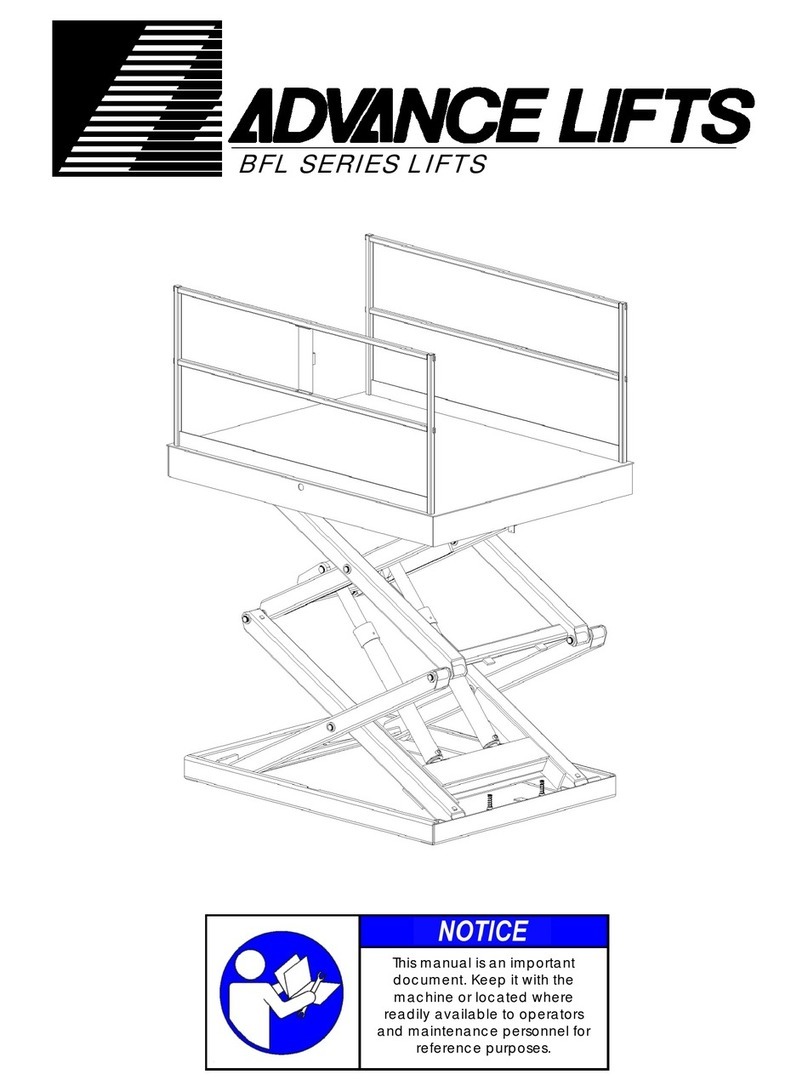

Advance Lifts 2000 Series User manual

Dock Lift Owner’s Manual

This manual is an important

document. Keep it with the

machine or located where

readily available to operators

and maintenance personnel

for reference purposes.

This manual is an important

document. Keep it with the

machine or located where

readily available to operators

and maintenance personnel

for reference purposes.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

FOR THE FOLLOWING DOCK LIFT MODEL NUMBERS

Throughout this manual, units are refered to by series. Each series has special

installation, maintenance and safety requirements.

2000 Series Lifts (2010, 2020, 2030, 2040, 2050, 2060, 2070, 2080, 2090, 2400)

2000K Series Lifts (2010K, 2500K)

3000 Series Lifts (3200, 3210, 3220, 3230, 3240, 3250, 3260, 3270,3280,3300, 3310,

3320, 3330, 3340, 3350, 3360, 3370, 3380, 3400, 3410, 3420, 3430,

3440, 3450, 3460, 3470, 3480, 3500, 3510, 3520, 3530, 3540, 3550,

3560, 3570, 3580, 3600, 3610, 3620, 3630, 3640, 3650, 3660, 3670,

3680)

4000 Series Lifts (4100, 4120, 4130, 4140, 4150, 4160, 4170, 4180, 4200, 4210,4220,4230,

4240, 4250, 4260, 4270, 4280, 4300, 4310, 4320, 4330, 4340, 4350,

4360, 4370, 4380, 4400, 4410, 4420, 4430, 4440, 4450, 4460, 4470,

4480)

T-Series Lifts (T2-50608, T2-60608, T2-55609, T2-55610, T2-55708, T2-55709, T2-50710,

T2-50808, T2-50809, T2-50810, T3-50608, T3-60608, T3-60609, T3-60610,

T3-60708, T3-60709, T3-60710, T3-60808, T3-60809, T3-60810)

OTHER______________________________________________________________________

Dock Lift Installation, Operation, and Maintenance Manual

In any correspondence with your distributor or the factory you will need the following

information:

Model Number________________________________ Serial Number______________________________

Installation location: __________________________________

__________________________________

__________________________________

Distributor Information: ____________________________________________

_________________________________

_________________________________

_________________________________

Advance Lifts, Inc.

701 S. Kirk Road

St. Charles, IL 60174-3428

Toll Free 1-800-843-3625

Sales Fax 1-630-584-9405

Parts and Service Fax 1-630-584-6837

E-mail: Parts@advancelifts.com

*Advance Lifts, Inc. furnishes one manual with each unit. Additional manuals are available at

$25.00 each.

P 1-1

At Initial Installation, determine proper motor/pump rotation by starting the motor in

very short intervals to prevent permanent pump damage. Running the pump

backwards will damage it. See the Installation Instructions, Section 4, for proper

procedure.

SECTION 2: INDEX & INTRODUCTION

Identification ………………………………………………………………………… Section 1

Index & Introduction …………………………………………………………….….. Section 2

*Responsibilities of Owners/Users ………………………………………………….Section 3

*Installation Instructions ……………………………………………….……………..Section 4

*Operating Instructions ………………………………………………...……………. Section 5

*Maintenance Instructions ………………………………………………………… Section 6

Power Unit Assemblies ……...………………………………………………………Section 7

Hydraulic Details …............................................................................................Section 8

General hydraulic information

Schematics

Fluid recommendations & seal compatibility

Pressure information for hoses & pipes

Component information

Electrical Details …………………………………………………………………….. Section 9

Schematics

Controller specifications

Component information

Wire size charts

Identification and Label Placement …………………………………………….. Section 10

Troubleshooting Hints ………………………………………………………….... Section 11

Warranty …………………………………………………………………………… Section 12

Optional Information……………………………………………………………… Section 13

*Mandatory reading before attempting installation.

INTRODUCTION

Congratulations, the equipment that you have purchased is of the highest quality. Your

Advance Lift will provide you with many years of trouble free service in return for the minimal

maintenance described in this manual.

