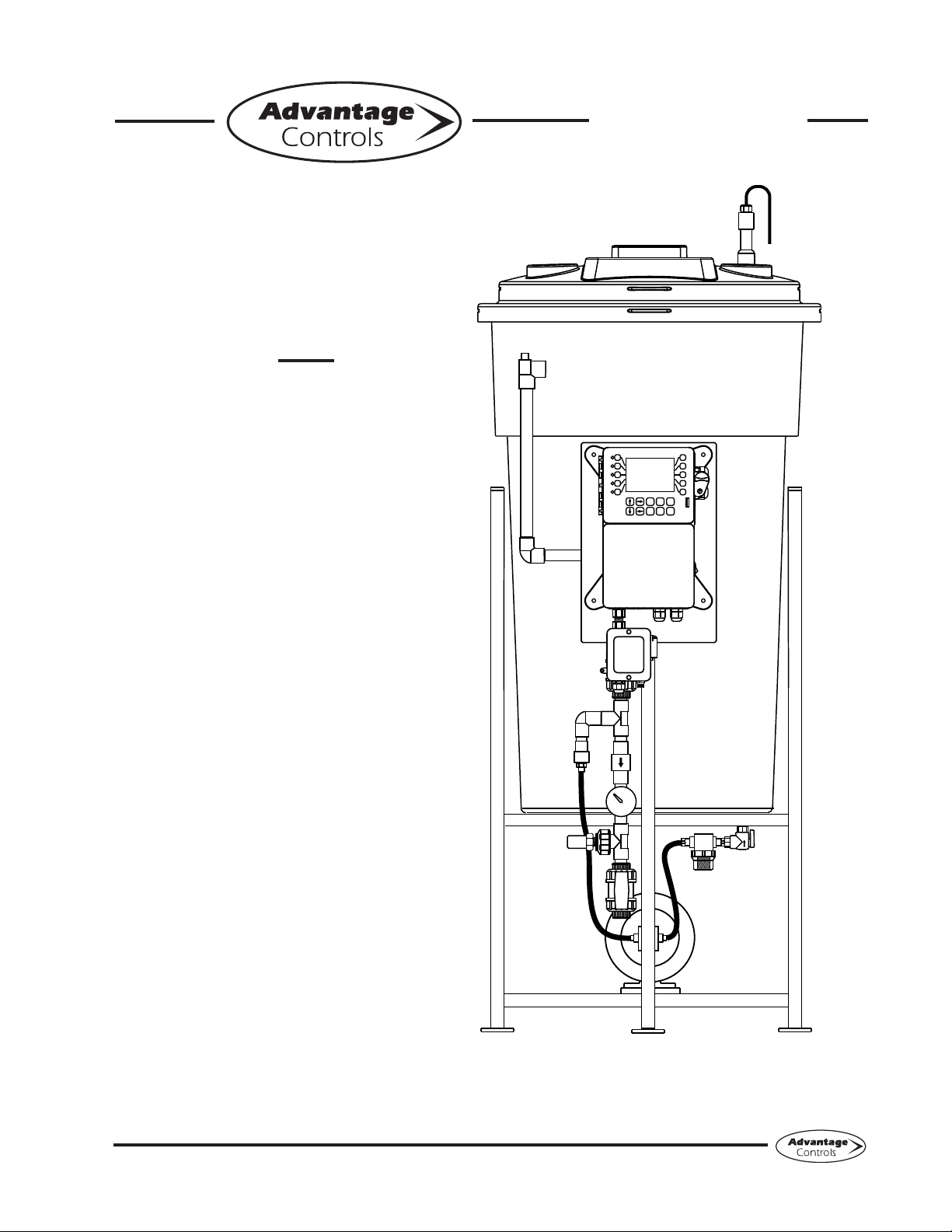

Advantage Controls GF with MegaTron XS Operating instructions

1

Manual

Model GF

Digital Glycol

Feeder with

MegaTron XS

Controller

Installation

Maintenance

Repair

Manual

Advantage Controls

P.O. Box 1472

Muskogee, OK 74402

Phone: 918-686-6211

Fax: 888-686-6212

www.advantagecontrols.com 11/2018

3

4

5

2

1

8

9

0

7

6

SET UP

RUN

CANCEL HELP BACK

ENTER HOME

2

Table of Contents

I. Introduction .................................................................................................2

............................................3

III. Installation...................................................................................................5

Electrical Wiring ...............................................................................5

Mounting Instructions.......................................................................5

Typical Installation and Measurements ............................................6

Start Up & Calibration Procedures...................................................7

IV. Front Panel Description ............................................................................10

V. System Operation Overview ..................................................................... 11

VI. Menu Navigation ....................................................................................... 11

VII. USB Functions ..........................................................................................20

VIII. Troubleshooting and Maintenance............................................................21

IX. Parts List ...................................................................................................23

X. Wiring Diagrams.......................................................................................25

XI. Warranty ...................................................................................................26

Reference Chart % Propylene Glycol.............................................................................27

Reference Chart % Ethylene Glycol...............................................................................27

I. Introduction

The Advantage Controls Glycol Feed Systems are design to regulate pressure in closed loop Hydronic

Heating and Cooling applications.

The Advantage Controls XS Series Glycol Feeders are our advanced design microprocessor based

controller with communication options previously unavailable with earlier models.

by ETL. With standard outputs of: (2) dry contact relays (one for alarms and our for pump on), (1) timer

for agitator control, 20 key data inlay, large multi-line display, audible alarm, motor starter / high amp

Advantage Controls Glycol Feeders are stand alone pre-wired, pre-plumbed systems designed for ease

of installation. Our systems are mounted on a powder coated steel frame with anchor points.

model number against the selection guide for better understanding of your system.

Please read this instruction manual to become familiar with your system.

3

II. ModelNumberingandGeneralSpecications

BUILD A MODEL GF - 1A1A1G- C1

TANK SELECTION

0 = No tank

1 = 55 gal (208L) poly

2 = 100 gal (378L) poly

3 = 30 gal (113L) poly

5 = 5 gal (18L) no stand, 30 gpd pump only

7 = 150 gallon poly (567L)

STAND SELECTION

A = Painted steel stand

B = Painted steel stand w/ mixer bracket

C = Tank top mount (no tank included)

D = Portable stand with built in rollers

E = No stand (for 5 gal tanks)

PUMP SELECTION

*Dual pump sys. require 2 pump selections (i.e., -11)

0 = No pump

5 = 30 gpd at 100 PSI; solenoid driven

PUMP CONFIGURATION

B = Alternating pumps for single loops

(requires 2 pump selections)

C = Pump plumbed for transfer duty into tank

LOOP SELECTION

*Dual loop sys. require 2 loop selections (i.e., -11)

0 = No loop

1 = Sch 80 PVC loop; 100 PSI max; 100°F max

2 = Copper loop; 100 PSI max; 180°F max

3 = Carbon steel loop; 100 PSI max

CONTROL SELECTION

existing single / dual pump system. Mounted to

replacement panel with (1) audible alarm and system

matching high amp / relay box(es)

prewired for a single pump system.

prewired for a dual pump system.

