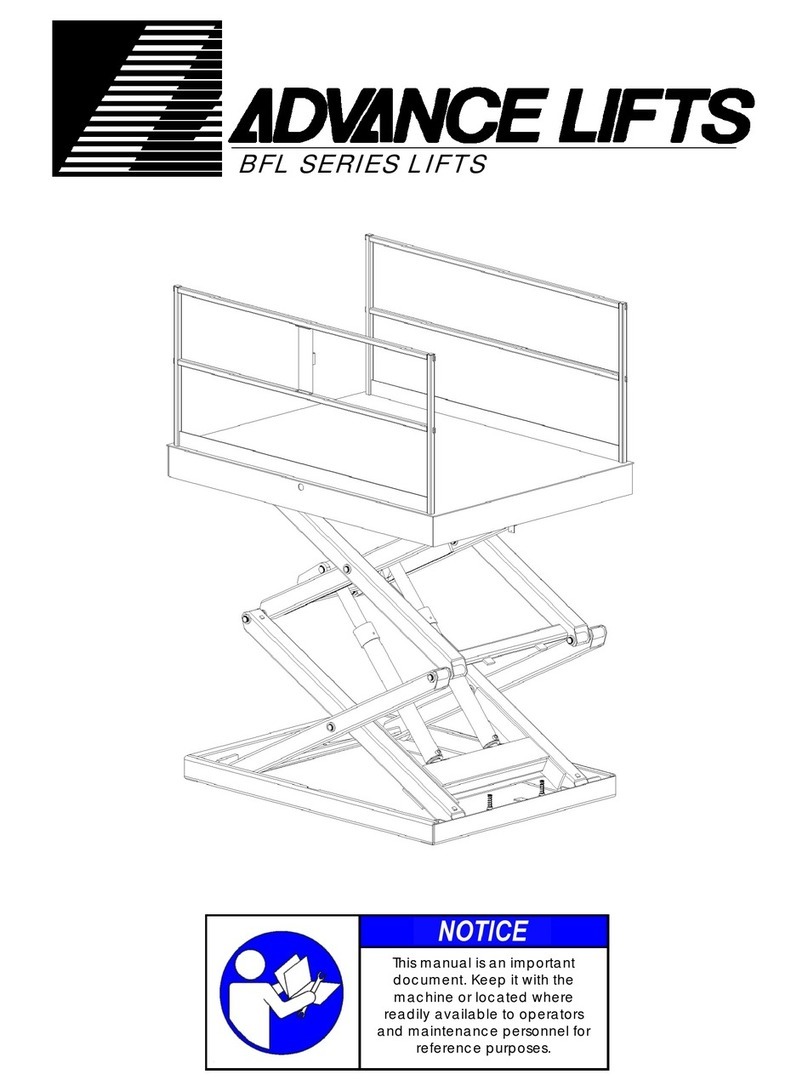

Advance Lifts 100 Series User manual

CAUTION!

THIS MANUAL IS AN IMPORTANT DOCUMENT IT

SHOULD BE KEPT WITH THE MACHINE OR LOCATED

WHERE READILY AVAILABLE TO OPERATORS AND

MAINTENANCE PERSONNEL FOR REFERENCE

PURPOSES.

100 SERIES

STRETCH WRAP MACHINES

OWNERS MANUAL

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

FOR THE FOLLOWING STRETCH WRAPPER MODEL NUMBERS

Throughout this manual, units are referred to by series. Each series has special

installation, maintenance and safety requirements.

100 Series Stretch Wrappers:

SW100L40, SW10H60

SW125L40, SW125H60

SW150L40, SW150H60

SW175L40, SW175H60

Stretch Wrapper Installation, Operation and Maintenance Manual

In any correspondence with your distributor or the factory you will need the

following information:

Model Number________________________________ Serial Number______________________________

Installation location: _________________________________

_______________________________

_______________________________

Distributor Information:____________________________________________

_________________________________

_________________________________

_________________________________

Advance Lifts Inc.

