Advance Lifts BFL Series User manual

This manual is an important

document. Keep it with the

machine or located where

readily available to operators

and maintenance personnel for

reference purposes.

BFL SERIES LIFTS

Installation, Operation and Maintenance

Manual for the Following Equipment:

All BFL Series Lifts

This manual contains specific information for your equipment, see manual inserts.

In any correspondence with your distributor, you will need the following information:

Model Number______________________ Serial Number_____________________________

Installation location: __________________________________

__________________________________

__________________________________

Distributor Information: ______________________________

_______________________________

_______________________________

Advance Lifts, Inc.

701 S. Kirk Road

St. Charles, IL 60174-3428

Toll Free 1-800-843-3625

Sales Fax 1-630-584-9405

Parts and Service Fax 1-630-584-6837

E-mail: Parts@advancelifts.com

*Advance Lifts, Inc. furnishes one manual with each unit. Additional manuals are available for

$25.00 each.

P 1-1

At Initial Installation, determine proper motor/pump rotation by starting the

motor in very short intervals to prevent permanent pump damage. Running the

pump backwards will damage it. See the Installation Instructions, Section 4, for

proper procedure.

SECTION 2. INDEX & INTRODUCTION

Identification Sheet…………………………………………………………. Section 1

Index & Introduction………………………………………………………… Section 2

*Responsibilities Of Owners & Users….………………..……………….. Section 3

*Installation Instructions……………………………..…………………….. Section 4

*Operation Instructions……………………………………………………… Section 5

*Maintenance Instructions……………………………………………….. … Section 6

*Maintenance Device Placement

Warning Label Specifications & Locations ………………………………. Section 7

Hydraulic Details…………………………………………………………….. Section 8

General hydraulic information

Oil recommendation & seal compatibility

Hydraulic schematic

BFL Series power unit photograph

Hydraulic component lists

BFL Series cylinder drawings and parts lists

Cylinder repair procedures

Electrical Details…………………………………………………………….. Section 9

General electrical information

Electrical schematics

Mechanical Details………………………………………………………….. Section 10

Exploded view and parts descriptions

Spare Parts List

Troubleshooting Hints………………………………………………………. Section 11

Warranty……………………………………………………………………… Section 12

Attachments: Material Safety Data Sheets…………….………………… Section 13

*Mandatory reading before attempting installation.

OPTIONS:

ADVANCE LIFTS ENCLOSURE

ADVANCE LIFTS LANDING LOCKS

P 2-1

SECTION 2. (CONTINUED) INTRODUCTION

Congratulations, the equipment that you have purchased is of the highest quality

available. Advance Lifts industrial scissors lifts are designed and manufactured to

comply with ANSI Standard MH29.1, “Safety Requirements for Industrial Scissors Lifts”.

Your Advance Lift will provide you with many years of trouble free service in return for

the minimal maintenance described in this manual.

Please be sure that no individual is allowed to operate the lift until they have been fully

familiarized with the operating instructions in this manual. Also, insure that at least one

person at the lift site is familiar with the maintenance section of this manual and is

assigned responsibility for doing the maintenance on a regular basis.

Please note that the lift has a metal nameplate attached to it that contains information

such as the model number, capacities, and serial number. Do not remove the

nameplate. Be sure that no operator ever exceeds the capacities shown on the

nameplate or they may injure personnel or cause damage to the lift.

Also, be sure to have the serial number of the lift handy if you have to call your

distributor. That number identifies your specific lift and will allow your distributors

personnel to give you the most thorough and timely assistance possible.

This manual is under constant review and we would appreciate any constructive

suggestions that may enhance its usefulness. Please send your suggestions to

Advance lifts, Inc. Attn: Customer Service Department.

Thank you for purchasing our product.

P 2-2

SECTION 3. RESPONSIBILITIES OF OWNERS & USERS

Basic Principles: Owners/users shall apply sound principles of safety, training, inspection,

maintenance, and expected operating environment.

It shall be the responsibility of the owner/user to advise the manufacturer where deflection may

be critical to the application.

Manuals: Owners/users shall keep and maintain a copy of the operating and maintenance

manual(s) and ensure its availability to operating and maintenance personnel.

Inspection and Maintenance: It shall be the responsibility of the users to inspect and maintain

the industrial scissors lift as required to ensure proper operation. The frequency of inspection

and maintenance shall be based upon the manufacturer’s recommendations and be compatible

with operating conditions and the severity of the operating environment.

Industrial scissors lifts that are not in proper operating condition shall be immediately removed

from service until repaired. Maintenance and repairs shall be made by a qualified person and

the repairs shall be in conformance with the manufacturer’s recommendations.

Maintenance Safety Precautions: Before adjustments and repairs are started on an industrial

scissors lift, the following precautions shall be taken as applicable:

1. Remove the load from the platform.

2. Lower platform to the full down position, if possible or secure by maintenance device

and/or blocking as described by the manufacturer to prevent unintended platform

movement.

