Advanjet HV-2100 Jet Manual instruction

Setup and Operation

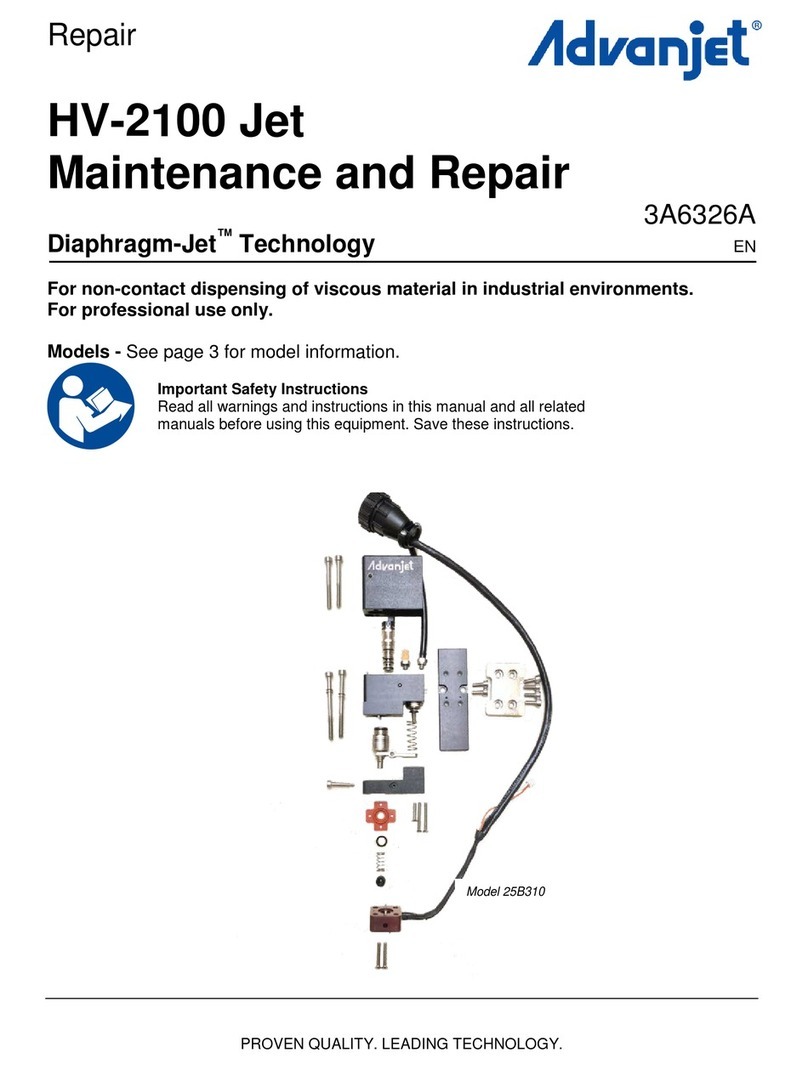

HV-2100 Jet

3A6244A

Diaphragm-Jet™Technology EN

For non-contact dispensing of viscous material in industrial environments.

For professional use only.

Models - See page 3 for model information.

Important Safety Instructions

Read all warnings and instructions in this manual and all related

manuals before using this equipment. Save these instructions.

Model 25B310

PROVEN QUALITY. LEADING TECHNOLOGY.

Table of Contents

Models............................................................................................................................ 3

Related Manuals............................................................................................................ 3

Warnings........................................................................................................................ 4

1. Specifications..................................................................................................... 5

1.1 Technical Specifications ............................................................................5

1.2 Technical Assistance.................................................................................5

1.3 HV-2100 Jet Dimensions........................................................................... 6

2. Installation and Setup ........................................................................................ 7

2.1 Dispensing Components............................................................................ 7

2.2 Pneumatic Connections.............................................................................8

2.3 Cable Connections ....................................................................................9

2.4 Jet Cable Input/Output............................................................................. 10

3. Assembling the HV-2100 Jet............................................................................ 11

3.1 Jet Assembly Overview............................................................................ 11

3.2 Inspect the Nozzle Plate for Cleanliness.................................................. 12

3.3 Install the Nozzle Insert............................................................................13

3.4 Install the Diaphragm and Nozzle Plate...................................................14

3.5 Install the Feed Tube and Fluid Syringe ..................................................15

3.6 Prime the Jet............................................................................................ 16

3.7 Check for Fluid Leaks.............................................................................. 17

4. Cleaning the Jet................................................................................................ 18

4.1 Cleaning the Exterior of the Jet................................................................ 18

4.2 Cleaning the Interior of the Jet................................................................. 18

4.3Solvent and Diaphragm Compatibility......................................................19