OPTIONS

1 = 240V

3 = Solenoid valve for pressure relief

5 = Position backcheck to use tank for expansion

C1 = Communications card Internet *

C11 = Communications card Modbus *

C12 = Communications card BacNet *

G = PUMP ON - dry contact relay

H = 1/4” PVC pipe instead of pump suction tubing

M = Mixer controls (order mixer separate)

O4= Four 4-20mA outputs *

* Options C1, C11, C12, O4 require control option D, G or H.

3

4

5

2

1

8

9

0

7

6

SETUP

RUN

CANCEL HELP BACK

ENTER HOME

System

Connection

Circulation Pump

Specications

Electrical

• Input 120 VAC, 60 Hz

• Alarm Dry Contact

•

Plumbing

• Standard Schedule 80 PVC

• Optional Copper or Black Iron

Enclosure

Heavy Duty NEMA 4X style, high

impact thermoplastic with padlockable

gasketed Lexan viewing door

Pressure Gauge 0-100 psi (0-6.9 bar)

Dimensions

See measurements on page 6.

Shipping Weight

330 lbs (149.69 kg) approx.

Most units include

poly tank and stand,

low level switch with

audible alarm (100db),

motor starter / high

amp relay, dry contact

alarm, pressure relief

valve and plumbing

assembly with

pressure gauge and

sensor.

4

Base Functions

MegaTronXS units have several base system control functions and unit optional features. Your unit may

be supplied with one or more of the features described in this manual. To determine what features apply to

your unit check the model number label located on the controller enclosure.

Base System Control Functions

F1 - (1) Timer Standard

Whole Unit Optional Features

A- Conduit Connections

C1 - Communications card Internet

C11 - Communications card Modbus

C12 - Communications card BacNet

Model numbers start XS followed by the System Control functions. A dash separates the whole unit options

listed after all base system control functions. Example: XSCPF3E-N4.

Notice: Your unit may not have all features and functions described in this manual. This list represents our

most popular options, additional option codes are available.

Description of Unit

MegaTronXS controllers control a single recirculating water system including closed loop applications and

may have various features depending on the model number.

Standard Timer

The standard timer is designed to automate a mixer action activating a relay output. This timer can be

programmed to be one of the following types.

*1. Pulse Time - Accepts pulses from a make-up water meter (supplied separately). It can accumulate

1-9999 gallons before activating the timer to run.

*2. Feed with Bleed - Activates the relay output simultaneously with the bleed and limits the amount

of time the relay output will be on during the bleed cycle.

*3. Feed after Bleed

for the set percentage of that bleed cycle.

4. Recycle

cycle time.

5. 28 Day - The timer is based on a 28 day cycle with four independent programmable feed cycles

with prebleed and bleed lockout settings.

* Note: These functions are for application other than glycol feeders.

5

III. Installation

Electrical Wiring

The MegaTron XS series digital glycol feeder controller has an internal regulated power supply that will

operate in the range of approximately 90 to 250 VAC at 47 to 63 Hz on the incoming wiring. Output relay(s)

are protected with a replaceable fuse. Each relay’s output voltage will equal incoming line voltage. The

Standard prewired units are supplied with a 8 foot, 16 AWG, 3 wire grounded, 120 VAC USA power cord for

incoming power.

NOTE:Liquidtightttingsandlabeledsignalleadcablesareprovidedforallsignal(lowvoltage)

connections,lowdrumlevelandpressuretransducer.

WARNINGS:

1. The controller should be connected to its own isolated circuit breaker, and for best

results, the ground should be a true earth ground, not shared. Wiring must be done

according to all applicable local codes.

2. Power(linevoltage)mustbedisconnectedwhilemakinganyconnections.Ifpoweris

suppliedtotheunit,linevoltagewillbepresentontherelaycards.

3. Lowvoltagesignalwires(transducer,level,alarm,etc.)shouldneverberuninconduit

withhighvoltagewires.

Mounting Instructions

Select a mounting location that provides the operator easy access to the unit and a clear view of the controller.

The location should be convenient to grounded electrical connections and system plumbing connections.

Mount the glycol feeder stand to a level concrete pad using the ½” mounting holes in the base of the stand.

Concrete pad construction and anchoring bolts must comply with local building codes. The required sample

line plumbing should be connected to the return header of the Hydronic system

WARNING:

Avoid locations that expose the controller to direct sunlight, vapors, vibration,

liquid spills or extreme temperatures; less than 0°F (-17.8°C) or greater than 120°F (50°C).

EMI(electromagnetic interference) from radio transmissions and electric motors can also

causedamageorinterferenceandshouldbeavoided.

!

!

