Advanced Amplifiers AA-20M1G-50 User manual

1 | Page - Ver. 1. 0

Instruction Manual and Quick Start Guide

Exodus Advanced Communications

Solid State RF Amplifier System

AA-20M1G-50

20 - 1000 MHz, 50 Watt Min., 47 dB Min.

2 | Page - Ver. 1. 0

Table of Contents

SAFETY INSTRUCTIONS ........................................................................................................................................... 3

SPECIFICATIONS ...................................................................................................................................................... 4

ELECTRICAL SPECIFICATIONS............................................................................................................................... 4

ENVIRONMENTAL CHARACTERISTICS ................................................................................................................. 4

MECHANICAL SPECIFICATIONS............................................................................................................................ 4

OPERATING INSTRUCTIONS & GENERAL INFORMATION ........................................................................................ 5

INTRODUCTION................................................................................................................................................... 5

INCOMING INSPECTION...................................................................................................................................... 5

RF & AC CABLE CONNECTION ............................................................................................................................. 5

RF TURN ON PROCEDURE ................................................................................................................................... 5

RF TURN OFF PROCEDURE .................................................................................................................................. 5

DECLARATION OF CE CONFORMITY .................................................................................................................... 6

LIMITED WARRANTY ........................................................................................................................................... 6

CONTACT INFORMATION .................................................................................................................................... 6

FRONT & REAR PANEL DESCRIPTIONS .................................................................................................................... 7

FRONT PANEL VIEW ............................................................................................................................................ 7

REAR PANEL VIEW............................................................................................................................................... 8

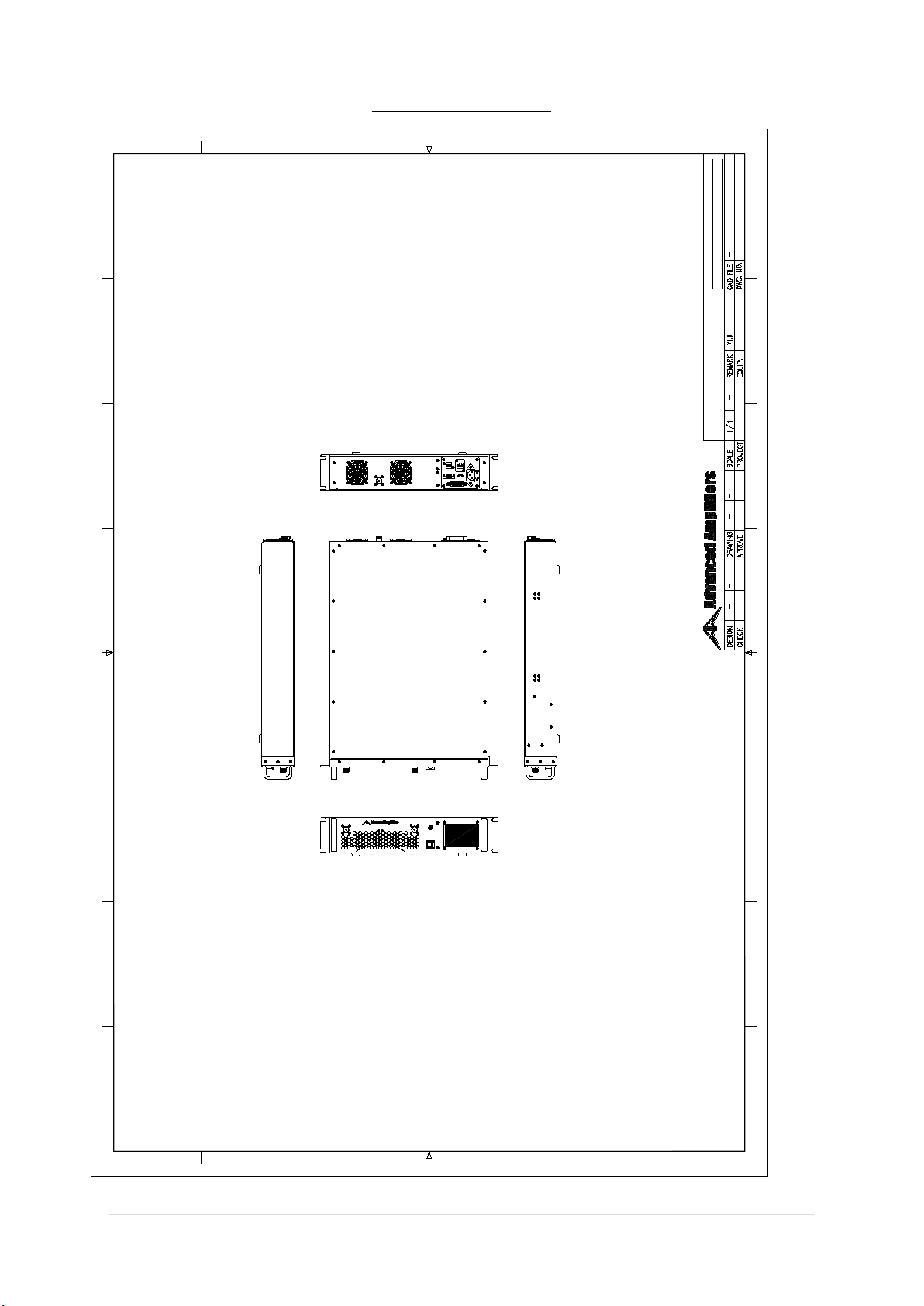

SYSTEM OUTLINE VIEW .......................................................................................................................................... 9

SYSTEM BLOCK DIAGRAM..................................................................................................................................... 10

