Advanced Radio Smart Bus User manual

Smart Bus

Quick Start Guide

2

Thank you for your purchase of the Advance Radio Smart Bus.

In this quick start guide we will show you how to connect your new Smart Bus,

General use and Set Up. Please take the me to understand this guide before

installaon

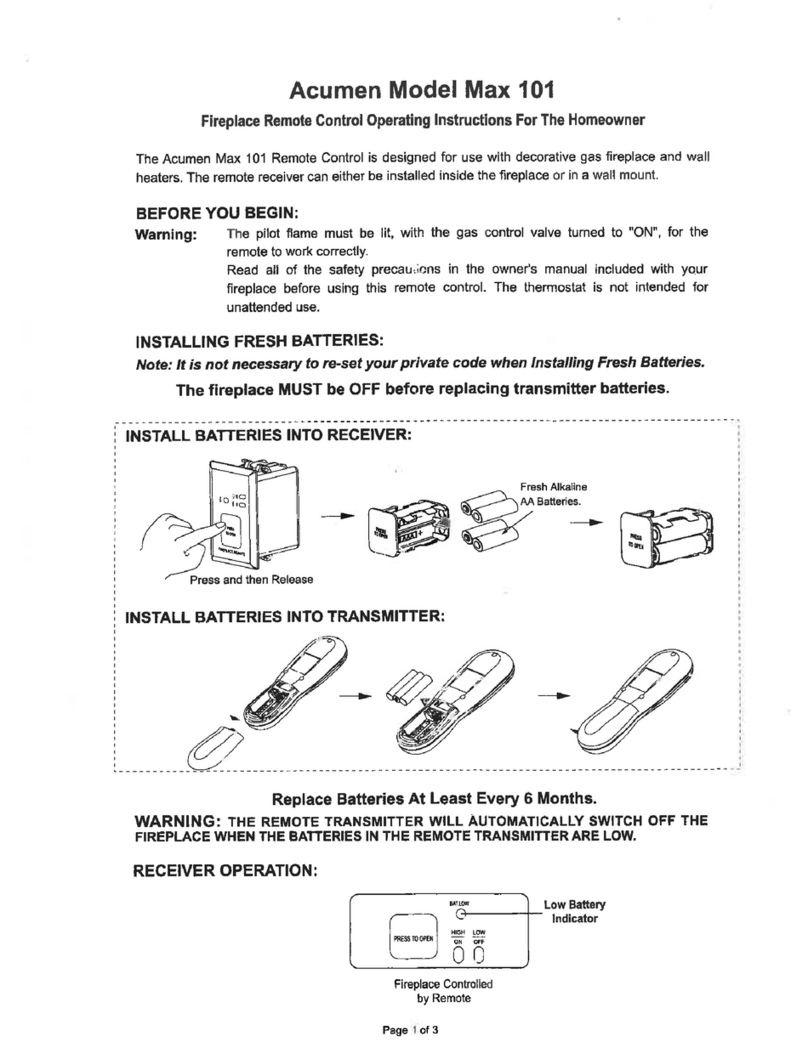

IMPORTANT

The touch screen display supplied with the Smart Bus should be protected from

vibraon.

Before installaon please ensure that your baeries are fully charged. The

Smart Bus relies on this to know how much you have used in each pack.

WARNING

The Smart Screen shows you how much you have used out of each pack and

displays this as an indicator on the Smart Screen. NEVER FLY WITH BATTERY

PACKS THAT HAVE 35% OR LESS CAPACITY (RED ZONE ON THE BATTERY INDICA-

TOR). Doing so might put your model at risk.

3

Features:

• Built in Baery Guard Technology. The Smart Bus constantly monitors baery voltage

and current draw and displays this on the Smart Screen display.

• Works with single or dual baery conguraon. Recommended with dual baery.

• Works with all major baery chemistries. LiFe. LiPo, Lion, NiMh, NiCD. Baery voltage

range can be from 6volts to 8.4volts (6volt to 12volts only for 3S version.)

• Full Dual Baery Redundancy - If one baery fails the other baery takes full control.

• 12 input Channels.

• 12 output channels with 26 buered servo outputs.

