Advanjet HM-2600 Setup guide

Repair

HM-2600 Hotmelt Jet

Maintenance and Repair

3A6328A

Diaphragm-Jet™Technology EN

For non-contact dispensing of hot melt material in industrial environments.

For professional use only.

Kits – See page 3 for kits information

Important Safety Instructions

Read all warnings and instructions in this manual and all related

manuals before using this equipment. Save these instructions.

Model 25B315

PROVEN QUALITY. LEADING TECHNOLOGY.

Table of Contents

KITS..............................................................................................................................................................4

RELATED MANUALS ..................................................................................................................................4

WARNINGS ..................................................................................................................................................5

1. REQUIRED TOOLS AND PARTS ......................................................................................................... 6

1.1 Maintenance Kits ..........................................................................................................................6

1.1.1 Bushing Kit (P/N BK-2001)..............................................................................................6

1.1.2 Heater Kit (P/N HK-2600)................................................................................................7

1.1.3 Jet Repair Kit (P/N JK-9500) ...........................................................................................8

1.2 Required Tools..............................................................................................................................9

2. JET DISASSEMBLY............................................................................................................................10

2.1 Overview.....................................................................................................................................10

2.2 Disassembled Jet (Melter Cover Removed)...............................................................................11

2.3 Remove Syringe and Feed Tube Enclosure...............................................................................12

2.3.1 Remove the Melter Cover..............................................................................................12

2.3.2 Remove the Receiver Head...........................................................................................12

2.3.3 Remove the Syringe ......................................................................................................12

2.3.4 Remove the Feed Tube Enclosure................................................................................12

2.4 Remove Mounting Plates and Top Cover...................................................................................13

2.4.1 Remove Nozzle Plate (if present)..................................................................................13

2.4.2 Remove the Dovetail Plate............................................................................................13

2.4.3 Remove the Mounting Plate ..........................................................................................13

2.4.4 Disconnect Heater Block ...............................................................................................13

2.4.5 Remove Heater Bearing ................................................................................................13

2.5 Remove Melter, Top Cover, and Heater Block...........................................................................14

2.5.1 Remove the Top Cover Screws.....................................................................................14

2.5.2 Detach the Top Cover....................................................................................................14

2.5.3 Remove the Melter Assembly........................................................................................14

2.5.4 Remove the Nozzle Plate Screws .................................................................................14

2.5.5 Remove the Heater Assembly (HK-2600 only)..............................................................14

2.6 Remove Spacer Assembly .........................................................................................................15

2.6.1 Remove the Spacer.......................................................................................................15

2.6.2 Remove the Air Cylinder................................................................................................15

2.6.3 Remove the Air Valve Mount and Silencer....................................................................15

2.7 Check for Parts Set Aside...........................................................................................................16

3. INSTALL NEW PARTS AND REASSEMBLE THE JET.....................................................................17

3.1 Overview.....................................................................................................................................17

3.2 Install the Main Air Valve and Hammer Cylinder........................................................................18

3.2.1 Install the Air Valve........................................................................................................18

3.2.2 Install the Silencer .........................................................................................................18

3.2.3 Install the Air Cylinder....................................................................................................18

3.2.4 Tighten the Air Cylinder Setscrew .................................................................................18

3.3 Assemble the Spacer..................................................................................................................19

3.3.1 Assemble the Spacer Parts ...........................................................................................19

3.3.2 Check the Lever Assembly............................................................................................19

3.3.3 Attach the Spacer ..........................................................................................................19

3.3.4 Align the Lever with the Shoulder Bolt...........................................................................19

3.3.5 Install the Shoulder Bolt.................................................................................................19

Page 2 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

Table of Contents

3.4 Reassemble the Heater Block....................................................................................................20

3.4.1 Install New Heater Seal and Washer.............................................................................20

3.4.2 Install New Spring..........................................................................................................20

3.4.3 New Heater Block Bearing.............................................................................................20

3.4.4 Position Heater Block ....................................................................................................20

3.4.5 Attach Heater Block.......................................................................................................20

3.4.6 (Optional) Connect New Heater Block...........................................................................20

3.5 Attach the Valve Mount...............................................................................................................21

3.5.1 Verify O-Rings................................................................................................................21

3.5.2 Install Valve Mount Screws............................................................................................21

3.6 (Optional) Replace Melter Cable ................................................................................................22

3.6.1 (Optional) Remove the Melter Cable.............................................................................22

3.6.2 (Optional) Identify Cartridges on New Melter Cable......................................................22

3.6.3 (Optional) Shorter Heater Cartridge ..............................................................................22

3.6.4 (Optional) Longer Heater Cartridge...............................................................................22

3.6.5 (Optional) Install Cartridges and Tighten Setscrews....................................................22

3.7 Reassemble the Jet....................................................................................................................23

3.7.1 Insert the Nozzle Plate Screws......................................................................................23

3.7.2 Position the Melter Assembly ........................................................................................23

3.7.3 Position the Top Cover ..................................................................................................23

3.7.4 Attach Top Cover...........................................................................................................23

3.7.5 Connect the Melter ........................................................................................................23

3.7.6 Install Feed Tube Spacer...............................................................................................23

3.7.7 Attach Upper Feed Tube Enclosure ..............................................................................23

3.7.8 Tuck the Cables.............................................................................................................24

3.7.9 Trim the Cables..............................................................................................................24

3.7.10 Connect the Air Valve....................................................................................................24

3.7.11 Position Mounting Plate.................................................................................................24

3.7.12 Attach the Mounting Plate..............................................................................................24

3.7.13 Attach the Dovetail Plate ...............................................................................................24

4. SET THE JET HAMMER GAP............................................................................................................. 25

4.1 Using the Gap Set Fixture ..........................................................................................................25

4.2 Prepare the Gap Set Fixture.......................................................................................................26

4.2.1 Check the Zeroing Plate ................................................................................................26

4.2.2 Zero the MIcrometer ......................................................................................................26

4.2.3 Remove the Zeroing Plate.............................................................................................26

4.2.4 Attach the Jet.................................................................................................................26

4.3 Measure the Gap........................................................................................................................27

4.3.1 Connect the Jet..............................................................................................................27

4.3.2 Reading the Dial ............................................................................................................27

4.4 Adjust the Gap............................................................................................................................27

GRACO STANDARD WARRANTY ...........................................................................................................28