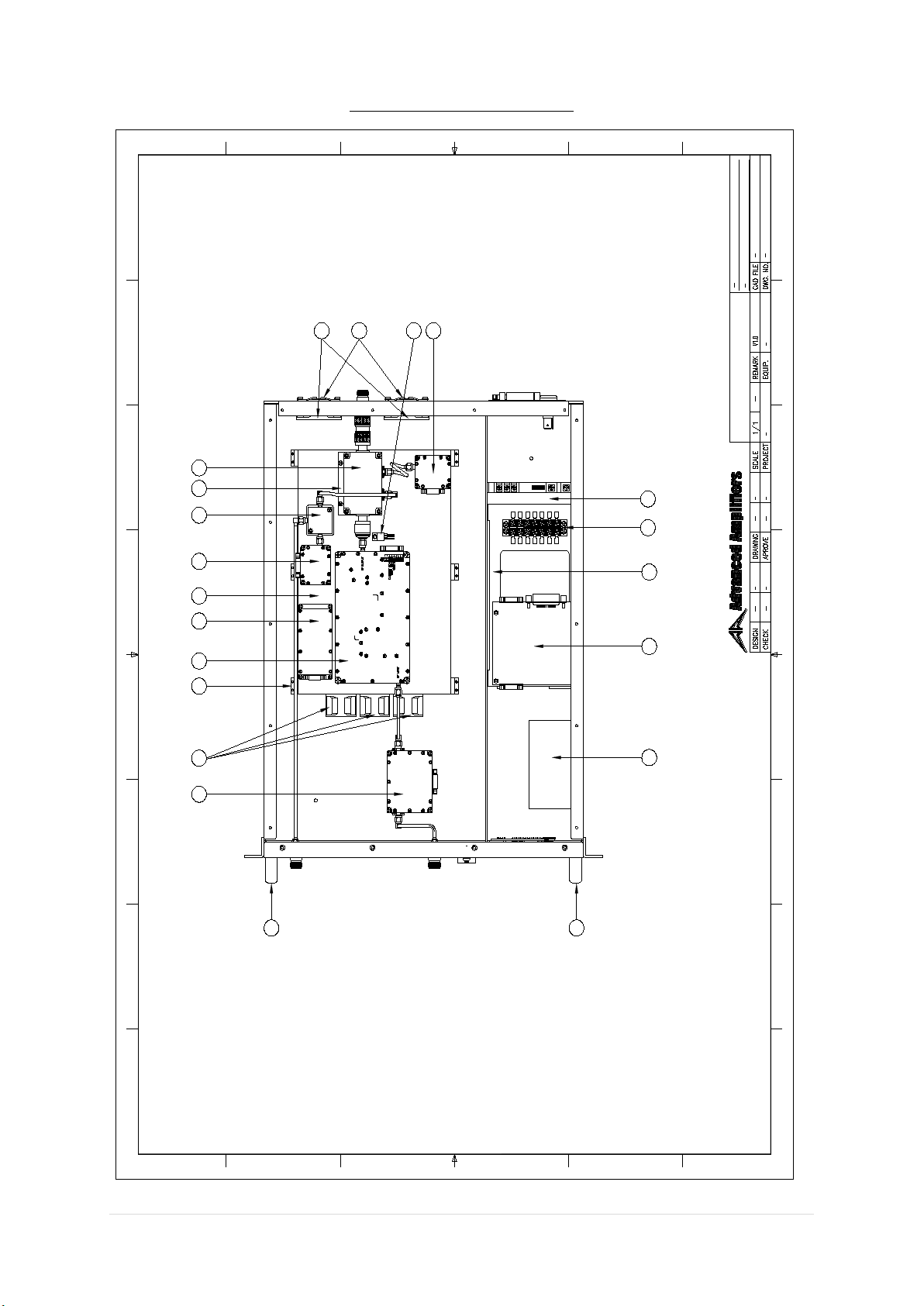

SYSTEM VIEW, TOP INTERIOR ............................................................................................................................... 11

SYSTEM VIEW, BOTTOM........................................................................................................................................ 12

SYSTEM PARTS LIST ............................................................................................................................................... 13

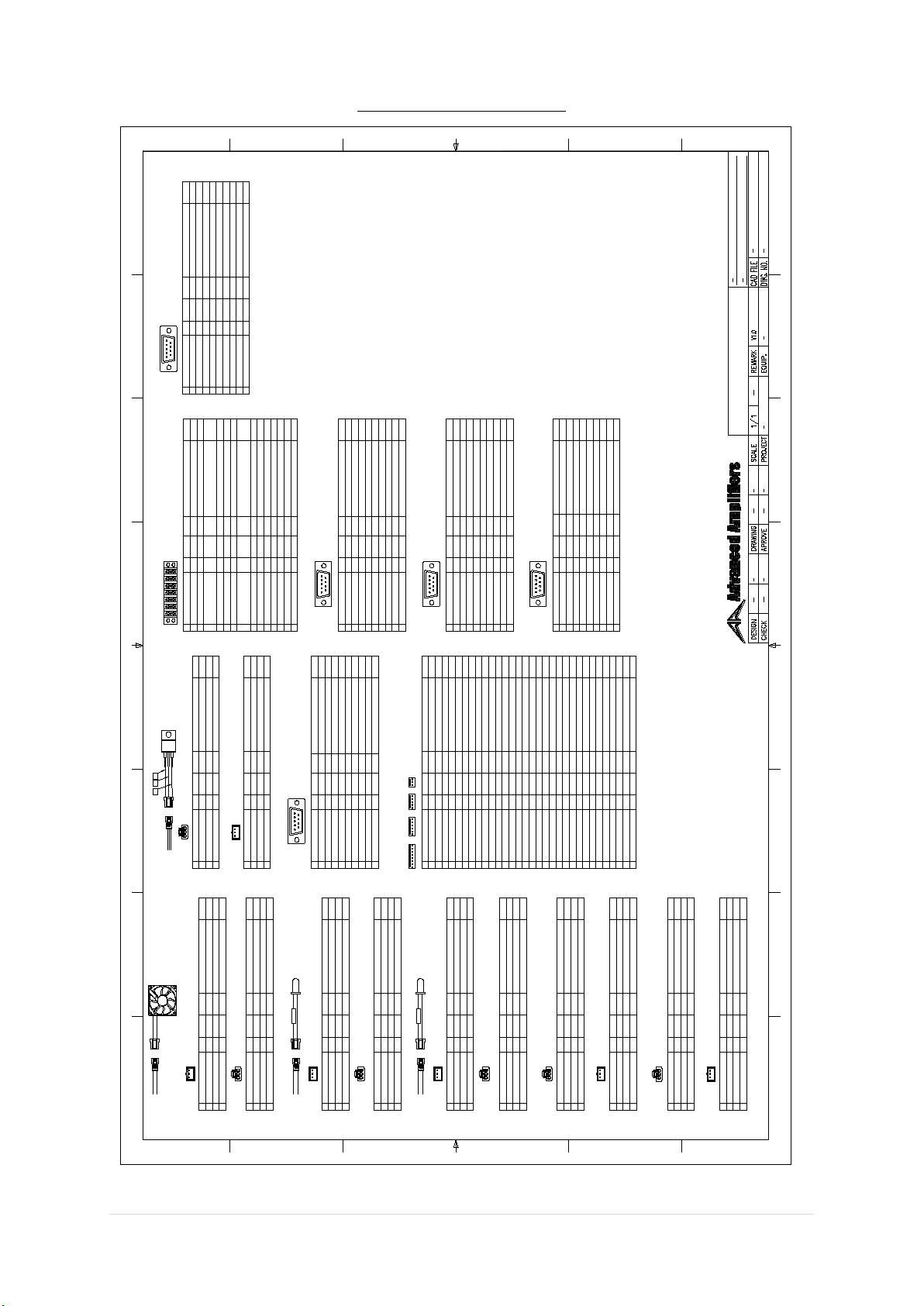

SYSTEM WIRING DIAGRAM................................................................................................................................... 14

