Templari KITA ARIA Manual

Installaon and maintenance manual

versione ARIA - ACQUA

vers. 24/01/19 G

Summary

1 Introducon ........................................................................................................... 6

1.1 General warnings.................................................................................................... 6

1.2 Recommended equipment ..................................................................................... 6

1.3 Series descripon ................................................................................................... 6

2 Read carefully before use ....................................................................................... 7

2.1 Important informaon ............................................................................................ 7

2.2 Proper use .............................................................................................................. 7

2.3 Rules and law provided .......................................................................................... 7

2.4 Energy saving.......................................................................................................... 7

3 Intended use of the heat pump ............................................................................... 7

3.1 Fields of work and safety devices ............................................................................ 7

3.2 Allowed operang zone .......................................................................................... 8

3.3 System structure with heat pump ........................................................................... 8

3.4 Components ........................................................................................................... 9

3.5 Mode of operaon ............................................................................................... 10

4 Equipment of supply ............................................................................................. 10

4.1 Main unit .............................................................................................................. 10

4.2 Name of the type and registraon number ........................................................... 10

4.3 Components scheme of external device of the heat pump KITA S/M/M3Phase

Templari® ............................................................................................................. 11

4.4 Components scheme of the external device of the heat pump KITA L33/L42/L66

Templari® ............................................................................................................. 12

5 Trasport ................................................................................................................ 13

6 Assembly and installaon ..................................................................................... 13

6.1 Oponal components on demand......................................................................... 13

6.2 Measures of the device ......................................................................................... 13

6.3 Free spaces for the assembly ................................................................................ 14

6.4 Choice of installaon place ................................................................................... 14

6.5 Assembly of the heat pump .................................................................................. 14

6.6

Preparaon of the condensate drain ........................................................................... 14

6.7 Alignment of the heat pump KITA Templari® ......................................................... 16

6.8 Probe installaon ................................................................................................. 16

7 Hydraulic connecons .......................................................................................... 16

7.1 Equipment control ................................................................................................ 16

7.2 Parcular Components ......................................................................................... 16

7.3 Installaon of hydraulic part ................................................................................. 17

7.4 Choice of the system scheme ................................................................................ 17

7.5 Scheme 1: Cooling/heang system ad DHW, with buer on return pipes. ............. 18

7.6 Scheme 2: Cooling/heang system, with buer on return pipes. .......................... 19

7.7 Scheme 3: System only DHW, with buer. ............................................................. 20

7.8 Scheme 4: Cooling/heang system and DHW with buer. ..................................... 21

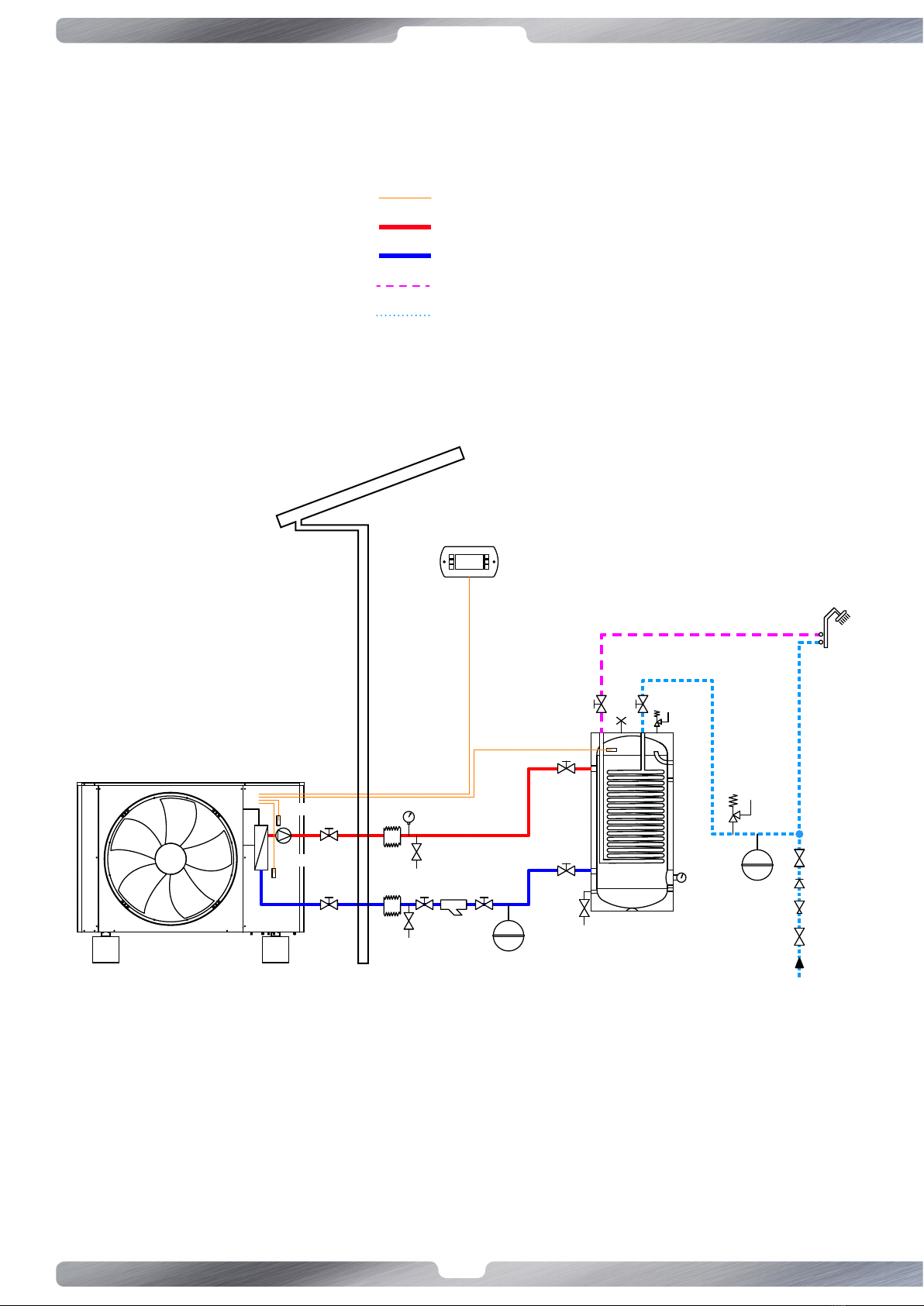

7.9 Scheme 5: System with heat pump, solar thermic for heang and producon DHW,

with buer. ........................................................................................................... 22