701 S. Kirk Road

St. Charles, IL 60174-3428

Toll Free 1-800-843-3625

Sales Fax 1-630-584-9405

Parts and Service Fax 1-630-584-6837

E-mail: [email protected]

*Advance Lifts Inc. furnishes one manual with each unit. Additional manuals are

available at $25.00 each.

P 1-1

SECTION 2. INDEX & INTRODUCTION

Identification……………………………………………………………….. Section 1

Index & Introduction ……………………………………………………… Section 2

*Responsibilities of Owners/Users ……………………………………… Section 3

*Installation Instructions ……………………………………….…………. Section 4

*Operating Instructions ………………………………………...………… Section 5

*Maintenance Instructions ……………………………………………….. Section 6

Electrical Details …………………………………………………………. Section 7

Schematics

Identification and Label Placement ………………………………………Section 8

Troubleshooting Hints ……………………………………………………..Section 9

Warranty …………………………………….………………………………Section 10

Parts Lists……………………………………………………………………Section 11

INTRODUCTION

Congratulations, the equipment that you have purchased is of the highest quality.

Your Advance Lifts Stretch Wrapper will provide you with many years of trouble

free service in return for the minimal maintenance described in this manual.

Please be sure that no individual is allowed to operate the stretch wrapper until

they have been fully familiarized with operating instructions in this manual. Also

insure that at least one person at the stretch wrapper site is familiar with the

maintenance section of this manual and is assigned responsibility for doing the

maintenance on a regular basis.

Please note that the stretch wrapper has a metal nameplate attached to it that

contains information such as the model number, capacities and the serial

number. Do not remove the nameplate. Be sure that load weight never exceeds

the capacity shown on the nameplate or they may cause damage to the stretch

wrapper or injure personnel. Also, be sure to have the serial number of the

stretch wrapper handy if you have to call the factory. The serial number identifies

your specific stretch wrapper and will allow factory personnel to give you the

most thorough and timely assistance possible.

This manual is under constant review and we would appreciate any constructive

suggestions that may enhance its usefulness. Please send your suggestions to

Advance Lifts Inc. Stretch Wrappers, Attn: Service Manager

Thank you for purchasing our product.

*Mandatory reading before attempting installation.

P 2-1

SECTION 3. RESPONSIBILITIES OF OWNERS & USERS

Owner responsibility: The owner shall be responsible for:

1. Ensuring that the installation of the advance stretch wrapper is in

conformance with applicable local, state and federal codes and ordinances.

2. Providing a properly maintained stretch wrapper that meets all applicable

safety standards.

3. Setting up and following a program of training and instructing employees in

safe methods of work before assigning them to operate or maintain a stretch

wrapper. The employer shall maintain records of this training to include the

day(s) of the training and the content of the training received. The employer

shall ensure, by adequate supervision, that correct operating and

maintenance procedures are understood and followed. The employer should

refer to the manufacture’s and installer’s instructions for this purpose.

4. Operating the stretch wrapper in accordance with the design specifications as

recommended by the manufacturer.

5. Repairing, prior to operation, all malfunctions or breakdowns that results in

unsafe operating conditions of the stretch wrapper.

6. Specifically inspecting safety interlocks, switches and other protective

devices, to ensure that these devices are not disabled or bypassed, and to

not permit the stretch wrapper to be operated unless these devices are fully

functional. These inspections will be in accordance with an established

program of periodic and regular inspections that are recorded along with a

complete history of all maintenance performed on the equipment.

User Responsibility: The User shall be responsible for:

1. Using all applicable safety features provided on the stretch wrapper.

2. Operating, maintaining and using the stretch wrapper only after being

properly instructed and trained in accordance with the instructions given in

item # 3 above.

3. Immediately reporting any damage to or malfunction of the stretch wrapper to

the employer or responsible authority.

4. Ensuring that all individuals are aware and clear of the operation and pinch

point areas before actuating the controls.

5. Not placing hands or fingers in or near moving portions of the machine during

use.

6. Ensuring that all individuals are standing clear of the rotating load and moving

carriage during the stretch wrapping operation.