3. Relieve system pressure from all circuits before loosening or removing any components.

4. All controls in the “off’ position and all operating features secured from inadvertent

motion by brakes, blocks, or other means.

5. Disconnect power and follow established owner/user lockout/tag out policies.

6. Follow precautions and directions as specified by the manufacturer.

Replacement Parts: When parts or components are replaced, they shall be replaced with parts

or components approved by the original manufacturer of the industrial scissors lift.

Maintenance Training: The owner/user shall ensure only qualified personnel inspect and

maintain the industrial scissors lift in accordance with the sections: Inspection and Maintenance,

Replacement Parts and Operator Training and the manufacturer’s recommendations as

described in the maintenance manual.

Operator Training: An owner/user, who directs or authorizes an individual to operate an

industrial scissors lift, shall ensure that the individual has been:

1. Trained in accordance with the manufacturer’s operating manual.

2. Made aware of the responsibilities of operators as outlined under the Operators Section

of this manual.

3. Retrained, if necessary, based on the owners/user’s observation and evaluation of the

operator.

Modifications: Modifications and additions shall not be performed without the manufacturer’s

prior written approval. Where such authorization is granted, capacity, operation, and

maintenance instruction plates, tags, or decals shall be changed accordingly.

P 3-1

SECTION 3. RESPONSIBILITIES OF OWNERS & USERS (Continued)

Responsibility of Operators

Basic Principles: Operators shall apply sound principles of safety and good judgment in the

application and operation of the scissors lift, with consideration given to its intended use and

expected operating environment. Since the operator is in direct control of the industrial scissors

lift, conformance with good safety practices is the responsibility of the operator. The operator

shall make decisions on the consideration for the fact that his or her own safety as well as the

safety of other personnel on or near the scissors lift is dependent on those decisions.

General Training: Only personnel who have received general instructions regarding the

inspection, application and operation of industrial scissors lifts, including recognition and

avoidance of hazards associated with their operation, shall operate an industrial scissors lift.

Such topics covered shall include, but not necessarily be limited to, the following issues and

requirements:

1. A pre-start inspection

2. Responsibilities associated with problems or malfunctions affecting the operation of the

industrial scissors lift

3. Factors affecting stability

4. The purpose of placards and decals

5. Workplace inspection

6. Safety rules and regulations

7. Authorization to operate

8. Operator warnings and instructions

9. Actual operation of the industrial scissors lift. Under the direction of a qualified person,

the trainee shall operate the industrial scissors lift for a sufficient period of time to

demonstrate proficiency in actual operation of the industrial scissors lift.

Prestart Inspection: Before use each day or at the beginning of each shift, the industrial

scissors lift shall be given a visual inspection and functional test including but not limited to the

following:

1. Operating and emergency controls

2. Safety devices

3. Air or hydraulic system leaks

4. Electrical cables and wiring harness

5. Loose or missing parts

6. Wheels and casters

7. Nameplates, precautionary and instructional markings and/or labeling

8. Guardrail system

9. Items specified by the manufacturer

Problem or Malfunctions: Any problems or malfunctions that affect the safety of operations

shall be repaired prior to the use of the industrial scissors lift.

Before Operations: The operator shall:

1. Read and understand the manufacturer’s operating instruction(s) and user’s safety rules

or have them explained

2. Understand all labels, warnings, and instructions displayed on the industrial scissors lift

or have them explained

P 3-2

SECTION 3. RESPONSIBILITIES OF OWNERS & USERS (Continued)

Responsibility of Operators

Workplace Inspections: Before the industrial scissors lift is used and during use, the operator

shall check the area in which the industrial scissors lift is to be used for possible hazards such

as, but not limited to:

1. Bumps, floor obstructions and uneven surfaces

2. Overhead obstructions and electrical hazards

3. Presence of unauthorized persons

4. Other possible unsafe conditions as noted in the operating manual.

Operator Warnings and Instructions: The operator shall ensure the operation of the industrial

scissors lift is in compliance with the following:

1. Slope. The industrial scissors lift shall only be operated on flat and level surfaces.

2. Guardrail system. Guardrails shall be installed and positioned, and access gates or

openings shall be secured per the manufacturer’s instructions.

3. Distribution of load. The load and its distribution on the platform and any platform

extension(s) shall be in accordance with the manufacturer’s rated capacity for that specific

configuration.

4. Maintaining overhead clearance. The operator shall ensure that adequate clearance is

maintained from overhead obstructions and energized electrical conductors and parts.

5. Point of Operation. The operator shall not place any part of their body under the platform.

6. Personnel footing. Personnel shall maintain firm footing on dock lifts and work access lifts

while working thereon. Climbing by occupants on the guardrail system is prohibited. The use

of planks, ladders, or any other devices on the platform for achieving additional height is

prohibited.

7. Precaution for moving equipment. When other moving equipment or vehicles are

present, special precautions shall be taken to comply with the safety standards established

for the workplace.