4.4 Flush the Fluid System............................................................................ 20

4.5 Clean the Nozzle ..................................................................................... 21

Graco Standard Warranty........................................................................................... 22

Page 2 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

Models

Part Number

Model

25B310

HV-2100 Jet, 30 cc syringe

25B311

HV-2100 Jet, 30 cc syringe, heated feed tube

25B312

HV-2100 Jet, 6 oz syringe, heated feed tube

Related Manuals

Manuals are available at www.graco.com. Component manuals below are in English:

Part Number

Manual

3A6226

HV-2100C Jet Controller Setup and Operation

3A6326

HV-2100 Jet Maintenance and Repair

3A5937

Jet Dispensing Parameters Supplement

3A5908

Jet Maintenance Tool Kits

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 3 of 22

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of

this equipment. The exclamation point symbol alerts you to a general warning and the

hazard symbols refer to procedure-specific risks. When these symbols appear in the

body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the

body of this manual where applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded..Improper grounding, setup, or usage of the system can cause

electric shock.

Turn off and disconnect power cord before servicing equipment.

Connect only to grounded electrical outlets.

Use only 3-wire extension cords.

Ensure ground prongs are intact on power and extension cords.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

Store hazardous fluid in approved containers and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns: Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes

but is not limited to:

Protective eyewear, and hearing protection.

Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

Do not operate the unit when fatigued or under the influence of drugs or alcohol.

Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

Do not alter or modify equipment. Alterations or modifications may void agency approvals and

create safety hazards.

Make sure all equipment is rated and approved for the environment in which it is used.

Use equipment only for its intended purpose. Contact your distributor for information.

Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

Do not kink or over bend hoses or use hoses to pull equipment.

Keep children and animals away from work area.

Comply with all applicable safety regulations.

Page 4 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

1. Specifications

1.1 Technical Specifications

Size

(including mounting bracket)

Width: 25.4 mm (1.00 in)

Height: 116.1 mm (4.57 in)

Depth: 106.8 mm (4.20 in)

Weight:446 grams (0.98 lb)

Viscosity Range

1-400K mPa•s (cPs)

Speed

Up to 300 drops/sec

Fluid Syringes

5, 10, 30 and 55 cc

Nozzle Features

Tungsten Carbide and long-life ceramic

Sizes from 50 µm to 600 µm

Extended tips available from 3 mm to 6 mm

Wetted Parts

17-4 Stainless Steel, Tungsten Carbide,

Ceramic, FKM, FFKM, Silicone

Nozzle Heater

Heating up to 70 °C max (158 °F)

Fluid Pressure

0.41 MPa (60 psi) max

Jet Pressure

0.24 MPa (35 psi) min

0.62 MPa (90 psi) max

Operating Temperature

15 °C to 50 °C (59 °F to 122 °F)

Operating Noise

Sound pressure measured 1.5 m

(4.9 ft) from applicator at 40 psi

(225 kPa), per EN ISO 3746

79.4 dB(A)

1.2 Technical Assistance

For customer service and technical assistance:

Advanjet

926 Andreasen Dr. # 108

Escondido, CA 92029

USA

Phone: +1 800 333 4877

Web: www.advanjet.com

E-mail: info@advanjet.com

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 5 of 22

1.3 HV-2100 Jet Dimensions

Shown below are the mechanical dimensions of the HV-2100. Units are in millimeters

[inches].

The HV-2100 can be mounted to a variety of robots when X-Y-Z motion is desired.

It can also be mounted rigidly over a transporting mechanism like a conveyor belt or

shuttle table.

The HV-2100 provides a dovetail rear mounting plate for rigid attachment to a

robot’s XYZ stage. An optional mating dovetail mount is available from Advanjet

(P/N 03-2312).

The dispense tip relative to the mounting holes and the rear mounting plate

dimensions are shown in mm in the figure below. It is highly recommended that any

mounting scheme allow for vertical adjustment so the dispensing tip to dispensing

surface can be easily adjusted.

116.1

[4.57]

105.1

[4.14]

28.9 [1.14]

106.8

[4.20]

25.4 [1.00]

38.1

[1.5]

44.5

[1.75]

52.8 [2.08]

Page 6 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

2. Installation and Setup

2.1 Dispensing Components

The HV-2100 has three essential components that contact the fluid: the nozzle plate,

the diaphragm, and the feed tube. The feed tube is disposable; the other components

can be disassembled, cleaned and reused. Cleaning procedures are in Section 4 -

Cleaning the Jet.