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 3 of 28

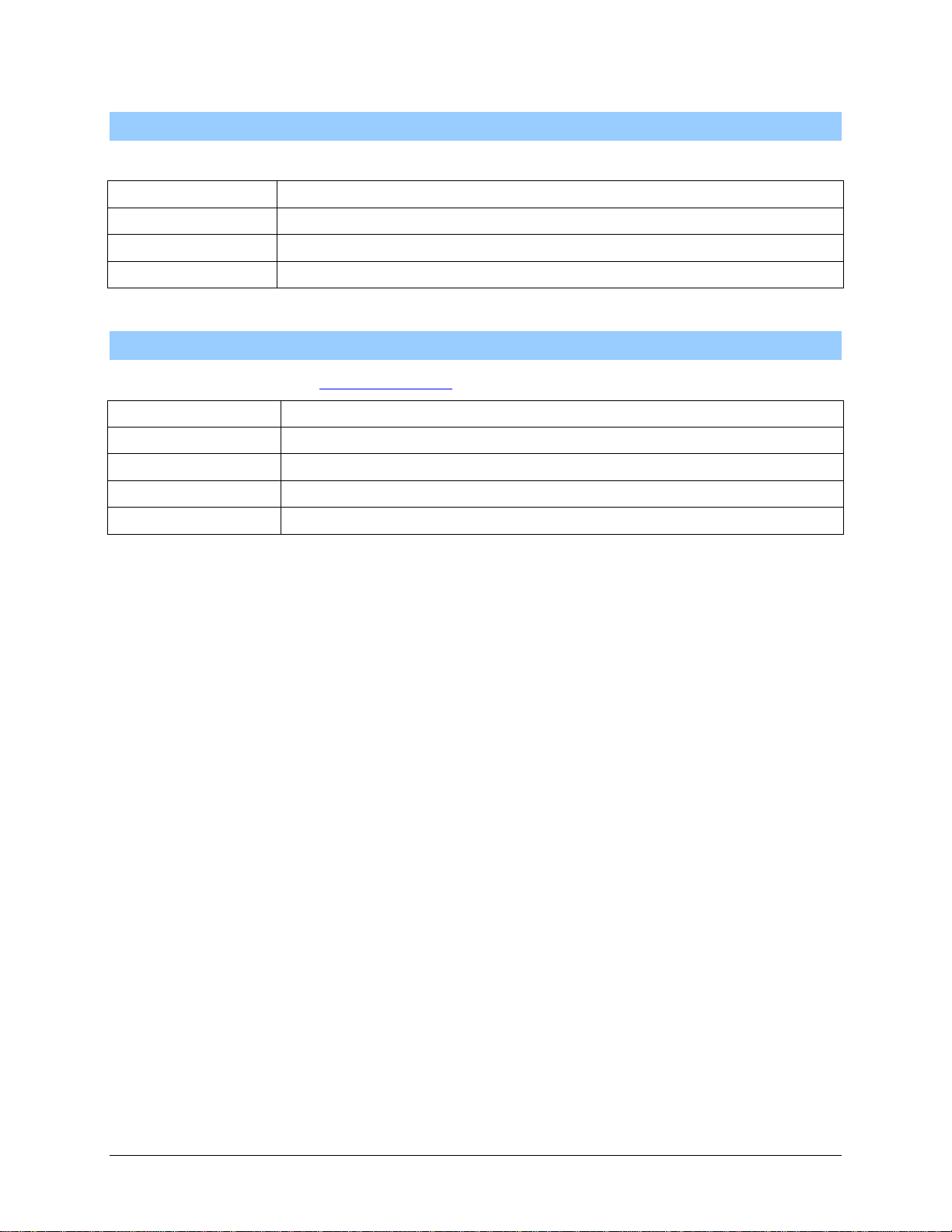

Kits

This manual accompanies these HM-2600 Jet Repair kits:

Part Number

Kit

BK-2001

Bushing Kit

HK-2600

Heater Kit

JK-9500

Jet Repair Kit

Related Manuals

Manuals are available at www.graco.com. Component manuals below are in English:

Part Number

Manual

3A6327

HM-2600 Hotmelt Jet Setup and Operation

3A6166

HM-2600C Hotmelt Jet Controller Setup and Operation

3A5937

Jet Dispensing Parameters Supplement

3A5908

Jet Maintenance Tool Kits

Page 4 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of

this equipment. The exclamation point symbol alerts you to a general warning and the

hazard symbols refer to procedure-specific risks. When these symbols appear in the

body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the

body of this manual where applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

Turn off and disconnect power cord before servicing equipment.

Connect only to grounded electrical outlets.

Use only 3-wire extension cords.

Ensure ground prongs are intact on power and extension cords.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

Store hazardous fluid in approved containers and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns: Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes

but is not limited to:

Protective eyewear, and hearing protection.

Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

Do not operate the unit when fatigued or under the influence of drugs or alcohol.

Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request SDSs from distributor or retailer.

Turn off all equipment and relieve air pressure when equipment is not in use.

Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

Do not alter or modify equipment. Alterations or modifications may void agency approvals and

create safety hazards.

Make sure all equipment is rated and approved for the environment in which it is used.

Use equipment only for its intended purpose. Contact your distributor for information.

Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

Do not kink or over bend hoses or use hoses to pull equipment.

Keep children and animals away from work area.

Comply with all applicable safety regulations.

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 5 of 28

1. Required Tools and Parts

For optimal jet performance, it is suggested to perform periodic preventive maintenance.

These HM-2600 jet maintenance kits are available for this purpose:

BK-2001: Replaces just the heater block bushing, jet spring, washer, and heater

seal.

HK-2600: Replaces the heater block assembly (heater block with bushing and

cable assembly). Also includes the jet spring, washer and heater seal.

JK-9500: Replaces the jet hammer cylinder, lever, shoulder bolt, main air valve,

muffler, and heater block assembly.

This document describes procedures for installing the HM-2600 jet maintenance kits.

Whenever the jet hammer spring is removed, as in these maintenance kits, the jet

hammer gap must be set before dispensing can proceed. The gap set fixture and

specific tools required for this procedure are included in the Advanjet Jet Maintenance

Kit (P/N JKT-2600).