8. Reporting problems or malfunctions. The operator shall immediately report to a

supervisor any problem(s) or malfunction(s) that become evident during operation. The

operator shall ensure all problems and malfunctions that affect the safety of operations are

repaired prior to continued use.

9. Capacity limitation. Rated capacity shall not be exceeded when loads are transferred to

the platform at any level.

10. Work area. The operator shall ensure the area surrounding the industrial scissors lift is

clear of personnel and equipment before lowering the platform.

11. Battery charging. Batteries shall be charged in strict accordance with the lift

manufacturer’s instructions.

12. Securing the industrial scissors lift. The operator shall comply with the means and

procedures provided to protect against use by an unauthorized person(s).

13. Altering safety devices. Safety devices shall not be altered or disabled.

14. Modifications. Modifications or alterations of an industrial scissors lift or the fabrication and

attaching of frameworks or the mounting of attachments for holding tools or materials onto

the platform or the guardrail system shall only be accomplished with prior written permission

of the manufacturer.

15. Assistance to the operator. If an operator encounters any suspected malfunction or any

hazard or potentially unsafe condition relating to capacity, intended use or safe operation

the operator shall cease operation of the industrial scissors lift and request further

instruction from the owner/user.

16. Problems or malfunctions. Any problem(s) or malfunction(s) that affect the safety of

operations shall be repaired prior to the use of the industrial scissors lift.

P 3-3

Before securing the unit to

the floor, shim or grout the

entire base frame assembly

to achieve a perfectly level

installation/ if unit is not

level, proper installation is

not possible. Continuous

base frame support is

essential for proper

installation.

SECTION 4. INSTALLATION INSTRUCTIONS

INSTALLATION NOTES:

A. If this job was ordered with Enclosures and/or Landing Locks, read and

understand the accompanying installation manuals for these products before

attempting to install this product.

B. A level and rigid installation is critical to the success of the installation, step #6 of

the installation instructions cannot be overlooked.

C. Some systems are designed with a timed travel function. If lift does not reach the

desired upper or lower targets within the programmed period, the unit will shut

down. Pressing either the up or down button will reset the timer and resume

function. Notice: Continual timing out may damage the pump.

INSTALLATION INSTRUCTIONS:

1. Move the lift to the usage area; insuring the mounting surface is clean and level. If

slings are used, encircle the entire lift, not just the platform. If unit is being lowered

into a pit, make final hose connections before lowering into the pit. See # 2. Note: If

enclosures are used, lift shall be orientated so the Maintenance Devices can be

deployed from the lower enclosure opening without going under the lift.

2. Connect the hydraulic hoses to lift. NOTE: The hoses, valve block and connection

points at the lift are marked with “A”, “B” & “C”. The letters correspond with the

connection points at the power unit. Do not cross hose connections or lift will not

function. Note: if you are using Landing Locks, additional hydraulic connections are

necessary, see Landing Lock Manual.

3. If a pit is being utilized, lower lift into pit and square the unit to the pit using a heavy

pry bar. Be careful with the hoses when lowering lift into pit. Do not cut the steel

bands until the lift is in the final position and no further movement is required.

4. Plug hydraulic power unit into power supply.

Switch the controls to “Maintenance”. Note:

motor will run anytime the controls are switched

to “Maintenance. Using the “Maintenance”

controls raise and lower the unit several times

to begin the air bleeding process. Continued

use will completely remove all air from system.

No other bleeding is necessary. It is

recommended that the power unit be located

within visual range of lift so that any

maintenance operations can be observed when

using the “maintenance mode”.

5. Once unit is in final position, raise unit fully then deploy the maintenance devices.

Lower unit onto devices and lock out the electrical system to disable unit movement.

Follow your companies lock out and tag procedures.

P 4-1

SECTION 4. INSTALLATION INSTRUCTIONS (CONTINUED)

6. Level the unit using steel shims. Shim or grout any portion of the base frame that is

not fully supported by the surface.

7. Lag the unit in place using 3/4” x 6-1/4”, “Rawl-Studs” or wedge anchors in the holes

provided, minimum embedment depth of 3-3/8”.

8. The upper travel target switch is mounted and prewired. The upper travel target

reflector must be field mounted so that the bottom of the reflector is used to signal

the power unit to shut down at the desired raised height.

9. Lower proximity switch mounting hole is located on the base frame near the point

where scissors legs and base frame meet. To set the lowered height, place a metal

straight edge between the base frame structures over the top of the proximity switch.

Insert the proximity switch from below and raise it until it senses the straight edge.

Install the locking nut and tighten.

10.Connect the pushbutton wiring and bi-parting gate wires from the junction box on the

base frame to the control box per the provided schematic.

11.Install pushbutton station(s) if unit is a “Call/Send” and wire to the control box per the

provided schematic.

12.Operate the unit several times making certain the lift stops flush with the upper level.