7. Ensuring that no one disables or bypasses any safety interlocks, switches

and other protective devices and that the stretch wrapper is not operated

unless these devices are fully functional.

P 3-1

SECTION 4. INSTALLATION INSTRUCTIONS

Series 100 Stretch Wrap Machines

Equipment and Supplies Required:

1. Equipment to maneuver the Advance Lifts Stretch Wrapper into position. All

units are manufactured with forklift pockets for maneuvering.

2. An electrical fused disconnect (if required), wiring and fittings for the branch

circuit and the appropriate receptacle. While not necessary, Advance Lifts

recommends that this unit be connected to a dedicated circuit.

Shipping and Packaging Warning:

The stretch wrapper is shipped from the factory in one piece. No assembly is

required. The unit comes with a pre-wired electrical system that is ready to plug

in and is fully tested at the factory for ease of installation. However, if the installer

does not carefully follow these installation instructions, it is possible to damage

the equipment, so please read this entire procedure before proceeding with the

installation.

Equipment Location:

1. The floor should be flat and level concrete that is strong enough to support

the weight of the unit.

2. The equipment is suitable for indoor operation only.

3. Advance recommends a minimum of 3 feet clearance at the sides and behind

the stretch wrapper. An area in the front or the side of the stretch wrapper

must be obstruction free to accommodate the loading of pallets. The area

around the controls of the unit must be kept clear in order to prevent tripping

hazards during the loading and wrapping process.

Unloading and Final Positioning:

1. The preferred system of unloading is with a fork lift. Most stretch wrappers

are shipped attached to a shipping pallet or skid. Remove the unit from the

truck using the shipping skid. Once the unit is off the truck and safely on

the floor, remove all the banding and straps holding the unit to the skid.

2. There are fork pockets located on all Advance stretch wrappers

specifically for the purpose of lifting and moving the units. Forks should be

spaced so as to slide into both fork pockets and should be inserted as far

as possible. Care should be taken to prevent damage to the machine with

the forks. Lift the stretch wrapper off the skid and place it in the final

location.

3. After the unit is in position, clearance around the unit should be checked.

A minimum of 3 feet is recommended.

4. Optionally, drill the concrete and insert the four (4) anchors at the

locations provided in the base and tighten securely.

5. Assure power outlet voltage is the same as the voltage identified on the

machine. Depress E-Stop button (Model 150 & 175) and connect machine

to electrical power.

P 4-1

SECTION 5. OPERATING INSTRUCTIONS, FILM LOADING

Model 100

This model is designed to use hand wrapping film with a core tube which

extends beyond the film edge.

Model 125

This model is designed to use 12-18” wide hand wrap film. Any standard

film gauge is acceptable for use with this machine. Film tensioning is by means

of a frictional brake. Wrap tension can be varied by rotating an adjustment knob

located on the top of the film carriage. Rotating the knob clockwise increases film

tension. To load film, remove the friction adjustment knob assembly by rotating it

counter clockwise until it disengages from the carriage. Slide film roll down over

shaft until it engages the lower film support bearing at the bottom. Replace top

film bearing and adjustment knob assembly and tighten until the desired tension

is obtained.

Model 150

This model is designed to use 20” wide industrial film with a 3” core. Any

standard film gauge is acceptable for use with this machine. Film tensioning is by

means of a frictional brake. Wrap tension can be varied by rotating an adjustment

knob located on the top of the film carriage. Rotating the knob clockwise

increases film tension. To load film, remove the friction adjustment knob

assembly by rotating it counter clockwise until it disengages from the carriage.

Slide film roll down over shaft until it engages the lower film support bearing at

the bottom. Replace top film bearing and adjustment knob assembly and tighten

unit the desired tension is obtained.

Model 175

This model is designed to use 20” wide industrial machine film with a 3”

core. To load film, rotate the core retainer up, load film on stationary lower

retainer then rotate the top retainer back into place to secure film. This unit

utilizes a geared mechanical pre-stretch which must be loaded, in accordance

with the illustration below. Due to the nature of pre-stretch, heavier gauge films

are recommended for use.