Please be sure that no individual is allowed to operate the lift until they have been fully

familiarized with operating instructions in this manual. Also insure that at least one person at the

lift site is familiar with the maintenance section of this manual and is assigned responsibility for

doing the maintenance on a regular basis.

Please note that the lift has a metal nameplate attached to it that contains information such as

the model number, capacities, and the serial number. Do not remove the nameplate. Be sure

that no operator ever exceeds the capacities shown on the nameplate or they may cause

damage to the lift or injure personnel. Also, be sure to have the serial number of the lift handy if

you have to call the factory. That serial number identifies your specific lift and will allow factory

personnel to give you the most thorough and timely assistance possible.

This manual is under constant review and we would appreciate any constructive suggestions

that may enhance its usefulness. Please send your suggestions to Advance Lifts, Inc Attn:

Service Manager

Thank you for purchasing our product.

P 2-1

SECTION 3:RESPONSIBILITIES OF OWNERS & USERS

Basic Principles: Owners/users shall apply sound principles of safety, training, inspection,

maintenance, and expected operating environment.

It shall be the responsibility of the owner/user to advise the manufacturer where deflection may

be critical to the application.

Manuals: Owners/users shall keep and maintain a copy of the operating and maintenance

manual(s) and ensure its availability to operating and maintenance personnel.

Inspection and Maintenance: It shall be the responsibility of the users to inspect and maintain

the industrial scissors lift as required to ensure proper operation. The frequency of inspection

and maintenance shall be based upon the manufacturer’s recommendations and be compatible

with operating conditions and the severity of the operating environment.

Industrial scissors lifts that are not in proper operating condition shall be immediately removed

from service until repaired. Maintenance and repairs shall be made by a qualified person and

the repairs shall be in conformance with the manufacturer’s recommendations.

Maintenance Safety Precautions: Before adjustments and repairs are started on an industrial

scissors lift, the following precautions shall be taken as applicable:

1.Remove the load from the platform.

2.Lower platform to the full down position, if possible or secure by maintenance device

and/or blocking as described by the manufacturer to prevent unintended platform

movement.

3.Relieve system pressure from all circuits before loosening or removing any components.

4.All controls in the “off’ position and all operating features secured from inadvertent motion

by brakes, blocks, or other means.

5.Disconnect power and follow established owner/user lockout/tag out policies.

6.Follow precautions and directions as specified by the manufacturer.

Replacement Parts: When parts or components are replaced, they shall be replaced with parts

or components approved by the original manufacturer of the industrial scissors lift.

Maintenance Training: The owner/user shall ensure only qualified personnel inspect and

maintain the industrial scissors lift in accordance with the sections: Inspection and Maintenance,

Replacement Parts and Operator Training and the manufacturer’s recommendations as

described in the maintenance manual.

Operator Training: An owner/user, who directs or authorizes an individual to operate an

industrial scissors lift, shall ensure that the individual has been:

1.Trained in accordance with the manufacturer’s operating manual.

2.Made aware of the responsibilities of operators as outlined under the Operators Section of

this manual.

3.Retrained, if necessary, based on the owners/user’s observation and evaluation of the

operator.

Modifications: Modifications and additions shall not be performed without the manufacturer’s

prior written approval. Where such authorization is granted, capacity, operation, and

maintenance instruction plates, tags, or decals shall be changed accordingly.

P 3-1

SECTION 3. RESPONSIBILITIES OF OWNERS & USERS (Continued)

Responsibility of Operators

Basic Principles: Operators shall apply sound principles of safety and good judgment in the

application and operation of the scissors lift, with consideration given to its intended use and

expected operating environment. Since the operator is in direct control of the industrial scissors

lift, conformance with good safety practices is the responsibility of the operator. The operator

shall make decisions on the consideration for the fact that his or her own safety as well as the

safety of other personnel on or near the scissors lift is dependent on those decisions.

General Training: Only personnel who have received general instructions regarding the

inspection, application and operation of industrial scissors lifts, including recognition and

avoidance of hazards associated with their operation, shall operate an industrial scissors lift.

Such topics covered shall include, but not necessarily be limited to, the following issues and

requirements:

1. A pre-start inspection

2. Responsibilities associated with problems or malfunctions affecting the operation of the

industrial scissors lift

3. Factors affecting stability

4. The purpose of placards and decals

5. Workplace inspection

6. Safety rules and regulations

7. Authorization to operate

8. Operator warnings and instructions

9. Actual operation of the industrial scissors lift. Under the direction of a qualified person,

the trainee shall operate the industrial scissors lift for a sufficient period of time to

demonstrate proficiency in actual operation of the industrial scissors lift.

Prestart Inspection: Before use each day or at the beginning of each shift, the industrial

scissors lift shall be given a visual inspection and functional test including but not limited to the

following:

1. Operating and emergency controls

2. Safety devices

3. Air or hydraulic system leaks

4. Electrical cables and wiring harness

5. Loose or missing parts

6. Wheels and casters

7. Nameplates, precautionary and instructional markings and/or labeling

8. Guardrail system

9. Items specified by the manufacturer

Problem or Malfunctions: Any problems or malfunctions that affect the safety of operations

shall be repaired prior to the use of the industrial scissors lift.

Before Operations: The operator shall:

1. Read and understand the manufacturer’s operating instruction(s) and user’s safety rules

or have them explained

2. Understand all labels, warnings, and instructions displayed on the industrial scissors lift or

have them explained

P 3-2

SECTION 3. RESPONSIBILITIES OF OWNERS & USERS (Continued)

Responsibility of Operators

Workplace Inspections: Before the industrial scissors lift is used and during use, the operator

shall check the area in which the industrial scissors lift is to be used for possible hazards such

as, but not limited to:

1. Bumps, floor obstructions and uneven surfaces

2. Overhead obstructions and electrical hazards

3. Presence of unauthorized persons

4. Other possible unsafe conditions as noted in the operating manual.

Operator Warnings and Instructions: The operator shall ensure the operation of the industrial

scissors lift is in compliance with the following:

1. Slope. The industrial scissors lift shall only be operated on flat and level surfaces.

2. Guardrail system. Guardrails shall be installed and positioned, and access gates or

openings shall be secured per the manufacturer’s instructions.

3. Distribution of load. The load and its distribution on the platform and any platform

extension(s) shall be in accordance with the manufacturer’s rated capacity for that specific

configuration.

4. Maintaining overhead clearance. The operator shall ensure that adequate clearance is

maintained from overhead obstructions and energized electrical conductors and parts.