7.10 Scheme 6: Cooling/heang system, with buer. ................................................... 23

7.11 Scheme 7: Cooling/heang system, DHW and integraon, with buer on return

pipes. ................................................................................................................... 24

8 Maintenance and cleaning .................................................................................... 25

8.1 Cleaning of the baery ......................................................................................... 25

8.2 Cleaning of the condensate drain .......................................................................... 25

8.3 Cleaning of hydraulic system side ......................................................................... 25

9 Electrical connecons ........................................................................................... 25

9.1 General informaon ............................................................................................. 25

9.2 Laying operaons ................................................................................................. 25

9.3 Supply .................................................................................................................. 26

9.4 Probes and remote panel ...................................................................................... 27

9.5 Terminal block wiring

KITA S/S Plus/M/M3Phase/ M3Phase plus ..................................... 27

9.6 Terminal block wiring single-phase models supply ................................................ 28

9.7

Terminal block wiring KITA L33/L42/L66 ........................................................................ 29

9.8 Terminal block wiring for three-phase models ...................................................... 30

9.9 Network wiring pLAN - “mul-KITA” ..................................................................... 30

10 Electronic board ................................................................................................... 31

10.1 Digital outputs ...................................................................................................... 31

10.2 Digital inputs ........................................................................................................ 31

10.3 Analogic outputs .................................................................................................. 31

10.4 Analogic inputs ..................................................................................................... 31

10.5 Wiring diagram KITA S/S Plus/M ........................................................................... 32

10.6 Wiring diagram KITA S 3Phase/S Plus 3Phase/M 3Phase / M Plus ......................... 33

10.7 Wiring diagram KITA L33/L42/L66 ......................................................................... 34

10.8 Internal wiring connecon diagram ...................................................................... 35

11 Inial operaon .................................................................................................... 36

11.1 Preliminary checks ................................................................................................ 36

11.2 Tesng and startup ............................................................................................... 36

12 Control terminal ................................................................................................... 38

12.1 Fixing of the panel ................................................................................................ 38

12.2 Unit control measures .......................................................................................... 38

12.3 Menu overview .................................................................................................... 39

12.4 Terminal buons .................................................................................................. 40

12.5 Display of the terminal ......................................................................................... 40

12.6 Main menu ........................................................................................................... 41

12.7 ON-OFF menu ....................................................................................................... 41

12.8 SETPOINT menu .................................................................................................... 41

12.9 Clock/metable menu .......................................................................................... 42

12.10 Input/Output menu .............................................................................................. 43

12.11 Alarms history menu ............................................................................................ 43

12.12 Board change menu .............................................................................................. 43

12.13 Assistance menu ................................................................................................... 43

13 Alarms .................................................................................................................. 48

13.1 Alarms resoluon ................................................................................................. 50

13.2 Nocaons ......................................................................................................... 51

14 Performances ....................................................................................................... 53

15 Declaraon of Conformity .................................................................................... 55

15.1 Declaraon of conformity KITA S/M/M3Phase ...................................................... 55

15.2 Declaraon of conformity KITA L/L42/L66 ............................................................. 56

6

www.templari.com

1 Introducon

This guide wants to give every informaon necessary to the

installaon and the correct funoning of the heat pump KITA

Templari®, from its put in acon during its whole life cycle . The

document is divided in chapters, in each of them there are general

informaon and mode of the operaons to be performed.

1.1 General warnings

• The choice and the use of the unit to serve the condioning

system have to be made by a competent sta according to

the current regulaons in place so to completely sasfy the

requests of the system.

• The installaon, the put in acon and the maintenance

have to be made by a competent sta able to evaluate the

possible presence of risk factors or malfuncon of the

machine.

• The unit is supplied complete with all the opons and the

operaons directly by the constructor, every manumission

of the fridge part or the soware aren’t allowed. Any

manumissions will make fall the operaons of the machine

and constructor’s responsibility.

• Periodic inspecons and a proper manintenance of the

heat pump KITA Templari®, can avoid damages to the unit

and possible costs for repairs.

• The warranty expires in case of installaon not complying

the specicaons.

• Keep this guide with the necessary diagrams in places

easily accessible.

• In case of malfuncon verify the error code on the control

panel, if necessary contact the installer; if necessary

require original spare parts.

• On the label of the heat pump KITA Templari® you can

nd all the informaon in relaon to current regulaons of

labeling, in parcular you can nd:

• Power to the machine in tension e frequency;

• Thermal power in heang and cooling schemes;

• Maximum power absorpon;

• Sound power level;

• Refrigerant used.

1.2 Recommended equipment

• Set of star and shear e screwdrivers;

• Nippers;

• Scissors;

• Set of wrenches or pipe wrench;

• Ladder;

• Hydraulic material for thread gasket;

• Electric equipment for connecons;

• Protecve gloves;

• Tester and current clamp;

1.3 Series descripon

The series of the heat pumps KITA Templari® presents monoblock

water heat engines for the producon of heang and cooling

thermal energy and the producon of domesc hot water with

the best technologies in the market.