6

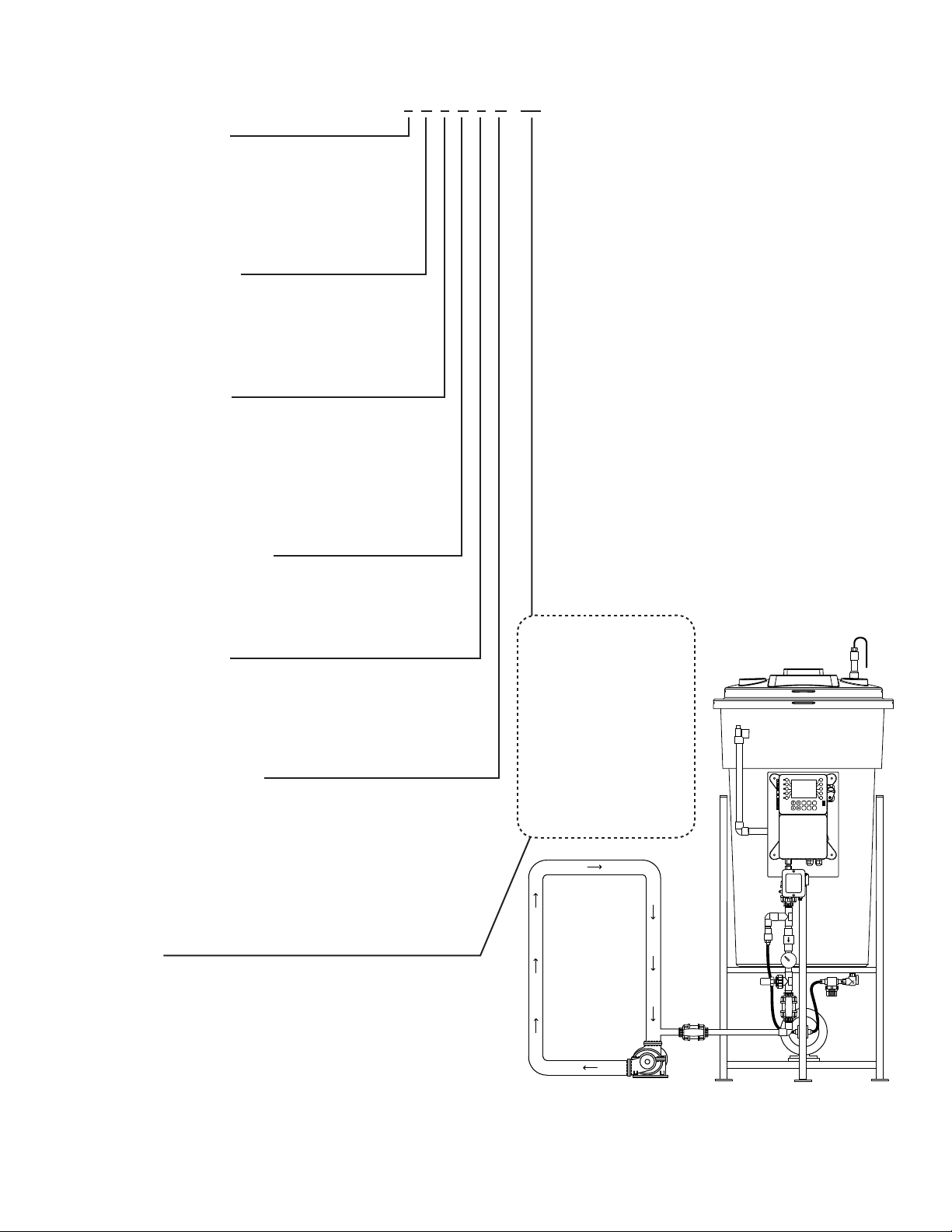

Typical Installation and Measurements

3

4

5

2

1

8

9

0

7

6

SETUP

RUN

CANCEL HELP BACK

ENTER HOME

System

Connection

Circulation Pump

B

A

E

Side View Shown

1/4” bolt hole drilled

3/4” from outside edge

Note: This is for mounting

holes only. Controller will

extend beyond this depth.

GLYCOL STAND FOOT PRINT

C

D

A B C D E

30gal

113.5L

23 ¾”

60.3 cm

51”

129.5 cm

27 ½”

69.8 cm

25 ½”

64.7 cm

30 ½”

77.4 cm

55gal

208.1L

27 ½”

69.8 cm

65”

165.1 cm

27 ½”

69.8 cm

25 ½”

64.7 cm

32”

81.2 cm

100gal

378.5L

31 ¼”

79.3 cm

66”

167.6 cm

37”

93.9 cm

35”

88.9 cm

38”

96.5 cm

7

Glycol Feeder Start-Up Procedure

Complete all installation steps before beginning this procedure. Ensure that all controlled devices (pumps,

solenoid valves, etc.) are operational and connected to the controller.

WARNINGS:

Before applying power to the controller, remove the fuse(s) from the fuse holder(s) located on the

high amp relay extension. There will be two (2) fuses on duel pump system. Reasoning behind

this is, factory settings may not agree with your system and this gives time for you to set your

parameters before applying power to the pump or pumps.

construction debris.

2. Check plumbing as it may have become loose from vibrations during shipping.

3. Fill Tank

4. Open the valve closest to the drain port of the plumbing assembly by turning the handle clockwise.

Water will pass through the sample stream assembly.

5. Ensure that the system pressure does not exceed 100 psi.

gauge agrees with system pressure. This value may vary do to connection to Hydronic systems

placement.

8. Once you are familiar with the controller from either reading the instruction manual or trial and error,

proceed with setting perimeters that are correct for your hydronic system.

extension.

10. Power ON the control to verify proper operation.

PressureReliefCongurationProcedure

1. Pressure relief values are set at 75 psi by default from the factory.

2. To increase the psi, spin the valve clockwise.

3. To decrease the psi, spin the valve counter clockwise.

4. Close drain port valve slowly to raise system pressure to the relief level.

5. Open drain port valve to relieve system pressure and conclude test.

Alarm Buzzer Disable and Enable Procedure

1. Press the 0 key at the home screen to enter into the relay status screen.

2. Press the 2 key twice after entering into the relay status screen to disable the alarm buzzer.

3. Press the 2 key once more to set the relay back to the normally pressure automated state.

4. Press the 2 key once more to force the alarm buzzer relay ON.

!

8

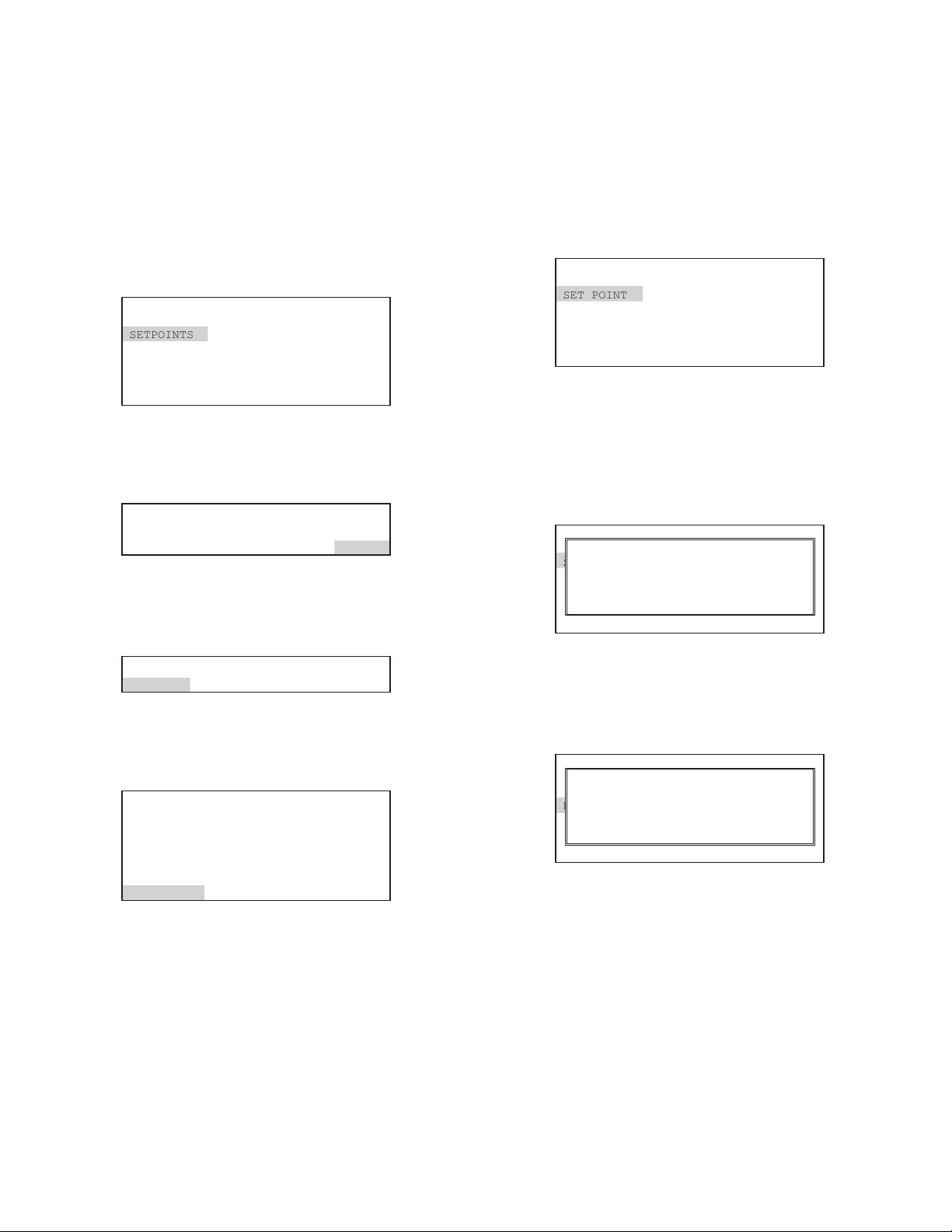

PressureSetpointCongurationProcedure

IftheseareimproperlysetbyenteringanA/Dvalue

for the settings while the input is not seeing the

correct signal a signal generator will be required to

reset the calibration.