5. Point of Operation. The operator shall not place any part of their body under the platform.

6. Personnel footing. Personnel shall maintain firm footing on dock lifts and work access lifts

while working thereon. Climbing by occupants on the guardrail system is prohibited. The use

of planks, ladders, or any other devices on the platform for achieving additional height is

prohibited.

7. Precaution for moving equipment. When other moving equipment or vehicles are present,

special precautions shall be taken to comply with the safety standards established for the

workplace.

8. Reporting problems or malfunctions. The operator shall immediately report to a

supervisor any problem(s) or malfunction(s) that become evident during operation. The

operator shall ensure all problems and malfunctions that affect the safety of operations are

repaired prior to continued use.

9. Capacity limitation. Rated capacity shall not be exceeded when loads are transferred to

the platform at any level.

10. Work area. The operator shall ensure the area surrounding the industrial scissors lift is

clear of personnel and equipment before lowering the platform.

11. Battery charging. Batteries shall be charged in strict accordance with the lift

manufacturer’s instructions.

12. Securing the industrial scissors lift. The operator shall comply with the means and

procedures provided to protect against use by an unauthorized person(s).

13. Altering safety devices. Safety devices shall not be altered or disabled.

14. Modifications. Modifications or alterations of an industrial scissors lift or the fabrication and

attaching of frameworks or the mounting of attachments for holding tools or materials onto

the platform or the guardrail system shall only be accomplished with prior written permission

of the manufacturer.

15. Assistance to the operator. If an operator encounters any suspected malfunction or any

hazard or potentially unsafe condition relating to capacity, intended use or safe operation

the operator shall cease operation of the industrial scissors lift and request further

instruction from the owner/user.

16. Problems or malfunctions. Any problem(s) or malfunction(s) that affect the safety of

operations shall be repaired prior to the use of the industrial scissors lift.

P 3-3

SECTION 4:INSTALLATION INSTRUCTIONS

Series 2000, 2000K, T-Series, 3000, 4000

Equipment and Supplies Required:

Mechanical:

Equipment to maneuver the lift into position

Nylon Slings or Chains

Support Timbers

Plate Grab/Clamp

Heavy Pry Bar

Standard Hand Tools

Shims

Anchor Bolts

Grouting Material

Fish Tape and Rope

Electrical:

Electrical Disconnect

Standard Hand Tools

Wire (see Section 9 for Branch and Control Circuit requirements)

Electrical Fittings

Equipment and Supplies Notes:

The appropriate amount and type of Hydraulic Fluid is included with the lift.

A standard length and quantity of the appropriate hose is supplied with the lift.

Anchor Specifications: Series 2000, 2500K & T-Series Units Use 5/8” X 6”. Series 3000

& 4000 use 1” X 9”.

P 4-1

T-Series models require the

hose to be routed under the

base frame. Routing the

hose in any other manner

will result in hose damage.

See page P 4-5 for pit

details.

Standard Remote Power

Units are not weatherproof.

If power unit is to be

installed outdoors, a factory

approved cover must be

used.

SECTION 4: INSTALLATION INSTRUCTIONS (CONTINUED)

Installation Procedure:

1. Read the Installation, Operating, and Maintenance instructions completely before

attempting installation. You may also find it helpful to read the remaining sections of

the manual for a better understanding of how the equipment works.

2. If you are installing a pit mounted unit, check the pit dimensions against the pit

drawing for conformity (length, width, and depth including bridge recesses) and be

sure to check the diagonal of the pit for square. Also be sure whatever surface the

base frame will sit on is flat and level or is shimmed to achieve that end. (See p 4-6

for a typical pit drawing).

3. Locate the power unit, check to insure that

there is no water contamination in the reservoir.

Fill the reservoir through the breather hole with

the appropriate hydraulic fluid (see fluid

recommendation section of this manual).

Ideally, you should mount the reservoir on a

wall approximately 6 ½’ above the ground. This

prevents people from standing on or placing

objects on the power unit. It will free up floor

space and because the reservoir is higher than the lift, it will allow any air in the

system to naturally rise to the highest point and purge itself from the system.

4. Run the hydraulic and blue breather lines from

the power unit to the lift and flush the hydraulic

lines with clean fluid before connecting them. If

the lines must be pushed through chases or

enclosures, be sure to cap the lines to prevent

contaminates from entering the hose. The

breather line must not be pinched or restricted

during installation. Cleanliness is the single

most important factor in the maintenance of any

hydraulic system.

5. Following the electrical diagrams in the electrical section of this manual, make the

electrical connection to the motor and controls for the unit. Be sure that you have

correct motor rotation! Continued operation of a hydraulic pump in reverse

rotation will destroy it! You can detect the rotation by making short motor jogs and

watching the clear suction line from the reservoir to the pump. If the rotation is

correct, the fluid will leap up the line into the pump. If the rotation is reversed, there

will be no fluid in the suction line. You may change the rotation of a 3-phase motor

by simply exchanging the positions of any two of the three power wire connections.

With single-phase motors, rotation is set at the factory. Remember to have the

discharge end of the hosing secure and discharging into a container or someone

may take an oil bath. (continued on next page)

P 4-2

Do not allow

anyone to get

under the unit

during installation.

Serious injury or

death could occur.

SECTION 4: INSTALLATION INSTRUCTIONS (CONTINUED)

6. Figure out the proper orientation of the lift. (Surface mounted units may simply be put

into place). Note: All dock lifts are built so that loads are transferred over the hinged

(clevis) end of the platform when elevated to truck height and this is the end to which

the hinged bridge is usually welded. Occasionally, the bridges are side mounted.

Surface mounted units are equipped with approach ramps for transitioning on and off

the unit from the ground level. The ramps are usually much larger than the bridge

and located on the roller end of the platform and should never ever be used as a

bridge to the truck!

7. For pit mounted units, place timbers diagonally across the

corners of the pit and with shipping restraints still in place,

but shipping blocks removed, place the lift on the timbers.

Then you may make temporary hose connections being

careful not to over-tighten and crack the hydraulic fittings.

Finally, you may remove the timber supports and lower the

lift into the pit.