The heat pump KITA Templari® is a series of machines full-

inverter that is with high performance components and widely

dimensioned to privilege the eciency of the machine. One

more parcularity is the implementaon of EVI technology

(Enhanced Vapour Injecon) in models KITA L, L42 and L66,

that broaden the eld of work and the power output to the

heat pump. The use of the gas R410A permits to reach high

performances and a low environmental impact. The presence of

two electronic valves, reversing valve, pressure transducers and

temperature sensors ensure, through the soware integrated in

the electronic board as microprocessor, the full funconality and

reliability of the machine in the dierent operaong regimes.

The control of the machine is done through a remote control that

permits to monitor the operaon of the machine and change

the temperature set of the water produced and the mode of

operaon (summer/winter).

7

www.templari.com

2 Read carefully before use

2.1 Important informaon

WARNINGS!

The pracce and the maintenance of the heat pump KITA

Templari®, are subject to legal systems of the countries where it

is used. According to the quanty of cooling uid it is necessary

to check e annotate the hermec seal of the heat pump at

regular intervals resorng to a qualied sta.

• During the transport it is possible to lt the heat pump no

more than 45° (in each direcon).

• The safety for the transport has to be removed before of

the put in acon.

• The aspiraon and unloading zone mustn’t be reduced or

covered.

• Respect specic building regulaons of each countries.

• For the installaon near the wall you have to consider degli

inuences due to building physiscs factors. In the area of

unload of the fan there must be no windows or doors.

• With the installaon near the wall the air ow in the

aspiraon and unloading zone can give a greater deposit

of impurity. The colder outside air has to go out so to not

increase the heat loss of bordering heated rooms.

• the dirt trap, not included but supplied on demand of

the customer, must be assembly on the heang return

upstream of the heat pump.

• The istallaon in niches or inner courtyards isn’t allowed,

because the cooled air accumulates on the ground and in

case of prolonged operaon it would be aspirated back by

the heat pump.

• The freezing limit can change following the climac region.

Respect the regulaons in force for the countries concerned.

• Respect the right-handed rotaon eld: in case of incorrect

wiring the start of the heat pump is hindered. The programmer

of the heat pump shows the relevant warning indicaon (to

correct the wiring).

• The operaon of the heat pump with too low temperature

system can cause its total block. Aer a prolonged power cut

you have to use the method of put in acon described below.

• Clean at regular intervals the dirt trap.

• Before opening the device cut o power to all the electrical

circuits.

• Works on the heat pump can be done only by authorized and

competent people of the customer care.

2.2 Proper use

The heat pump KITA Templari® is homologate just for the use

providede by the manufacturer. A dierent use moving away

from the provided one is considered not-compliant. The proper

use also includes the respect of the informaon included in

the relevant informave. It’s forbidden to make changes or

transformaons to the device.

2.3 Rules and law provided

This heat pump is desned, according to the arcle 1, chapter 2

k) of Direcve CE 2006/42/CE (Machines Direcve), to the use in

domesc and for this reason it is subject to the requirements of

the Direcve 2006/95/CE (Low power Direcve). In this way it

is arranged to be used by inexperienced people to heat shops,

oces and similar work environments, farms, hotels, small

hotels and similar or other residenal buildings.

In the planning and realizaon of the heat pump all the

correspondant CE direcves and DIN and VDE regulaons are be

respected (see Dichiarazione di conformità CE).

The electrical connecon of the heat pump KITA Templari® has to

be made following the current rules VDE, EN e CEI. Furthermore

the connecon condions of network operators of supply have

to be respected.

Concerning the heang system connecon you have to follow

current provisions.

People, in parcular kids, who on the base of physical, sensory

or mental abilies, or for inexperience or incompetence aren’t

able to use the device in safety, must’t use the device without a

responsible person’s supervision or guide.

Make sure kids don’t play with the device.

2.4 Energy saving

Using the heat pump KITA Templari® you contribute to the

respect of the environment. Condion for a energi saving

operaon mode is the correct disposion of heat sources and of

the system for the ulizaon of thermal energy.

Very important for the eciency of a heat pump is to keep the

dierence of temperature between the heang water and the

heat source as low as possible. For this reason we strongly

recommend an accurate sizing of the heat source and of the

heang system. A dierence of temperature higher than a degree

Kelvin (a °C) causes an increase of energy consumpon of 2,5 %

about. It is necessary to be careful, during the heang system

sizing, how special users are considered, as for example hot water

producon, and and how they are sized for low temperatures. An

underoor heang (surface heang) is the ideal to use a heat

pump thanks to ow temperatures (from 30 °C to 40 °C).

During the operaon it is important that impuries aren’t

accumulated in the heat exchangers, because the make increase

the dierence of temperature, worsening then the coecient of

performance.

3 Intended use of the heat

pump

3.1 Fields of work and safety devices

The heat pump KITA Templari® is enable to work at outdoor

temperature between -22°C (for the version S and M) and -32°C

(for the version L) and +46°C.

The machine allows following operaons elds relang to the

temperatures of the water produced:

• Heang: mimimum temperature 10°C, maximum

temperature 55°C

• Producon of domesc hot water: minimum temperature

35°C, maximum temperature 55°C

• Cooling: minimum temperature 7°C, maximum

temperature 40°C.

The heat pump KITA Templari® is equipped with a safety pressure

switch that stop the operaon of the machine when a pressure

8

www.templari.com

of 4,5 MPa (45 bar) is reached.

The product is provided with a ow sensor by volume (ow

switch). The ow switch ensures the stop of the machine if the

ow of water falls below the minimum threshold equal to 35-

40% of the nominal ow (1400 l/h).

The machine is equipped with an anfreeze system prevenng

the freezing of the water content in hydraulic pipes linked to the

heat pump in case of outdoor low temperature. The anfreezing

protecon, when working, keep the circulator is state of ON,

even if the heat pump is set in OFF. The machine stays in state of

“alert” when the protecon is acve because it could start if the

condions require it (even if it is in OFF)

WARNINGS!

