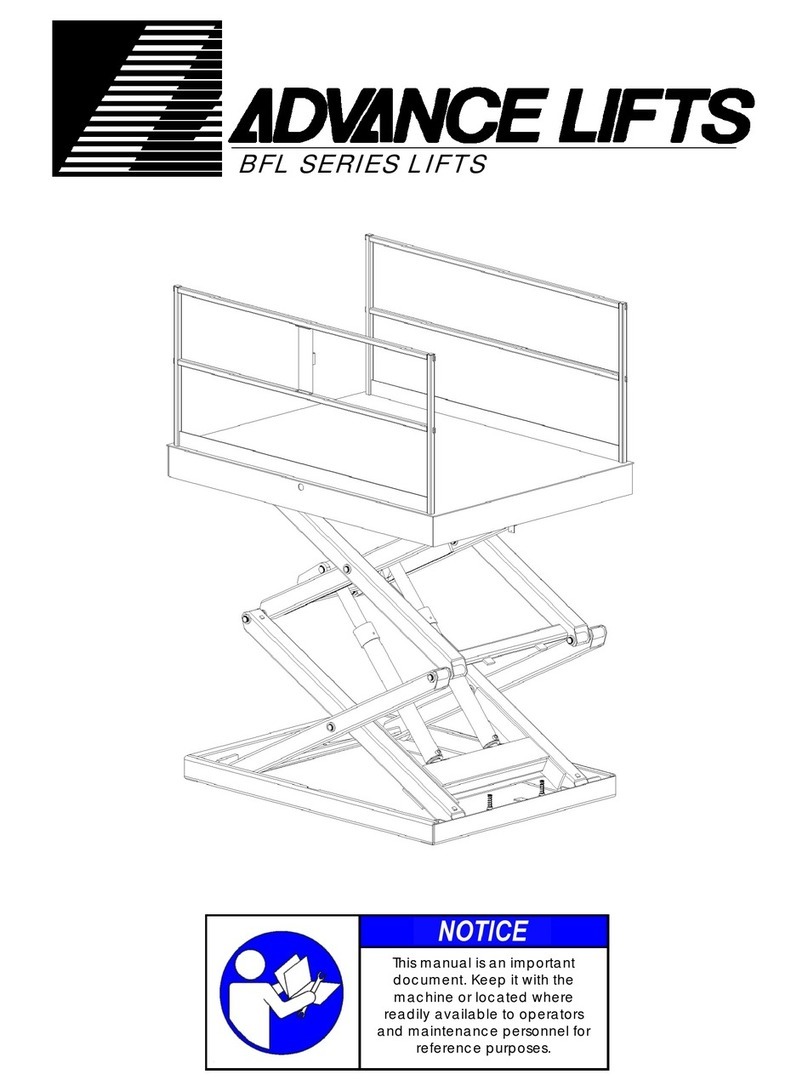

Responsibility of Operators

Workplace Inspections: Before the industrial scissors lift is used and during use, the operator

shall check the area in which the industrial scissors lift is to be used for possible hazards such

as, but not limited to:

1. Bumps, floor obstructions and uneven surfaces

2. Overhead obstructions and electrical hazards

3. Presence of unauthorized persons

4. Other possible unsafe conditions as noted in the operating manual.

Operator Warnings and Instructions: The operator shall ensure the operation of the industrial

scissors lift is in compliance with the following:

1. Slope. The industrial scissors lift shall only be operated on flat and level surfaces.

2. Guardrail system. Guardrails shall be installed and positioned, and access gates or

openings shall be secured per the manufacturer’s instructions.

3. Distribution of load. The load and its distribution on the platform and any platform

extension(s) shall be in accordance with the manufacturer’s rated capacity for that specific

configuration.

4. Maintaining overhead clearance. The operator shall ensure that adequate clearance is

maintained from overhead obstructions and energized electrical conductors and parts.

5. Point of Operation. The operator shall not place any part of their body under the platform.

6. Personnel footing. Personnel shall maintain firm footing on dock lifts and work access lifts

while working thereon. Climbing by occupants on the guardrail system is prohibited. The use

of planks, ladders, or any other devices on the platform for achieving additional height is

prohibited.

7. Precaution for moving equipment. When other moving equipment or vehicles are

present, special precautions shall be taken to comply with the safety standards established

for the workplace.

8. Reporting problems or malfunctions. The operator shall immediately report to a

supervisor any problem(s) or malfunction(s) that become evident during operation. The

operator shall ensure all problems and malfunctions that affect the safety of operations are

repaired prior to continued use.

9. Capacity limitation. Rated capacity shall not be exceeded when loads are transferred to

the platform at any level.

10. Work area. The operator shall ensure the area surrounding the industrial scissors lift is

clear of personnel and equipment before lowering the platform.

11. Battery charging. Batteries shall be charged in strict accordance with the lift

manufacturer’s instructions.

12. Securing the industrial scissors lift. The operator shall comply with the means and

procedures provided to protect against use by an unauthorized person(s).

13. Altering safety devices. Safety devices shall not be altered or disabled.

14. Modifications. Modifications or alterations of an industrial scissors lift or the fabrication and

attaching of frameworks or the mounting of attachments for holding tools or materials onto

the platform or the guardrail system shall only be accomplished with prior written permission

of the manufacturer.

15. Assistance to the operator. If an operator encounters any suspected malfunction or any

hazard or potentially unsafe condition relating to capacity, intended use or safe operation

the operator shall cease operation of the industrial scissors lift and request further

instruction from the owner/user.

16. Problems or malfunctions. Any problem(s) or malfunction(s) that affect the safety of

operations shall be repaired prior to the use of the industrial scissors lift.

P 3-3