Adjust the photo eye reflector and test for accuracy, when complete, secure the

reflector.

13.Clean any debris or spilled fluid as they may later be misinterpreted as mechanical

trouble or a cylinder leak. Due to the rigors of shipping it may be necessary to

tighten some hose fittings. Remove maintenance bars and lower the unit.

14.Instruct user(s) in the proper operation of the lift, safety precautions and equipment

capacity. Supply maintenance personnel with this service manual.

P 4-2

SECTION 5. OPERATING INSTRUCTIONS

Hydraulic scissors lifts have an excellent safety record overall, but as with all moving

equipment, they can be dangerous. Operators must use common sense and take

responsibility for the safety of everyone near the lift. They must use the safety devices

provided and be careful not to surprise anyone in the area with the movement of the lift.

Pre-operational checks:

1. Check all electrical wiring and connections to be sure that they are completed

properly and are operational.

2. Check for obstructions or debris that may interfere with the safe operations of the lift.

3. Be sure that all personnel in the area are a safe distance away from the lift and

aware that you are about to operate it.

4. If there are any optional safety devices such as gate interlocks and proximity

switches, check them for proper operation.

Test operate the equipment:

1. Station yourself so that you will always see the equipment when it is in operation.

Never operate the equipment blind!

2. Raise the equipment and by pressing the “UP” and “DOWN” buttons with the unit in

automatic mode or use the “Call/Send” buttons to raise and lower the lift, depending

on the lift configuration.

3. Adjust upper proximity switch to stop platform at desired raised height, if needed.

4. Cycle the equipment several times to be sure that it is operating smoothly with no

jerking or sudden movement. On initial startup, there may be some air in the lines or

the cylinders may be dry due to storage so it may take several cycles to smooth out

the operation. If the operation is not smooth after several cycles, contact your

maintenance personnel. Any evidence of binding or scraping in the operation shall

cause you to immediately stop using the lift.

5. Check all safety devices for proper operation.

6. If you elect to test load the equipment be sure that you do not exceed the capacities

shown on the nameplate. Overloading may cause structural stresses that may not

show up for some time, but will diminish the life and capacity of the unit. If you have

any questions about testing the unit, call our customer service department at 1-800-

843-3625.

Daily operation:

1. All personnel shall be required to read the entire operating instruction section of this

manual prior to operating the lift.

2. Operators must know the capacity of the unit and be aware of any loads that may

exceed the capacity.

P 5-1

SECTION 5. OPERATING INSTRUCTIONS (CONTINUED)

Daily operation (continued):

3. WARNING! Operators must be alert to personnel in the vicinity of the lift. Avoid any

surprises to these personnel in regard to movement of or the position of the lift.

Never operate unit if you cannot see it and the personnel around it.

4. On the first use of the lift each day, the operator shall check to see that the lift is

functioning properly and smoothly. All safety devices shall be in place and operating

correctly.

5. Loads shall be centered before raising or lowering the lift as this will help insure

even wear on all moving parts

P 5-2

Only authorized personnel should perform inspection or maintenance and

service procedures. Unauthorized personnel attempting these procedures

do so at the risk of severe injury or death.

Always use the maintenance device when working under the lift. Failure to

use the maintenance devices properly can result in serious injury or death.

SECTION 6. MAINTENANCE INSTRUCTIONS

1. Always remember that machinery with large moving parts can seriously injure you.

2. Read and understand this manual before attempting any service work.

3. Always use the maintenance device when working on the unit in the elevated

position or reaching under the platform. (See photo on page 6-3, at the end of this

section for proper positioning and engagement of the maintenance device).

4. When using the maintenance device, adhere to the following rules:

A. The unit must be unloaded.

B. Be sure the maintenance devices are properly engaged.

C. Hold the “Maintenance Down” button an extra 10 seconds when lowering onto

the maintenance devices to be sure that all the weight of the lift is on the bars

and hydraulic pressure is relieved.

D. Follow your companies Lock Out/Tag Out procedures to prevent accidental

movement of the lift by other personnel.

E. Spend as little time as possible under the lift.

5. Only use replacement parts recommended by the manufacturer.

6. Do not let the equipment stay in disrepair; fix small problems before they become big

problems. A unit in disrepair can become a severe hazard if left unattended.

7. Inspect the equipment on a regular schedule, preferably monthly.

8. Never work on the hydraulics or electrical systems unless the unit is fully lowered or

properly sitting on the maintenance device.

9. Never apply a load to the equipment until the base frame is continuously supported.

10.Never expect to hold the leg assemblies open by simply lifting one end of a platform.

The only safe way to hold a lift’s legs open is the factory designed maintenance

device.

P 6-1

SECTION 6. MAINTENANCE INSTRUCTIONS (CONTINUED)

Routine Maintenance:

Monthly:

Check the hydraulic fluid level. When checking fluid levels, make sure the unit is fully

lowered. Proper fluid level is 1” from the top of the reservoir.