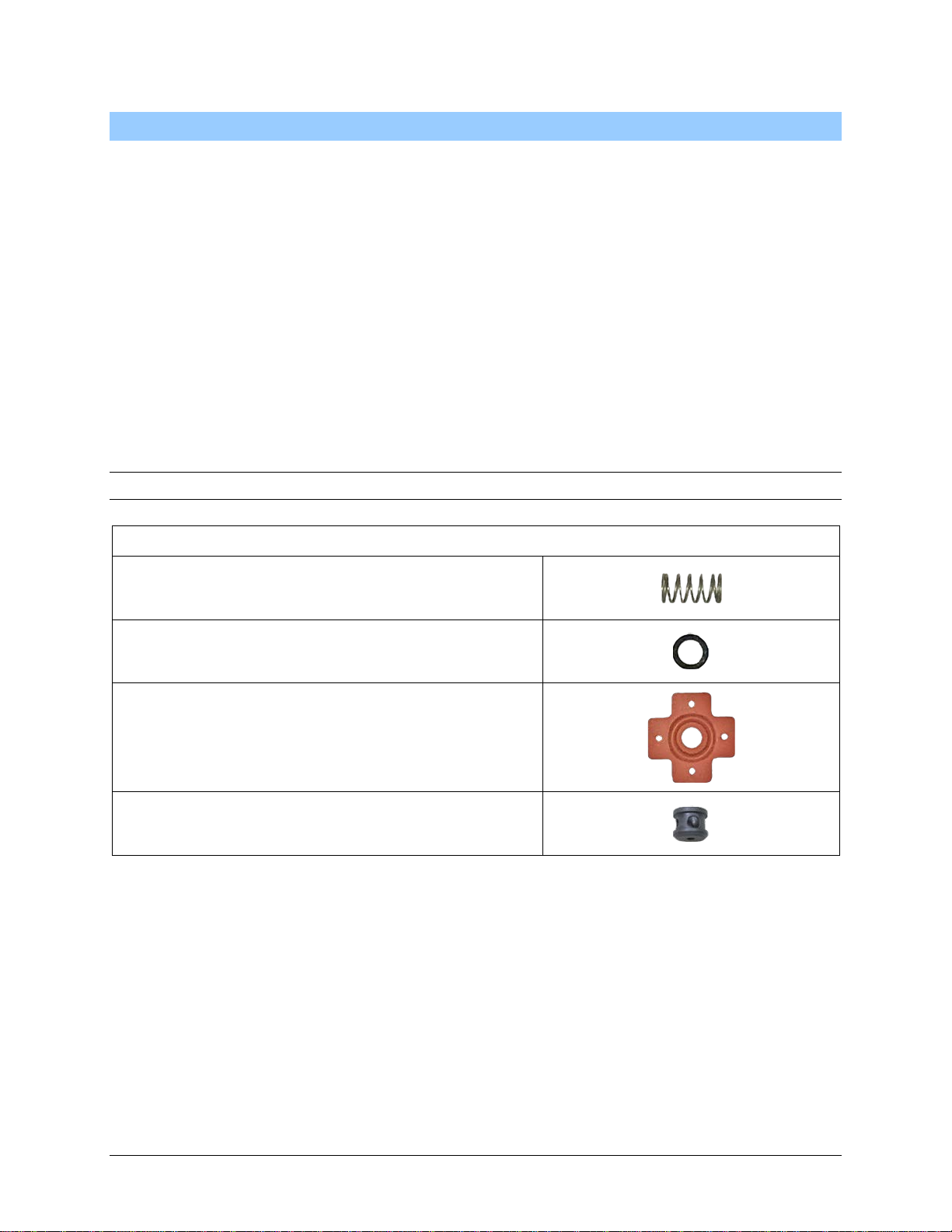

1.1 Maintenance Kits

1.1.1 Bushing Kit (P/N BK-2001)

JET SPRING P/N 60-2102

WASHER P/N 60-2116

HEATER SEAL P/N 03-2261-00

BUSHING P/N 03-2162-00

Page 6 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

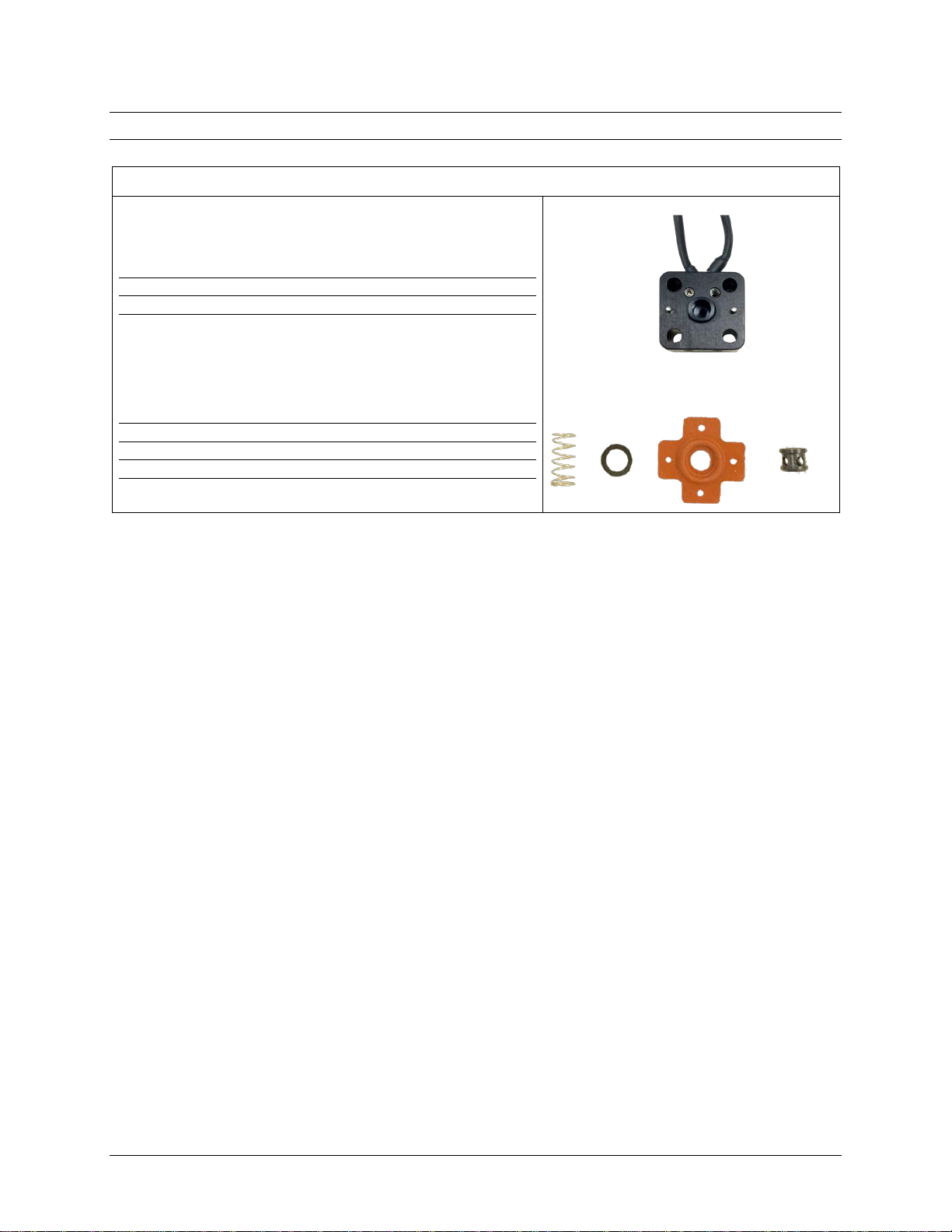

1.1 Maintenance Kits (continued)

1.1.2 Heater Kit (P/N HK-2600)

HK-2600 (STANDARD, 40W)

HEATER BLOCK 03-2214-02

HEATER CABLE 06-1043-00

HEATER BLOCK SCREWS (2) M3 X 25 FHMS

- and –

JET SPRING P/N 60-2102

WASHER P/N 60-2116

HEATER SEAL P/N 03-2261-00

BUSHING P/N 03-2162-00

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 7 of 28

1.1 Maintenance Kits (continued)

1.1.3 Jet Repair Kit (P/N JK-9500)

MAIN AIR VALVE P/N 60-2105

MAIN AIR (JET HAMMER)

CYLINDER ASSEMBLY P/N 60-2266

SILENCER P/N 60-2107

LEVER P/N 03-2281-00

PIVOT BOLT P/N 60-2104