• Easy-to-use pre-routed servo roung.

• Independent servo reverse on 5 channels and all 6 adjustable outputs.

• 3 point matching on 5 channels and all 6 adjustable outputs.

• 15 point matching on 5 channels and 6 adjustable outputs (Smart Bus Extreme only)

• Digitally selectable regulator output via the Smart Screen.

• Regulator selectable to 6.0 volts, 7.2volts and 8.4volts (8.4volts Extreme 3s only)

• Maximum Baery Power Balancing – Using dual baery perfect diode technology.

• Ignion light pipe transmier for oponal ignion/ECU module.

Included Items:

1 x Live feedback touch screen Smart display (Elite and Extreme versions)

1 x Smart Bus power distribuon module.

1 x 12 connector Receiver cable.

1 x Instrucon manual.

1 x Pin Flag Switch with mounng hardware.

1 x Ultra bright power LED

Oponal Items:

RF Switch

Opcal light pipe single or dual ignion module.

4

Installaon and Mounng Instrucons

In this secon we will explain how to mount both the Smart Bus and the Smart Display.

The Advanced Radio Smart System gives you the choice of mounng the Smart Screen in

the model or leaving it disconnected for normal ying and connecng the Smart Screen only

when you need to review baery performance. The Smart Bus will operate in norma ying

mode just ne without the Smart Screen Connected.

Smart Screen Mounng Preparaon

Included with you new Smart Bus are 3M Velcro

Dots or 3M hook and loop. Either the dots or hook

and loop provide an eecve vibraon damping

system for mounng the Smart Screen in the select-

ed model.

Before applying the 3M dots, we recommend clean-

ing both surfaces you wish to use the 3M Dots on

with isopropyl alcohol or methylated spirits. Wait a

moment for this to dry.

Mounng the Smart Bus

The Smart Bus is supplied with 4 rubber shock mounts in the base plate, Similar to rubber

mounts on servos, these can be used to give the Smart bus a Shock mount.

Elite and Extreme versions

The Smart Bus Extreme and Smart Bus Plus have a built in digital regulator that uses the

base plate as a heat sink. It is important that the Smart Bus should be mounted so aire

can ow over the base plate to allow eecve heat dissipaon. We recommend

mounng with minimum stando spacers of 1/2 inch or 12mm to allow adequate air ow

over the base plate.

Extreme 3S (12.0v) version

The Smart Bus Extreme 3S version is designed to run with 8.4volt servos and is supplied

with acve cooling from a high ow fan. This fan MUST have clearance to allow air to

pickup and ow through the Smart Bus. We suggest a mounng strategy of mid fuselage

suspension.

You can view video examples of eecve mounng of the Smart Bus by vising the prod-

uct page as www.boomarc.com.

5

Mounng the Smart Display

There are 2 opons of mounng the Smart display.

NOTE: Which ever method of mounng you choose, ensure the cable that comes out of

the Smart Display is not crushed in anyway. Doing so will reduce the longevity of the ca-

bles.

Opon 2. For hard mounng, the screen case has 2 eyelet holes on each edge of the screen.

If you are mounng the screen in a scale cockpit, or in a non vibraon model. (e.g. Turbine)

these holes can be used to ax the Smart Display.

Simply place the Smart Display where you wish to mount it. Holding it in place, make a dot

using a pen or pencil in each eyelet hole. Removing the screen, drill a hole where you placed

the dots.

Now simply screw the Smart Display in place.

NOTE: Hard mounng the Smart Display provides lile to no protecon against vibraon.

Use this method if you are using a non vibraon model or only where there is lile to no

vibraon. AVOID MOUNTING IN HIGH VIBRATION AREAS.

Opon 1. Using the 3M Velcro Dots, we can mount the back of the screen to a surface.

NOTE: This is a semi hard mount, and will provide a good resistance to vibraon. AVOID

MOUNTING IN HIGH VIBRATION AREAS. VIBRATION DAMAGE IS NOT COVERED UNDER

WARRANTY. Clean both the back of the smart screen and surface that it is being mounted

to. Place one of the 3M dots each side of the cable. Trimming as necessary. IMPORTANT: DO

NOT APPLY FORCE DIRECTLY ON TO THE SCREEN Press on the black case around the screen

to ensure it is secure

6

Installing the Receiver

The Smart Bus comes with a 12 cable JST header. This detachable

connector makes it easy to plug the correct channel into your re-

ceiver before installing the receiver into the plane.