Top view of film loading model 175 (only)

P 5-1

FILM ROLL

FILM IDLER

ROLLERS FILM TO

LOAD

SECTION 5. OPERATING INSTRUCTIONS (Continued)

MODELS 100 & 125

1. Place a loaded pallet on the turntable platform making sure that the load is

centered. Loads should be centered before rotating the unit as this will help

insure even wear on all moving parts and reduce the possibility of items

falling off the load being wrapped.

2. Place the loose end of the stretch wrap film onto the product, trapping the film

so that is will not pull out.

3. Make certain there are no obstructions around or under the stretch wrapper.

Make sure that the power cord and footswitch cord are not in contact with the

pallet or product.

4. Raise the stretch wrap film holder to the desired starting position and hold.

Depress the footswitch and start the turntable.

WARNING !

Operators must be alert to all personnel in the vicinity of the unit to avoid any

surprises to these personnel in regard to movement of position of the unit at any

time. Never operate the unit if you cannot see it or the personnel around it.

5. As the product begins to turn, adjust tension of the stretch wrap film dispenser

to achieve the desired wrapping tension.

6. When the desired amount of film has been placed on the load, remove

pressure from the footswitch.

7. After the platform has stopped rotating, break the film midway between the

product and attach film tail to product.

8. The pallet may now be removed from the platform.

CAUTION !

Exercise caution when removing the load from the unit. Make sure that the

device that is being used to remove the load picks up only the load and pallet

and not the turntable platform.

CONTROL FUNCTIONS:

Footswitch: Depress to rotate, realease to stop.

On/Off Switch: (on motor controller) Turn to “ON” postion for wrapping.

Speed Adjustment Knob: (On motor controller) Rotate clockwise to increase

turntable speed.

P 5-2

SECTION 5. OPERATING INSTRUCTIONS (Continued)

MODEL 150 & 175

Note: Hitting the “Emergency Stop” switch on the control panel cuts out all power

to the unit and stops all movement. If the “Emergency Stop” is used, all control

switches on the control panel must be placed in the “OFF” position prior to

disengagement of the “Emergency Stop”

1. Place a loaded pallet on the turntable platform making sure that the load is

centered. Make sure that there are no obstructions around or under the load.

2. Make sure that switches on the control panel are “OFF”. Turn the “ON/OFF”

key to the “ON” position.

3. Move the film carriage to the desired starting point using the carriage “UP”

and “DOWN” selector switch. Return the film carriage switch to the “OFF”

position.

4. Place the loose end of the stretch wrap film onto the product, trapping the film

so that it will not pull out.

5. Make sure all personnel are clear of the stretch wrap machine. Step back

away from the turntable and off to the side of the unit by the control panel.

WARNING !

Operators must be alert to all personnel in the vicinity of the unit to avoid any

surprises to these personnel in regard to movement of position of the unit at any

time. Never operate the unit if you cannot see it or the personnel around it.

6. Turn the turntable control switch to the “ROTATE” position.

7. Use the carriage “UP” and “DOWN” selector switch to place the film in the

desired starting location on the pallet.

8. The film carriage and turntable speeds can be adjusted by rotating their

respective adjustment knobs. Film tension can be adjusted by rotating the

knob on the top of the roll.

9. When the pallet has been fully wrapped, return the film carriage and turntable

selector switches to the “OFF” position.

10.After the platform has stopped rotating, break the film midway between the

product and attach film tail to product.

11.The pallet may now be removed from the platform.

CAUTION !

Exercise caution when removing the load from the unit. Make sure that the

device that is being used to remove the load picks up only the load and pallet

and not the turntable platform.

P 5-3

SECTION 5. OPERATING INSTRUCTIONS (Continued)

MODEL 150 & 175

CONTROL FUNCTIONS:

Power – Key switch: On/Off

Platform Rotation Switch: Off/Rotate

Platform Speed Knob, 0 – 100%: Rotate clockwise to increase platform speed.