HEATER SEAL P/N 03-2261-00

WASHER P/N 60-2116

JET SPRING P/N 60-2102

BUSHING P/N 03-2162-00

Page 8 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

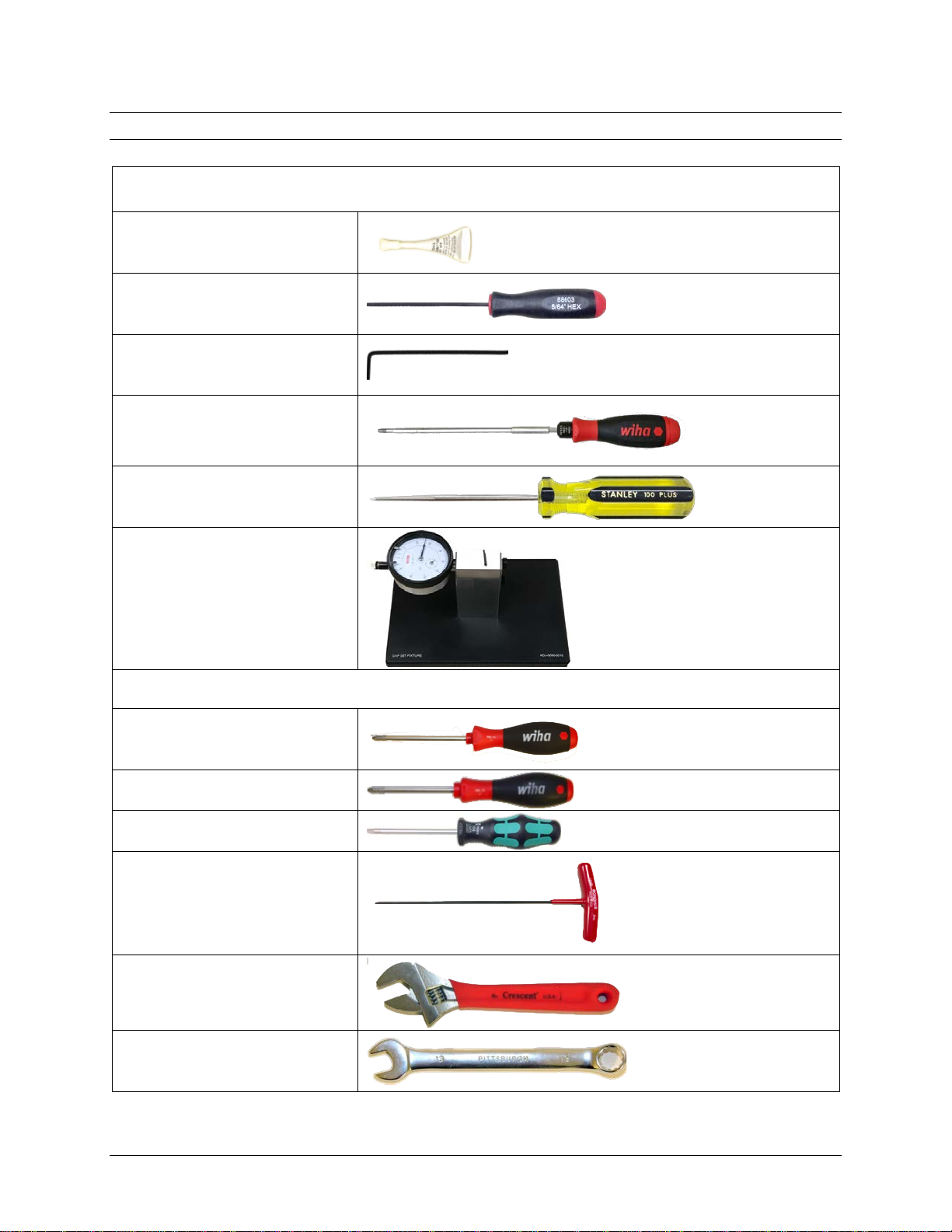

1.2 Required Tools

Jet Maintenance Tool Kit (P/N JKT-2600)

Loctite® 242 small screw

threadlocker

(P/N 113500)

5/64 in. hex wrench

(P/N 60-2293)

0.050 in. hex wrench

(P/N 60-2294)

Torque tool

(P/N 60-2264)

Awl

(P/N 60-2296)

Gap Set Fixture

(P/N 90-0010)

Other Tools

#1 Phillips screwdriver

#2 Phillips screwdriver

2.5 mm hex wrench

3 mm hex wrench (9 in.)

150-mm adjustable wrench

13 mm open end wrench

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 9 of 28

2. Jet Disassembly

2.1 Overview

Note: It is important to flush and clean the jet prior to making repairs. Follow the steps

for cleaning the jet in the HM-2600 Jet Setup and Operation manual 3A6327.