The diaphragm should be inspected each time the nozzle plate is removed. If there are

signs of wear, cracks, or deformation, the diaphragm should be replaced. Consideration

should be made of dispensing and cleaning fluids that could damage the jet’s wetted

parts. The materials of these components are listed in Section 1.1 - Technical

Specifications. In particular, cyanoacrylates or pre-mixed two-part adhesives with a

short pot life are not recommended, as these materials can harden in the nozzle plate.

See Section 4.3 - Solvent and Diaphragm Compatibility for details.

Figure 2-1: HV-2100 Jet Dispensing Components

DIAPHRAGM

NOZZLE PLATE &

O-RING

FEED TUBE

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 7 of 22

2.2 Pneumatic Connections

Main Air Supply: Connect a filtered (40-micron filter or better) and independently

regulated main air source. It is highly recommended to place a drying system or

desiccant dryer in line with the main air line. A 6mm OD air tube with a slip connect

coupler is supplied to connect the HV-2100C to the main air supply. The main air supply

pressure should be between 70 and 100 psi (0.48 and 0.70 MPa).

Fluid Syringe Air Pressure:The HV-2100C delivers fluid syringe air pressure through

clear 4 mm OD tubing that is attached to the receiver head and has a twist-lock

connector to the controller. The fluid syringe air supply should be at maximum 60 psi

(0.41 MPa); normal fluid pressure is usually between 10 and 50 psi (0.06 and 0.34 MPa).

Variations in the air pressure source can adversely affect the consistency of the drop

size.

Jet Air Pressure:The HV-2100C delivers jet air pressure through black 6 mm OD

tubing with a quick-connect coupler to the controller and an air fitting for the jet. The jet

air supply must be clean and dry and at a maximum pressure of 75 psi (0.51 MPa);

normal jet air operation is usually between 35 and 75 psi (0.24 and 0.51 MPa).

NOTICE

It is imperative that the air supplied to the HV-2100 is clean, dry, and free from debris and water. A 40-micron filter

is highly recommended. If the air is not clean and dry, serious damage can occur to the air solenoid valves.

Figure 2-2: HV-2100 Pneumatic Connections

Page 8 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

2.3 Cable Connections

The cable connections for a typical dispensing system are illustrated below. To assure

proper connections, each of the component cables supplied by Advanjet has a distinct

connector. Be sure that all power is off when connecting and disconnecting any cable to

the Advanjet controller.

Jet:A 28-pin cable (P/N 06-1095-00) mates with the HV-2100 jet cable to connect it to

the HV-2100C controller. Section 2.4 provides HV-2100 Jet Cable pin assignments.

I/O:When using the HV-2100 jet with the HV-2100C controller and a robot, six TTL

trigger lines control jet operations through a 26-pin cable (P/N CB26-005).

COMM:A PC can be connected to the controller via RS-232C/USB to operate the

HV-2100 using software instead of the front panel touch screen.

Figure 2-3: Cable Connections for the HV-2100 in a Typical Dispensing System

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 9 of 22

2.4 Jet Cable Input/Output

A 28-pin cable is supplied with the HV-2100 Jet. The table lists the jet cable pin

assignments.

JET CABLE

PIN ASSIGNMENTS

PIN

1

--

2-3

Jet Solenoid

4-5

Jet Heater

6-7

Jet RTD

8-28

--

Figure 2-4: CPC-28 Jet Cable

Page 10 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

3. Assembling the HV-2100 Jet

The HV-2100 jet is shipped fully assembled except for the diaphragm and nozzle plate.

A specific diaphragm material and nozzle plate orifice diameter should be chosen based

on the application and dispensing fluid. The steps required to correctly assemble the

diaphragm and nozzle plate on the jet body are detailed below.

Before assembling the jet, make the necessary pneumatic and electrical connections as

described in Sections 2.2 and 2.3.

3.1 Jet Assembly Overview

Figure 3-1 below shows the alignment of the heater block, diaphragm, O-ring, and

nozzle plate.

There is a grooved pattern on the bottom face of the heater block that matches

the raised embossments on the diaphragm. The grooves position the diaphragm

correctly on the heater block.

The diaphragm also has a metal insert with a post that must be inserted into the

central hole on the heater block.