8. You may now break the shipping restraints (banding). Use the lifts power unit to

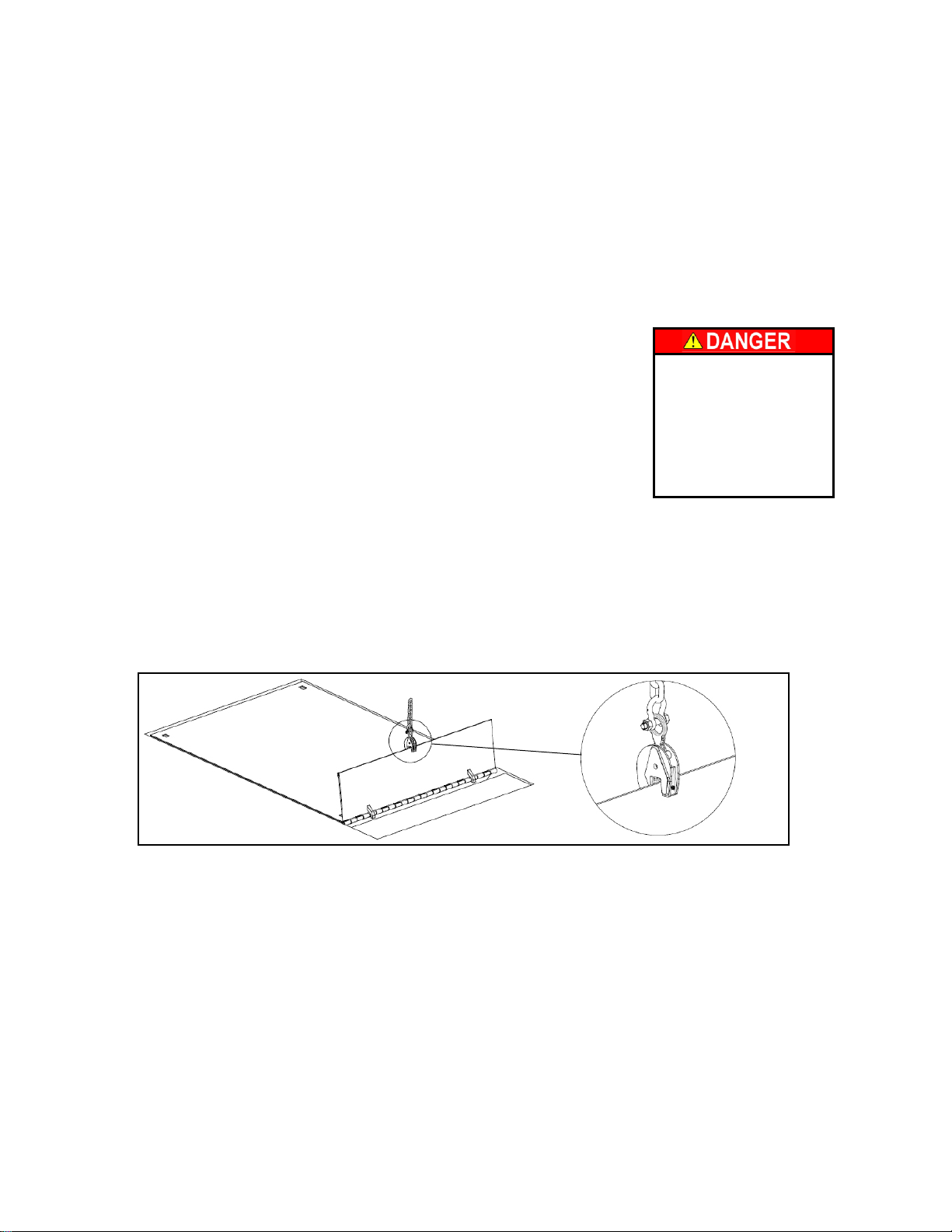

open the lift a few feet and use your crane to raise the clevis end (hinged bridge

end) of the lift by hooking the bevel toe guard or use a plate grab attached to the

hinged bridge, figure 1. This will allow you to remove your chains or slings and the

banding material from beneath the unit’s base frame. The tipping may not be

necessary if you hooked your lift chains through the guardrail sockets of the platform

and the shipping bands slide out from under the lift.

9. Carefully lower the unit insuring that the platform edges clear the sides of the pit.

The heavy pry bar may be used to reposition the unit with even clearance from all pit

walls. Note the lowered height in relation to the surrounding pit edges for later

shimming adjustments. !The lift shall be installed so that no part of the lift platform is

more than ¼” above or below the surrounding surface.

10.Once the lift is properly positioned, (whether it is pit mounted or surface mounted),

you may begin the lag down procedure. Surface mounted T-Series models have

special lag down instructions located on page P 4-5.

P 4-3

Figure 1

SECTION 4: INSTALLATION INSTRUCTIONS (CONTINUED)

12. Raise the unit and position the maintenance leg or bar as shown in the maintenance

section of this manual (pages 6-3 through 6-7). Lower the unit onto the maintenance

leg and press the down button for an extra 10 seconds to relieve all hydraulic

pressure. Drill the lag down holes and set the lag bolts. Check the unit for side to

side level and then shim or grout the base frame for continuous support. The

shimming should enhance the match between the platform and the surrounding

surfaces when fully lowered, but not at the expense of side to side levelness. A

slight slope from clevis end to roller end is not a problem, but side to side slope will

cause premature wear on all the moving parts of the lift. Tighten the lag bolts.

13. If a temporary hydraulic connection was made to lower the unit into the pit, now is

the time to switch to your permanent hydraulic connection. Note: on T-Series

models the hose must run under the base frame, see page P 4-5 for pit

details. Also, if there are any electrical options such as limit switches or electrical

toe guards, now is the time to do that wiring.

14. Check that there are no tools or debris in the pit or beneath the unit, raise the unit

and remove the maintenance leg, then fully lower the unit. On pit mounted units,

check that the bridges are flush with their curb angles and that they do not pivot

when loads roll over them, shim any movement accordingly.

15. Operate the equipment through several cycles, holding the down button an extra 20

seconds after the lift is fully lowered to bleed air from the cylinders. Check the

reservoir fluid level with the unit fully lowered and top off the fluid to 1” from the top

of the reservoir on 5-gallon reservoirs and 2.5” from the top of 10-gallon reservoirs.

16. Adjust accessories such as limit switches and if the unit has electric toe guards or

roller shades, fasten the hose in the pit so that it does not move and interfere with

proper operation.

17. Raise the unit one final time, install the maintenance leg, and thoroughly clean the

entire area. Be sure all fluid spills are cleaned up so that they are not later

misinterpreted as new fluid leaks. Check all hydraulic fittings for leaks.

18. Meet with the facility manager or maintenance foreman and turn over this

maintenance manual with the reminder that no one should be allowed to operate

the unit unless they are familiar with the operating instructions. Show them the

maintenance leg and any other maintenance devices. Point out the metal nametag

on the unit with the serial number and capacity ratings. Make it clear that some

specific person in their organization must be charged with responsibility for the

maintenance of the unit and if they have no further questions, lower the unit and

consider your job complete.

P 4-4

SECTION 4.1: Special instructions for T - Series Only

Ground Mounted Toe Guards (GMTG)

1. T-Series lifts not installed in pits require additional toe guard protection not outlined

in the previous instructions. The toe guards are placed around the perimeter of the

unit and are used to keep personnel a safe distance from the platform as the unit

raises and lowers. All personnel shall stay to the outside of the toe guards when the

lift is in operation.