To avoid personal injury:

Move the nozzle close to the collection device

so there is minimal misting of the solvent

during flushing.

Be sure there is proper ventilation and wear appropriate eye and skin protection as

instructed by the solvent manufacturer.

Material inside the applicator can be near setpoint temperature. Wear protective clothing to

avoid severe burns.

Turn off the power switch and the air switch on the HM-2600C Jet Controller before

beginning disassembly of the jet. Allow all parts of the jet to cool. Refer to the

HM-2600C Jet Controller Setup and Operation manual 3A6166.

The extent of jet disassembly depends on which kits are being installed.

For all repair kits, remove and keep:

Nozzle plate and two screws with two washers each

Top cover and two screws

Mounting plate and two screws

For the Bushing and Heater Kits (BK-2001 and HK-2600):

Detach the Heater Block; keep for BK-2001, discard for HK-2600

Remove and discard the heater seal, washer, and jet hammer spring

For the Jet Maintenance Kit (JK-9500), remove and discard jet parts in this order:

Heater block and cable

Heater seal, washer, and jet hammer spring

Hammer air cylinder

Pivot bolt

Lever

Bullet air valve

Muffler

When noted, use the tool specified.

Section 2.7 provides a checklist of parts and screws that should be set aside. Take care

to set aside screws as they are removed so they can be easily located for installing the

new parts.

Page 10 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

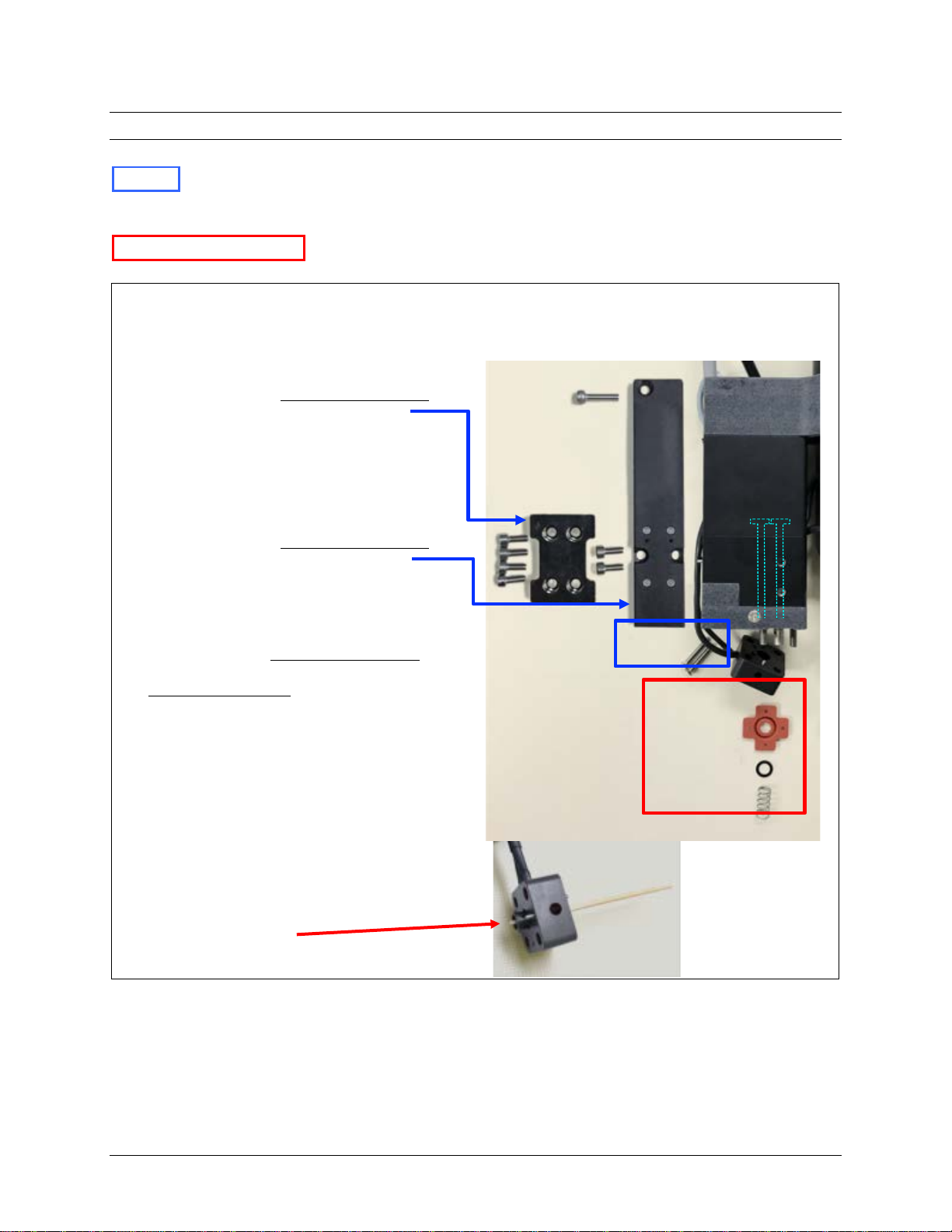

2.2 Disassembled Jet (Melter Cover Removed)

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 11 of 28

2.3 Remove Syringe and Feed Tube Enclosure

KEEP these parts and screws to set aside and reinstall. A checklist is provided in

section 2.7.

2.3.1 Remove the Melter Cover

Use the 2.5 mm driver to remove and set

aside the four screws securing the melter

cover to the syringe holder (two on each

side).

2.3.2 Remove the Receiver Head

Loosen the receiver head thumbscrews and

remove the receiver head.

2.3.3 Remove the Syringe

Loosen the luer lock securing the feed

tube.

2.3.4 Remove the Feed Tube Enclosure

Loosen the thumbscrew securing the

lower feed tube enclosure.

Use the 2.5 mm driver to remove and

set aside the two screws securing the

upper feed tube enclosure.

Detach the

luer from

the feed

tube. Keep

luer to

clean and

reuse.

Discard

feed tube.

