5

SERIES J

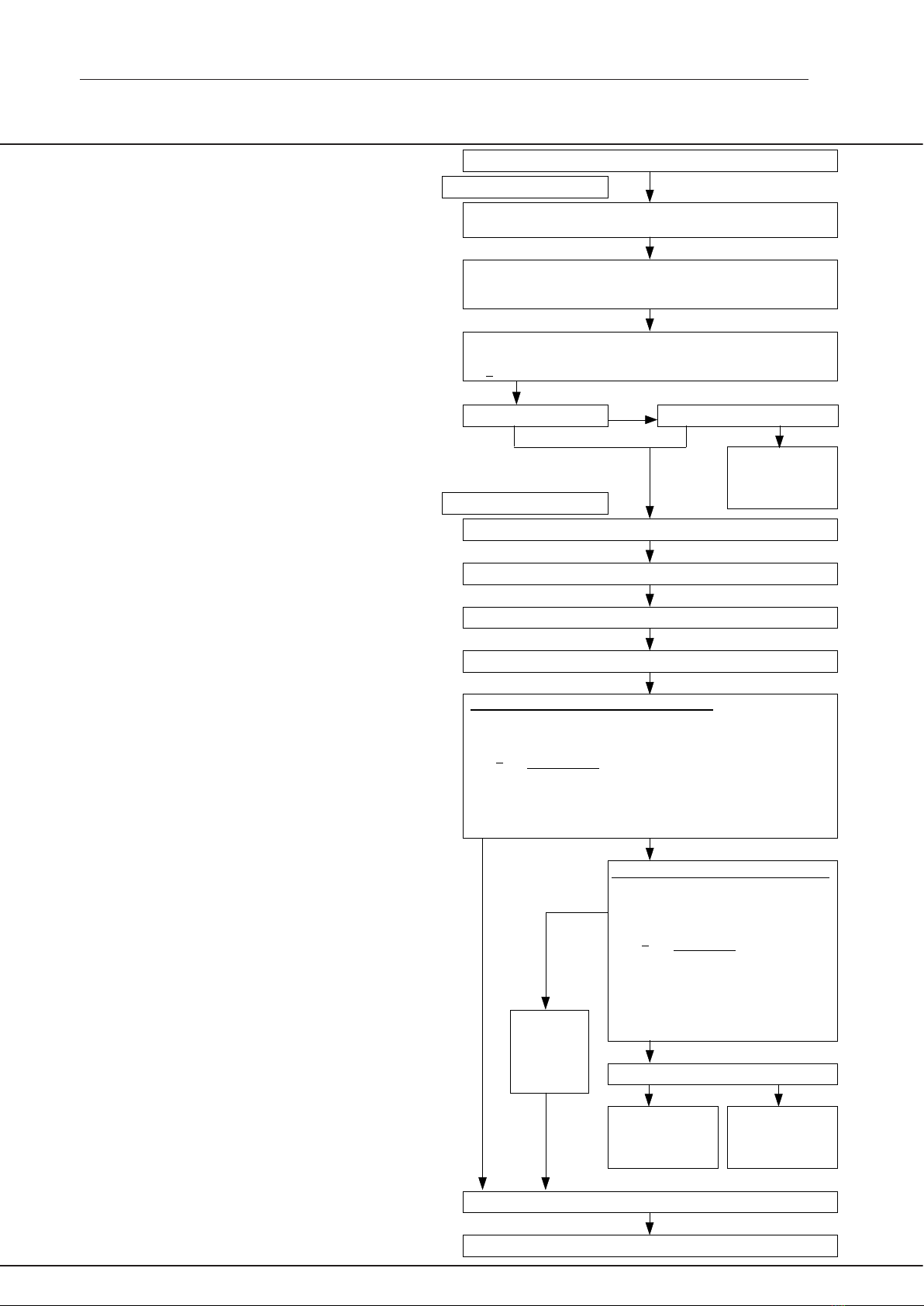

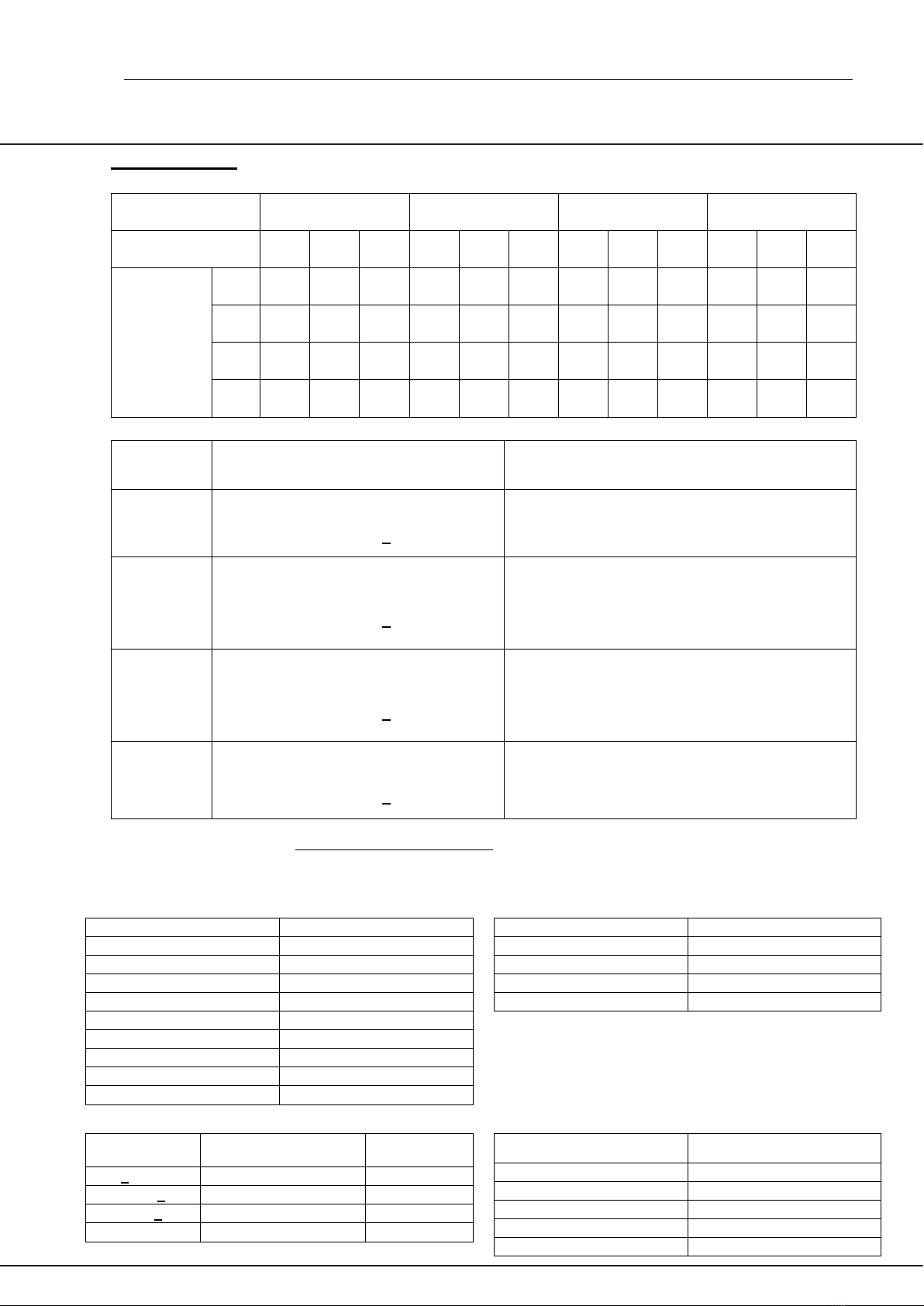

Definition of service factor

The torque ratings apply to service factor fb = 1,0.

The service factor fb = 1,0 gives continual operation 4 to

8 hours a day at a uniform load without shocks and with

10 to 200 starts an hour. The moment of inertia of the dri-

ven machines is less than 20 % of the electric motor iner-

tia and occasional peak torque may not exceed 1,8

times the torque rating. For other running conditions com-

pensate with service factors according to tables.

Definitions

P

e

= Demand of power from driven machine (kW)

T

e

= Demand of torque from driven machine (Nm)

n

e

= Speed on driven machine (min

-1

)

T

emax

= Max peak torque from driven machine (Nm)

T2 = Max allowed torque at service factor fb =1,0

Thermal rating

Thermal rating is the power in kW (without service factor)

that the gear unit can transmit at continuous operation in

1 hour or more without getting overheated.

Control of thermal rating is essential because if the service

generates more heat than it can emit, severe damage may

occur.

Thermal rating does not need to be controlled if the duty time

is less than 1 hour.

When the duty time is longer than 1 hour the gear unit and

cooling method must be selected so that the drive

transmission has enough thermal rating.

In the tables the thermal rating Pt is given in the following

conditions:

- 25 °C ambient temperature

- 0 to 750 m altitude above sea level

- Ambient air velocity between 1,4 and 3,7 m/s

(sheltered outdoor space)

- Continuous operation

For sizes J100 to J190 standardized solutions for cooling

of the gears are available. An electric fan can be mounted

on the gear. The gear may also be provided with a

water-based oil cooler (contact our Application Engineers for

selection of correct size).

1) At V-belt drive when the motor is placed beside the gear,