Although a diaphragm can be inserted without the jet connected to an air source,

it will not sit flat on the heater. It is recommended to OPEN the jet before

assembling the diaphragm. Detailed instructions are in Section 3.4 - Install the

Diaphragm and Nozzle Plate.

Figure 3-1: HV-2100 Heater Block, Diaphragm, O-Ring and Nozzle Plate

HEATER BLOCK

DIAPHRAGM

O-RING

NOZZLE PLATE

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 11 of 22

3.2 Inspect the Nozzle Plate for Cleanliness

It is important to inspect the jet nozzle plate for debris before mounting it onto the Jet.

A clean nozzle looks like this:

If the nozzle plate is not clean, it could affect the dispensing quality. These dispensing

problems are symptoms of a contaminated jet:

Unclean or uneven dispensing

Drops become irregular or vary in size

Residual flow or drooling out of the tip when the jet is in the closed position

Interrupted dispensing (places where fluid no longer is dispensed)

Splatter or satellites

For best results, Advanjet cleaning kits contain tools appropriately sized to the nozzle

plate. For example, if you are using the 125 μm nozzle plate, order the 125 μm cleaning

kit (Advanjet P/N CL-125).

Refer to Section 4 for complete instructions on cleaning the jet.

NOTICE

Never submerge the diaphragm in solvents as it might result in damage.

Diaphragms can be cleaned successfully with

a small amount of solvent and a soft brush and cotton swab.

Do not submerge the diaphragm into the ultrasonic cleaner because

it will deteriorate the diaphragm and shorten its life.

Figure 3-2: A Clean Nozzle

Page 12 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

3.3 Install the Nozzle Insert

When the nozzle becomes damaged or plugged, a new nozzle insert and O-ring may be

required. Installation is simple, but correct and careful assembly is important.

NOZZLE INSERT O-RING PART NUMBER

NOZZLE PLATE O-RING PART NUMBER

SILICONE

FKM

SILICONE

FKM

NP09-2830

NP09-2851

NP09-2820

NP09-2850

Disassemble the nozzle plate by1. removing the three screws from

the nozzle plate bottom.

Flip over and remove the nozzle2. plate top and the nozzle insert.

Save the O-ring.

Clean as needed.3.

Set the nozzle insert with the4.

O-ring facing up in the groove of

bottom plate as shown below.

Replace the nozzle plate top.5.

Holding the top and bottom plates

together, flip the nozzle over.

Replace the three screws.

Flip the nozzle top side up and set the nozzle plate O-ring6.

in the groove.

Note: When installing the nozzle, the O-ring must face up.

NOZZLE INSERT

O-RING

NOZZLE PLATE

O-RING

Figure 3-3: Nozzle Insert O-Ring (left) Compared to Nozzle Plate O-ring (right)

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 13 of 22

3.4 Install the Diaphragm and Nozzle Plate

Material inside the applicator can be near setpoint temperature.

To avoid severe burns, wear protective gloves.

1. Turn the main power ON.

2. Set the jet pressure to 40 psi (.28 MPa).

3. On the Advanjet controller home screen, tap Jet to OPEN the jet.

4. Note the

rectangular

grooves on the

heater block that

align with the

grooves on the

diaphragm.

5. Gently press the

diaphragm into the

heater block until the

diaphragm pin is

inserted in the center

and the rectangular

grooves are firmly in

place.

6. Note that the

heater block has

two pins that align

with two holes in

the nozzle plate.

7. Use the pins to align the

nozzle plate

on the heater

block. The nozzle plate O-

ring faces up, and the fluid

barb faces the fluid syringe.

8. Tighten the two

embedded screws

with a 3-mm hex

driver. Do not over-

tighten; it is possible

to strip the screws.

An optional torque

wrench is available

for this purpose (P/N

NT09-2500).

9. Before installing the fluid syringe, CLOSE the jet.

ALIGN

THE

G

ROOVES

ALIGN PINS TO HOLES

NOZZLE

PLATE

O-RING

FACES UP

FLUID BARB

FACES

SYRINGE

Page 14 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

3.5 Install the Feed Tube and Fluid Syringe

Material inside the applicator can be near setpoint temperature.

To avoid severe burns, wear protective gloves.

1. If the syringe is smaller than 30 cc,

insert a syringe spacer ring.

Adapters are available in 3-cc, 5-cc,

and 10-cc.

2. Check the receiver head O-ring for

wear, debris, or

deformity. These

conditions could cause fluid to leak.

Clean or replace if necessary.