KEEP

KEEP

Page 12 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

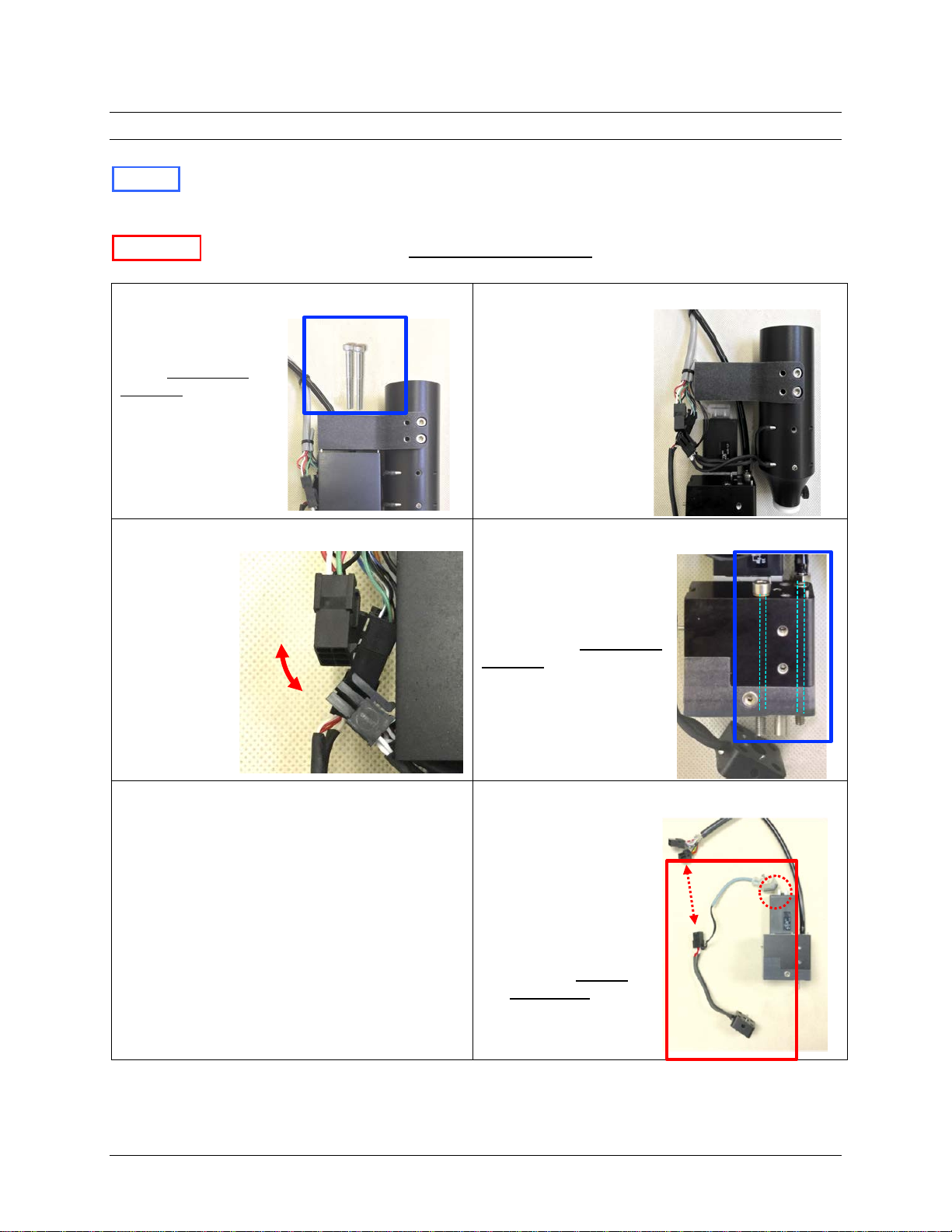

2.4 Remove Mounting Plates and Top Cover

KEEP these parts and screws to set aside and reinstall. A checklist is provided in

section 2.7.

BK-2001 or HK-2600 kit replaces these parts.

2.4.1 Remove Nozzle Plate (if present)

Going through the melter holder, use the 3 mm driver to loosen the two screws that secure the nozzle

plate. Remove the nozzle plate and set aside; nozzle plate screws will be removed later.

2.4.2 Remove the Dovetail Plate

Using the 3 mm driver, remove and set aside the

four screws securing the dovetail plate.

2.4.3 Remove the Mounting Plate

Using the 3 mm driver, remove and set aside the

three screws securing the mounting plate.

2.4.4 Disconnect Heater Block

Use the #1 PH to remove and set aside the two

screws securing the heater block.

Remove and discard the heater seal and

washer, and the jet compression spring.

2.4.5 Remove Heater Bearing

Use a cleaning swab or similar tool to push out

the heater bearing.

Leave any lubricant in place in the heater block;

Discard the bearing.

KEEP

DISCARD

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 13 of 28

2.5 Remove Melter, Top Cover, and Heater Block

KEEP these parts and screws to set aside and reinstall. A checklist is provided in

section 2.7.

HK-2600 kit replaces these parts. Do not discard screws.

2.5.1 Remove the Top Cover Screws

Use the 3 mm hex to

loosen the two screws

securing the top

cover; remove and

set aside.

2.5.2 Detach the Top Cover

Separate the top cover

from the melter

assembly, set aside

2.5.3 Remove the Melter Assembly

Separate the

melter

connector from

the end of the

jet cable;

remove the

melter

assembly and

set aside.

2.5.4 Remove the Nozzle Plate Screws

The loosened nozzle plate

screws were captured in

place by the melter

holder. After the melter

holder is removed from

the top cover, remove and

set aside the nozzle plate

screws.

To replace the heater block,

continue to step 2.5.5.

To keep the heater block,

skip to step 2.6.1

2.5.5 Remove the Heater Assembly

(HK-2600 only)

Loosen the screw

on the air valve

cable connector

and separate the

connector.

Separate the heater

block connector

from the end of the

jet cable; remove

and discard.

JET

CABLE

MELTER

CABLE

REMOVE

KEEP

DISCARD

Page 14 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

2.6 Remove Spacer Assembly

KEEP these parts and screws to set aside and reinstall. A checklist is provided in

section 2.7.

JK-9500 kit replaces these parts.

2.6.1 Remove the Spacer

Remove and set aside the spacer screws

(#1 PH), the nylon spacer, and the automatic

shutoff spring.

Remove and discard the shoulder bolt (2 mm

hex) and the lever.

2.6.2 Remove the Air Cylinder

Use the 2 mm hex driver to loosen the

setscrew that locks the main air cylinder.

Use the 13 mm wrench to remove and discard

the air cylinder.

2.6.3 Remove the Air Valve Mount and Silencer

Use the 3 mm driver to remove and set aside the screws

securing the valve mount to the jet body.