2. Place the toe guards 3” from the lift platform’s beveled toe guards as illustrated in

figure 1 below. Insure all four corners line up and lag the guards to the concrete

through the holes provided using 3/8” concrete anchors as shown in figure 2.

3. Units with 8’ platforms require eight (8) concrete anchors and ten (10) anchors are

needed for units over 8’ in length.

4. One of the guards has ¾” drilled mounting holes in it as opposed to the normal ½”

mounting holes. This guard mounts to the base frame “lag-down angle” as illustrated

in figure 3.

P 4-5

Concrete Pad

Ground Mounted

Toe Guard

Lift Platform

(Fig. 1)

Concrete Pad

(Fig. 2)

Ground

Mounted

Toe Guard

Lift Platform

Concrete Anchor

Ground

Mounted

Toe Guard

Lift Platform

(Fig. 3)

Base frame

Angle

Concrete Pad

3”

ADVANCE LIFTS PIT DIAGRAM (K’s, T’s, 2000, 3000, & 4000 SERIES)

*When mounting a “T-Series” lift on a pad it is necessary to supply a cutout in the concrete to allow passage of the hose under the

base frame. T-Series lifts have no clearance between the platform and ground, any hose run through or over the base frame will be

damaged when the platform is lowered.

Installation Bill of Material*

1. One (1) Advance Lift Model Number __________.

2. 3” x 3” x ¼” curb angle as required.

3. One (1) 3” conduit from power unit location to pit for hydraulic hose.

4. One (1) electric disconnect switch for 5 HP or 7.5 HP motor.

5. 5 gallons of Chevron Rykon ISO 46 hydraulic fluid for T’s & K’s, 10 gallons for 2000 & 3000 series and 15

gallons for series 4000 units.

6. One (1) ½” SAE 100R2 hydraulic hose from the power unit location to the lift base with ½” female JIC

threads on both ends. (4000 series lifts require two (2) hoses).

7. Concrete anchor bolts and material for shimming and/or grouting.

*Seller furnishes Advance dock lift only unless otherwise agreed to in writing

Notes:

A. Reinforce concrete to suit local soil conditions.

B. All pit work and materials shown are the responsibility of the owner or his agent (by pit contractor)

C. Installer to run ½” diameter hose(s) through the 3” conduit from the power unit to the lift base.

D. Dimension tolerances are plus ¼”, minus 0” (+1/4” – 0).

E. 180º steel hinge bridges require a bridge recess length equal to bridge length minus 2-3/4”.

F. 180º aluminum hinge bridges require a bridge recess length equal to bridge length minus 3-3/4” and a pit

length equal to platform length plus 7-1/2”.

G. Consult factory for bridges longer than 30”. (18” on 4000 series).

P 4-6

16”

PLATFORM LENGTH +2”=

BRIDGE LENGTH MINUS 3-3/4”=

BRIDGE WIDTH + 2”

USE 32” LONG 2X4 LUMBER TO FORM HOSE

RECESS (FOR T-SERIES ONLY)

PIT DRAIN

PLATFORM WIDTH +2”=

PLATFORM LENGTH + 6-1/2”=

(If no bridge, platform length + 2”)

PIT FLOOR MUST BE LEVEL

FOR CASES WHERE BRIDGE

AND PLATFORM ARE THE

SAME WIDTH

50”

PIT CUTOUT FOR

OPTIONAL WHEEL

CHOCK

¾” DEEP BRIDGE

RECESS

T-SERIES HOSE

RECESS

PIT DRAIN

LIFT LOWERED

HEIGHT + ¼”

3” CONDUIT WITH

MINIMUM 14-1/2” RADIUS

BEND

Obstructions and

debris in the pit can

cause the lift to

remain partially

raised above the

surrounding surface

causing a trip

hazard.

SECTION 5:OPERATING INSTRUCTIONS

Hydraulic scissors lifts have an excellent safety record overall, but as with all moving

equipment they can be dangerous. Operators must use common sense and take

responsibility for the safety of everyone near the lift. They must use the devices

provided and be careful not to surprise anyone in the area with the movement of the lift.

The most common accidents that occur are people walking off the end of the lift and

people tripping over the hinged bridge or knocking the bridge over onto someone’s foot.

These are prevented by simply using guardrails and safety chains, and by being aware

of the bridge position and size. Be alert!

Pre-operational checks:

1. Check all electrical wiring and connections to be sure that they are completed

properly and are operational.

2. Check for the proper operating condition of all safety devices such as guardrails,

safety chains, and optional equipment such as electric toe guards, warning bells, or

automatic chocks.

3. Check for obstructions or debris that may interfere with the

safe operation of the lift.

4. Be sure that all personnel in the area are a safe distance

away from the lift and aware that you are about to move

it.

5. Know the capacity of the lift to be sure not to overload it.

Test operate the equipment:

1. Station yourself so that you always see the equipment and surrounding area when it

is in operation. Never operate the equipment in the blind.

2. Raise the equipment and note that the pushbutton is a constant pressure, “dead-

man” type. When you release the up or down button, the unit should stop moving

immediately and maintain its elevation. If it does not, notify your maintenance

personnel immediately.

3. Cycle the equipment several times to be sure that it is operating smoothly with no

jerking or sudden movement. On initial start up there may be some air in the lines or

the cylinders may be dry due to storage so it may take several cycles to smooth out

the operation. If the operation is not smooth after several cycles, contact your

maintenance personnel. If there is any evidence of binding or scraping in the

operation you should immediately stop using the lift.

4. Check all safety devices for proper operation.

5. If you elect to test load the equipment be sure that you do not exceedthe capacities

shown on the nameplate. Overloading may cause structural stresses that may not

show up for some time, but will diminish the life and capacity of the unit. If you have

any questions about testing the unit, call the engineering department at the factory at

1-800-843-3625.

P 5-1

COMPATIBLE LOADING EQUIPMENT GUIDE:

Each Advance lift is designed with a weight capacity and platform design for specific

types of loading equipment. Using the wrong type of loading equipment on a given

series of lifts will invite unintentional overloading. For safe operation, follow these

guidelines and be careful to never exceed the nameplate.

Calculate the weight of the heaviest types of loads you expect to handle to be sure that

they are within the rated capacity. Beware of surprisingly heavy materials such as

liquids, grains, powder, and paper; all of which can weigh much more than you suspect

because of their density.

A little effort to determine the true weight of your heaviest loads before you start to use

your equipment can save damage to your equipment and possible injury to your

personnel. If you discover that some loads will exceed the capacity of the unit, make

arrangements to have the loads split. All operating personnel should be warned about

heavy loads, warning signs should be placed in the dock lift area as a reminder.