Before of performing maintenance works on the machine make

sure to unplug the machine from the power supply.

• During the summer operaon an anfreezing protecon

prevents the freezing of the water in the system.

• Heat pump KITA Templari® is provided of a sonde that

controls the compressor discharge temperature. The

computer of the machine ensures that the discharge

temperature doesn’t exceed the maximum allowed value.

N O T E !

The device isn’t suitable to be used with a frequency converter.

If the machine is powered o (unplugged from the network)

for long periods, don’t stop oil heang procedure starng when

the machine is powered again. This procedure serves to prevent

compressor breakage.

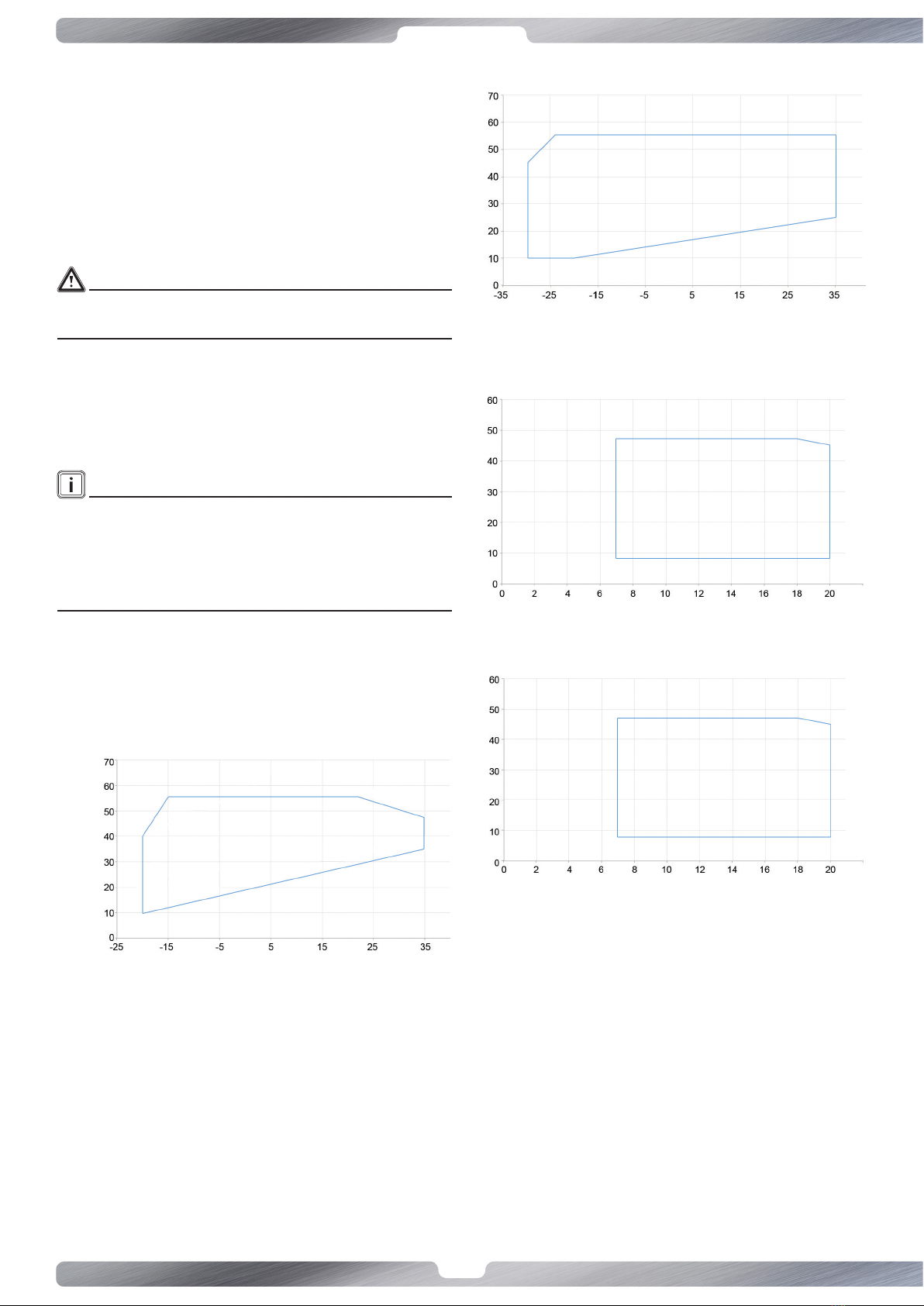

3.2 Allowed operang zone

KITA S - S 3phase - S plus - S plus 3phase / M

- M 3phase - M plus: heat pump

Water output temperature +/-2 [°C]

Outdoor air temperature +/-1 [°C]

KITA L - L42 - L66: heat pump

Water output temperature +/-2 [°C]

Outdoor air temperature [°C]

KITA S - S 3phase - S plus - S plus 3phase / M

- M 3phase - M plus: chiller

Outdoor air temperature +/-2 [°C]

Produced water temperature +/-1 [°C]

KITA L - L42 - L66: chiller

Water output temperature +/-2 [°C]

Water output temperature +/-1 [°C]

3.3 System structure with heat pump

The system with heat pump includes following components:

• Heat pump KITA Templari®;

• Control command of heat pump;

• Oponal hydraulic components, that can be required to

the manufacturer: a heang resistor for the condensate

drain, una a three-way valve for the combined system and

domesc hot water management, mesh lter, switching

relé operang with boiler integraon.

The control of machine funcons is totally done by command.