2 of the 12 connectors (Channel 1 and Channel 12 ) have signal

and power wires connected. These connectors supply power to

the receiver. Channel 1 and/or 12 must be connected to the

Smart Buss to power the receiver.

Smart Bus is designed to supply the power to all the models ser-

vos. Please do not connect servos directly to the receiver when

using Smart Bus.

The other 10 connectors have just the orange signal wire con-

nected. It is OK to connect just the required signal (channels)

that will be used. Le over (unused) signal wires can be removed

from the 12 channel JST header. Addional 12 channel JST head-

ers can also be purchased as a spare part.

Channel Assignment

The numbers below the “Receiver Inputs” correspond to

the output channel near the center of the Smart Bus. For

example: Receiver input 1 connects to output 1 (AIL-1A

and AIL-1B). Likewise Receiver input 2 connects to output

2 (AIL-2A and AIL-2B). Input 3 to output 3 and so on.

See picture le for details.

The rst 5 (B and C) channels on the Smart Bus are adjust-

able. These channels are highlighted with a colour. These

channels are designed for any primary controls such as

aileron, elevator, rudder and throle.

Channel 12 is a special dual funcon channel. It is linked

to the (oponal) opcal ignion output and AUX7-A and

AUX7-B. You can use either the opcal ignion module

OR (AUX7-A and AUX7-B).

Step 1

Locate the channels on your receiver and plug in the corresponding JR connectors from the header,

these cables can be extended using extension leads if needed. Repeat this for all channels needed.

Step 2

Now install the pin header into the Smart Bus. Ensure the header is pushed snug into the Smart Bus

Input port.

7

Oponal Ignion Module

If you purchased the Smart Bus oponal ignion module then you will be able to easily control the igni-

on system in your model via the Smart Bus. This ignion module is a high quality opcally isolated design

that minimises ignion noise and provides regulated 6 volts supply at up to 3A to power your gas engines’

ignion system. It can be used as the master ignion controller for single or mul engine conguraons.

To use the oponal ignion module:

- Connect the opcal cable to the ignion port on the side of the Smart Bus.

- Connect an ignion baery to the JR FEMALE yellow baery lead.

- Connect the ignion system to the JR MALE yellow power output lead.

- Connect a signal from the receiver to input 12 of the Smart Bus.

- Set the channel connected to input 12 on the transmier to switch ON/OFF the ignion system.

Informaon: Input channel 12 is a special dual funcon channel. It is linked to the opcal ignion output

and AUX7-A and AUX7-B. You can use either the opcal ignion module OR (AUX7-A and AUX7-B).

Please Note: The opcal ignion module is supplied with a blue ignion LED. This ignion LED operates

directly from the ignion power and requires the ignion baery to be connected to operate.

8

Remote Smart Switch Opon

If you purchased the Remote Smart

Switching Opon for the Smart Bus

then you can enjoy turning you model

ON and OFF via the remote key FOB.

This is great for a true scale model ap-

pearance and will be a great conversa-

on piece at the eld.

To operate the Smart Bus with the Remote Smart Switch simply connect the Remote receiver module to

the switch input of the Smart Bus. And you are ready to go.

Please Note: When you st connect the remote smart switch to the Smart Bus the Smart Bus will stay

switched ON. This is normal and part of the fail safe design.

To switch the Smart Bus ON or OFF do the following:

Press buon “A” and within 2 seconds press buon “B”. If the Smart Bus is in the ON posion it will

turn OFF. If the Smart Bus is in the OFF posion it will turn on.

Pressing buon “A” and “B” too fast will do nothing. Also pressing buon “A” and buon “B” too slow

will do nothing. These are safety features so you cannot accidentally switch Smart Bus ON or OFF.