Daily operation:

1. All personnel should be required to read the entire operating instruction section of

this manual prior to operating the lift.

2. Operators must know the capacity of the unit and be aware of any loads that may

exceed capacity.

3. Operators must be alert to all personnel in the vicinity of the lift and avoid any

surprises to these personnel in regard to movement of or the position of the lift at

any time. Never operate the unit if you cannot see it and the personnel around it.

4. On the first use of the lift each day, each operator should check to see that the lift is

operating properly and smoothly. All safety devices should be in place and operating

properly and the hinged bridge should be swung through its full arc of movement.

The bridge stops should prevent the bridge from drooping more than 45 degrees

below the horizontal in the forward position and the bridge should swing back 20

degrees beyond vertical toward the platform in the upright position. Any problems

should be immediately reported to the maintenance personnel.

P 5-2

All of the above and small powered

pallet jacks.

2000 SERIES, T & K SERIES

3200 & 3300 SERIES

All of the above & straddle stackers,

small stand-up & sit-down rider fork

trucks.

All of the above & medium fork

trucks.

3400, 3500, 3600 & 4000 SERIES

UNIT

TYPE OF LOADING EQUIPMENT

Daily Operation (Continued)

5. If the unit has a traveling electrical cord, the operator must insure that it is kept away

from the lift as it raises and lowers.

6. When raising or lowering the lift, the load should be centered on the platform (that is,

the load should be evenly distributed and its center of gravity should be at the center

of the platform).

7. If a unit is equipped with both a hinged bridge and a hinged ramp, be sure that the

operators know the difference and never use the ramp for load transfer in the raised

position. The ramps are usually much longer than the bridges which means they

can work as a long lever creating severe eccentric loads and they are often

positioned on the weakest side of the lift for load movement in the fully lowered

position only. Use ramps in the fully lowered position only!

8. Do not allow bridges or ramps to “free fall” from near vertical positions to the position

against their hinge stops. This type of abuse will definitely cause damage to the

stops, hinges, and platform edges, eventually rendering the unit unsafe. Lower

ramps by hand and lower bridges to the down stop position with the restraining

chains.

Efficient lift usage:

The following procedures will help you maximize the efficient use of your lift in your

loading and unloading operations.

1. First it should be noted that there is a long restraining chain on each lift that is

designed to run from the hinged bridge to the guardrail post farthest away from the

bridge. The purpose of this chain is to allow an operator to pull the hinged bridge

back from anywhere on the platform with minimal movement, once the bridge is

raised to the near vertical position by the truck bed as the lift is lowered.

2. This means that the hinged bridge only has to be manually lifted once in a loading or

unloading sequence. It should be raised to the vertical standing position before the

lift is raised to truck height. Once the top of the bridge is just above the truck bed

height, the bridge can be pushed against the truck and allowed to cam into truck.

Then when you lower the unit, the bridge is allowed to cam up on the truck bed to

the near vertical position and then pulled back to a safe resting position with the

chain. There is a second snap on the chain that allows you to lock the bridge in the

raised position whenever the load or guardrails prevents the bridge from swinging

back at least 20º beyond vertical. (See illustration at end of section.)

3. If your unit is equipped with an approach ramp, do not raise the ramp on each cycle.

In fact, the ramp is to be raised only when the lift is being moved to a new location.

Many of the ramps are designed with built in wheel chocks which help prevent a

wheeled vehicle from rolling off the platform and only work properly when the ramp

is lowered.

P 5-3

Placing Bridge in Truck

With bridge folded back toward platform, raise the dock

lift until the top the bridge is just above the opening of the

truck, push the bridge against the truck with your foot

while controlling the fall with the safety chains. As the

dock lift is raised, the bridge will cam over onto the truck

bed and lay flat for loading and unloading.

Removing Bridge from Truck and Securing

Begin to lower the dock lift until the bridge starts to cam

up over the end of the truck bed. With foot, chain, or

hand, flip bridge back toward platform. Once bridge is

folded back toward platform attach Snap Hook (A) to

secure the bridge in place and continue lowering the unit.

Bridge starts to cam up over

end of truck bed as the dock lift

raises or lowers.

How To Use Dock Lifts Efficiently

Palletized Loads: One (1) man removes pallet from

truck, places it in storage area and returns for next

pallet until truck is offloaded.

Non-Palletized Loads: One (1) man in truck stacks

material on pallet or 4-wheeled cars, second man

removes pallet or cart from truck places it in storage

area and returns for nest load until truck is

unloaded.

Objective: Free up the truck as quickly as possible.

•Do not remove bridge stops or allow bridge to hang vertically.

•Shear Hazard

SECTION 6:MAINTENANCE INSTRUCTIONS

The routine maintenance of this equipment is minor and consists of periodic checks.

Weekly: Once a week, or after repetitive operation, the lift operator shall run the lift to

full height. This will get rid of cylinder oil seepage build-up and lubricate the upper

cylinder barrel.

Monthly: Check that the hydraulic fluid level in the reservoir is 1” to 2” from the top of

the tank, depending on model, with the unit fully lowered. It is strongly urged that a

maintenance log be maintained with the dates of monthly inspections, the name of the

inspector and results of the inspection.

Be sure the maintenance device is properly engaged before performing maintenance

checks 2 through 6 or reaching beneath a raised lift. (Read all of section 6 for proper

maintenance safety leg procedures).

1. Clean all debris from the pit or the vicinity of floor mounted units in order to avoid

interference with the lift mechanism or rollers.

2. Check for presence and proper seating of all snap rings and clips on all axles,

cylinders, and rollers.

3. Check rollers, pins and bushings for any signs of wear such as flat spots, missing

fasteners, or dislodged bearing material.

4. Check the hydraulic fittings for cracks or leaks and clean up any seepage on or

beneath the cylinders.

5. Check hoses and electrical lines for abrasions or other abuse and check for snug

connections.

6. Operate the unit and check for any abnormal noise or vibrations.

7. Check all safety devices on the unit such as guardrails, safety chains, etc. including

any options such as electric toe guards or chocks, for proper operation.

8. Check the hinged bridge to insure that its stops are not damaged, allowing it to droop

more than 45 degrees below horizontal, check the hinge spools for cracks and or

broken welds, be sure the bridge leans back over the platform at least 20 degrees

beyond vertical.

Seasonal or semiannual maintenance:

Change hydraulic fluid for ambient temperature changes if appropriate. Check the fluid

reservoir to see if there is any evidence of accumulated condensation creating water

contamination. The fluid will appear “milky” and light pink in color. Water accumulation

will damage the hydraulic pump.