LOCAL CONTROLLER LCD INTERFACE .................................................................................................................... 15

SCREEN 1........................................................................................................................................................... 15

SCREEN 2........................................................................................................................................................... 16

SCREEN 3........................................................................................................................................................... 17

SCREEN 4: ......................................................................................................................................................... 18

SCREEN 5: ......................................................................................................................................................... 19

REMOTE CONTROLLER INTERFACE SOFTWARE..................................................................................................... 20

PRIMARY (MAIN) WINDOW............................................................................................................................ 20

ALC ON/OFF Window........................................................................................................................................ 21

ALC OFF Window .......................................................................................................................................... 21

ALC ON Window ........................................................................................................................................... 22

FAULT Window.................................................................................................................................................. 23

COMM Window ................................................................................................................................................ 24

IP ADDRESS SETUP ............................................................................................................................................ 25

SYSTEM LOG STATUS ......................................................................................................................................... 25

3 | Page - Ver. 1. 0

OPTIONAL - IEEE-488 COMMAND LIST ................................................................................................................. 26

ETHERNET INITIAL PARAMETER SETUP VIA USB CONNECTION ............................................................................ 27

MONITORING WINDOW ................................................................................................................................... 30

SAFETY INSTRUCTIONS

BEFORE USING THIS EQUIPMENT

Read this manual and become familiar with safety markings and instructions.

Inspect unit for any sign of external damage. Do not use this equipment if there is physical damage or missing

parts.

Verify the input AC voltage to the main power supply

INTENDED USE

This product is intended for general laboratory use in a wide variety of industrial and scientific applications.

RF OUTPUT LOAD & PROPER GROUNDING REQUIRED

The RF output connector must be connected to a load before the AC switch is on.

AC & RF power must be off before disconnecting the output load or other components.

The main power source to the equipment must have an uninterrupted safety ground that has sufficient size to

the power cord.

REPAIR & MAINTENANCE

All repair or maintenance work must be performed by a factory authorized technician in order to extend the

operating life of this equipment and not to void any outstanding warranty.

FORCED AIR COOLING

This equipment requires forced air cooling. All air inlets and outlets must be cleared and free of blocking at all

time. Insufficient air flow will result in damaged equipment.

SAFETY SYMBOLS

This symbol is marked on the equipment when it is necessary for the user to refer to the

manual for important safety information. This symbol is indicated in the Table of Contents to

assist in locating pertinent information.

Dangerous voltages are present. Use extreme care.

CAUTION: The caution symbol denotes a potential hazard. Attention must be given to the statement to

prevent damage, destruction or harm.

This symbol indicates protective earth terminal.

4 | Page - Ver. 1. 0

SPECIFICATIONS

ELECTRICAL SPECIFICATIONS: 50Ω, 25°C

Parameter

Specification

Notes

Operating Frequency Range

20 - 1000 MHz

Power Output @ Psat

50 Watt Min 1

CW

Power Gain

47 dB Min

Power Gain Flatness

3.0 dB p-p Max

Input Return Loss

-10 dB Max

Relative to 50 Ohm

2-Tone Intermodulation (IMD)

<-30 dBc Typ

37dBm/Tone, Δ = 1MHz

Harmonics 2nd / 3rd

<-25 dBc Typ / -15 dBc Typ

At Rated Pout

Spurious

-60 dBc Max

Non-harmonics

Operating Voltage

100 - 240 VAC

Power Consumption

350 Watt Max

At rated Pout

Input Power Protection

+8 dBm Max

<10 Sec without damage

Load VSWR Protection

∞ : 1

<1 minute at rated Pout

ENVIRONMENTAL CHARACTERISTICS

Parameter Specification Notes

Operating Ambient Temperature

0 to +50 °C

Storage Temperature

-40 to +85 °C

Relative Humidity

5 to 95 %

Non-condensing

MECHANICAL SPECIFICATIONS

Parameter

Specification

Notes

Dimensions W x H x D

430 x 88 x 562 mm

2U excluding handles

Weight

10 kg.

RF Connectors In/Out

Type-N Female

Front or rear panel

AC Power / Interface Connector

IEC 60320-C14 / 9-Pin D-Sub

Cooling

Built in Fan Cooling

OPTIONAL: Digital Monitor & Control

FWD, REV, VSWR, GAIN, ALC, V & I, TEMP

Ethernet RJ-45 TCP/IP, RS422/485, USB

Optional GPIB Interface

Remote Bluetooth application

Notes:

1. LCD controller option may reduce output power by up to -0.5dB

5 | Page - Ver. 1. 0

OPERATING INSTRUCTIONS & GENERAL INFORMATION

INTRODUCTION

Advanced Amplifiers is a multinational RF communication equipment and engineering service company serving

both commercial and government entities and their affiliates worldwide.

Headquartered in San Diego, California, the company utilizes its global network of resources to effectively serve

customer requirements.

As a unique original equipment manufacturer of power amplifiers ranging from 500KHz to 51GHz with various

output power levels and noise figure ranges, we fully support custom designs and manufacturing requirements

for both small and large volume levels. We bring decades of combined experience in the RF field for numerous

applications including military jamming, communications, radar, EMI/EMC and various commercial projects with

all designing and manufacturing of our HPA, MPA, and LNA products in-house.

Advanced Amplifiers received its ISO9001:2009 and ISO14001:2009 certification on January 2013 by ITQA which

is an accredited member of JAS-ANZ.

With our in-house engineering capabilities and fully equipped manufacturing facilities, Advanced Amplifiers is

committed to provide the best in RF products with industry leading quality and lead time.

INCOMING INSPECTION

Inspect unit for any sign of external damage. Do not use this equipment if there is physical damage or missing

parts. Inspect all front and rear panel connectors for damage. Inspect fans and their airways for any damage or

blockings. For a unit with a digital controller option, the interface software USB is with the manual.

RF & AC CABLE CONNECTION

RF Input and Output connectors are Type-N female connectors. Use the standard AC cable that was supplied by

the manufacturer or higher power rating cables than the manual specifies. Refer to the front and rear panel

description page for the location of RF and AC connectors.

RF TURN ON PROCEDURE

Connect RF input to an RF generator. Connect a suitable load for the power rated and continuous operation to

the output connector. Turn on the AC switch, display will show STANDBY. Optionally, connect the unit to a digital

control Software or Ethernet connection. Set the RF generator to nominal 0dBm and set the desired frequency

in the specified range. Select Gain or ALC and set to the desirable output power level then press the ONLINE

button. Use the front panel LCD gain adjust or the remote function to adjust the output power on the power

meter and the LCD screen to desired levels.

Refer to Appendix 1 for detailed operating instructions of the local and remote controller.