check the operation according to the diagram.

Determine the demand of power (P

e

kW) or torque (T

e

Nm) and

speed (n

e

min

-1

) to the driven machine by calculation or measuring

Based on type of load / driven machine, operating hours a day

and number of starts an hour select service factor (fb) according

to table 1 and table 2

Select Series J gear from power rating tables on pages 22 - 52.

Select the mechanical rating:

T2 > fb x T

e

Nm

Shock load ?

Select operation time factor fu according to table 6

Control of thermal rating without extra cooling

Check that the thermal rating of the selected gear Pt is bigger than

required thermal rating:

Pt > P

e

ft x fa x fv x fu

Thermal rating Pt for mineral and synthetic oil are in the tables on

pages 8 - 13. The values are valid for horizontal applications. For

vertical applications 0,8 x Pt is used.

Control of thermal rating with electric fan

Check that the thermal rating of the

selected gear Pt is bigger than required

thermal rating:

Pt > P

e

ft x fa x fu

Thermal rating Pt for mineral and synthetic

oil with fan cooling are in tables on pages

8 -13. The values are valid for horizontal

applications. For vertical application

0,8 x Pt is used.

Can a water based oil cooler be used ?

Order gear with accessories according to 20-digit figure code page 5.

Order a water

based

oil cooler from us

Use a larger gear

size or contact our

Application

Engineers

Order an

electric fan

from us

No, cooling with fan is not enough

Mechanical Rating

Yes

Yes

NoNo

Yes

Start

No, extra cooling is needed

1)

SELECTION PROCEDURE

Select accessories (V-belt drive, motor mount, KIBO, backstop)

No

Yes

Yes

Select ambient air velocity factor fv according to table 5

Select altitude factor fa according to table 4

Select ambient temperature factor ft according to table 3

Thermal Rating

Use a larger gear

size or contact our

Application

Engineers

T

emax

< 1,8 x T2

0203