P 6-1

SECTION 6: (CONTINUED)

Maintenance Cautions:

1. Always remember that this is a piece of machinery with large moving parts that can

seriously hurt you.

2. Read this manual in its entirety before attempting service work.

3. Always use the maintenance device if you are going to work on the unit in the

elevated position or reach under the platform. (See the illustrations at the end of this

section for proper positioning and engagement of the maintenance supports.)

4. It may be necessary to bypass travel limit switches in order to properly position the

maintenance support.

5. When using the maintenance support observe the following rules:

A. There shall be no load on the platform

B. The maintenance support shall be properly engaged.

C. Hold the down button an extra 10 seconds when lowering onto the maintenance

support to be sure that all the weight of the lift is on the support.

D. Use shoring of blocking as a backup to the maintenance support.

E. Disconnect and tag the electricity to the unit to prevent accidental movement of

the lift by other personnel.

F. Spend as little time as possible under the lift.

6. Use only replacement parts recommended by the manufacturer.

7. Do not let the equipment stay in disrepair; fix little problems while they are little

problems or some of them may get severe very quickly.

8. Inspect the equipment on a regular schedule, preferably monthly.

9. Never work on the hydraulics or electrical systems unless the unit is fully lowered or

properly sitting on a maintenance device.

10.Never apply a load to the equipment unless the base is continuously supported and

non-portable units are securely lagged to the ground.

11. Never expect to hold leg assemblies open by simply lifting one end of a platform.

A. The roller end of most lifts are not gibbed or captured in any way, so lifting on the

roller end simply tilts the platform.

B. Even if you raise the clevis end of the platform, if the base frame is not firmly

lagged to the ground or held down by some other means, the legs will come up

with the platform in a spongy and unpredictable manner and could cause serious

injury.

C. If the maintenance device is unusable or missing, contact the factory (800-843-

3625) for other methods of blocking the lift up.

P 6-2

Section 6: (Continued)

Recommended Lift Blocking Procedures

This procedure describes the only factory-approved method of working under a lift.

Follow these instructions EVERY time you plan to reach or crawl beneath the lift to

perform service or maintenance – no matter how momentary that might be.

If the factory-provided maintenance device is damaged or missing, stop immediately

and consult the factory for assistance. The manufacturer is not liable for your failure to

use the approved maintenance device(s) and procedures that have been provided.

1. Any load must be removed from the lift prior to engaging the maintenance device(s).

These devices are designed to support an unloaded lift only. Failure to remove the

load from the lift prior to blocking could cause the failure of the maintenance

device(s) and allow the lift to fall unexpectedly. This can result in personal injury or

death, or permanent damage to the maintenance device(s) and/or the lift.

2. Raise the lift to its fully raised position. If you do not, the maintenance device(s) may

not be able to be placed properly in its/their designed blocking position.

3. Remove the maintenance device(s) from its/their storage location and place it/them

into the engaged position as shown on pages P 6-5, P 6-6 & P 6-7. Read and

understand the specific instructions for your model before proceeding.

4. Lower the lift until it makes complete contact with the maintenance device(s). Re-

check to ensure that all provided devices are fully and securely engaged. If the

device(s) is/are not fully engaged the lift could fall unexpectedly, resulting in

permanent damage to the device(s) or the lift.

P 6-3

Only authorized personnel should perform inspection or maintenance and

service procedures. Unauthorized personnel attempting these procedures

do so at the risk of severe injury or death.

Failure to properly adhere to lift blocking procedures is to risk the sudden

and uncontrolled descent of the lift during maintenance or inspection. A

falling lift can cause severe injury or death.