RF TURN OFF PROCEDURE

Decrease the RF drive from the RF generator to below -20dBm and press STANDBY on the LCD or via the control

software. Turn off AC switch on the front panel. Disconnect any unnecessary cable connections.

6 | Page - Ver. 1. 0

DECLARATION OF CE CONFORMITY

We, Advanced Amplifiers, declare under our sole responsibility that the product to which this declaration relates

is in conformity with the following standard(s) or other normative document(s):

Council Directive 98/37/EC on the Safety of Machinery Directive

Council Directive 2006/95/EC on Low Voltage Equipment Safety

LIMITED WARRANTY

Advanced Amplifiers warrants that goods delivered hereunder, at the time of delivery, will be free from defects

in workmanship and material and will conform to the requirements of the purchase order. Seller’s liability

hereunder shall be limited to the repair or replacement of defective goods F.O.B. factory of which Seller is

modified in writing by Buyer within three (3) years following delivery thereof to Buyer, and in no event will

Seller be liable for incidental, special or consequential damages. (Note: One (1) year warranty for moving parts

such as fans and power supplies). The foregoing warranty is in lieu of all other warranties express or implied

(except as to title), including any implied warranty of merchantability or suitability for purpose or against

infringement.

CONTACT INFORMATION

Please send all inquiries to:

Advanced Amplifiers

10401 Roselle Street

San Diego, CA 92121

WEB: WWW.ADVANCEDAMPLIFIERS.COM

EMAIL: SALES@ADVANECDAMPLIFIERS.COM

COPYRIGHT & TRADEMARKS

Copyright 2019 Advanced Amplifiers All rights reserved. All other trademarks and brand names are the

property of their respective proprietors.

7 | Page - Ver. 1. 0

FRONT & REAR PANEL DESCRIPTIONS

FRONT PANEL VIEW

No. Title Function

1

RF FOWARD

SAMPLE

System RF Forward Signal Sample Port, N type Female Connector.

2 RF INPUT System RF Input Connector, N type Female Connector.

3 FAULT LED

System Fault LED: Turn ON an LED when System Fault.

- Over Input, Over Temp, Over Current, Voltage Alarm, VSWR Alarm

4 LCD DISPLAY 4” Touch screen LCD Display, System Control LCD Panel.

5 POWER SWITCH AC Power Switch.

AA-20M1G-50

POWER

ONOFF

FAULT

31 24

5

0dBm InputRF Sample

8 | Page - Ver. 1. 0

REAR PANEL VIEW

No. Title Function

1 RF OUTPUT System RF Output Connector, N type Female Connector.

2 USB USB Communication Connector, Type A Female.

3 ETHERNET Ethernet Communication Female Connector, RJ-45.

4

AC POWER

CONNECTOR

AC Power Input 100 ~ 240 VAC, 50/60Hz, IEC60320-14 Connector.

5 DEBUG

System Controller Debugging Female Connector.

Port access requires factory authorization

6 GPIB GPIB Communication Female Connector.

7 RS-422

RS-422 Communication Female 9pin D-Sub Connector.

P1 Rx-, P2 Rx+, P3 Tx+, P4 Tx-, P5 GND.

AA-20M1G-50

100 ~ 240 VAC

50/60Hz

ETHERNET

DEBUG RS-422

USB

GPIB

112

1324

67

51

2

3

4

50Ω Output

9 | Page - Ver. 1. 0

SYSTEM OUTLINE VIEW

AA-20M1G-50 SYSTEM OUTLINE

POWER

ONOFF

FAULT

0dBm Inp utRF Sample

100 ~ 240 VAC

50/60Hz

ETHERNET

DEBUG RS-422

USB

GPIB

112

1324

50Ω Output

AA-20M1G- 50

AA-20M1G- 50

10 | Page - Ver. 1.0

SYSTEM BLOCK DIAGRAM

AA-20M1G-50 BLOCK DIAGRAM

TEMP MONITOR

CURR MONITOR

ENABLE

ATTEN C ONTROL

+5VDC

POWER

LAMP

(GREEN)

LCD

DISPLAY

FAULT

FAULT

LAMP

(RED)

+5VDC

LCD CONTROL

ENABLE

PS+

CURR MONITOR

INPUT DETECT

FWD DETECT

TEMP ALARM

+5VDC

ETHERNET

USB

RS-422

LCD CONTROL

SYSTEM

CONTROLLER

USB

USB

ETHERNET

ETHERNET

BLUETOOTH

RJ45

FEMALE

DEBUG

DUBEG

USB TYPE A

FEMALE

MINI USB

TYPE FEMALE

INPUT MODULE

HPA MODULE COUPLER

MODULE 1

R471-2

FRONT PANEL

REAR PANEL

TEMP MONITOR

ATTEN C ONTROL

PS+

FAN+

FAN 1~5

GPIB

TEMP

SENSOR

TEMP SENSE

+5VDC

+5VDC

RS-232

IEEE-488

CONTROLLER

IEEE-488

IEEE-488

IEEE-488

IEEE-488

FEMALE

INPUT DETECT

+5VDC

E1

RS-422

RS-422

9PIN D-SUB

FEMALE

REF DETECT

R471-1

SW

C: N WHITE

B: L BLACK

A: GND GREEN

N

L

GND POWER SUPPLY

750W V+

V-

PS+

GND

AC 100~240V

50/60Hz

AC INPUT

DEBUG

TEMP SENSE

FAN+

TEMP ALARM

TEMP SENSE

PS+

FAN

CONTROLLER

COUPLER

MODULE 2

FWD DETECT

+5VDC

RF DETECT

MODULE 1

REF DETECT

RF DETECT

MODUEL2

+5VDC

FAULT

FAN+

11 | Page - Ver. 1.0

SYSTEM VIEW, TOP INTERIOR

AA-20M1G-50 SYSTEM VIEW-TOP INTERIOR

Top Interior View

M3.0 M3.0 M3.0 M3.0 M3.0 M3.0

1

2

13

14

7

15

17 16

321

11

20

20

12

19

8

14

18

4 5 6 9 10

13

12 | Page - Ver. 1.0

SYSTEM VIEW, BOTTOM INNER

N/A

13 | Page - Ver. 1.0

SYSTEM PARTS LIST

No.

Part Number

Qty.