9

www.templari.com

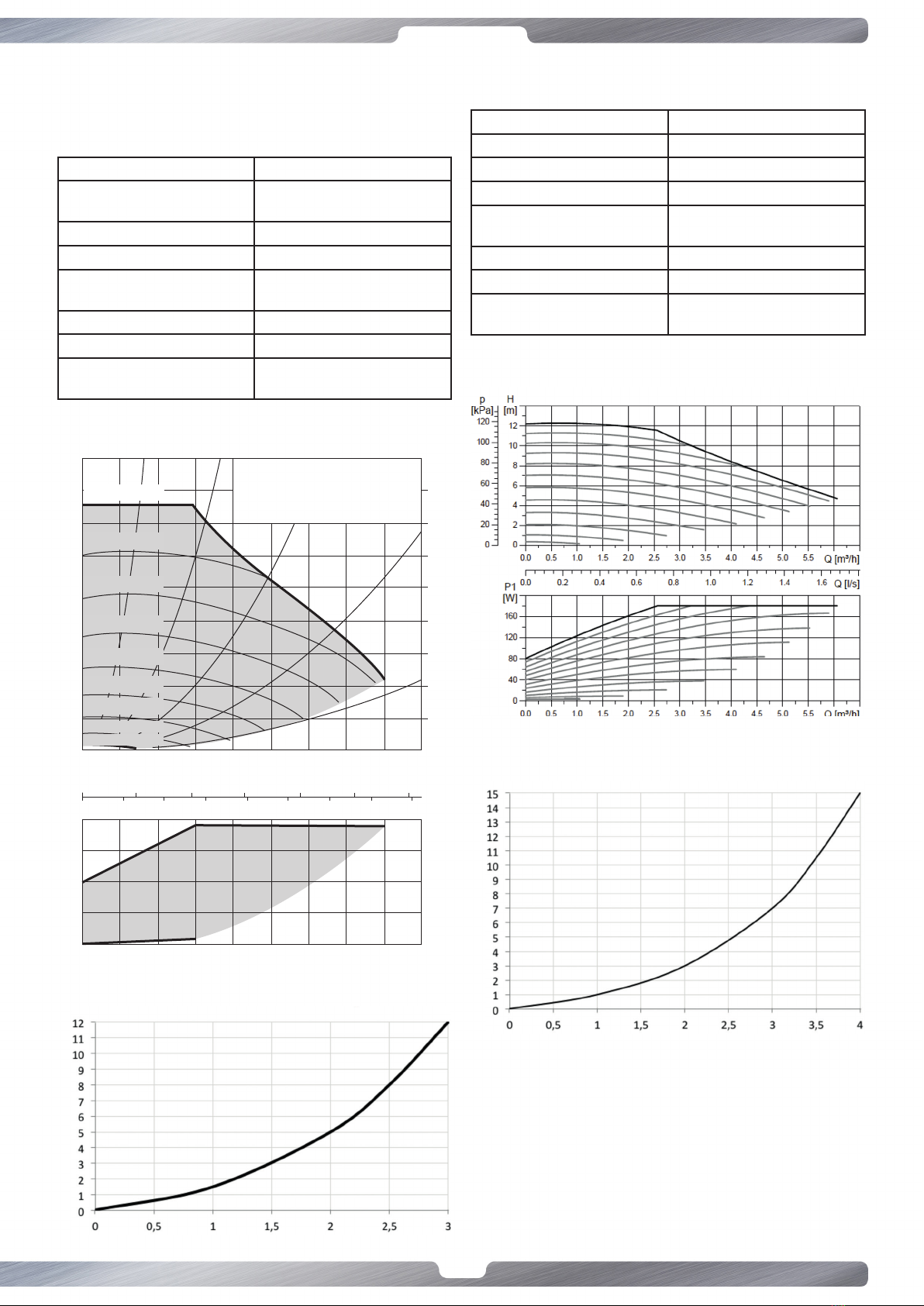

3.4 Components

KITA KITA S - S 3phase - S plus - S plus 3phase

/ M - M 3phase - M plus / L: Circulator Wilo

Yonos Para RS

Model Wilo Yonos Para RS 25/7.5

Voltage- frequenza di

alimentazione

1-230-V 50/60Hz

Indice di ecienza energeca A

Massima potenza assorbita 75 W

Massimo assorbimento di

corrente

0,6 A

Massima prevalenza 7,6 m

Minima pressione ingresso 0,5 bar

Temperatura producibile

dell’acqua

Da -10 a 95 °C

Characterisc curves of the circulator

max

max

80

70

60

50

40

30

20

10

0

8

7

6

5

4

3

2

1

0

p/kf

Q m3/h

Q m3/h

Q l/s

Q/lgpm

P1/W

H/m

4770/≤5PWM1

4270/15PWM1

3780/25PWM1

3280/35PWM1

2780/45PWM1

2280/55PWM1

1780/65PWM1

1290/75PWM1

790/85PWM1

0

0

0 2 4 6 8 10 12 14

0,2 0,4 0,6 0,8 1,0

0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0

0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0

Wilo - Yonos PARA RS

15/7.5 , 25/7.5 , 30/7,5

1-230 V - Rp ½, Rp 1, Rp ¼

n=1/min/ % PWM 1

60

40

20

0

Pressure loss in the plate heat exchanger

Water ow in heang [m³/h]

Loss of pressure [kPa]

KITA L42 - L66:

Circulator GRUNDFOS UPMXL

Model Grundfos UPMXL GEO 25-125

Tensione- supply frequency 1-230-V 50/60Hz

Energy eciency index A

Maximum power 180W

Maximum current

consumpon

1,4 A

Maximum head 12 m

Minimum input pressure 0,1 bar

Producible water

temperature

Da -10 a 95 °C

Characterisc curves of the circulator

Pressure loss in the plate heat exchanger

Water ow in heang [m³/h]

Loss of pressure [kPa]