Step 1:

Push the HOME button to leave Calibration and go back

to the HOME menu screen. From here push SETPOINTS

(Button 1) to go to the next screen

>HOME SETUP<

SETPOINTS DATE/TIME

CALIBRATION CONFIGURE

TIMERS HISTORY

CUSTOMIZE TOTALIZERS

ALARMS RELAYS

Step 2:

This is the Setpoints Setup Screen. From here push mA

IN (Button 7) to go to the next screen

>SETPOINTS SETUP<

SENSORS

mA IN

Step 3:

This is the mA Inputs Screen. From here push INPUT 1

(Button 1) to go to the next screen

>mA INPUTS<

INPUT 1

Step 4:

This is the mA Input 1 Setpoint Review Screen. From here

push SETPOINTS (Button 5) to go to the next screen

>mA INPUT 1 SETPOINT<

mAIN1

SET POINT: 500%

RISING CONTROL

DIFFERENTIAL: 20

HIGH ALARM AT: 1000(OFF )

LOW ALARM AT: 0(OFF )

LIMIT TIME: 00:01 HH:MM

SETPOINTS

Step5:

This is the mA Input 1 Setpoint Change Screen.

From here you can set SET POINT (Button 1),

DIFFERENTIAL (Button 2), HIGH ALARM

(Button 3), LOW ALARM (Button 4) and LIMIT

TIME (Button 5). Press the desired button to go

to the next screen

>mA INPUT 1 SETPOINT CHANGE<

SET POINT

DIFFERENTIAL

HIGH ALARM

LOW ALARM

LIMIT TIME

Step 6:

Set the value of SET POINT by using the number

keys. Use the left arrow to set the reaction

direction of the set point between RISING or

FALLING.Then press ENTER

to the previous screen

>mA INPUT 1 SETPOINT CHANGE<

SET POINT

DIFFERENTIAL

HIGH ALARM

LOW ALARM

LIMIT TIME

SET POINT (RISES TO 00500 %)

[RISES][__ ] %

USE NUMBER KEYS TO CHANGE, PRESS

ENTER TO ACCEPT OR BACK TO ERASE

Step7:

Set the value of DIFFERENTIAL by using the

number keys. Then press ENTER

go to the previous screen

>mA INPUT 1 SETPOINT CHANGE<

SET POINT

DIFFERENTIAL

HIGH ALARM

LOW ALARM

LIMIT TIME

DIFFERENTIAL 00020 %)

[__ ] %

USE NUMBER KEYS TO CHANGE, PRESS

ENTER TO ACCEPT OR BACK TO ERASE

9

Step 8:

Set the HIGH ALARM settings for VALUE (the reading

that will give a High Alarm) and NOTIFICATION. Press

ENTER

>mA INPUT 1 HIGH ALARM<

VALUE

ALARM NOTIFY

High Alarm 00020 %)

[__ ] %

USE NUMBER KEYS TO CHANGE, PRESS

ENTER TO ACCEPT OR BACK TO ERASE

Step 9:

Set the value of the ALARM NOTIFY by using the

arrow keys. Then press ENTER

previous screen.

Note: Display - will appear on controller display only,

Remote - appears through email if controller is online, or

both Dis/Remote

>mA INPUT 1 HIGH ALARM<

VALUE

ALARM NOTIFY

ALARM NOTIFY (OFF )

--> OFF

USE UP/DOWN KEYS TO CHANGE

PRESS ENTER TO ACCEPT

Step10:

Repeat Steps 19 and 20 for the LOW ALARM.

Press BACK to return the mA Input 1 Set Points

>mA INPUT 1 SETPOINT CHANGE<

SET POINT

DIFFERENTIAL

HIGH ALARM

LOW ALARM

LIMIT TIME

Step 11:

Set the value of LIMIT TIME by using the number

keys. Then press ENTER

previous screen. The Limit Time and the Alarm

HOME

HOME menu

>mA INPUT 1 SETPOINT CHANGE<

SET POINT

DIFFERENTIAL

HIGH ALARM

LOW ALARM

LIMIT TIME

Note: If the Limit Time is met a relay activated by

10

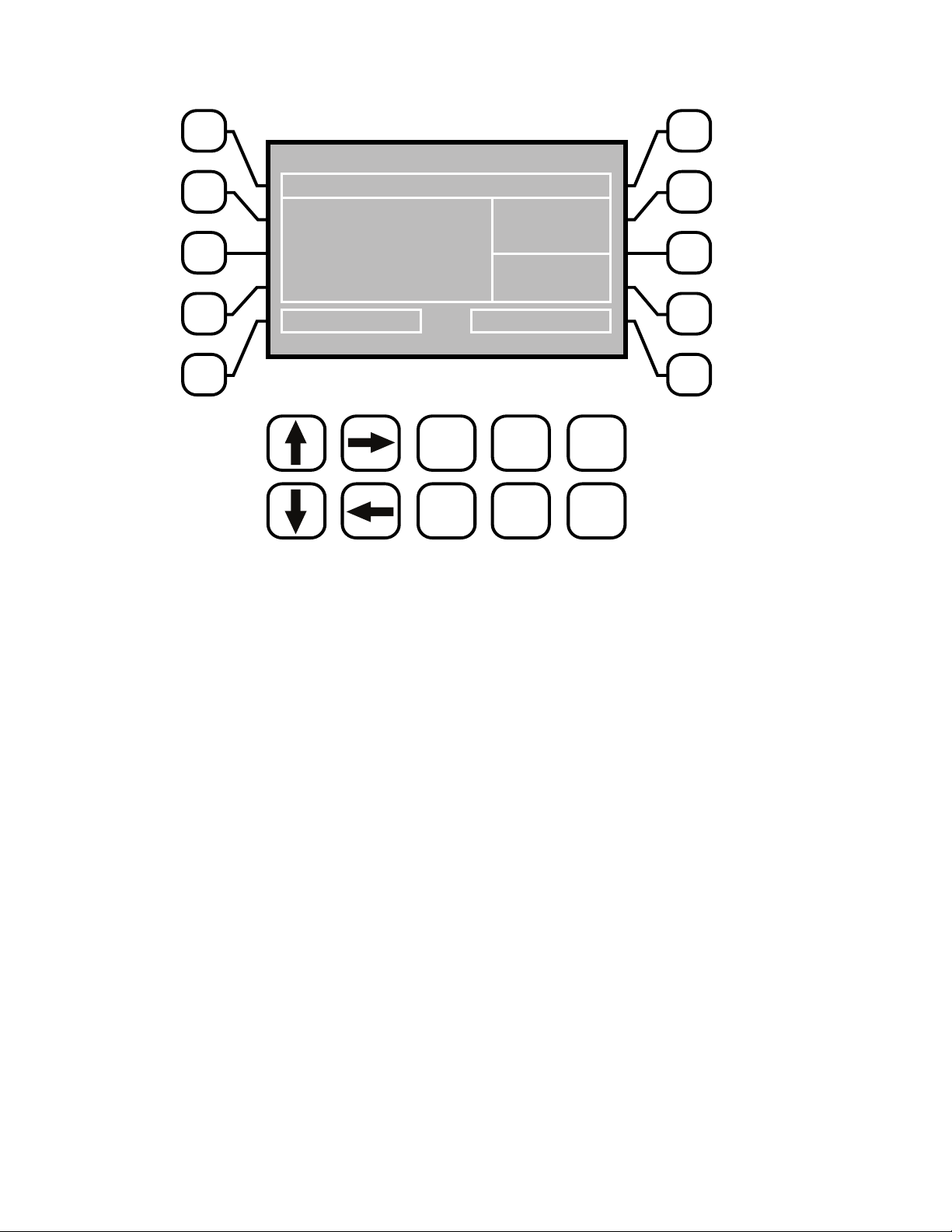

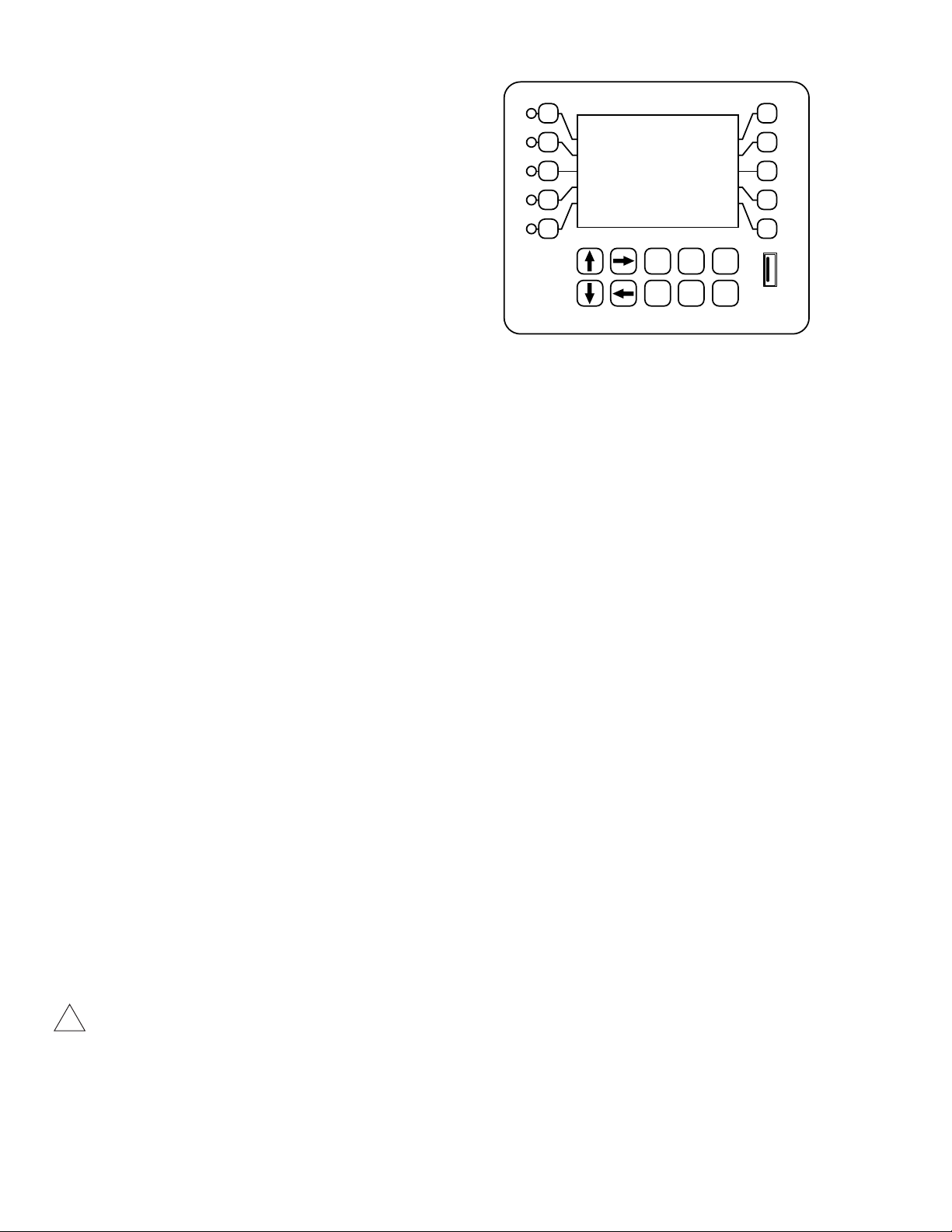

IV. Front Panel Description

3

4

5

2

1

8

9

0

7

6

SET UP

RUN

CANCEL HELP BACK

ENTER HOME

ACI MEGATRON

SYS1: TOWER CARD 1

COND 1,400 uS/cm

pH 7.2

ORP 375 mV

SYSTEM OK <HOT KEY>

STATUS

SYS OK

TEMP: 72.1F

FLOW: ON

Thursday, August 29, 2013 02:24:10 PM (Wk1)

NUMBER Keys- Used to enter new values in the SET UP mode and to access desired sub menus.

