Mod5 Series 0.50mm Pitch

Flip-Top™BGA Socket

5 Energy Way, West Warwick, Rhode Island 02893 USA

Tel: 800.424.9850 | 401.823.5200 | Fax: 401.823.8723

www.advanced.com

Specifications subject to change without notice. Dimensions shown: inch/(mm) Flip-Top is a trademark of Advanced Interconnections Corp.

Item FT-INS-003 (Rev 5/10)

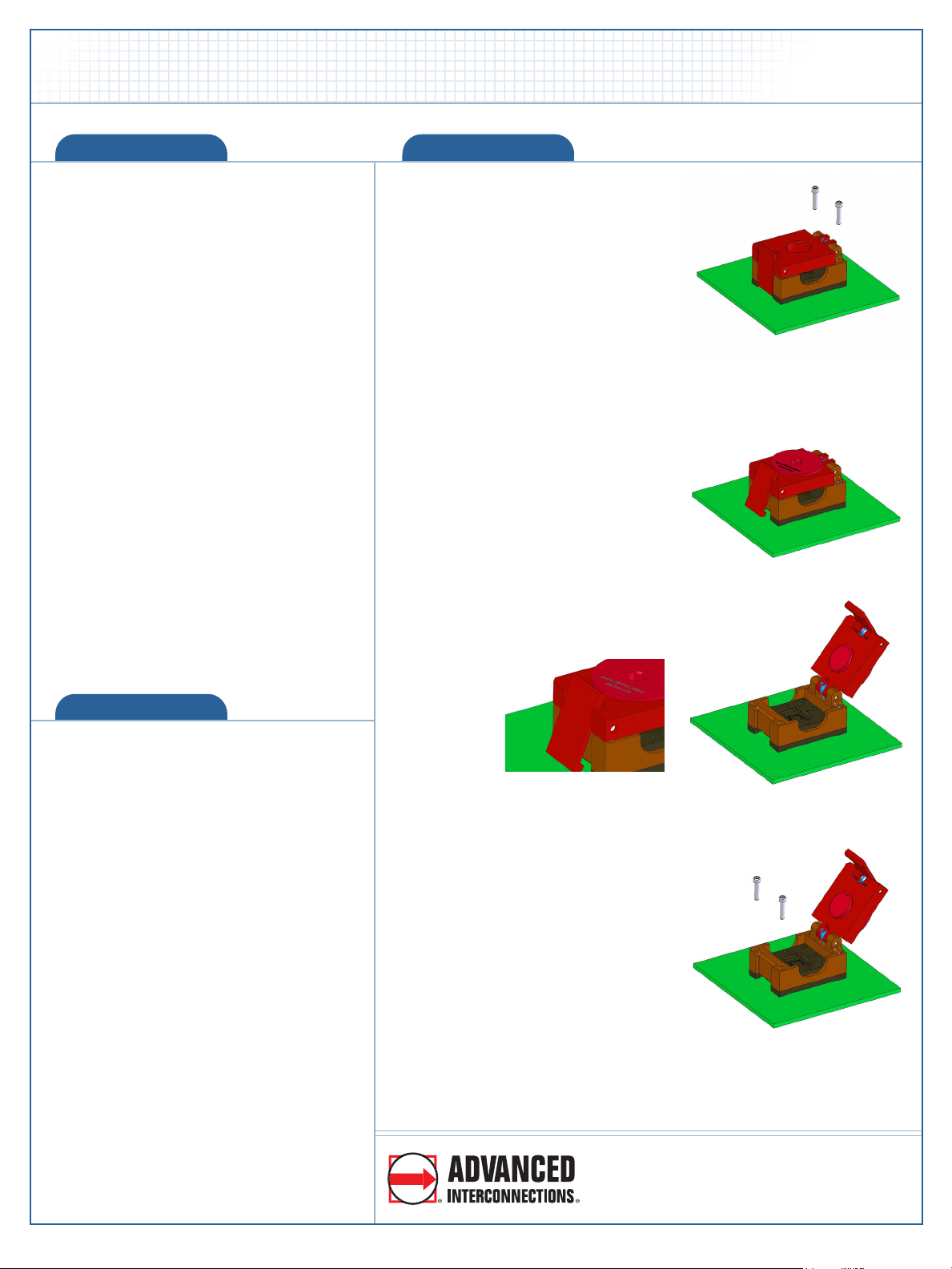

Usage Installation

BGA Device Removal

1. Loosen turn-screw heat sink until

support plate moves freely. To avoid

damage to the socket, do not attempt to

open the lid until the turn-screw heat

sink has been loosened.

2. Press latch mechanism. Refer to figure

4a in Step 4.

3. After lid is opened, remove the support

plate and set aside.

4. Remove BGA device. Use of vacuum

suction pen/tool is recommended.

Additional Info

After Installation

1. Place BGA device into opened Flip-Top

BGA Socket, aligning the A1 position on

the BGA with the chamfered corner of the

Flip-Top BGA Socket. Use of vacuum

suction pen/tool is recommended.

2. Insert support plate with the extended

square ram side toward the BGA device.

3. Close lid, making sure the latch is firmly

engaged.

4. Tighten turn-screw heat sink in a clock-

wise direction until it just makes contact

with the support plate. This may be done

by hand or with a 1/8” hex drive (sup-

plied).

5. Past this initial contact point, turn the

turn-screw heat sink 90º-110º (approx 1.0

lb-in); for the largest position counts, turn

to 110º-135º (approx 3 lb-in

MAX

). Over

tightening of turn-screw heat sink may

result in damage.

6. Socket is now ready for operation.

INSTALLATION & GENERAL USAGE

INSTRUCTIONS

Fig.4a

Fig.5

Fig.4

Fig.4b

Fig.3

STEP 3

Install supplied #0-80 screws in rear

of socket as shown in Fig. 3 and

tighten using the supplied hex

wrench (recommended torque value

is 1.20 lb-in).

STEP 4

Open lid by pressing upper portion

of latch mechanism back toward

socket (see Fig. 4 and 4a).

Lid will open approximately 115º,

allowing access to the front two

screw locations and allowing for

device insertion (see Fig. 4b).

STEP 5

Install supplied #0-80 screws, as

shown in Fig. 5, and tighten using

the supplied hex wrench

recommended torque value is

1.20 lb-in).