10

www.templari.com

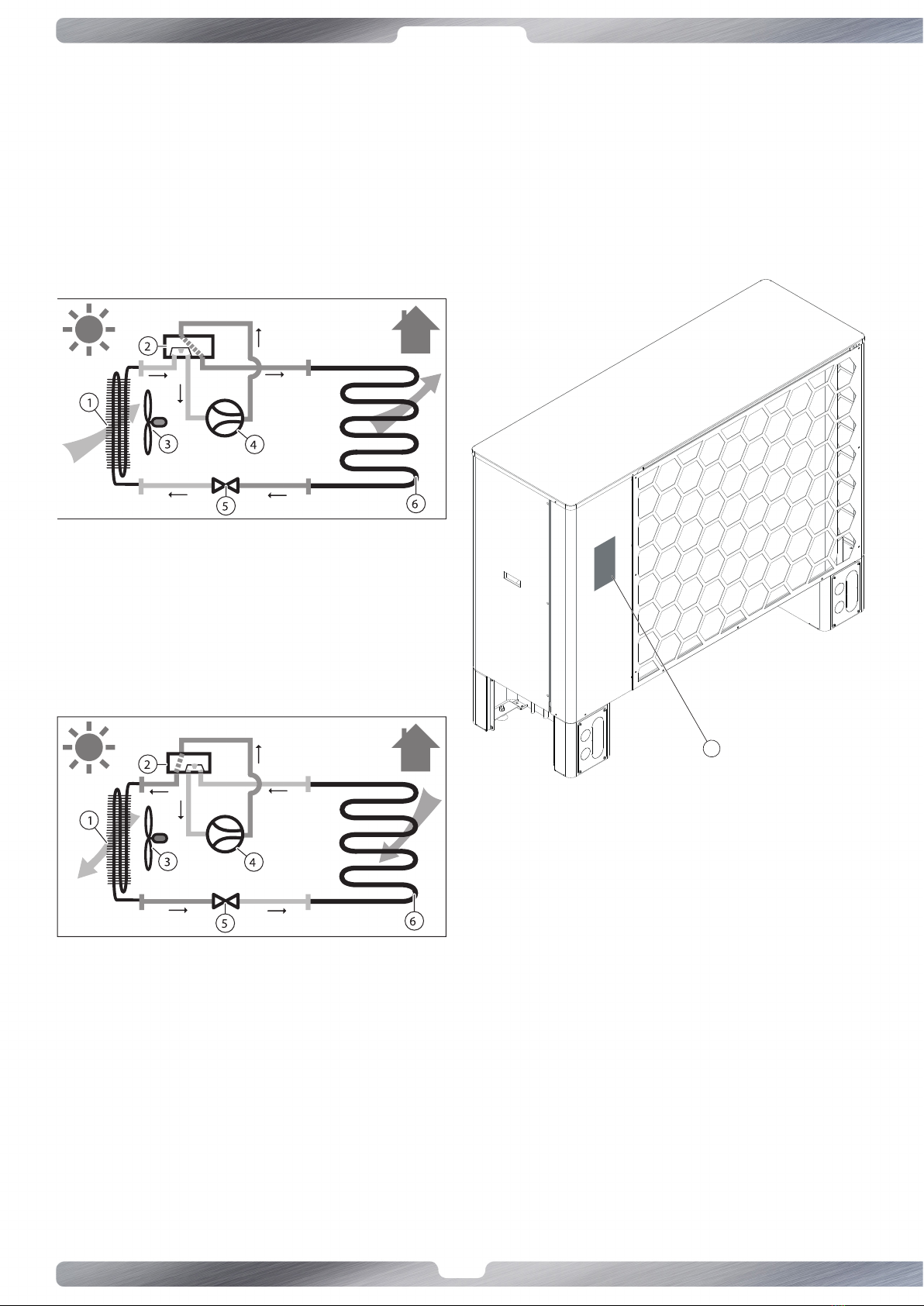

3.5 Mode of operaon

The heat pump can work in two ways, achievable through the

switching of the 4-way valve: as shown below, these modes are

heang and cooling/defrosng.

It’s also posssible to enter a special management module DHW

(domesc hot water) composed by relè, temperature sensors

and 3-way valves. Thanks to that the pump can manage the DHW

both in summer and in winter as a priority.

Heang mode

1 Evaporator

2 4-way valve

3 Fan

4 Compressor

5 Electronic expansion

valve

6 Plate heat exchanger

Cooling and defrosng mode

c

1 Evaporator

2 4-way valve

3 Fan

4 Compressor

5 Electronic expansion

valve

6 Plate heat exchanger

4 Equipment of supply

4.1 Main unit

The heat pump KITA Templari® is supplied in two units and it is

composed by the components showed in gure 1.

4.2 Name of the type and registraon

number

Model name and registraon number are on the plater (1) gure

1.