Be sure the maintenance device(s) are properly engaged before performing

maintenance checks 2 through 6 or reaching beneath a raised lift. (See instructions 3, 4

and 10 above).

1. Clean all debris from the vicinity of floor and pit mounted units in order to avoid

interference with the lift mechanism or rollers.

2. Check for presence and proper seating of all snap rings and clips on all axles,

cylinder and rollers.

3. Check rollers, pins and bushings for any signs of wear such as flat spots, missing

fasteners, or dislodged bearing material.

4. Check the hydraulic fittings for cracks or leaks and clean up any weepage on or

beneath the cylinder.

5. Check hoses and electrical lines for abrasions or other abuse and check for snug

connections.

6. Operate the unit and check for any abnormal noise or vibrations.

Seasonal or Semiannual Maintenance: Advance Lifts recommends that you change

your hydraulic fluid annually. Change hydraulic fluid for ambient temperature change if

appropriate or if there is any evidence of accumulated condensation creating water

contamination. Oil should be changed at least once per year under normal operating

conditions and more frequently in dirty environments or under heavy usage.

P 6-2

Failure to properly adhere to lift blocking procedures is to risk the sudden

and uncontrolled descent of the lift during maintenance or inspection. A

falling lift can cause severe injury or death.

Never use the lift unless the

maintenance devices are

properly stored or they may

be damaged by the scissors

legs.

MAINTENANCE DEVICE INSTRUCTIONS

Always use the maintenance device for any service or maintenance. Never go or reach

under the lift unless both maintenance devices are securely in place and the power to

the unit has been disconnected from its power source to prevent others from operating

the lift. Never use the maintenance device with a load on the platform.

Maintenance Device Usage

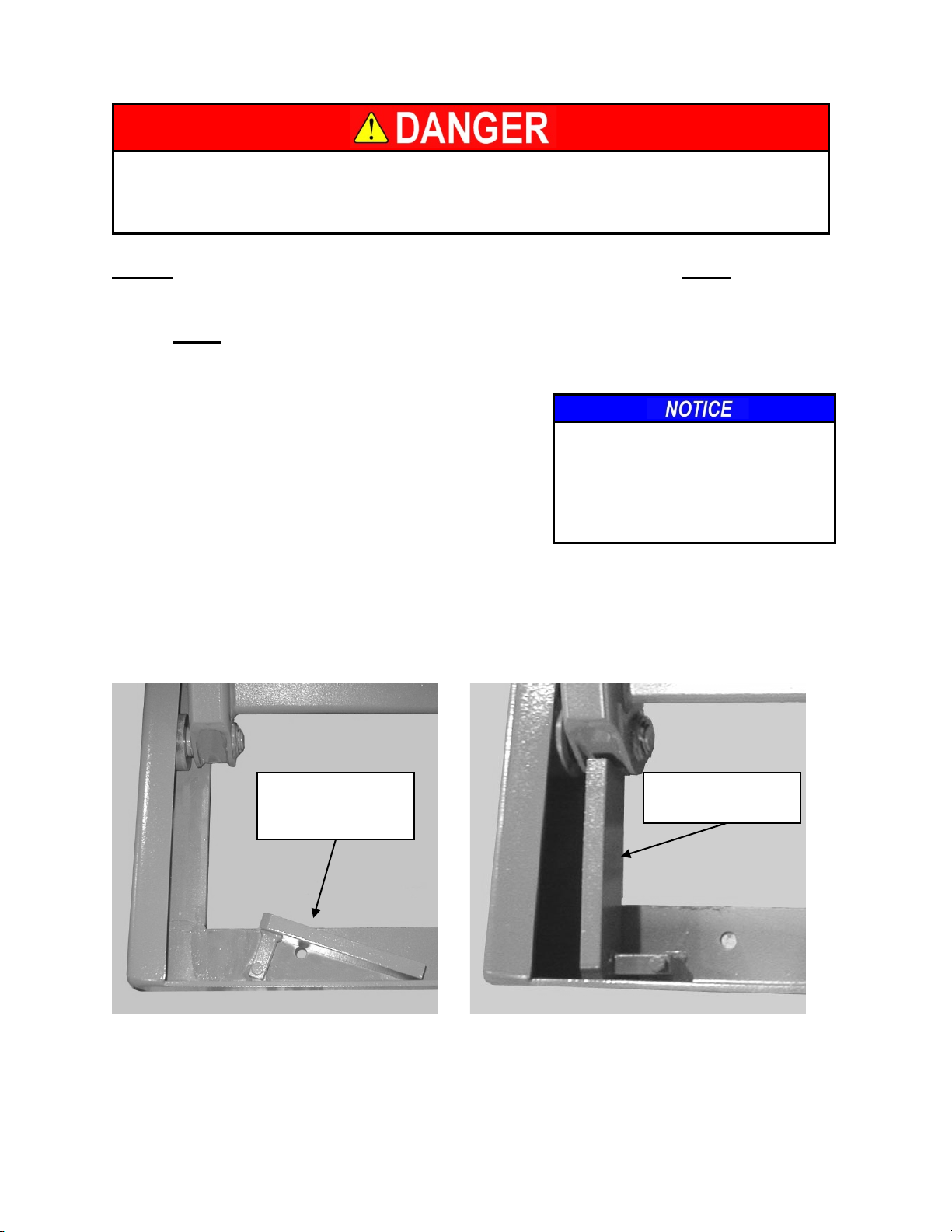

1. Rotate maintenance device until they come into

contact with the base frame. Always use both

devices when doing maintenance.

