VISLINK

Newswift 90-180 Motorised Antenna

4.29F12: POLARISATION SENSOR FAILURE 23

4.30F16: DCU FPGA PROGRAMMING FAILURE 23

4.31F17: MANUAL BRAKE OVERRIDE ON 23

4.32F18: AZIMUTH STOWING FAILURE 24

4.33F19: ELEVATION STOWING FAILURE 24

4.34F20: POLARISATION STOWING FAILURE 24

4.35F23: POWER UP STATE SUSPECT 24

4.36F25: STOW SENSOR POWER SUPPLY ERROR 24

4.37F26: MRD POWER SUPPLY ERROR 24

4.38F27: INCLINOMETER POWER SUPPLY ERROR 24

4.39F28: FPGA WATCHDOG TRIGGERED 24

4.40F31: HAND HELD CONTROLLER ACTIVE 24

4.41F33: FIN 1 OVER TEMPERATURE 25

4.42F34: FIN 2 OVER TEMPERATURE 25

4.43F35: FIN 3 OVER TEMPERATURE 25

4.44F36: FIN 4 OVER TEMPERATURE 25

4.45F37: FIN 5 OVER TEMPERATURE 25

4.46F38: WGS POWER SUPPLY FAILURE 25

4.47F39: BRAKE POWER SUPPLY FAILURE 25

4.48F40: FAN POWER SUPPLY FAILURE 25

4.49F44: AZIMUTH BRAKE DISCONNECTED 25

4.50F45: ELEVATION BRAKE DISCONNECTED 25

4.51F51:EP2PPROM CHECKSUM ERROR 25

4.52F52: SOFTLIMIT DATA ERROR 25

4.53F53: WOODED AREA DATA ERROR 26

4.54F54: CALIBRATION AREA DATA ERROR 26

4.55F55: FPGA COMPATIBILITY ERROR 26

4.56F56: EXTERNAL FLASH ERASING/WRITING ERROR 26

4.57REMOTE CONTROL 26

4.58SERIAL INTERFACE: SOFTWARE PROTO-COL 26

4.59PACKET PROTOCOL 27

4.60COMMANDS, QUERIES AND RESPONSES 28

4.61DCU COMMAND SET 28

4.61.1CONTROL REMOTE COMMANDS 30

4.61.2COMPASS INTERFACE COMMANDS 34

4.61.3UPDATE STATUS COMMANDS 37

4.61.4ANTENNA DATA 42

5.NEWSWIFT MAINTENANCE 45

5.1DISH 45

5.2AZIMUTH INTERNAL SPUR GEAR 45

5.3POLARISATION DRIVE 45

5.4REAR FEEDHORN PLASTIC BUSH 45

5.5FEEDHORN WINDOW 45

5.6FLEXIBLE WAVEGUIDE 45

5.7ALL SCREWS/BOLTS 46

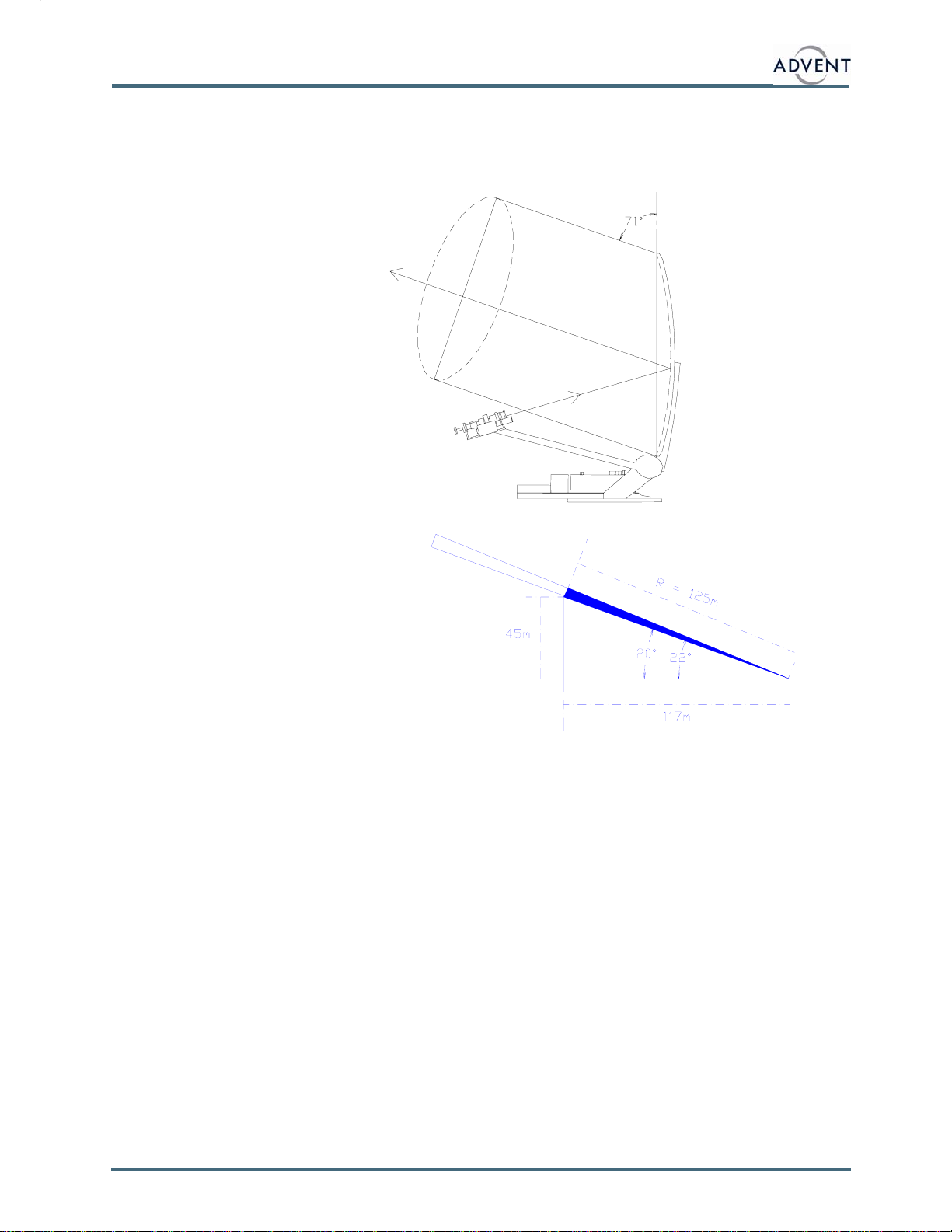

5.8RADIATION CHECK 46

5.9POLARISATION WAVEGUIDE SWITCH (KU ONLY) 46

5.10SATELLITE TRANSMISSION EQUIPMENT 46

6.WARRANTY 47

6.1WARRANTY INFORMATION 47

6.2CLAIM FOR DAMAGE IN SHIPMENT 47

6.3FIELD SERVICE 47

6.4SHIPMENT OF REPAIR PARTS TO FIELD 47