gure 1

1

11

www.templari.com

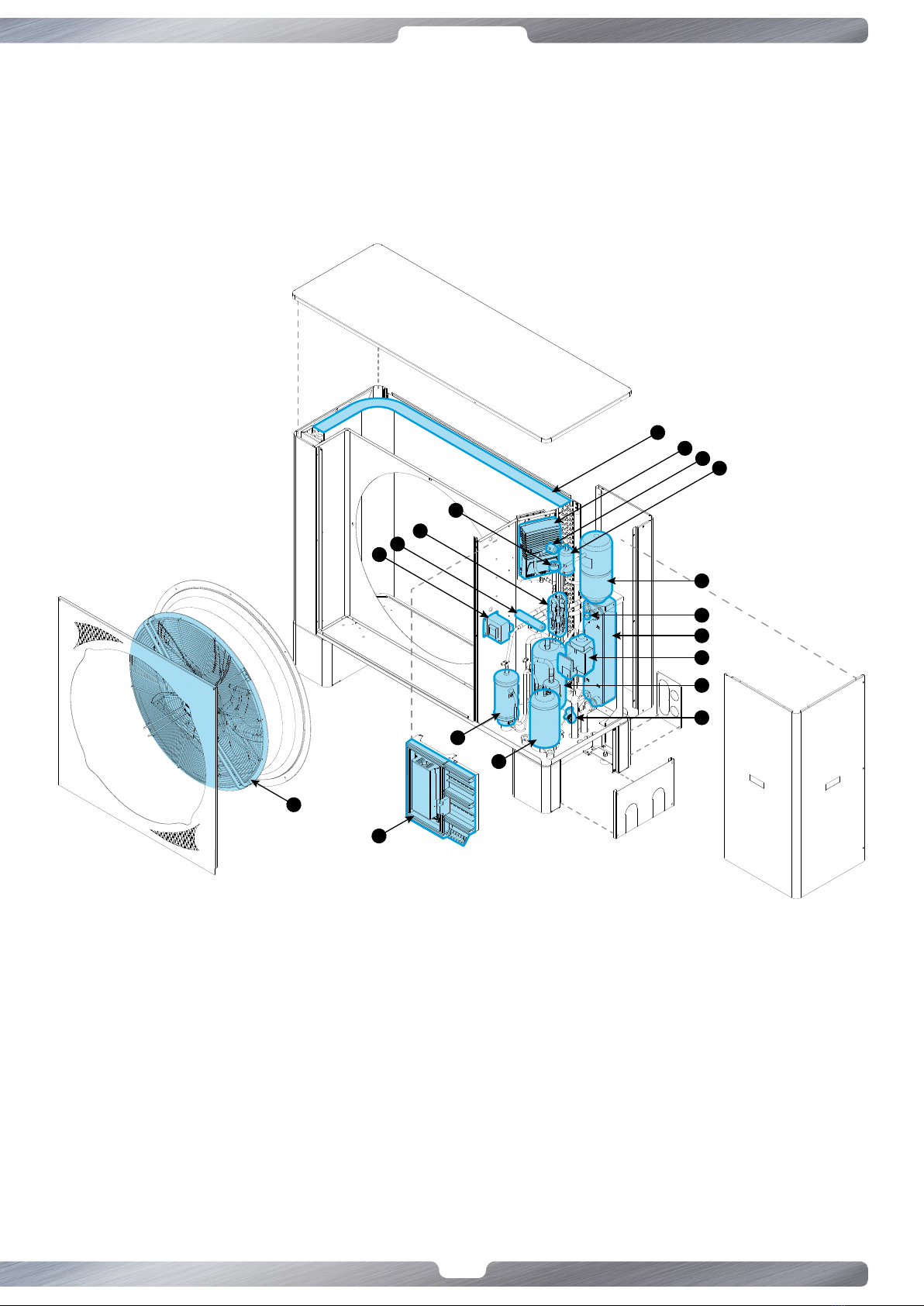

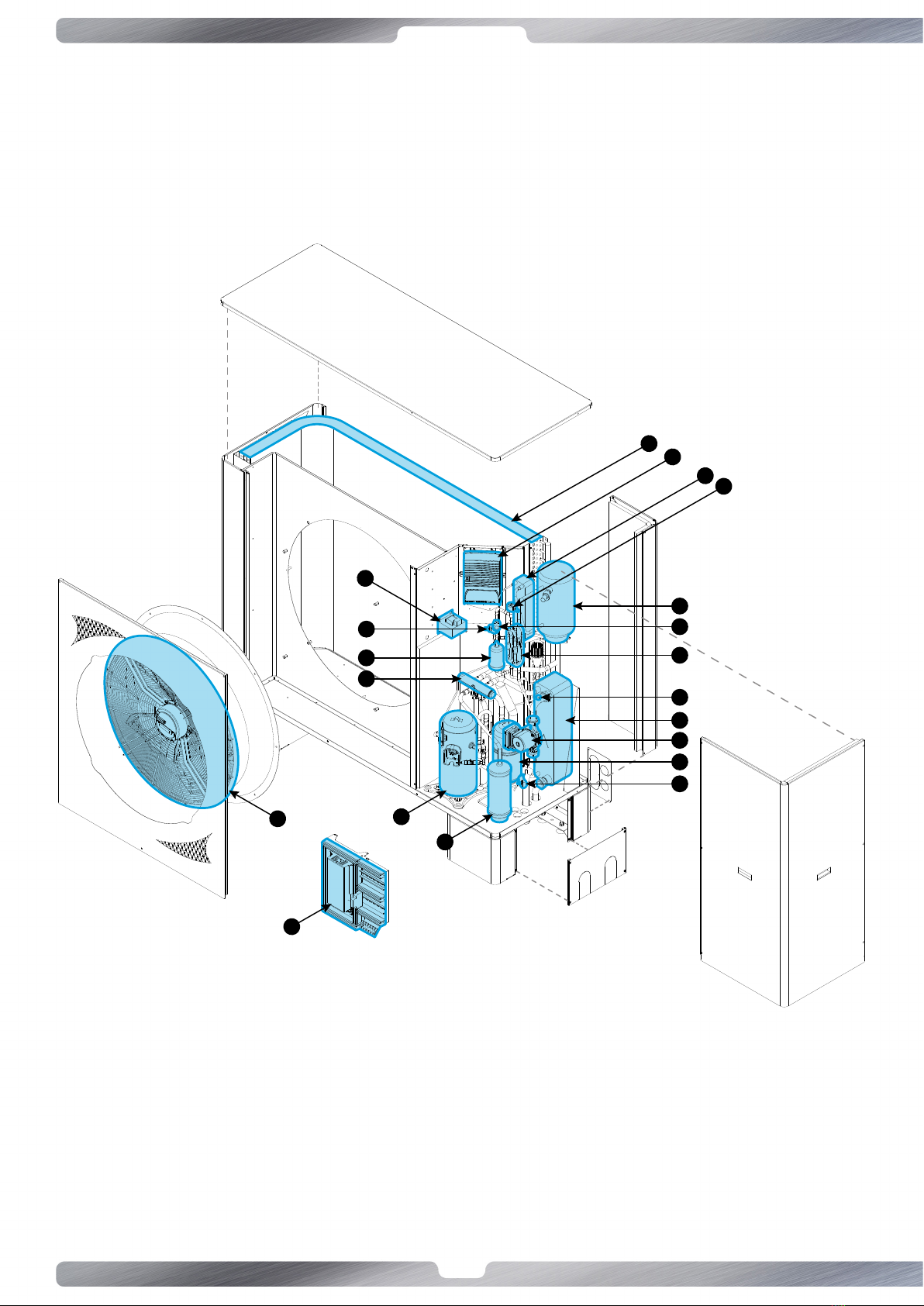

4.3 Components scheme of external device of the heat pump KITA S/M/M3Phase

Templari®

3

5

14

1

10

9

12

6

7

8

2

15

17

16

4

13

18

11

1 Vent valve

2 Inductance

3 Evaporaon/Condensaon baery

4 Compressor

5 Filter

6 Flowmeter

7 Liquid indicator

8 Inverter

9 Circulaon pump

The image is intended only to indicate the main internal components. The actual product may looks dierent.

10 Receiver of liquid

11 Electric board

12 Liquid separator

13 Oil separator

14 Heat plate exchanger

15 Check valves

16 Electronic expansion valve

17 4-way valve

18 Fan

12

www.templari.com

4.4 Components scheme of the external device of the heat pump KITA L33/L42/L66

Templari®

3

19

1

10

7

15

9

12

6

16

8

14

17

5

16

2

4

13

18

11

1 Vent valve

2 Inductance

3 Evaporaon/Condensaon baery

4 Compressor

5 Filter

6 Flowmeter

7 Liquid indicator

8 Inverter

9 Circulaon pump

10 Receiver of liquid

L’immagine ha il solo scopo di indicare i principali componen interni. Il prodoo può presentarsi diversamente.

11 Electric board

12 Liquid separator

13 Oil separator

14 Injecon plate exchanger

15 Check valves

16 Electronic expansion valve

17 4-way valve

18 Fan

19 Heat plate exchanger

13

www.templari.com

5 Trasport

WARNINGS!

Regardless of the type of transport, must never be inclined more

than 45°. Contrary you can have anomalies in the refrigerant

circuit in the next operaon. In severe cases this may have as a

consequence a failure inside.

The transport to the nal place of installaon should be done

on a pallelt. The heat pump KITA Templari® can be transported

using a forkli.

KITA S

KITA S PLUS

KITA S3Phase Kg. 180

KITA S3Phase Plus

KITA M

KITA M3Phase Kg. 220

KITA M3Phase Plus

KITA L33/L42/L66 Kg. 280

• Protect the sidewalls of the product coming into contact

with the forkli to prevent scratches and damages.

• Li the product only from the back and from the side of the

ngs.

• The liing of excessive weights can cause spinal injuries, for

example.

• Consider the weight of the product riported in the technical

data.

• In the transport of heavy loads, comply with the instrucons

and the provisions in force.

6 Assembly and installaon

6.1 Oponal components on demand

• Circulator for hydraulic system;

• Anvibraon for ground mounng support;

• Y lter;

• Anvibraon for piping.

6.2 Measures of the device