This manual suits for next models

116

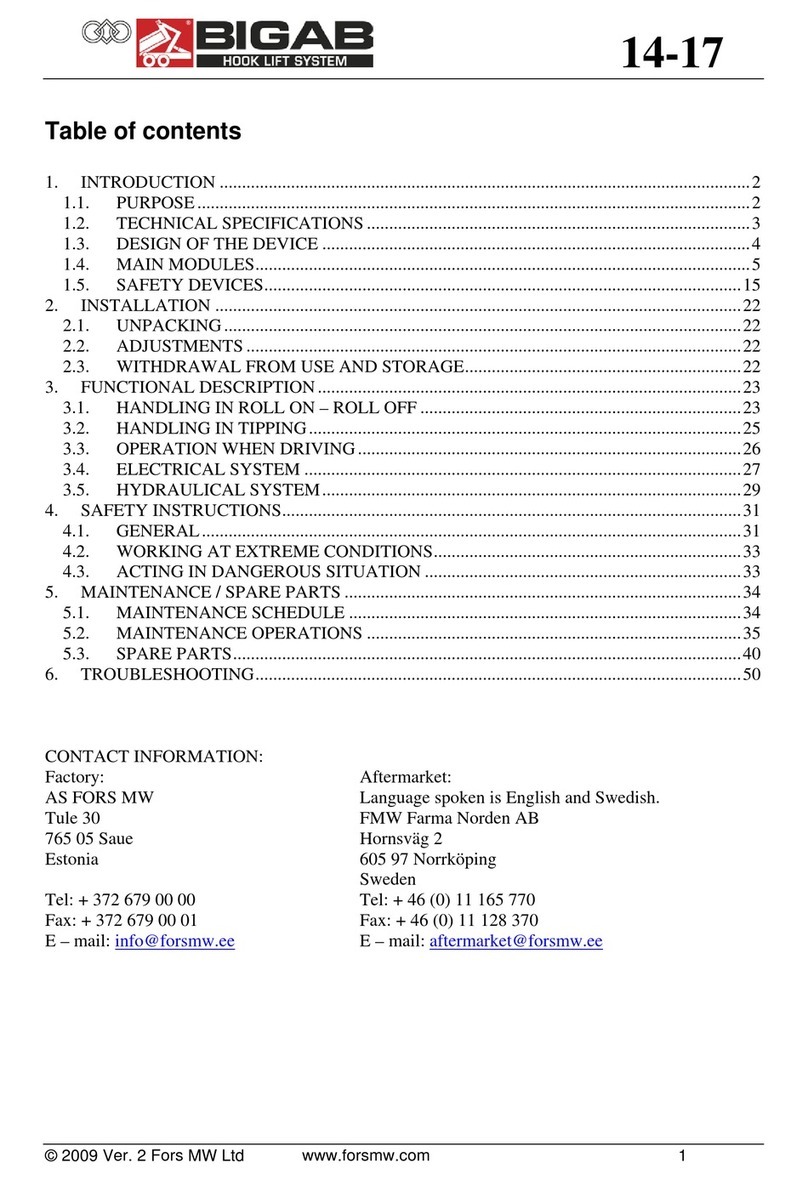

Table of contents

Other Advance Lifts Lifting System manuals

Popular Lifting System manuals by other brands

Evers

Evers SpanSet ASH 1t Operation manual

Conhersa

Conhersa ET-1000 user manual

Titan Lifts

Titan Lifts PREMIER Series Installation, operation & maintenance manual

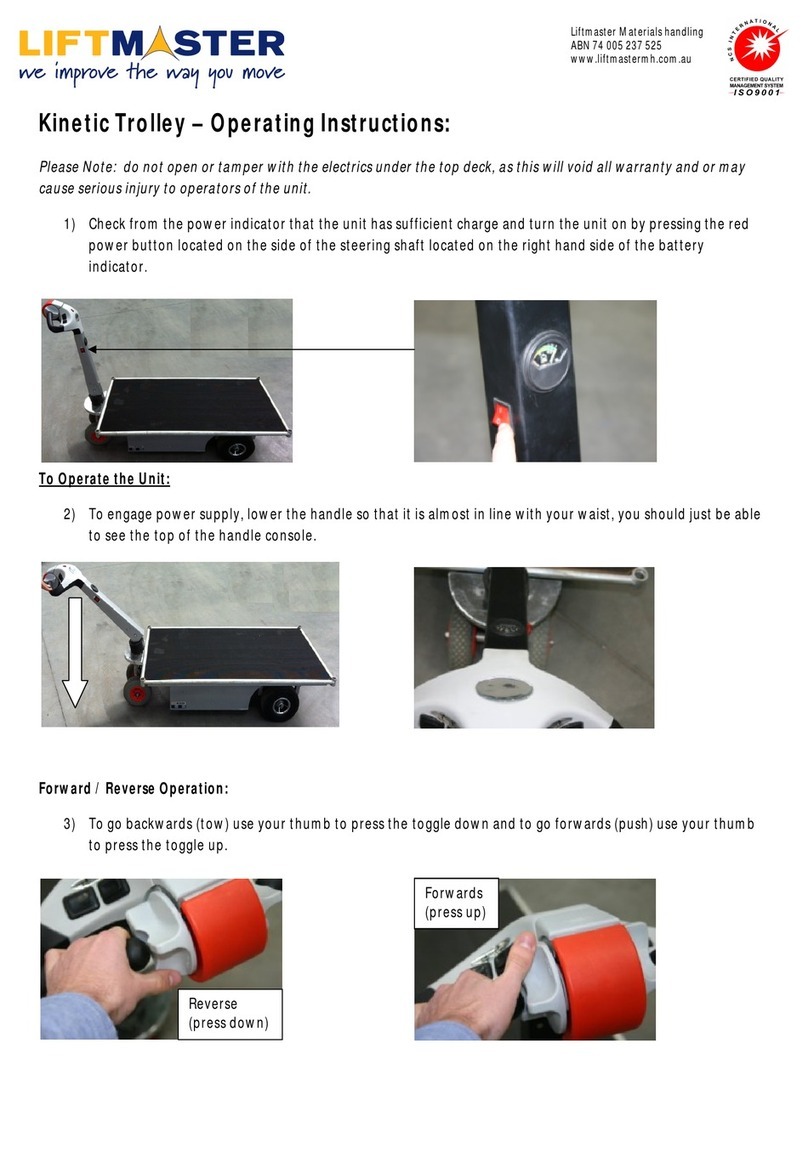

Chamberlain

Chamberlain Kinetic Trolley operating instructions

Versalift

Versalift VTL-135-F Operator's manual

BorMann

BorMann PRO BWR5204 manual

Tractel

Tractel Tirfor/greifzug TU-8 Operating and maintenance instruction

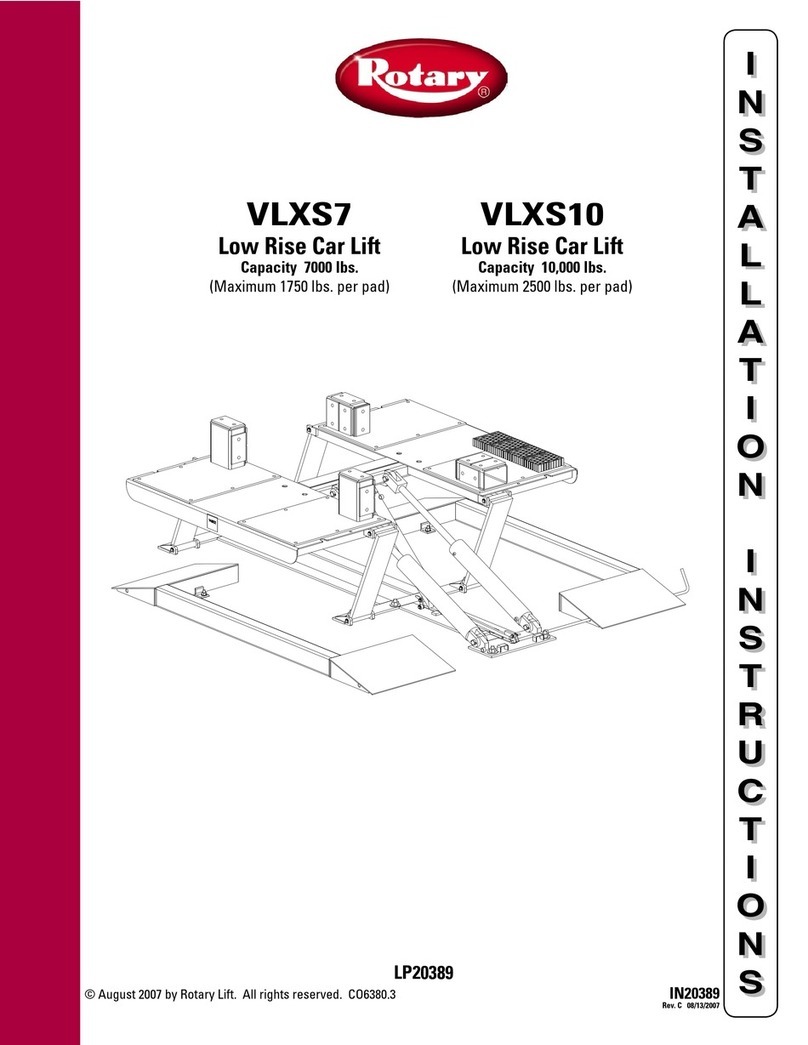

Rotary

Rotary VLXS7 installation instructions

S.R.Smith

S.R.Smith PAL2 Series owner's manual

Leguan

Leguan 165 Operator's and service manual

Atlas Equipment

Atlas Equipment 408-SL Super Deluxe Installation & operation manual

Terex

Terex Genie GTH1215M-101 Service and repair manual