Description

1

1

Input Module

2

3

40 x 28mm Cooling Fan

3

6

Support 1

4

1

HPA Module

5

1

Fan Controller

6

1

Heat Sink

7

1

RF Detect Module 1

8

1

Coupler Module 2

9

1

Support 2

10

1

Coupler Module 1

11

2

60 x 25mm Cooling Fan

12

2

60mm Cooling Fan Guard

13

1

Temp Sensor

14

1

RF Detect Module 2

15

1

Power Supply

16

1

7P Terminal Block

17

1

Support 3

18

1

GPIB Module

19

1

System Controller

20

2

2U Handle

14 | Page - Ver. 1.0

SYSTEM WIRING DIAGRAM

AA-20M1G-50 WIRING DIAGRAM

DESCRIPTION AWG COLOR TO POINT CHECK

FAN +

FAN -

24

24

RED

BLACK

LENGTH

FAN +

FAN -

DESCRIPTION AWG COLOR TO POINT CHECK

FAN +

GND 24

24 YELLOW

BLACK

LENGTH

TERMINAL BLOCK 6A

FAN 1 ~ 5

FAN 1 ~ 5

TERMINAL BLOCK 5A

PIN

1

2

3

PIN

1

2

3

FAULT LAMP +

24 BLACKGND TERMINAL BLOCK 2A

FAULT LAMP + 24 GRAY

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

POWER LAMP

PIN

1

2

3

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

POWER LAMP

PIN

1

2

3

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

FAULT LAMP

PIN

1

2

3

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

FAULT LAMP

PIN

1

2

3

POWER LAMP + POWER LAMP +

POWER LAMP - POWER LAMP -

24 BLACKGND TERMINAL BLOCK 2A

POWER LAMP + 24 RED TERMINAL BLOCK 3A

24 BLACK

24 RED

24 BLACK

24 GRAY

FAULT LAMP -

FAULT LAMP +

FAULT LAMP -

CON J7-4

R471-2

R471-1

DESCRIPTION AWG COLOR TO POINT CHECK

LENGTH

TERMINAL BLOCK

YELLOW

YELLOW

PIN

1A

1B

PS+

7A

DESCRIPTION AWG COLOR TO POINT

LCD PS+

LCD PS-

24

24

RED

BLACK

LCD PS+

LCD PS-

LCD

PIN

1

2

3

DESCRIPTION AWG COLOR TO POINT

LCD PS+

GND 24

24

BLACK

LCD

PIN

1

2

3

TERMINAL BLOCK 3A

TERMINAL BLOCK 2A

RED

DESCRIPTION AWG COLOR TO POINT

24

24

RED

BLACK

GPIB PS+

GPIB PS-

GPIB

PIN

1

2

3

1A 2A 3A 4A 5A 6A

1B 2B 3B 4B 5B 6B

7A

7B

24

24 FAN CON P6, CON J1-4, J3-3

PS+ POWER SUPPLY V+

2A GND 24 BLACK

FAN CON P9, POWER LAMP P3, FAULT LAMP P3,

CON J3-2, LM35 P2, INPUT MODULEP9,

RF DETECT MODULE 1~2 P9, LCD P3, GPIB P3

2B GND 24 BLACK POWER SUPPLY V-

3A SHUTDOWN 24 GRAY

3B SHUTDOWN 24 GRAY CON J7-5

HPA P5

4A +5V 24 RED

INPUT MODULE P3, LM35 P1, POWER LAMP P1,

RF DETECT MODULE 1~2 P3, LCD P1, GPIB P1

4B +5V 24 RED CON J3-1

5A FAN + 24 YELLOW

FAN CON 55B FAN + 24 YELLOW

FAN 1 ~ 5 P1, CON J1-7

6A GND 24 BLACK

POWER SUPPLY V-6B GND 24 BLACK

FAN 1 ~ 5 P2

7A

PIN

1

2

3

4

5

6

7

8

9

DESCRIPTION AWG COLOR TO POINT

N/C

N/C

N/C

GND

N/C

+5V 24

24 BLACK

RED TERMINAL BLOCK 4A

TERMINAL BLOCK 2A

CHECK

LENGTH

INPUT MODULE

INPUT DETECT 24 WHITE CON J1-3

ATTEN 24 BLUE CON J4-6

N/C

HPA

PIN

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

GND BLACK

VDD

SHUTDOWN

9

8

20 YELLOW

24

7

6

5

4

1

3

2N/C

N/C

VDD

GND

20 YELLOW

20 BLACK

20

GRAYGRAY24 TERMINAL BLOCK 3A

POWER SUPPLY V-

POWER SUPPLY V-

BROWN24CURRENT MONITOR CON J2-3

TEMP MONITOR CON J2-5

GREEN24

POWER SUPPLY V+

POWER SUPPLY V+

FAN_CURR

J7-1

LOCAL

J7-2

REMOTE

J7-3

FAULT

J7-4

ENABLE

J7-5

TEMP AL_IN

J7-6

J7-7

J7-8

FAN CON P1

TERMINAL BLOCK 4B

GREEN24

GRAY24

GRAY24 FAULT LAMP P1

N/C

PIN

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

J1-1

FORWARD 1 PURPLE24 RF DETECT MODULE1 P5

CONTROL BOARD (CON)