Film Direction Switch:

Up: Up position moves film carriage up until upper limit switch is reached.

Down: Moves film carriage down until lower limit switch is reached.

Off: Carriage does not move

Film Speed Knob: 0 – 100%

Emergency Stop: Press to stop all machine functions.

SECTION 6. MAINTENANCE INSTRUCTIONS

Read this manual carefully before attempting any maintenance on the stretch

wrap machine.

CAUTION !

Whenever inspecting the unit or performing maintenance on the unit, be sure to

follow OSHA Tag out/Lockout requirements as a minimum precaution to prevent

accidental movement of the unit by other personnel.

This unit does not require any weekly maintenance, aside from keeping the area

around the unit free of loose debris.

Semi-Annually (or more frequently if required by heavy usage)

1. Once every six (6) months, the chain on the drive unit should be lubricated

using any standard chain lubricant or a #2 amber grease.

2. Check the chain tension and adjust if needed.

3. Check all rollers, axles and bearings for wear and schedule replacement if

warranted.

4. Do not let the equipment stay in disrepair; fix little problems while they are still

little or some of them may become severe quickly.

5. On model 175’s lightly lubricate the mechanical pre-stretch gears with any

standard gear lubricant or a #2 amber grease.

P 6-1

SECTION 7. ELECTRICAL DETAILS

P 7-1

SECTION 9. TROUBLESHOOTING

A. Turntable does not rotate, motor will not run:

1. Check to make sure that unit is plugged into a working electrical

receptacle.

2. Check control box fuse. Warning! Disconnect power before checking

fuses. If fuse(s) are blown check for electrical short before replacing fuses

or restoring power.

B. Turntable or carriage will not move, but motor runs:

1. Chain on drive assembly is broken or off the sprockets. Chain coming off

sprockets can damage gear(s) and/or gear reducer. Maintain proper chain

tension as described in the maintenance section of this manual.

2. Defective or damaged gear reduction unit.

3. Turntable or load is obstructed.

C. Equipment turns too slowly:

1. Foreign material may be lodged under the platform or in the drive

mechanism.

2. The load may be rubbing against an adjacent obstruction.

3. Speed settings may be too low.

4. Load exceeding equipment ratings.

D. Equipment does not turn the rated load:

1. Unit may be overloaded.

2. Platform may be shifted or damaged from transit and binding.

3. Foreign material may be lodged below platform on in drive mechanism.

4. Load may be hitting an adjacent obstruction.

E. Film does not dispense properly or keeps breaking.

1. Film tension set too high.

2. Turntable speed too fast.

3. Film quality too low for pre-stretch capabilities, (175 Model only, see

alternative film loading detail below).

0% Pre-Stretch mode (Model 175 only)

FILM ROLL

FILM IDLER

ROLLERS FILM TO

LOAD

SECTION 10. WARRANTY

For a period of one year from date of shipment from the Company’s plant, the

Company agrees to replace or repair free of charge, any defective parts, material

or workmanship on new equipment.

For an additional two years beyond the first year of warranty, the company shall

replace or repair any parts returned to the Company freight prepaid, subject to

factory inspection and determination of cause of failure. This warranty is not

limited by the number of cycles, but does not include normal wear items such as

chains, sprockets, belts, rollers & shafts.

For a period of five years from date of shipment from the Company’s plant, the

company agrees to repair or replace any defective structural component.

Company authorization must be obtained prior to commencement of any work.

The Company reserves the right of final determination in all warranty

considerations. Evidence of low supply voltage, overloading, abuse, neglect or

field modification without written approval shall void this warranty. No contingent

liabilities will be accepted.

Damage incurred in transport is the responsibility of the carrier and is not

covered by this warranty. Any damage detected upon receipt of equipment

should be immediately reported to the carrier. If you need assistance filing your

claim please contact Advance Lifts.