2. Once both bars are in position, lower the unit on

to them. Be certain the devices are positioned

as shown in photo 1-2.

3. Once the unit has been lowered onto the

device, continue pressing the “Down” button to relieve all system pressure making

hydraulic disassembly possible.

4. When storing the maintenance device be certain they are rotated completely as

shown in photo 1-1 or they may be damaged or interfere with the unit collapsing

fully.

P 6-3

MAINTENANCE

DEVICE IN

STORED

MAINTENANCE

DEVICE IN USE

Photo 1-1

Photo 1-2

SECTION 7. REQUIRED IDENTIFICATION AND LABEL PLACEMENT

Label #1 placed on all sides of the platform.

Label #2 placed on all sides of the platform.

P 7-1

Label #3 placed on all sides of the platform.

Label #4 placed on outside of lower leg

assemblies.

Label #5 placed

on guardrail

uprights.

#6 Advance Lifts identification and data plate.

Data plate located on side of platform.

CAPACITY

LABELS

placed on

all sides of

the

platform.

4

5

3

2

1

6

Failure to relieve operating system pressure could result in the sudden and

unexpected release of high-pressure fluids (or air) during maintenance and/or

repair of the lift and result in severe injury or death.

SECTION 8. HYDRAULIC DETAILS

1. General Hydraulic Information

A. Over time, all hydraulic cylinders will require replacement seals depending on

usage and environmental conditions. Seal wear and replacement is normal

maintenance.

B. Always be careful when working around cylinders, not to nick the extended rod or

dent the cylinder casing, as this may cause damage to cylinder seals.

C. If you elect to repaint any part of the lift, cover exposed rods with plastic or

soluble grease, which can be removed after painting to insure that no paint sticks

to the rods and damages the seals.

2. General precautions:

A. Be sure that all pressure is relieved from the hydraulic system before

disassembling any components. Continue to hold the “Maintenance Down”

control for several seconds after fully lowering the unit on its maintenance device

or the ground, before opening a hose line or hydraulic component.

B. Always be careful to avoid contamination entering the system. Be especially

careful with the ends of hoses, which may fall into oil dry, or dirt. If you suspect

contamination, flush the system and components.