If still attached, use a #1PH to loosen the screw on the jet

cable connector.

Loosen screws attaching the air valve to the valve mount.

Remove and discard the air valve.

Use a wrench to remove and discard the muffler.

DISCARD

DISCARD

KEEP

DISCARD

DISCARD

KEEP

KEEP

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 15 of 28

2.7 Check for Parts Set Aside

Check that these parts have been set aside. If necessary, remove built-up threadlocker.

FEED TUBE ENCLOSURE

(2) M3 X 14 SHCS

MELTER COVER

(4) M4 X 8 BHCS

DOVETAIL PLATE

(4) M4 X 10 SHCS

MOUNTING PLATE

(2) M4 X 10 SHCS

NOZZLE PLATE

(2) M4 X 55 SHCS

TOP COVER

(2) M4 X 40 SHCS

HEATER BLOCK

(2) M3 X 20 FHMS

SPACER

(1) M3 X 16

(2) M3 X 25

SHUTOFF SPRING

JET VALVE MOUNT

(2) M4 X 20 SHCS

Page 16 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

3. Install New Parts and Reassemble the Jet

3.1 Overview

In general, parts are reinstalled in the reverse order that they were removed.

Gather the screws set aside as shown in Section 2.7.

Install the Main Air Valve and Hammer Cylinder

Attach the air valve

Attach the silencer

Install the hammer air cylinder.

Assemble the Spacer

Assemble the lever and lever spring

Attach the spacer

Align the lever

Install the pivot (shoulder) bolt

Reassemble the Heater Block

Install the heater seal, washer, and hammer spring

Install the bushing

Align and attach heater block

Attach the Valve Mount

(Optional) Replace Melter Cable

Reassemble the Jet

Insert nozzle plate screws

Position and attach melter assembly and top cover

Tuck cables

Attach air valve connector

Attach the mounting plate

Attach the dovetail plate

NOTICE

Use Loctite®242 threadlocker as indicated. To avoid damage to the jet,

do not substitute with other products.

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 17 of 28

3.2 Install the Main Air Valve and Hammer Cylinder

3.2.1 Install the Air Valve

Apply a small amount of Loctite 242 to the air

valve screws and install the new air valve on the

valve mount as shown.

NOTICE

Over-tightening

can easily break

this plastic.

3.2.2 Install the Silencer

Apply a small amount of Loctite 242 to the new

muffler and install into the valve mount. The fit

should be snug, but not so tight that it crushes the

rubber washer.

3.2.3 Install the Air Cylinder

Install the new air cylinder and use the 13 mm

wrench to tighten the cylinder in place until it hard

stops.

3.2.4 Tighten the Air Cylinder Setscrew

Apply a small amount of Loctite 242

to the

setscrew and use the 2 mm hex driver to tighten.

Page 18 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

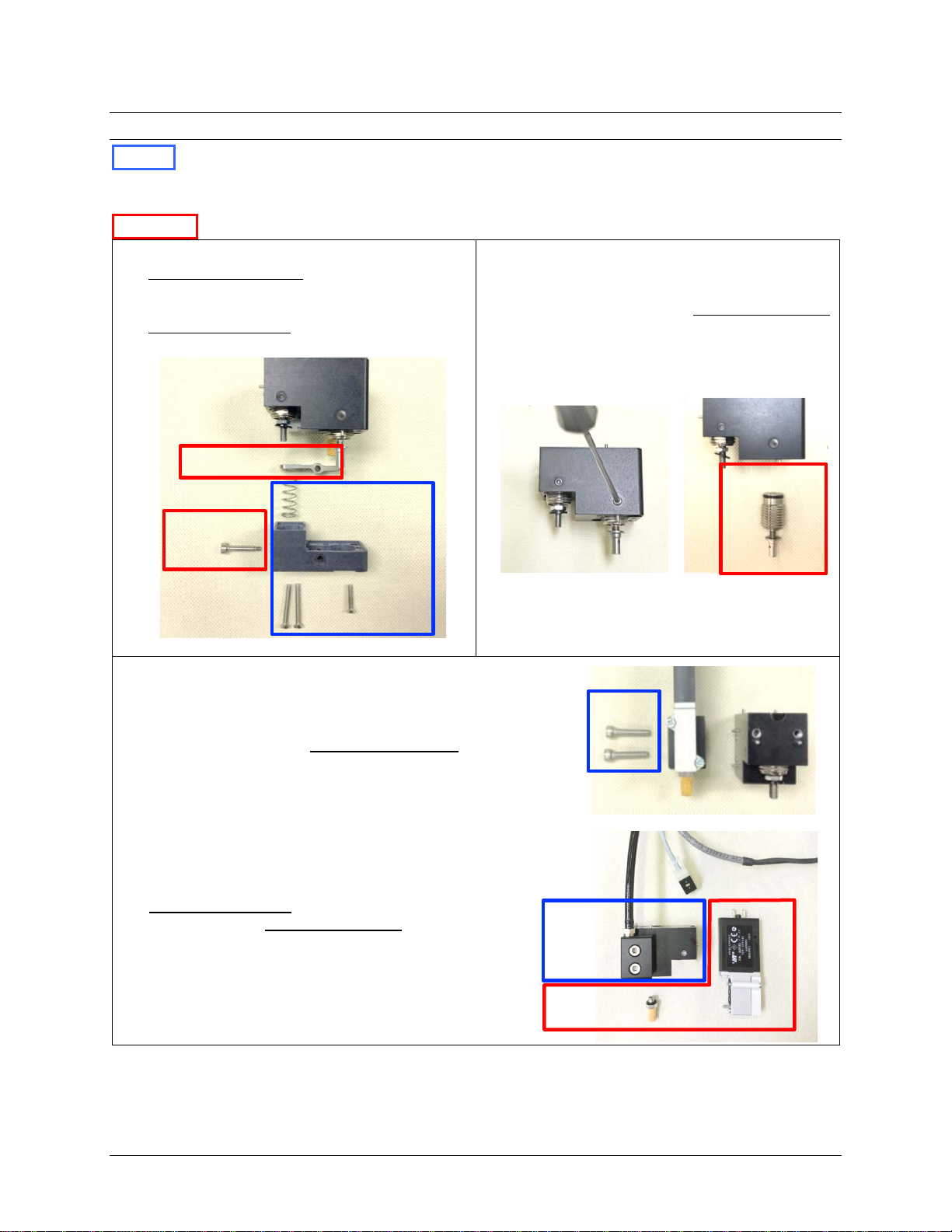

3.3 Assemble the Spacer

3.3.1 Assemble the Spacer Parts

Locate the new lever and shoulder bolt, and also

the nylon spacer, spacer screws, and automatic

shutoff spring that were set aside.