Please also note. The remote switch is a receiver and while connected it draws several milliamps of

power from your baeries. This is minimal in normal operaon over a weekend BUT to save the receiv-

er baeries from being aened over a few weeks you SHOULD ALWAYS disconnect your baeries

from the Smart Bus aer a weekly ying session.

9

General Usage and Screen Informaon

Important: The Smart Display that is supplied with the Smart Bus is a touch screen display.

It is used in both setup and provides feedback to the user about baery voltage and milliamps

used. The screen is designed to be mounted in a model for quick and easy use. However the

Smart Bus will operate win normal ying mode without the Smart Screen connected.

Main Smart Screen

Baery 1 (B1) and Baery 2 (B2)

Shows input voltage of both baery packs.

Servo

Shows Regulated voltage to servos

Total mA

Shows total milliamps since last charge.

Press here to enter the Main Menu

Last mA

Shows milliamps since model has was last powered up

and resets when model is turned o. Press here to reset

ight mer and Last mA.

FL-T

Flight mer since model was turned on. The mer only

operated while on the main screen.

FL-N

Flight number since reset. Gives an indicaon about how

many ights on the models airframe.

Baery Indicators

Shows the remaining capacity in the baeries from 100%

- 0%. NEVER FLY IF THE INDICATORS ARE IN THE RED.

Main Menu

Return

Returns you back to the previous screen.

Power Buon

Press here to go to the baery setup and reset

menu.

Servo Buon

Press here to go to the Servo programming menu.

System Buon

Pressing here will take you to the System Screen

fro version informaon etc.

Below is an overview of each screen on the Smart Bus

10

Power Setup Screen

Return

Takes you back to the previous screen.

RES-mA

Resets total mA used. Please ensure both packs

are FULLY charged before you reset.

RES-FLT

Resets ight counter and mer to zero. Use this

feature mostly when installing in a new airframe

or before the maiden ight.

Bat Capacity mA

Shows the capacity of the baeries you are us-

ing. We will go through how to set this in the

First Time Setup secon on page 10.

System Screen

Return

Takes you back to the previous screen.

Calibrate

Takes you to Screen calibraon. For more

informaon see page 12.

Credit

Shows credits screen.

Servo Voltage Selector

Sets the regulator output voltage (servo voltage).

Please make sure your baery packs are fully charged before making the servo output volt-

age selecon. The Smart Bus will read the baery voltage and will make available only the

voltages that will work for your selected baery type. All other choices will be greyed out and

are not selectable.

For example: if you are using Lion 2S packs then the choice will be 6.0v or 7.2v.

Servo voltage choices when using dierent baery types:

LiFe 2S packs = 6.0v

Lion2S and Lipo 2S = 6.0v or 7.2v

LiFe 3S, Lion 3S or Lipo 3S = 8.4v (only available with Extreme 3S model).

11

Servo Sub Trim Screen

Return

Takes you back to the previous screen.

AIL-1B

Aileron 1B slave channel select. Selects this servo

for sub trim.

AIL-2B

Aileron 2B slave channel select. Selects this servo

for sub trim.

ELE-1B

Elevator 1B slave channel select. Selects this ser-

vo for sub trim.

ELE-2B

Elevator 2B slave channel select. Selects this ser-

vo for sub trim

RUD-B

Rudder B slave channel select. Selects this servo

for sub trim.

RUD-C

Rudder C Slave channel select. Selects this servo for

sub trim.

3 Point Match

Return

Returns you back to the previous screen.

Norm/Reverse

Reverses the selected servo direcon.

Reset

Resets sub trim values to default.

Mul

Takes you to the Mul-point match page

(only available on Smart Bus Extreme).

Vercal Bars

Shows the current sub trim amount at the

center and endpoints for that servo. These

values are changed by the INC, DEC

buons.

12

15 Point Servo Matching

Return

Takes you back to the previous screen.

Reset

Resets the sub trim values back to default.

Vercal Bars

Shows the sub trim applied to the servo. The sub

trim values can be changed using the DEC, INC

buons.

13

First Time Baery Setup

We are now going to go proceed with a rst me setup of the Smart Bus . Please ensure

your baeries are fully charged before you setup the Smart Bus. If you need any addi-

onal help with what each buon or item does please read the General Usage and

Screen informaon page located on page 7 of this manual. We recommend you do not

have any servos connected to the Smart Bus during the rst me setup.