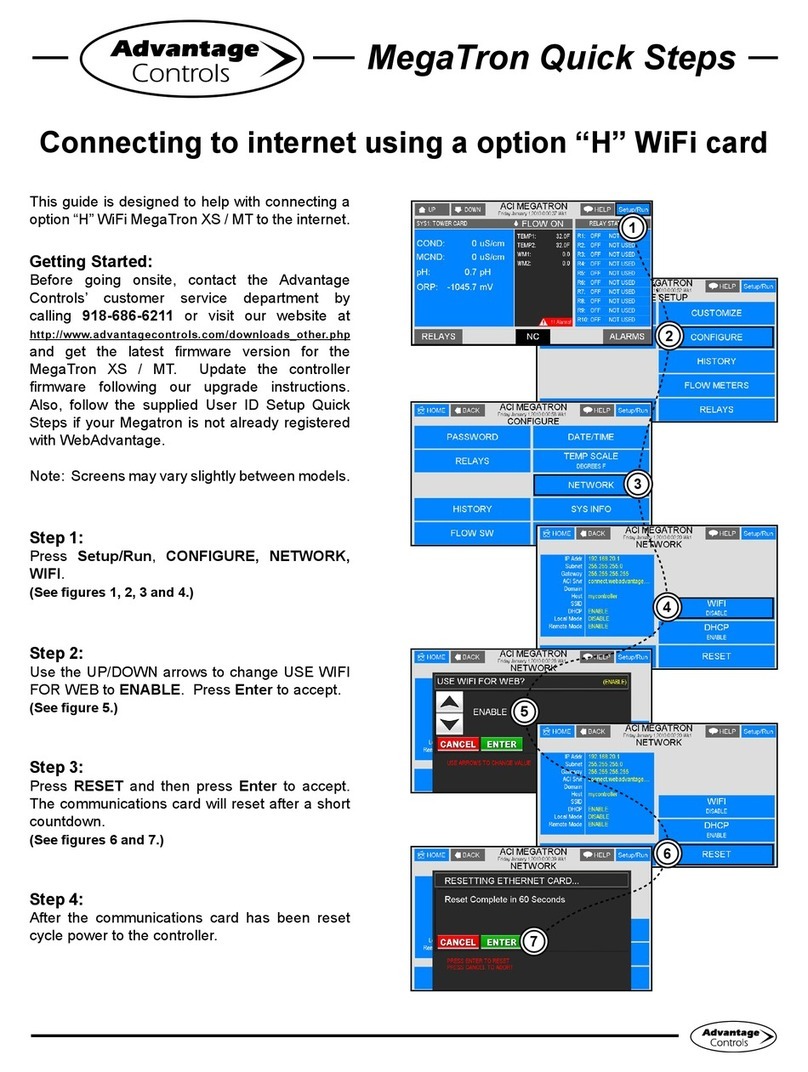

SET UP/RUN - System initializes into RUN mode. Press this key to put the controller in SET UP

Mode and see HOME menu page.

ENTER - Used to log a changed value into program.

HOME - Used to go back to the HOME menu page.

CANCEL - Used to cancel a pop-up screen if no change is desired.

HELP - Used to access help screens.

BACK - Used to go back to last menu screen viewed or clear values keyed in that are not

wanted.

The bottom right box in the RUN screen mode is a hot key that will take you directly to a particular menu

screen. The default is the RELAY status menu but this can be changed by navigating to the desired screen

and pressing the HELP button. Follow the on-screen instructions to set the new hot key location.

11

V.SystemOperationOverview

Operation

MegaTronXS controllers have two modes of operation, RUN and SET-UP.

RUN - This mode is for normal operation. In the RUN mode the display will show each system’s parameters.

or changed in the RUN mode. Readings are updated every 6 seconds on the screen while in the RUN mode.

SET-UP - This mode is used to make adjustments to settings and readings on the controller. To access the

SET UP mode from the RUN screen, press the SETUP/RUN key.

VI.MenuNavigation

To access the menus press the Set Up / Run key on the front panel. This takes you to the Home menu.

MegaTronXS controller’s menus are easily navigated by pressing the associated number key next to a menu

box on the screen. Once you have stepped through the sub menus to reach a point at which a value or

selection is made a Pop-up window will appear prompting you to enter a desired value or selection.

NOTE: When entering new numeric values, enter all available digits (characters).

1. Home Menu

From the HOME menu select the desired menu.

The menu name explains what parameters can be

programmed in the menu.

SET POINTS - Setting control set points for pressure.

CALIBRATION - Calibrating pressure.

TIMERS - Menu for selecting type and settings for all present feed timers.

CUSTOMIZE

ALARMS - View current alarms.

DAY/TIME - Menu for setting date and time.

CONFIGURE

switch, contrast, temperature scale.

HISTORY - Allows for view history on board in a graph form.

WATER METER

RELAYS - Menu for resetting accumulated “ON” times and manual relay activation.

>HOME SETUP<

SETPOINTS DATE/TIME

CALIBRATION CONFIGURE

TIMERS HISTORY

CUSTOMIZE WATER METER

ALARMS RELAYS

12

2. Set Points

SET POINTS - For setting the relay set points for the

available analog probe readings such as 4-20 mA

inputs for pressure.

NOTE: In the Setpoints pop-up screen the direction (Rising or Falling) of the setpoint can also be set. If

setpoint. The pump output relay will remain activated until the PSI reading falls below the setpoint by the

the PSI reading falls below the setpoint. The pump output relay will remain activated until the PSI reading

2.5 AuxInputs

Auxiliary inputs are the digital inputs for optional Flow Switch and other digital inputs such as low drum level

both or none.

Note: Digital inputs can have the direction selected

between OPEN or CLOSED as the alarm polarity. If

set for CLOSED the input will be in alarm when it sees

a closed contact.

2.6 4-20mAOut

Units with a 4-20mA output option will have a menu for setting up the 4-20mA output. The 4mA and 20mA

PSI.

SIGNAL SOURCE - Select which probe reading the

mA will use as its reading source.

4 mA VALUE - What the 4mA signal equals

20mAVALUE - What the 20mA signal equals on the

assigned signal sources scale.

2.7 4-20mAInput

SET POINT - What reading turns the relay on

DIFFERENTIAL - Amount reading changes by before

HIGH ALARM - What reading generates a High alarm

LOW ALARM - What reading generates a Low alarm

>SYSTEM 1 SET POINTS<

mA OUT

mA IN

AUX INPUTS

>SYSTEM 1 DIGITAL INPUTS ALARM<

ALARM NOTIFICATION DIGITAL 1

FLOW SW = DISPLAY DIGITAL 2

DIGITAL 1 = DISPLAY DIGITAL 3

DIGITAL 4

FLOW ALARM DIGITAL 5

>OUT 1 SETUP<

SIGNAL SOURCE

4mA VALUE

20mA VALUE

>mA INPUT 1 SETPOINT<

SET POINT

DIFFERENTIAL

HIGH ALARM

LOW ALARM

13

3. Calibration

Calibration is for adjusting the displayed value of a probes reading to match your tester or known solution.

All MegaTronXS controllers are factory calibrated. All units are shipped with the date preset, and the clock

the instructions listed below.

3.3 4-20mAOutputCalibration

4-20mA outputs can be calibrated to insure that the

output generated by the controller and received by the

external device match. With a volt meter connected

across the out and return wires (see page 24) of the

4-20mA output channel to be calibrated go into the

output’s Low or High calibration.

The number displayed in the Calibration dialog box

can range from 0-4095 with 800 equal to 0 mA output

and 4030 equal to 20 mA. This number range of

0-4095 is the raw digital to analog (D/A) values and is

strictly used for a reference. The D / A numbers you

get will vary based on your installation conditions.

While in the High or Low calibration pop-up screen use

the up and down arrows to change the output value

being read with the volt meter. Adjust the High value

for the 20 mA reading and the Low value for the 4 mA

value.

3.4 4-20mAInputCalibration

4-20mA inputs can be calibrated to insure that the input seen by the controller from the external device match.

It also allows for setting the 4-20mA input into a number range that relates to the value being read.