3.3.2 Check the Lever Assembly

Observe the orientation of the lever and washers

as shown:

The bore in the lever faces the shutoff spring.

There is one washer on the shutoff cylinder

below the lever.

Proper positioning is critical.

3.3.3 Attach the Spacer

With the spring resting in the bore of the lever, position the

spacer over as shown.

Locate the three spacer screws that were set aside. Apply a

light coating of Loctite 242 to the threads. Firmly squeeze the

spacer closed and install the spacer screws.

3.3.4 Align the Lever with the Shoulder Bolt

Use an awl to line up the hole for the pivot (shoulder) bolt

with the hole in the lever. Insert the 2 mm driver from the

opposite side and line it up with the awl.

Push out the awl with the driver.

3.3.5 Install the Shoulder Bolt

Apply a light coating of

Loctite 242 to the threads of

the pivot bolt and wipe off

any excess.

Note: Do not allow Loctite

from the shoulder bolt tip

to transfer to the lever.

Push out the driver with the

shoulder bolt.

Screw in the shoulder bolt

with the 2 mm driver until it

is barely snug. Do not over-

tighten.

Verify that the lever is not

binding—the hammer

cylinder hat should move up

and down freely.

HAT MOVES

UP & DOWN

SPRING

FITS INTO

LEVER

BORE

3A6328A Advanjet HM-2600 Hotmelt Jet Maintenance and Repair Page 19 of 28

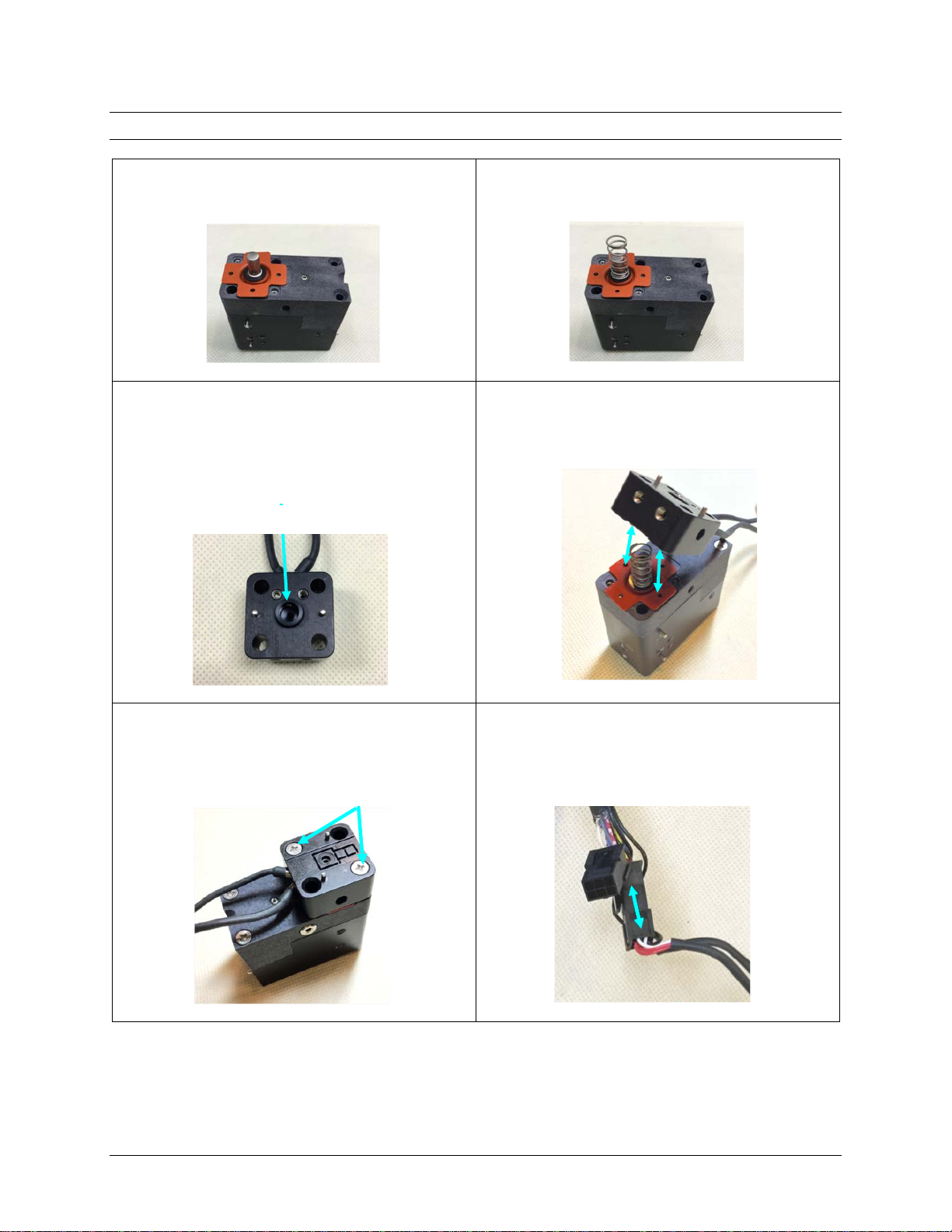

3.4 Reassemble the Heater Block

3.4.1 Install New Heater Seal and Washer

Install the heater seal and washer on the tip of the

air cylinder with the indent positioned as shown.

3.4.2 Install New Spring

Install the new jet compression spring.

3.4.3 New Heater Block Bearing

If a new heater block is being installed, the new

bearing will be in place. If the existing heater block

is being used, use a wooden cotton swab to push

the new bearing into place, leaving any existing

lubricant in place.

3.4.4 Position Heater Block

Align the pins in the heater block with the heater

seal as shown.

3.4.5 Attach Heater Block

Locate the two heater block screws that were

set aside.

Apply Loctite 242 to the tips of both screws

and attach the heater block.

3.4.6 (Optional) Connect New Heater Block

If using the HK-2600 to install a new heater block,

attach the heater block connector to the jet cable.

PUSH BEARING INTO PLACE

Page 20 of 28 Advanjet HM-2600 Hotmelt Jet Maintenance and Repair 3A6328A

Table of contents

Other Advanjet Industrial Equipment manuals