Step 1

Ensure that both baeries are plugged into

the Smart Bus. You will also need to ensure

the Smart display is plugged into the switch

as it is used for programming.

Upon power up, you will see the AR logo.

Aer a few seconds the Smart Screen will

be shown.

Step 2

Press the green Total mA text on the smart

display, this will take you to the main menu.

Step 3

You should now see the Main Menu

Screen. Press the yellow Power

buon on the screen.

14

Step 4

This is the baery setup screen. Using the arrows

(DEC, INC) next to Bat Capacity mA cycle through

unl you see the correct capacity that matches

your baery packs.

Note: Step 4 is extremely important, Please en-

sure the capacity is set correctly to the baery

packs you are using.

The Smart Bus uses this capacity value to show

the remaining baery capacity on the main

screen. If you set this value incorrectly then the

remaining capacity indicators may not show the

correct remaining baery capacity.

Important

The Smart display main Screen shows how much capacity you have le using

the baery indicators on the le and right of the baery screen It is important

that the capacity you enter is correct and accurate. If you are unsure about the

capacity of your baeries or if your packs are not new. We recommend cycling

your packs by discharging them and recharging them to full. This will give you

the best possible result for the baery packs you are using.

Step 5

Using the 6.0v, 7.2v and 8.4v buons, select the regulator voltage of your choice. This will change

the output voltage to your servos. The regulator may take some me, please wait unl the volt-

age you select is the same as the number on the screen.

Note: Please ensure your servos are capable of the voltage you select. Selecng a higher volt-

age than your servos are capable of might cause damage the them.

Step 6

Once you have setup these parameters, press the RETURN buon to save and return to the main

menu. Press RETURN again to go back to the Smart Screen. You have successfully setup the Smart

Bus Baery monitoring.

15

Receiver and Servo Setup

During this stage, we will install the receiver and servos. Note: Before plugging any ser-

vos into the Smart Bus, ensure you have set the regulator to the desired voltage range.

Important: Check the recommended voltage range of your servos, supplying to high of

a voltage to your servos may cause them damage. During this stage if you have mul-

ple servos on a control surface (Example: 2 servos on an aileron), ensure they are closely

mechanically matched (Lile to no Buzz Sound) and both servos are moving in the same

direcon before connuing.

Step 1

Ensure that both baeries are plugged into

the Smart Bus. You will need to plug the

smart display is into the switch as it is used

for programming. Ensure your receiver is

plugged into the Smart Bus and your trans-

mier is on and bound to your receiver. For

more informaon on this see page 6

Upon start up, you will see the AR logo.

Aer a few seconds the Smart Screen will

be shown.

Step 2

Press the green Total mA text on the smart

display, this will take you to the main menu.

Step 3

You should now see the Main Menu

Screen. Press the red SERVO buon

on the screen.

16

Step 3

The buons on the screen match up with the

rst 5 channels on the Smart Bus. Press the

buon for the channel you wish to work on.

Step 4

You should now see the 3-point matching

screen. At the boom of the screen you will

see the name of the servo channel you are

sub trimming for example “AIL1-B”.

Note: Before proceeding make sure both ser-

vos are moving in the same direcon. If not.

Press the NORM/REVERSE buon to change

the direcon of the slave servo.

Leaving the transmier sck in the middle

for that servo channel, the center column

should change colour to green. Use the DEC,

INC buons with ther transmier sck in the

middle will sub trim the servo at the center

point.

Step 5

Move and hold the transmier sck for that

channel in 1 direcon, either the Min or

Max columns will change colour from blue

to green. Use the DEC, INC buons to move

and sub trim the servo at this point.

Step 6

Move and hold the transmier sck for that

channel in the other direcon, the other

MIN or Max column will change colour from

blue to green. Use the DEC, INC buons to

move and sub trim the servo at this point.

Repeat Step 4-6 unl there is lile to no

buzz from your servos. Press the save

buon to save your changes and return to

the previous screen. This process can be

repeated as many mes as you wish with

each programmable output. Note: you can

press the reset buon at any me to reset

the sub trim values back to 0.