P 10-1

SECTION 11. PARTS LIST

SW100H60/L40 & SW125H60/L40 PART #

MECHANICAL:

TURNTABLE WHEEL 003-892

TURNTABLE WHEEL BOLT 004-067

TURNTABLE WHEEL NUT 004-065

TURNTABLE SPROCKET ASSEMBLY 035-132

ELECTRICAL

DRIVE BOARD (KBMD240D) 002-900

TURNTABLE GEAR REDUCER (920MDN30R56) 015-211

MOTOR 115/1 003-580

MOTOR 230/3 003-579

SSW150H60 & SW175H60

MECHANICAL:

TURNTABLE CASTER 015-724

TURNTABLE SPROCKET ASSEMBLY 035-132

ELECTRICAL

TURNTABLE DRIVE MOTOR 115/1 003-580

TURNTABLE DRIVE MOTOR 230/3 003-579

TURNTABLE BOARD (KBMM225) 003-582

TURNTABLE GEAR REDUCER (920MDN30R56) 015-211

CARRIAGE GEAR REDUCER (920MDN50R56) 015-213

CARRIAGE MOTOR 115/1 001-393

CARRIAGE MOTOR 230/3 003-581

CARRIAGE DRIVE BOARD 015-349

LIMIT SWITCH 026-184

LIMIT SWITCH ARM 027-470

SWL150L40 & SW175L40

MECHANICAL

TURNTABLE WHEEL 003-892

TURNTABLE WHEEL BOLT 004-067

TURNTABLE WHEEL NUT 004-065

TURNTABLE SPROCKET ASSEMBLY 035-132

ELECTRICAL

TURNTABLE DRIVE MOTOR 115/1 003-580

TURNTABLE DRIVE MOTOR 230/3 003-579

TURNTABLE BOARD (KBMM225) 003-582

TURNTABLE GEAR REDUCER (920MDN30R56) 015-211

CARRIAGE GEAR REDUCER (920MDN50R56) 015-213

CARRIAGE MOTOR 115/1 001-393

CARRIAGE MOTOR 230/3 003-581

CARRIAGE DRIVE BOARD 015-349

LIMIT SWITCH 026-184

LIMIT SWITCH ARM 027-470

P 11-1

013108

CAUTION!

THIS MANUAL IS AN IMPORTANT DOCUMENT IT

SHOULD BE KEPT WITH THE MACHINE OR LOCATED

WHERE READILY AVAILABLE TO OPERATORS AND

MAINTENANCE PERSONNEL FOR REFERENCE

PURPOSES.

300 AND 200 SERIES

SEMI AUTOMATIC

STRETCH WRAP MACHINES

OWNERS MANUAL

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

FOR THE FOLLOWING STRETCH WRAPPER MODEL NUMBERS

Throughout this manual, units are refered to by series. Each series has special

installation, maintenance and safety requirements.

300 Series Stretch Wrappers (SW300L40 & SW300H60)

200 Series Stretch Wrappers (SW200L40 & SW200H60)

Stretch Wrapper Installation, Operation and Maintenance Manual

In any correspondence with your distributor or the factory you will need the following

information:

Model Number________________________________ Serial Number______________________________

Installation location: _________________________________

_______________________________

_______________________________

Distributor Information:____________________________________________

_________________________________

_________________________________

_________________________________

Advance Lifts Inc.

701 S. Kirk Road

St. Charles, IL 60174-3428

Toll Free 1-800-843-3625

Sales Fax 1-630-584-9405

Parts and Service Fax 1-630-584-6837

E-mail: [email protected]

*Advance Lifts Inc. furnishes one manual with each unit. Additional manuals are available

at $25.00 each.

P 1-1

SECTION 2 INDEX & INTRODUCTION

Identification………………………………………………………………. Section 1

Index & Introduction …………………………………………………….. Section 2

*Responsibilities of Owners/Users ……………………………………… Section 3

*Installation Instructions ……………………………………….………… Section 4

*Operating Instructions ………………………………………...………… Section 5

Film Selection

*Maintenance Instructions ………………………………………………. Section 6

Electrical Details …………………………………………………………..Section 7

Schematics

Identification and Label Placement ………………………………………Section 8

Troubleshooting Hints ……………………………………………………. Section 9

Warranty …………………………………….………………………………Section 10

Glossary of Terms………………………………………………………… Section 11

Parts Lists……………………………………………………………………Section 12

INTRODUCTION

Congratulations, the equipment that you have purchased is of the highest quality.