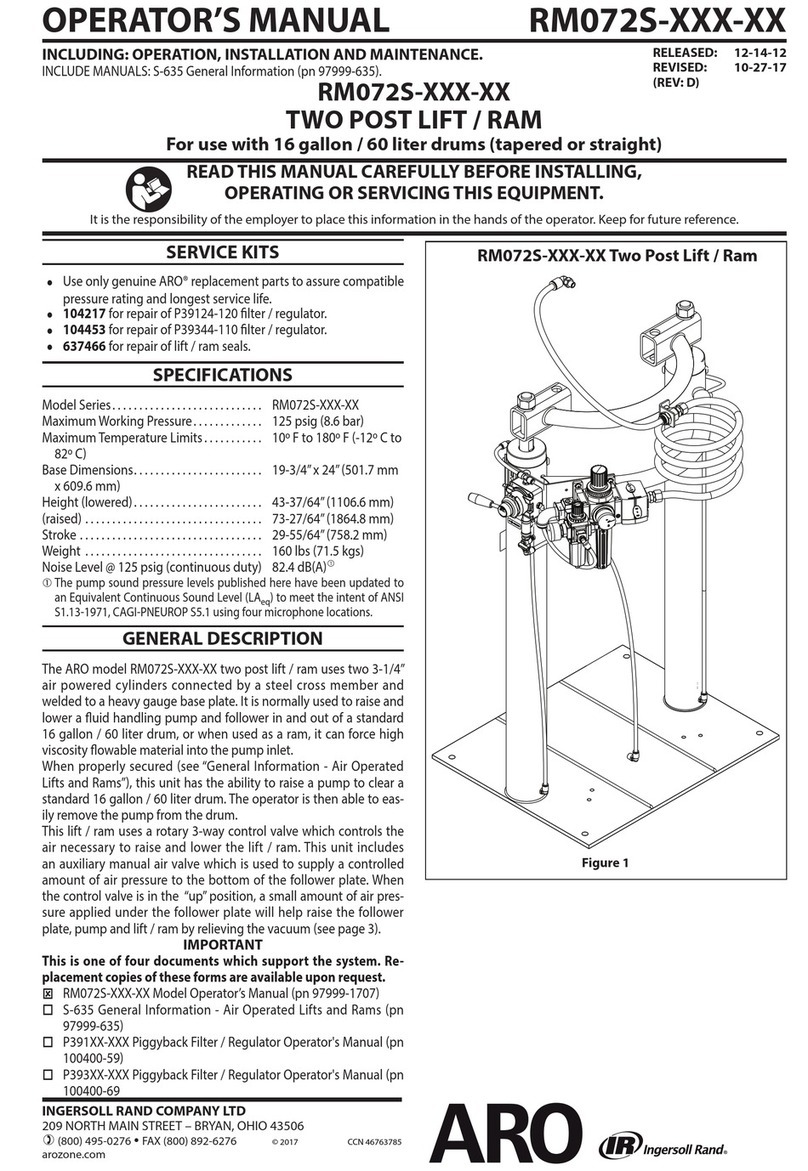

3. Hydraulic fittings, sealant and torque’s:

A. Advance Lifts may be equipped with either NPT fittings (tapered), or SAE fittings

(with O-ring seals), or JIC fittings (37˚ flare). None of these fittings are

interchangeable, know the difference.

B. Be careful when tightening NPT fittings not to over-tighten and crack them.

Swivel fittings are especially vulnerable and shall only be tightened enough to

stop leaking.

C. If leakage persists after tightening the fittings fairly hard, inspect fittings for burrs

on the mating edges or replace the fitting.

D. When using Teflon tape on NPT fittings, be sure the tape is started 1-1/2 threads

back from the leading edge and only use 2 wraps to be sure that tape does not

break off and contaminate the system. You may substitute pipe sealant with

Teflon paste from “Pro Lock” or “Loctite”, but again do not over apply. Never use

sealant or tapes on JIC, or SAE O-ring fittings.

E. Be extremely careful not to over-tighten SAE fittings, thread the fitting finger tight

and then tighten the nut on the fitting.

F. Never reuse old Teflon tape. Once a connection has been opened, remove all

tape and apply fresh tape.

P 8-1

OIL RECOMMENDATIONS AND SEAL COMPATIBILITY

Fluids:

1. The current standard hydraulic fluid is a multi-viscosity ISO-46 group II base oil

hydraulic fluid. This is the fluid normally supplied by the factory and is suitable for a

temperature range of –10 to +100 degrees Fahrenheit. When replacing or adding

fluid to an Advance Lift, use only ISO 46 hydraulic fluid that is manufactured with a

group II base oil.

2. Unless approved by the Advance lifts engineering department do not use any other

fluid. Brake fluids and other hydraulic fluids may damage the system’s seals or

hoses. If it is required to switch from one fluid to another, drain the reservoir and

system completely, and then refill with the new fluid.

3. Biodegradable and fire retardant fluids are available. Contact the factory for

specifications. It may be necessary to change some seals and/or hoses for total

system compatibility, depending upon the specific model lift and the requested fluid.

Options:

For oil options, contact the factory, 800-843-3625.

Seals:

Generally, the seals in the unit are Buna-N-Nitrile and polyurethane. The hoses are

either PVC for suction lines or braided wire for pressure lines. Always call the factory

about special fluids rather than make assumptions on your own.