3-point servo matching with the

transmier sck at the

center posion

17

15 Point Matching

(Smart Bus All Versions)

15 point matching is useful for geng the best possible match between servos. This in-

cludes mechanically matched servos (aileron) or non mechanically matched (le and right

elevator). We are now going to go through the 15 point servo matching process. For best

results please do 3 point match before proceeding.

Step 1

From the 3 point matching screen. Press the

Mul buon.

Step 2

You should now see the mul point match

screen. Similar to the 3 point match, as you

move the transmier sck for that channel.

The bars will changes colour from blue to

yellow. Step 3

Slowly move the transmier sck for that

channel from one side to the other, if at any

point you hear servo buzz. Hold the trans-

mier sck in that posion and use the DEC,

INC buons to sub trim at that point. Sub trim

the servo unl the servo buzz lessens or dis-

appears.

Step 4

Repeat step 3 for the enre range of the ser-

vo, this can be repeated as many mes as you

wish.

Step 5

Once you are happy with the sub-trim press

the back buon to move back to the 3-point

sub-trim page. Pressing back again from the

3-point sub-trim page will save the trim val-

ues to memory.

Note: If the servo is only moving a small amount. (Example: 10-15 degrees each way)

You will only be able to use a small number of bars on the 15 point match. To use more

bars, we recommend you increase the servo range by using a smaller servo arm.

Note: You can return the servos sub trim

values back to default by pressing the

Reset buon.

18

Factory Reset

When you use the sub-trim and other funcons these funcons are saved to the permanent

memory of the Smart Bus. There may be situaons where you will want to inialise your

Smart Bus back to the original factory sengs. Switching the Smart Bus to a dierent model

for example would be one of the situaons. When you select the Factory Reset feature all the

sub-trim data and baery sengs will be erased and the Smart Bus will be returned to “Out-

Of-The-Box” sengs.

WARNING

Performing a Factory Reset will erase all sub-trim data and is an irreversible pro-

cess. Only do this if you are sure you want to reset the Smart Bus to factory

sengs.

Step 1

Using the Smart Display, go into the sys-

tem menu, once here press the FACTORY

RESET buon.

Step 2

A warning and instrucons will appear on

screen. Please Read this as it is an im-

portant process. When ready press Yes to

connue or No to go back to the system

screen.

Step 3

During the reset process the saving data

screen will show for up to 20 seconds.

Please DO NOT turn o the Smart Bus dur-

ing this process.

Step 4

Aer the Factory Reset process is complete

the Saving Data Screen will disappear indi-

cang you have reset all data.

19

Screen Calibraon

WARNING

Screen calibraon is a simple but extremely important process and could render

the Smart Screen unusable if done incorrectly. Only do this if the touch screen

does not respond properly when touched. We recommend you use a blunt ne

point to follow this process. Avoid using a sharp object as it may damage the

screen. This process should be undertaken with cauon.

The Smart Display is a touch screen display. It has been pre-calibrated at the factory and very

rarely will need calibraon. If the screen buon become miss-aligned due to changes in oper-

ang condions it may be necessary to recalibrate the touch screen. Screen calibraon is

ONLY used to realign the touch screen with the display.

Note

Before starng, nd something with a ne

point, avoid using sharp items..

Step 1

Using the Smart Display, go into the sys-

tem menu, once here press the Calibrate

buon

Step 2

A warning and instrucons will appear on

screen. Please Read this as it is an important

process. When ready press Yes to connue

or No to go back to the system screen.

Step 3

Small crosshairs will appear on the screen,

using the ne pointer. Press in the center of

each of the crosshairs. Once you have

pressed all the crosshairs, the Smart Screen

will restart and you will be taken back to the

system screen. You have now nished the

screen calibraon.

20

Addional Screens

Cockpit Simulaon Screens

The Smart Bus also comes with addional

simulaon screens that simulate a real

cockpit. These include an arcial hori-

zon and instrumentaon. To view these

new screens touch the boom center of

the smart screen page. An example can

be seen to the right. If you want to return

to the smart screen, simply press the

center of the display.

Table of contents