J1-2

FORWARD 2

J1-3

INPUT DET WHITE24 INPUT MODULE1 P1

VOLTAGE 1 YELLOW24 TERMINAL BLOCK 1A

J1-4

CURRENT 3

J1-5

CURRENT 5

J1-6

VOLTAGE 2

J1-7

J1-8

REFLECTED 1 PURPLE24 RF DETECT MODULE3 P5

J2-1

REFLECTED 2

CURRENT 1

J2-2

BROWN24 HPA P3

CURRENT 2

J2-3

TEMP

J2-4

GREEN24 HPA P4

PS+ YELLOW24 TERMINAL BLOCK 1A

J3-1

GND BLACK24 TERMINAL BLOCK 2A

J3-2

+5VDC RED24 TERMINAL BLOCK 3B

J3-3

COM2_OUT

J4-1

COM2_IN

J4-2

COM1_OUT

J4-3

COM1_IN

J4-4

RF POWER

J4-5

ATTEN

J4-6

BLUE24 INPUT MODULE P5

DESCRIPTION AWG COLOR TO POINT

GND 24

24

BLACK

GPIB

PIN

1

2

3

TERMINAL BLOCK 3A

TERMINAL BLOCK 2A

RED

WHITE CON J1-1DET

PIN

1

2

3

4

5

6

7

8

9

RF DETECT MODULE 1

DESCRIPTION AWG COLOR TO POINT

N/C

N/C

N/C

N/C

GND

N/C

+5V 24

24 BLACK

RED TERMINAL BLOCK 3A

TERMINAL BLOCK 2A

24

/ / /

CURRENT 4

J2-5

GREEN24

J2-6

HEATSINK LM35 P3GREEN24

S/D_IN

S/D_OUT

PIN

1

2

3

4

5

6

7

8

9

FAN CON

DESCRIPTION AWG COLOR TO POINT CHECK

LENGTH

TEMP ALRAM

TEMP SENSE

FAN+

PS+

24

24

24

24

BLACK

YELLOW

GREEN

YELLOW

TERMINAL BLOCK 5B

LM35 P3

TERMINAL BLOCK 1A

TERMINAL BLOCK 2A

LENGTH

LENGTH

LENGTH

LENGTH

CHECK

CHECK

CHECK

CHECK

CHECK

LENGTH

PURPLE CON J1-8DET

PIN

1

2

3

4

5

6

7

8

9

DESCRIPTION AWG COLOR TO POINT

N/C

N/C

N/C

N/C

GND

N/C

+5V 24

24 BLACK

RED TERMINAL BLOCK 3A

TERMINAL BLOCK 2A

24

N/C

CHECK

LENGTH

PIN

1

2

3

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

LM35 + 24 RED

LM35 - 24 BLACK

TEMP SENSE 24 GREEN

DESCRIPTION AWG COLOR TO POINT CHECKLENGTH

LM35

PIN

1

2

3

+5V 24 RED

GND 24 BLACK

TEMP SENSE 24 GREEN FAN CON P4, CON J2-1

TERMINAL BLOCK 2A

TERMINAL BLOCK 3A

LM35

GND

TEMP SENSE

23

24 GREEN CON J7-6

N/C

N/C

N/C

GND

N/C

RF DETECT MODULE 2

+5V

GPIB PS+

GPIB PS-

GPIB PS+

YELLOW

24 TERMINAL BLOCK 5A

1

15 | Page - Ver. 1.0

APPENDIX 1

LOCAL CONTROLLER LCD INTERFACE

SCREEN 1

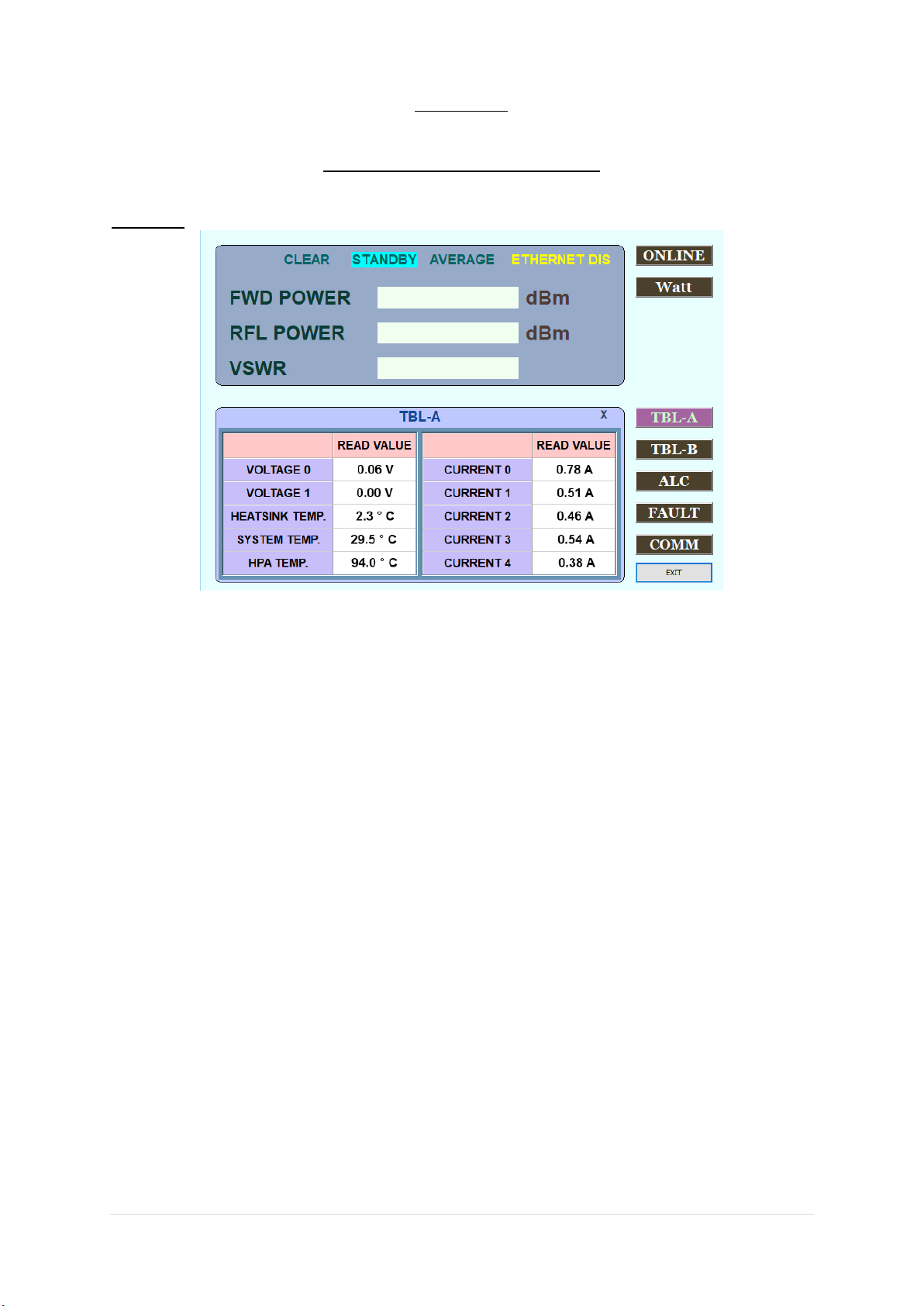

(Illustrates unit in standby mode, showing table A parameters, fault indicator on, and output in Watt scale)

ONLINE / STANDBY

When the HPA system starts up, HPA goes into a standby mode. By pressing ONLINE button, unit goes into online

(transmission) mode. ONLINE button will now change & show STANDBY and top middle “Standby” indication will

change to “ONLINE.” By pressing STANDBY button, unit will stop transmitting and go into idle mode (no

transmission).

<NOTE> Internal computer will scan for any possible fault conditions and attempt to clear them BEFORE the

system goes ONLINE. If the system still detects faulty conditions, system will automatically go to STANDBY mode

and will display a RED “FAULT” line which is highlighted left top side of display. An operator should click and

check FAULT menu to review fault conditions. (No FAULT test at the top of the screen next to STANDBY).

FWD POWER

Displays current output of the system.

RFL POWER (or REV POWER)

Displays current reflected power at the output of system.

VSWR

Based on FWD/REV reading, internal computer calculates and displays current VSWR ratio.

TBL (A) (or Table (A))

Pending on system configurations, it will display some or all of below internal system parameters.

System level temperature

Modular (HPA) level temperature

Additional temperature spots

System input level voltage

Modular input level voltage

Current consumption for internal modules or elements

Current consumption for the entire system

Other custom parameters per customer requirements.

16 | Page - Ver. 1.0

SCREEN 2

(Illustrates unit in standby mode, showing table B parameters, fault indicator on, and output in dBm scale)

dBm / Watt

This button enables FWD and RFL POWER readings to be in either WATT or dBm scale.