P 8-2

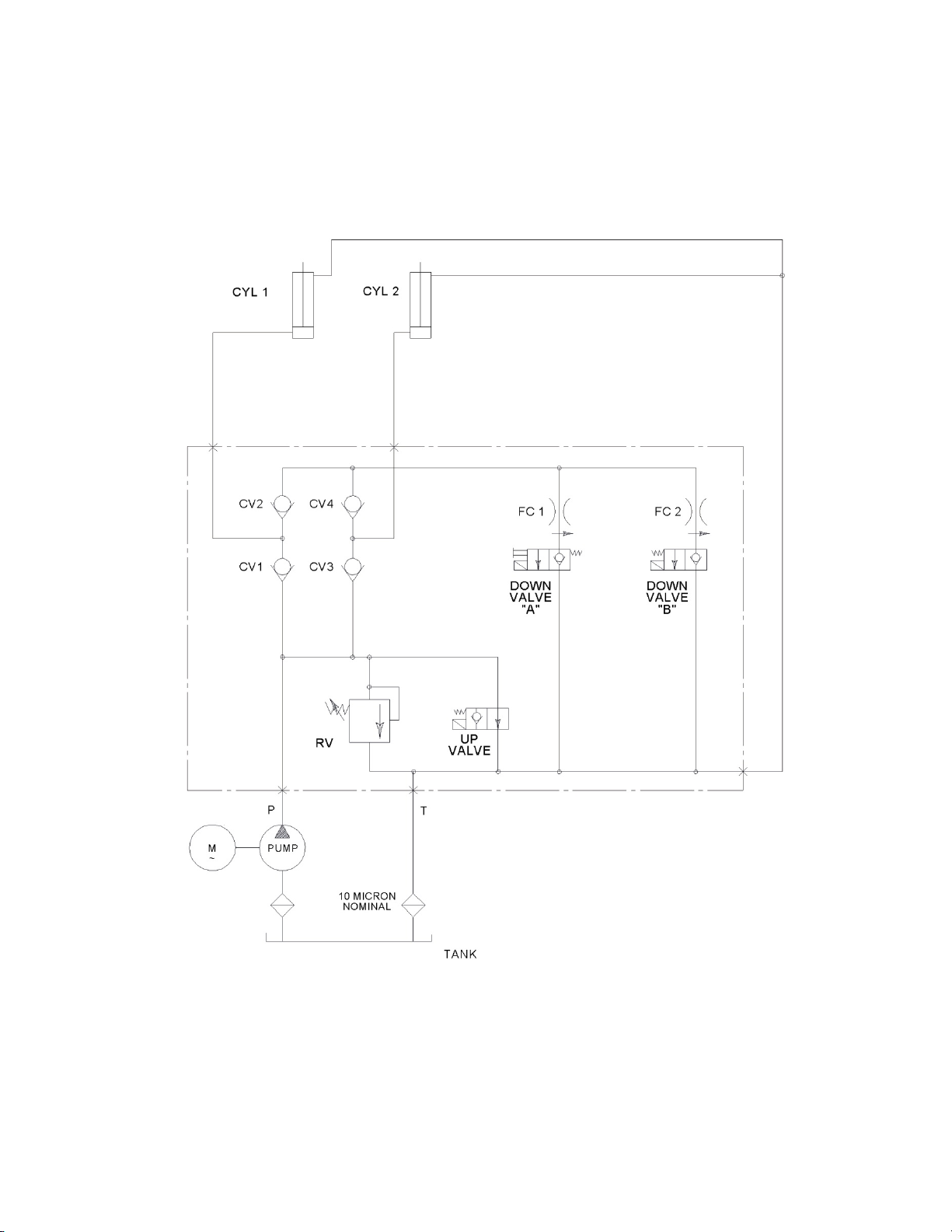

HYDRAULIC SCHEMATIC

P 8-3

MOTOR

RESERVOIR

BFL SERIES CYLINDER

P 8-4

ROD

BEARING

HOUSING

PISTON

RETAINING

NUT

HOSE

CONNECTION

WEAR RING

WEAR

RING

STATIC

SEAL

PISTON

SEAL

ROD

SEAL

O-RING

SEAL

ROD

WIPER

RETAINING

CLIP

BEARING

Cylinder Removal Procedure for BFL-Series Lifts

Tools & Supplied required:

Factory recommended hydraulic fluid

Snap-ring pliers

Hammer

Drift pin

Cylinder Removal, BFL-Series units:

NOTE: Some BFL-Series cylinders can weigh in excess of 500lbs. great care

should be taken when removing cylinders.

1. Raise the empty lift and settle it securely on its maintenance devices. See page P 6-

3 for proper lift blocking.

2. Once settled securely, depress the “Maintenance Down” control an additional 20

seconds to relieve any pressure from the hydraulic system. Disconnect the electrical

supply following your companies Lock Out/Tag Out procedures.

3. Disconnect the hydraulic hoses from the cylinder and plug the hose to prevent

contamination.

4. Secure the cylinder with a web sling connected to the structure. Remove the lower

pin and remove the cylinder from the scissors legs. On larger units or units with a

heavy lifting capacity, secure the web sling to a chain hoist from above. Note: It may

be necessary to weld a chain hook to the underside of the platform to achieve this.

On very large units, it may be necessary to remove the platform prior to removing

the cylinder. Call the factory with any questions concerning your particular unit, 800-

843-3625.

5. Carefully remove the lower pin and using the chain hoist, lower the cylinder to the

ground

6. Place the hose connection end of the cylinder in a 5-gallon bucket and force the

cylinder closed to drain the hydraulic fluid from the cylinder. Do not reuse the fluid

unless you are sure it is contamination free by careful straining.

Cylinder Repair:

All Advance Lifts cylinders use a high grade two-piece seal design comprised of a

standard size O-ring with a glass-filled PTFE cap. These seals are not replaceable in

the field without specialized tools. Advance recommends that you consult with a

professional who has the necessary tools to install the seals.

P 8-5

Table of contents

Other Advance Lifts Lifting System manuals

Popular Lifting System manuals by other brands

WALTCO

WALTCO GT-33 installation manual

OMCR

OMCR B01.24 Use and maintenance manual

ATLAS PLATINUM

ATLAS PLATINUM PVL14OF-EXT Installation & operation manual

Duarib

Duarib Altitude 150 Assembly, Disassembly and Use Instructions

Scaleo medical

Scaleo medical Poweo 200 user manual

Braun

Braun RA300 Operator, Installation, Service Manual