3. Turn Fluid Air OFF.

Insert the receiver head into the

syringe and twist to lock.

4. Attach a new feed tube to the luer

(metal luer shown; selection of feed

tube material depends on the

dispensing fluid.

5. Attach the feed tube to the syringe

and place the syringe in the jet.

Tighten the thumbscrew to secure.

6. Slip the feed tube onto the barb end

of the nozzle plate.

CLEAN O-RING

SPACER

RING

THUMB

SCREW

NOZZLE PLATE BARB

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 15 of 22

3.6 Prime the Jet

Note: HV-2100C Controller shown for illustrative purposes.

1. Prior to dispensing, it is necessary to prime the jet in order to purge residual air

from the system. In order to do this, the fluid must be brought to dispensing

temperature.

From the HV-2100C front panel, use the following procedure to turn on the

heater.

Press (INDEX) until Run-Stop (r-S)

is displayed on the Present Value (PV)

line.

Use the

arrows to select the rUn

setting on the Set Value (SV) line.

Press (ENTER) to save the change.

Heater is ON.

Press again to return to the main screen

Use the

arrows to change Set Value (SV) to the dispensing temperature for

the fluid being used.

Wait ten minutes for the temperature of the nozzle to be stable.

2. Position a purge cup under the jet nozzle.

3. Turn the Fluid Air OFF (“O” on Air switch).

4. On the controller touch panel:

Tap on Fluid Pressure and set to 0.

Tap on Jet to OPEN.

5. Turn the Fluid Air ON (“I” on Air switch).

6. Keep the purge cup positioned under the

nozzle. While watching for fluid flow from the

nozzle, increase Fluid Pressure in small

increments.

Once fluid begins to slowly flow, continue at that pressure until there are no

bubbles in the fluid.

7. Tap on Jet to CLOSE.

8. Tap on Jet Pressure and set to 45 psi.

9. It is useful to designate a recipe on the HV-2100C controller for the priming

process. Use these parameters:

Refill = 10.0 ms

Dwell = 10.0 ms

Refill+ = 0.3 ms

Drops = 250

This recipe allows most fluids to flow through the jet easily.

Figure 3-4: Turn the Heater ON

Figure 3-5: Fluid Pressure 0, Jet OPEN

Page 16 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

3.6 Prime the Jet, continued

10. Remove the purge cup and place a glass slide or piece

of substrate under the nozzle.

Press the Trigger button to run the recipe once.

Observe the quality of the drops.

Repeat this several times to ensure adequate priming.

11. Wipe the nozzle tip of any accumulation. The jet is ready

to operate with the appropriate recipe settings for dispensing.

3.7 Check for Fluid Leaks

Before running a program, it is important to check for fluid leaks. Fluid should not drip

through the orifice. If fluid is leaking through the nozzle tip when the jet valve is closed,

check to see if the jet pressure is set to at least 35 psi (0.24 MPa). Increase the

pressure to 60 psi (0.42 MPa) and check to see if

the leak stops.

There are several areas to check for fluid leaks:

Check to see if fluid leaks out of the weep

hole in the heater block shown in

Figure 3-7. If fluid is leaking, the

diaphragm is either missing or damaged

and should be replaced. The heater block

will need to be removed and the leaking

fluid should be cleaned.

Fluid can leak out of the Luer fitting that attaches the syringe to the feed tube.

Sometimes the Luer fitting is a little snug and hard to twist in completely. If fluid is

leaking, give the fitting an extra turn to seat it completely. If this does not solve

the leaking, change the feed tube and/or the syringe and check again.

Fluid can leak at the junction between the feed tube and the nozzle plate inlet

fitting. The feed tube is connected using a standard barb to the inlet fitting. If fluid

is leaking at the barb end of the fitting, replace the feed tube.

Check for leaks between the diaphragm and the nozzle plate. The nozzle plate

must be attached correctly with screws well tightened. Make sure the Jet valve is

closed. If fluid can be seen leaking under the diaphragm, then the Jet has not

been assembled correctly. Disassemble the dispensing components and inspect,

clean, and/or replace the diaphragm as required. If the leak continues, the

diaphragm or nozzle plate is most likely damaged or dirty, and it should be

cleaned or replaced.

If fluid leaks between the diaphragm and the nozzle plate, the jet will not function

correctly. Dispensing should be discontinued, and the components should be cleaned or

replaced as required.