TBL (B) (or Table (B))

Pending on system configurations, it will display some or all of below internal system parameters.

STANDBY H, _Min Sec

It records total hours (H, M, S) of the system from the moment that an AC power switch is in ON position

RADIATE H, _Min Sec

It records total hours (H, M, S) of the system from the moment that ONLINE button is pushed.

IP

Displays the IP number of the amplifier.

PORT

Displays the Port number.

ALLOWED TIME

Allowed time is the waiting period for TCP port communication (ethernet) between two units.

17 | Page - Ver. 1.0

SCREEN 3

(Illustrates unit in standby mode, showing AGC setting under ALC menu, fault indicator on, and output in dBm

scale)

ATTEN GAIN CONTROL (or ATTENUATING GAIN CONTROL / AGC)

This menu is active when ALC (Automatic Level Control) is OFF. This feature enables an operator to set the total

gain of the system within 20 to 25dB range of maximum gain (If a total system gain is 50dB, maximum attenuation

cannot exceed 50dB).

AG READ

This button recalls and display a current attenuation level.

AG SET

This button sets AGC value entered by an operator to the system.

<NOTE: Operator can always return to no attenuation by setting attenuation value to “0”>

+1, +0.1, -1, -0.1

Operator can set attenuation value by an increment of 1dB or 0.1dB.

18 | Page - Ver. 1.0

SCREEN 4:

(Illustrates unit in standby mode, showing ALC setting under ALC menu, fault indicator on, and output in dBm

scale)

ALC CONTROL (or AUTOMATIC LEVEL CONTROL / ALC)

This menu is active when ALC feature (Automatic Level Control) is ON. This feature enables an operator to set

the total output of the system within 20 to 25dB range at a given output setting (If a total system output is 50dBm,

maximum ALC level cannot be configured above 50dBm).

ALC READ

This button recalls and display a current ALC level.

ALC SET

This button sets ALC value entered by an operator to the system.

<NOTE: Operator can always return to no ALC by pressing “ALC OFF” button>

+1, +0.1, -1, -0.1

Operator can set ALC value by an increment of 1dB or 0.1dB.

ALC OFF / ALC ON

These buttons are used to turn on and off the ALC feature of the system. By default, ALC is OFF unless factory

presetting is set for automatic activation for over power protection feature (If an operator overdrives the system

by mistake, onboard computer may automatically activate ALC feature at preset output level to protect the

system). Please do not turn off ALC feature if an over power protection feature is built in and the ALC feature

activates during maximum output operations.

19 | Page - Ver. 1.0

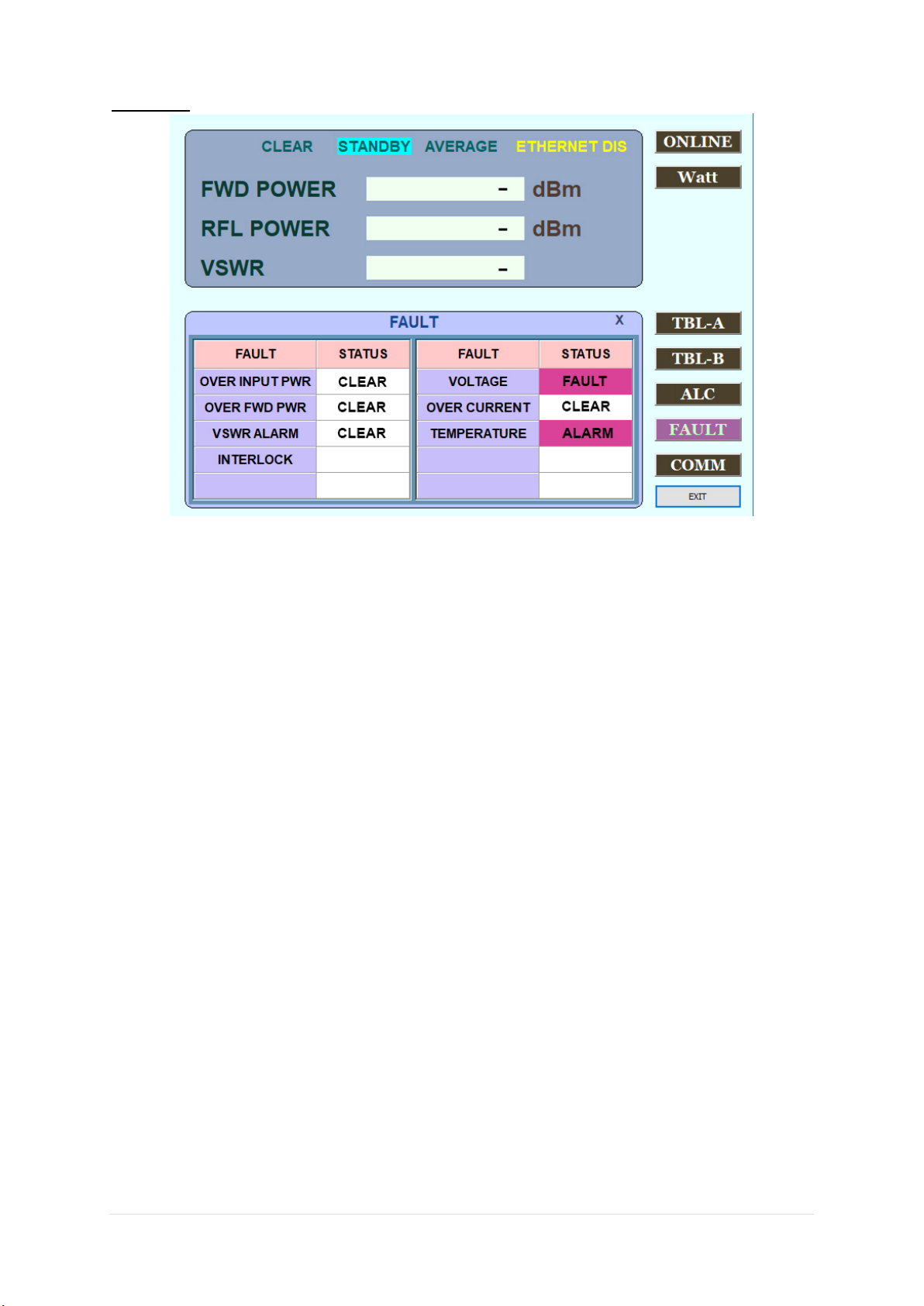

SCREEN 5:

(Illustrates unit in standby mode, showing status windows under FAULT menu, fault indicator on, STAT shows

CLEAR, FAULT, ALARM and output in dBm scale)

FAULT Indications

Pending on system configurations, FAULT section will display some or all of below monitoring parameters.