Your Advance Lifts Stretch Wrapper will provide you with many years of trouble free

service in return for the minimal maintenance described in this manual.

Please be sure that no individual is allowed to operate the stretch wrapper until they

have been fully familiarized with operating instructions in this manual. Also insure that

at least one person at the stretch wrapper site is familiar with the maintenance section

of this manual and is assigned responsibility for doing the maintenance on a regular

basis.

Please note that the stretch wrapper has a metal nameplate attached to it that

contains information such as the model number, capacities, and the serial number.

Do not remove the nameplate. Be sure that load weight never exceeds the capacity

shown on the nameplate or they may cause damage to the stretch wrapper or injure

personnel. Also, be sure to have the serial number of the stretch wrapper handy if

you have to call the factory. The serial number identifies your specific stretch

wrapper and will allow factory personnel to give you the most thorough and timely

assistance possible.

This manual is under constant review and we would appreciate any constructive

suggestions that may enhance its usefulness. Please send your suggestions to

Advance Lifts Inc Stretch Wrappers, Attn: Service Manager

Thank you for purchasing our product.

*Mandatory reading before attempting installation.

P 2-1

SECTION 3. RESPONSIBILITIES OF OWNERS & USERS

Owner responsibility: The owner shall be responsible for:

1. Ensuring that the installation of the Advance Lifts Stretch Wrapper is in conformance

with applicable local, state and federal codes and ordinances.

2. Providing a properly maintained stretch wrapper that meets all applicable safety

standards.

3. Setting up and following a program of training and instructing employees in safe

methods of work before assigning them to operate or maintain a stretch wrapper.

The employer shall maintain records of this training to include the day(s) of the

training and the content of the training received. The employer shall ensure, by

adequate supervision, that correct operating and maintenance procedures are

understood and followed. The employer should refer to the manufacture’s and

installer’s instructions for this purpose.

4. Operating the stretch wrapper in accordance with the design specifications as

recommended by the manufacturer.

5. Repairing, prior to operation, all malfunctions or breakdowns that results in unsafe

operating conditions of the stretch wrapper.

6. Specifically inspecting safety interlocks, switches and other protective devices, to

ensure that these devices are not disabled or bypassed, and to not permit the

stretch wrapper to be operated unless these devices are fully functional. These

inspections will be in accordance with an established program of periodic and

regular inspections that are recorded along with a complete history of all

maintenance performed on the equipment.

User Responsibility: The User shall be responsible for:

1. Using all applicable safety features provided on the stretch wrapper.

2. Operating, maintaining and using the stretch wrapper only after being properly

instructed and trained in accordance with the instructions given in item # 3 above.

3. Immediately reporting any damage to or malfunction of the stretch wrapper to the

employer or responsible authority.

4. Ensuring that all individuals are aware of and clear of the operation and pinch point

areas before actuating the controls.

5. Not placing hands or fingers in or near moving portions of the machine during use.

6. Ensuring that all individuals are standing clear of the rotating load and moving

carriage during the stretch wrapping operation.

7. Ensuring that no one disables or bypasses any safety interlocks, switches and other

protective devices and that the stretch wrapper is not operated unless these devices

are fully functional.

Modifications or Alterations: Modifications or alternations of industrial stretch

wrappers shall be made only with written permission of the original manufacturer,

Advance Lifts Stretch wrappers. These changes shall be in conformance with all

applicable provisions of this standard and shall be as safe as the equipment was

before modification. These changes shall also satisfy all safety recommendations of

the original equipment manufacturer of the particular application of the stretch

wrapper.

P 3-1

This manual suits for next models

8

Table of contents

Other Advance Lifts Lifting System manuals