Figure 3-7: Check for Leaks at Weep Hole

Figure 3-6: Trigger Button

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 17 of 22

4. Cleaning the Jet

4.1 Cleaning the Exterior of the Jet

To clean the exterior of the jet, use a soft cotton or cellulose cloth. If the jet exterior is

extremely dirty, a small amount of alcohol can be used.

To avoid personal injury, move the nozzle

close to the paper so there is minimal

misting of the solvent during flushing. Be

sure there is proper ventilation and wear

appropriate eye and skin protection as

instructed by the solvent manufacturer.

NOTICE

To prevent damage to the jet:

Do not use a dripping wet cloth or pour solvents, alcohol, water, or

other liquids directly on the jet.

Do not submerge the jet in the cleaning agent.

4.2 Cleaning the Interior of the Jet

The Advanjet HV-2100 is a high precision jet for dispensing minute amounts of fluid.

Dispensing nozzles can become blocked or clogged by the smallest contaminates,

which will adversely affect dispensing results.

These are symptoms of a contaminated jet:

Unclean or uneven dispensing

Drops become irregular or vary in size

Residual flow or drooling out of the tip when the jet is in the closed position

Interrupted dispensing (places where fluid no longer is dispensed)

Splatter or satellites

The importance of clean jetting is a key design element of the HV-2100, resulting in a jet

that is quick and easy to clean. Following these simple cleaning steps will optimize

jetting quality and maximize productivity.

Page 18 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

4.3 Solvent and Diaphragm Compatibility

Advanjet uses four different diaphragm materials: FKM (fluoroelastomers), silicone,

FFKM (perfluoroelastomers), and EPDM (ethylene propylene diene terpolymer). In

general, if the diaphragm material is incompatible with a solvent, the diaphragm will

exhibit slight swelling around the metal insert. If swelling occurs, the performance of the

jet will be adversely affected.

Use this table as a guide for selecting an appropriate cleaning solvent.

FKM

Silicone

FFKM

EPDM

Chemical

Acetone

✗

✗

✔

✔

Ethanol

✗

✔

✔

✔

Isopropanol

✔

✔

✔

✔

Methyl Ethyl Ketone

✗

✗

✔

✔

Toluene

✔

✗

✔

✗

Xylene

✔

✗

✔

✗

✔= Compatible;✗= DO NOT USE

3A6244A Advanjet HV-2100 Jet Setup and Operation Page 19 of 22

4.4 Flush the Fluid System

1. Turn the fluid air OFF.

Note: It is important to first turn off the air before cleaning the jet. If the feed tube

is dismounted under pressure, the fluid from the syringe will make a mess.

2. Remove the receiver head.

3. Remove the feed tube from the nozzle plate.

4. Remove the syringe from the jet.

5. Install an empty syringe with a feed tube onto the fluid barb of the nozzle plate.

6. Fill the syringe with about 3 cc of mild solvent compatible with your fluid material.

7. Replace the receiver head onto the syringe.

8. Set up a test recipe using the following parameters:

10.0 msec Refill

10.0 msec Dwell

0.3 msec Refill+

250 Drops

9. Turn the fluid air ON.

10. Place a paper towel or aluminum-foil dish

under the nozzle.

11. Run the test recipe, which flushes the jet.

Continue to run the recipe until the liquid coming out of the nozzle is clear and

clean, or all 3 cc of the solvent is flushed. It normally requires about 5 or 6 flushes

of 250 drops.

If there is too much solvent in the syringe, you can open the jet to let out the

remaining solvent.

Note: It is easier to work with an empty syringe – let the remaining solvent

drain completely to manage the solvent in the cleanest way.

To avoid personal injury, move the nozzle

close to the paper so there is minimal

misting of the solvent during flushing. Be

sure there is proper ventilation and wear

appropriate eye and skin protection as

instructed by the solvent manufacturer.

RECEIVER

HEAD

SYRINGE

FEED

TUBE

Figure 4-3: Install an Empty

Syringe and Fill With Solvent

Figure 4-3: Disassemble

and Remove Syringe

Figure 4-3:

Replace Receiver Head

Page 20 of 22 Advanjet HV-2100 Jet Setup and Operation 3A6244A

Table of contents

Other Advanjet Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Emerson

Emerson PENBERTHY Series Installation, operation and maintenance instructions

SMC Networks

SMC Networks CJP Series Operation manual

MachineryHouse

MachineryHouse SW4000 instruction manual

probst

probst TAK Series operating instructions

KTR

KTR KTR-STOP RL Operating & assembly instructions

Bosch

Bosch Rexroth ABZSS operating instructions