OVER INPUT POWER

Activates when input power to the system is greater than factory preset safe operating levels.

OVER FWD POWER

Activates when system output power is exceeding factory preset safe operating levels.

VSWR ALARM

Activates when VSWR ratio exceeds factory preset safe operating levels.

INTERLOCK

N/A

VOLTAGE

Activates when irregular input voltages to the internal components are detected.

OVER CURRENT

Activates when irregular current consumption to the internal components are detected.

TEMPERATURE

Activates when irregular temperatures of internal components or system level are detected.

Other custom parameters per customer requirements

STAT (or STATUS)

Under normal operating conditions (no fault), STAT windows will display “CLEAR.”

In an event of fault conditions, STAT windows will change to either “FAULT” or “ALARM” highlighted in RED.

Once fault conditions are corrected, an operator can simply press ONLINE button to clear up fault conditions in

FAULT menu.

<NOTE> Internal computer will scan for any possible fault conditions and automatically attempt to clear them

when ONLINE button is pressed. If the system still detects faulty conditions, system will automatically go to

STANDBY mode and will display “FAULT” or “ALARM” in FAULT menu.

20 | Page - Ver. 1.0

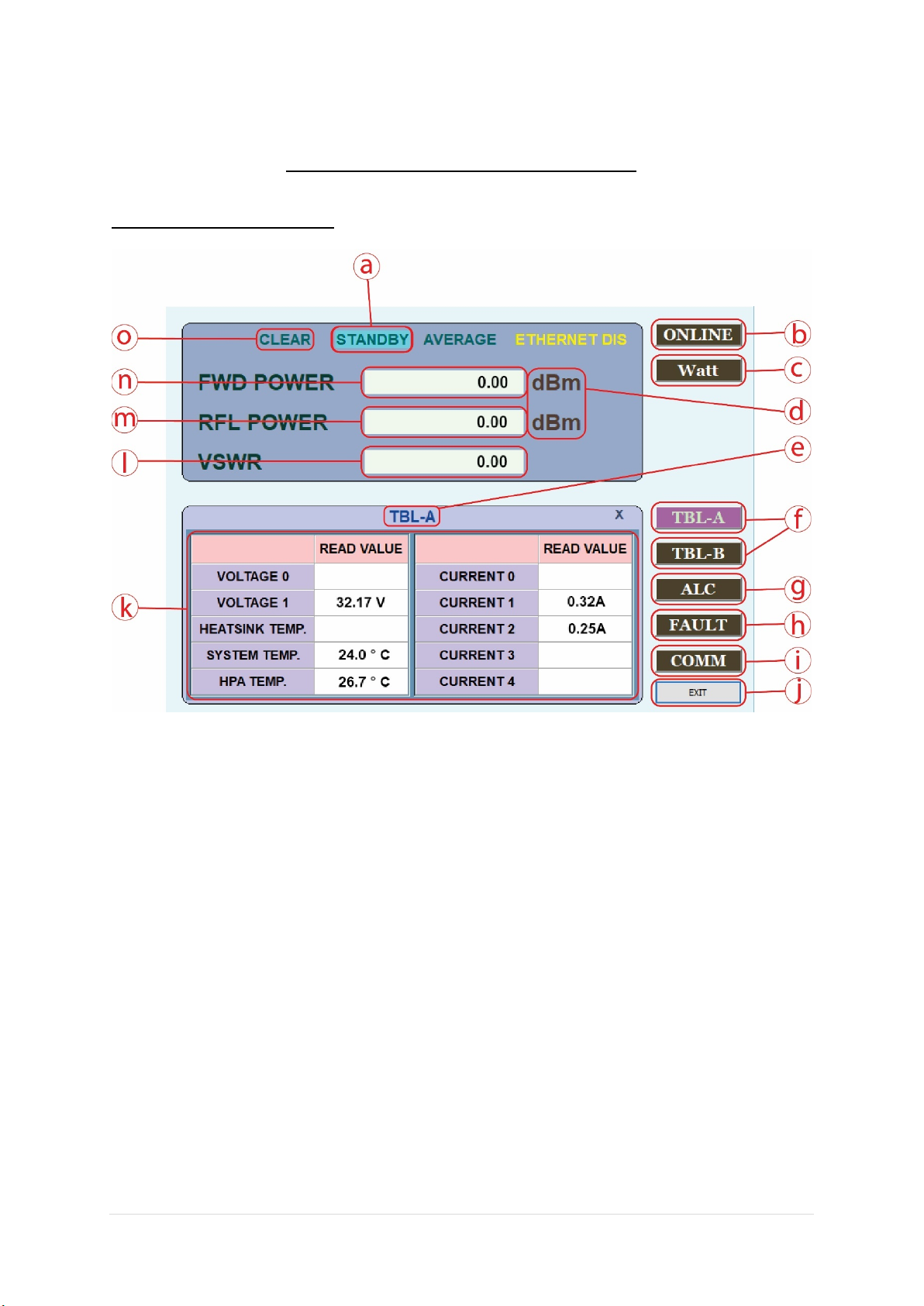

REMOTE CONTROLLER INTERFACE SOFTWARE

PRIMARY (MAIN) WINDOW

a STANDY/ONLINE: Display system STANDY/ONLINE status.

b ONLINE/STANDY: System ONLINE/STANDY button.

c Watt/dBm: Watt/dBm conversion button.

d dBm/Watt: Display dBm/Watt status.

e TABLE/ALE/FAULT/COMM: Display menu status.

f TABLE: TABLE menu button.

g ALC: ALC menu button.

h FAULT: FAULT menu button.

i COMM: COMM menu button.

j EXIT: Button to exit the program.

k Display status of the TABLE menu window.

l VSWR: Display VSWR value.

m RFL POWER: Display RFL POWER value.

n FWD POWER: Display FWD POWER value.

o CLEAR/FALUT: Display CLEAR/FAULT status.

Table of contents

Other Advanced Amplifiers Amplifier manuals

Advanced Amplifiers

Advanced Amplifiers AA-1M6G-30 User manual

Advanced Amplifiers

Advanced Amplifiers AMP2103P-LC User manual

Advanced Amplifiers

Advanced Amplifiers AA-1218G-3.5KW-PT User manual

Advanced Amplifiers

Advanced Amplifiers AA-10K250M-150 User manual

Advanced Amplifiers

Advanced Amplifiers AA-28G-2KW-PT User manual

Popular Amplifier manuals by other brands

Toa

Toa A-503A Specifications

Friedman

Friedman JJ-100 instruction manual

COM-power corporation

COM-power corporation ARI-6000-100W instruction manual

Dynavector

Dynavector P75 mk4 Instructions and specifications

Microh

Microh MT1201 owner's manual

Jensen Audio

Jensen Audio Power 2000.1 D Installation & operation manual