Select the Input to be calibrated

The 20mA and 4mA values are where the controller’s

raw analog to digital value is adjusted to match a 20mA

(full scale) and 4mA (bottom of scale) signal from the

external device inputting the 4-20mA input. The external

device must be connected to the controller and showing

either full scale or bottom of scale when calibrating

each. The number shown along with either the 20mA

or 4mA while calibrating is the raw A/D value and is only

>CURRENT LOOP CALIBRATION<

OUTPUT 1

OUTPUT 2

>mA OUTPUT 1 CALIBRATION<

HIGH 4030

LOW 800

>mA OUTPUT 1 CALIBRATION<

OUTPUT 1 CAL HIGH

4000

Use Up/Down arrows to change

Use Enter to save value

>CURRENT LOOP CALIBRATION<

INPUT 1

INPUT 2

>mA INPUT 1 CALIBRATION<

20mA 5500

4mA 1100

MAX 200

LOW 0

OFFSET FACTORY DEF.

14

a reference. A 20mA input should be around 5500 and 4mA around 1100. If the A/D numbers are not in this

range check input device.

The MAX and LOW calibration inputs are for telling the controller what to display for a 20mA input and a 4mA

input. For example if the input is a drum level sensor monitoring a 55 gallon drum the value for MAX should

be 55 and LOW should be 0. The controller then displays a number automatically ranging between 55 and

0 based on the input value. The units of measure (gallons for example) is set in the Customize menu from

the Home page.

OFFSET - Changes the current displayed value of the 4-20mA input reading to allow for a manual 1pt

calibration of the displayed value.

FACTORY DEFAULT - If the 20mA or 4mA calibration has been incorrectly set (not at 4 or 20) this will reset

the settings back to a factory value for 4 and 20.

4. Timer

A unit may have up to (1) timer standard for each system on a controller. All timers are associated with their

system, so for a % of post bleed timer looks at the bleed of that system.

TIMER - Select the type (28-day, pulse, limit, percent or

percent of post blowdown) as well as the run times of

each timer available per system.

4.1 Timer Type Selection

A pop-up screen lets you scroll through the various timer types available.

* Pulse - A water meter activated timer

* Limit - Feed with bleed with a maximum run time or

limit for one bleed cycle.

Recycle - A continuous recycle timer with ON and OFF

settings.

* Percent Post Bleed - For feed after bleed for a

settable percentage of the bleed time with a maximum

run time.

28-Day - A biocide or event timer.

* Main timer types used

4.2 Timer Set Up

Each timer type selected will have its own unique Set

the type of timer selected. The page displayed before

entering the Set Up menu of a timer provides an overall

review of the timers current settings.

>SYSTEM 1 TIMER<

TIMER 1

>SYSTEM 1 TIMER 1 SET UP<

>SET TIMER TYPE (PULSE)<

-> PULSE

USE UP/DOWN KEYS TO CHANGE

PRESS ENTER TO ACCEPT

SET UP TIMER TYPE

>SYSTEM 1 TIMER 1 SET UP<

TIMER TYPE: PULSE

GALLONS: 10

RUN TIME (MM:SS): 01:00

INPUT: WATER METER 1

SET UP TIMER TYPE

15

4.3 Recycle Timer

ON CYCLE

timer is to be on.

OFF CYCLE - The amount of time that the cycle is

going to be on.

ON/OFF TIMER - This is the displayed count down of

time for the cycle the timer is in.

4.7 28-DayTimer

Each 28-day timer has Program 1-4 for programming the various feed times. While the programming steps

for four programs are the same each can have it’s own independent settings.

WEEKS - The week(s) that the timer is to feed.

DAYS - The day(s) that the timer is to feed.

START - The time of day for the timer to start.

RUN - How long the timer is to run.

FEED LOCK - Which other system timer to lockout

during this timer’s run time.

FLOW LOCK

ignore it for this timer.

5. Customize

The user can also setup the Notepad for each system and 4-20mA Input’s name and unit of measurement.

RUN SCREEN - Allows the user to select what will be

shown on the screen while the controller is in the RUN

mode. Like displaying temperature readings, water

meter totals for a particular system or the conductivity

units of measure.

NOTE: When entering values for custom names use the numerical keys for numbers and the up / down

arrows to scroll through all the characters of a key board. Press the right arrow to advance the curser after

setting a desired value. Press the Help button to place the last entered character into the new cursor space

to speed up the process. The Help button will also jump advance through the characters.

5.1 Notepad

with ten notepad items. The NOTEPAD is ideal for setting up and storing into the controller’s history the items

typically tested for reporting a service call. The Notepad items come with no names but when an individual

note is selected a menu for setting it appears.

>SYSTEM 1 TIMER 1 CHANGE<

ON CYCLE (HH:MM)

OFF CYCLE (HH:MM)

OFF TIMER (HH:MM:SS): 0:10:40

>SYSTEM 1 TIMER 1 CHANGE<

WEEKS

DAYS FEED LOCK

START TIME

RUN TIME FLOW LOCK

>CUSTOMIZE<

UNIT NAMES

RELAY NAMES NOTEPAD

SYSTEM 1 NAME pH INDEX

mA IN

RUN SCREEN

16

NAME -

your own.

NUMBER - Set the number range.

UNITS - Set the units of measurement.

ALARMS - Set Hi/Low alarm points and how frequently

a new value is expected to be manually enter via the

History menu.

5.2 mAInputs

NAME - Name the input.

UNITS - Set the units of measurement.

NUMBER - Set the number range.

5.4 RunScreen

This lets you customize various aspects of the RUN screen.

MAIN SCREEN - Customize what is displayed on the

RUN screen.

SCREENS SHOWN - Pick if the mA input & Aux Flow

screens are scrolled.

CYCLE TIME - The amount of time between screen

scrolls.

COND UNITS - Select the units of measure to be

displayed with the conductivity reading.

6. Alarms

ALARMS - Shows any current alarms.

7. DateandTimeSetUp

DATE AND TIME - For setting the date, time, day and

week on the controller.

>NOTEPAD SYS 1 NOTE 1<

NAME

NUMBER

UNITS

ALARMS

>mA INPUT 1 CUSTOMIZE<

NAME

UNITS

NUMBER

>RUN SCREEN<

MAIN SCREEN

SCREENS SHOWN

CYCLE TIME

COND UNITS

>ALARMS<

SYS 1 ALARMS

>SET DATE AND TIMES<

SET DATE

SET TIME

SET DAY

SET WEEK

Friday May 14, 2005 03:04:56

17

8. Congure

inputs, history time stamps, factory set-up and system information.

CONTRAST - This screen allows for adjusting the

display contrast.

FLOW SW

FACTORY - A factory only menu

TEMP SCALE - Set Celsius or Fahrenheit

HISTORY - Sets the history time stamp interval.

SYS INFO

8.1 Password

ADMIN PASSWORD - The administrator password

gives access to all menus except factory set up.

USER PASSWORD - The user password allows the

user to access HOME menus that are made available

in USER SET UP.

8.2 Relays

CONFIGURE RELAYS - This menu lets you choose a

Main Action or function (timer 1, conductivity, alarms

etc...) to activates a relay.

A pop-up screen appears with a list of all available

activation functions to arrow through.

Additional relay logic is available with up to 3 additional Activators and up to 4 Disablers allowing multiple

functions to activate the same relay and multiple functions to prevent the relay from coming on. There is

also a Daily Max amount of time that a relay can be on. If a relay is on for the max amount it does not let

the relay come on anymore that day. (A 24 hour clock is used for the day with midnight being the start of

the day). The Delay setting is the amount of time a control function must come on before the relay will

point or alarm.

8.3 History

This menu is used to set the history “time stamp” interval, the water meter daily history starting hour and the

alarm delay period.

INTERVAL - The amount of time between each history

time stamp for probe readings.

W/M HOUR - The time of day that the daily water

meter history cycle is to start.

ALARM DELAY - The amount of time an alarm has to

be on before it is recognized as an alarm.

>CONFIGURE<

PASSWORD CONTRAST

RELAYS TEMP SCALE

NETWORK

HISTORY SYS INFO

FLOW SW FACTORY

>CONFIGURE PASSWORDS<

ADMIN PASSWORD

USER PASSWORD

USER SET UP

>RELAY 1 SETUP<

MAIN ACTION DISABLE 1

ACTIVATOR 2 DISABLE 2

ACTIVATOR 3 DISABLE 3

ACTIVATOR 4 DISABLE 4

DELAY DAILY MAX

>CONFIGURE HISTORY<

INTERVAL

W/M HOUR

ALARM DELAY

18

8.4 Flow Switch

8.5 Contrast

This menu is used to adjust the contrast of the display.

8.6 Temperature Scale

This menu is used to select the type of temperature scale to display.

8.7 Network (if applicable)

The Network menu is used when a controller is being remotely communicated with either a local network

connection or over the internet on the Web Advantage server.

NETWORK - This menu is used for setting up the

remote WebAdvantage communications and is

covered in a separate manual.

8.8 System Information

serial number.

9. History

The onboard history allows for viewing the history of the probe readings, relay activations, key-pad activity,

calibrations, water meter hourly and daily logs and alarms for each system present. It is also where Notepad

data is entered and reviewed. An initial overview page is displayed showing your current sample interval, the

calculated number of days the unit can keep probe history for before losing the oldest. The number of sensor

samples and relay/alarm events and Notepad entries currently stored is also displayed.

NOTE: The history can be reset by going to the

interval. After the new sample interval has been set

the onboard history is reset.

>CONFIGURE NETWORK<

IP ADDRESS HTTP REMOTE

IP MASK FTP

GATEWAY RESET

SERVER

HTTP LOCAL

>HOME REVIEW<

SYSTEM 1 Sample Time: 5 MIN

(Length 164.62 days)

Sensor Samples

882

Relay/Alarm Events

323

Notepad Entries

19

9.1 Viewing History

RELAY LOGS - Relay activations displayed in a log

form. Arrow up to advance through the log.

ALARM LOG - Alarm activations in log form.

SENSOR HISTORY - For selecting the parameters

and viewing of a given probe reading’s history in log or

graph form.

EVENT LOG - Displays various activities.

9.2 Notepad Entries

The Notepad section under History is where the user

goes to enter new values for the customized notepad

items. Each individual notepad item’s manually

entered entries are stored in the units history and

can be reviewed in log or graph form after 4 or more

values have been entered.

11. Relays

STATUS - Allows for viewing accumulated relay ON

times, temporary forcing relays ON or OFF or seeing

which relay is on.

RESET - Allows the accumulated run time of a

particular relay to be reset to zero.

FORCE - Allows a relay to be manually forced ON

for a single event from 0-99 minutes. When the event

is over the relay goes back to it’s normal automatic

control.

In the STATUS view the accumulated ON time is

shown along with the main activator, custom name and

current status:

ON = Relay on by relay activators

ON-A = Relay activated by activator other than main

action

H-ON = Relay manually forced on

>HISTORY<

RELAY LOGS WATER METER

ALARM LOGS

SENSOR HISTORY

EVENT LOG

NOTEPAD

>NOTEPAD: SYS 1 NOTE 1<

ENTER VALUE Total Hardness

LOG 8 Entries

GRAPH

517.2 Hrs to Alarm

>RELAYS<

STATUS

RESET

FORCE

>RELAY STATUS<

R01: ON 006:30:30

SYS1 COND BLEED

R02: OFF 008:56:35

SYS1 pH

R03: OFF-T 011:00:10

SYS1 TIMER1 INH

R04: OFF 007:00:00

SYS1 TIMER2 BIO1

R05: OFF 008:10:30

SYS1 TIMER3 BIO2

20

VII. USB Functions

The XS is capable of transferring information

using a FAT formatted USB drive. The XS has three

main functions that it can perform using the USB.

(1) Upgrade XS Firmware from USB Drive

(2) Save XS Log Data to USB Drive

(3) Clone User Settings between XS units.

Upgrade XS Firmware

USB DRIVE DETECTED pop-up window will appear. Use the up and down arrows to choose the “Update

Firmware” selection. Press ENTER. It may take a few minutes for the update process to complete. Do not

will automatically reboot. Once the system reboots, the USB DRIVE DETECTED screen will re-appear.

Remove the USB Drive and this window will close.

SaveXSLogDatatoUSB

History there is a selection called Save Format. The WebAdvantage format is the default for then uploading

history to WebAdvantage for cloud storage and graphing. Change to Comma Separated if using with Excel.

To transfer the contents of the XS history logs to the USB drive, plug a USB drive in to the XS USB port. The

USB DRIVE DETECTED pop-up window will appear. Use the up and down arrows to choose the “History-

>USB” selection. Press ENTER. It may take a few minutes for the process to complete. Status will be displayed

on the screen to show the percent completed of each log record type. Once the log is completely stored, the

Cloning an XS

The XS has the ability to copy the User Settings from one XS to another. This process is referred to as

cloning. To clone your XS, insert the USB drive into the XS with settings you want to save for cloning. Once

“CONFIG.BIN”. The pop-up window will close when the copy is completed.

Take the USB drive and plug it in to the XS that you would like to copy the User Settings to. When the

selection. Press ENTER. The User Data will be loaded in to the XS from the USB drive. Once the pop-up

window closes, the cloning is completed.

Warning: 1.Notallcustomizednamesaresaved.

2.USBdrivesmustbeFATformattedtoworkcorrectly.

!

USB

Port

3

4

5

2

1

8

9

0

7

6

SET UP

RUN

CANCEL HELP BACK

ENTER HOME

Table of contents

Other Advantage Controls Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens FM 450-1 Equipment manual

ATI Technologies

ATI Technologies QC-210 product manual

Eaton

Eaton DILM32-X L Series Instruction leaflet

TTM

TTM MAG 250 Installation, Operating and Maintenance Instruction

Endress+Hauser

Endress+Hauser Liquiport 2000 operating manual

ABB

ABB HT578689 Operation manual