KITA S / S 3Phase / S Plus / S Plus 3Phase

271

210

76120

1406

908259550

R30

225 949 225 188 170 186186 170 188

1167

550

121

AB

CD

KITA M/M 3Phase/ M Plus

1591

1271

259 1012

225 1134 225

546

R30

122 91

121

221

282

188 188168

546

AB

CD

KITA L33/L42/L66

1516

325 1133 325

259 1257

1791

121

122

89

292

352

233 170 231

641

231 170 233

A

B

C

D

A: condensate drain

B: OUT

C: IN

D: cable passages

14

www.templari.com

6.3 Free spaces for the assembly

Distance Measures in millimeters

A >300

B >2500

C>300 KITA S >400 KITA M >500 KITA L

D>3000

E >1000

Respect the minimum distances menoned above to ensure a

sucient air ow and facilitate maintenance works.

• Verify there is asucient space for the installaon of the

hydraulic piping.

• If the product is installed in areas prone to heavy snowfalls,

verify the snow doesn’t accumulate around the product

and the minimum distances menoned above are

respected. If these condions can’t be sased, install then

an addional heat generator in the heang circuit.

6.4 Choice of installaon place

• Observe all the rules in force.

• Install the product outside the building.

• Don’t install the product:

- near a heat source,

- near ammable substances,

- near venlaon opening of conguous buildings,

- Below deciduous trees.

• For the installaon of the product observe:

- prevailing winds,

- noise of the fan and the compressor,

- opcal impression on the environment

• Avoid place where on the air outlet of the product there is

the eect of strong winds.

• Don’t orient the fan towards the near windows.

• If necessary, install noise-protecon system.

• Install the product on one of the following supports:

- Concrete pavement,

- T steal beem

- Concrete block.

• Don’t expose the product to dusty and corrosive air (e.g.

near rough roads).

• Don’t install the product near wells of air discharge.

• Prepare the laying of electrical cables.

• In places where there are snowfalls, install the heat pump

at least 25 cm from the ground to avoid clogging at the

inlet and drain zone.

6.5 Assembly of the heat pump

1. Before installing the product, observe the safety warnings

content in this manual and service manuals.

2. Assembly the product on steel beams, blocks of concrete

or with the help of a wall holder (accessory).

3. Verify that under the product water doesn’t accumulate

non si accumuli.

4. Verify that the oor in front of the product can well absorb

water to avoid ice formaon.

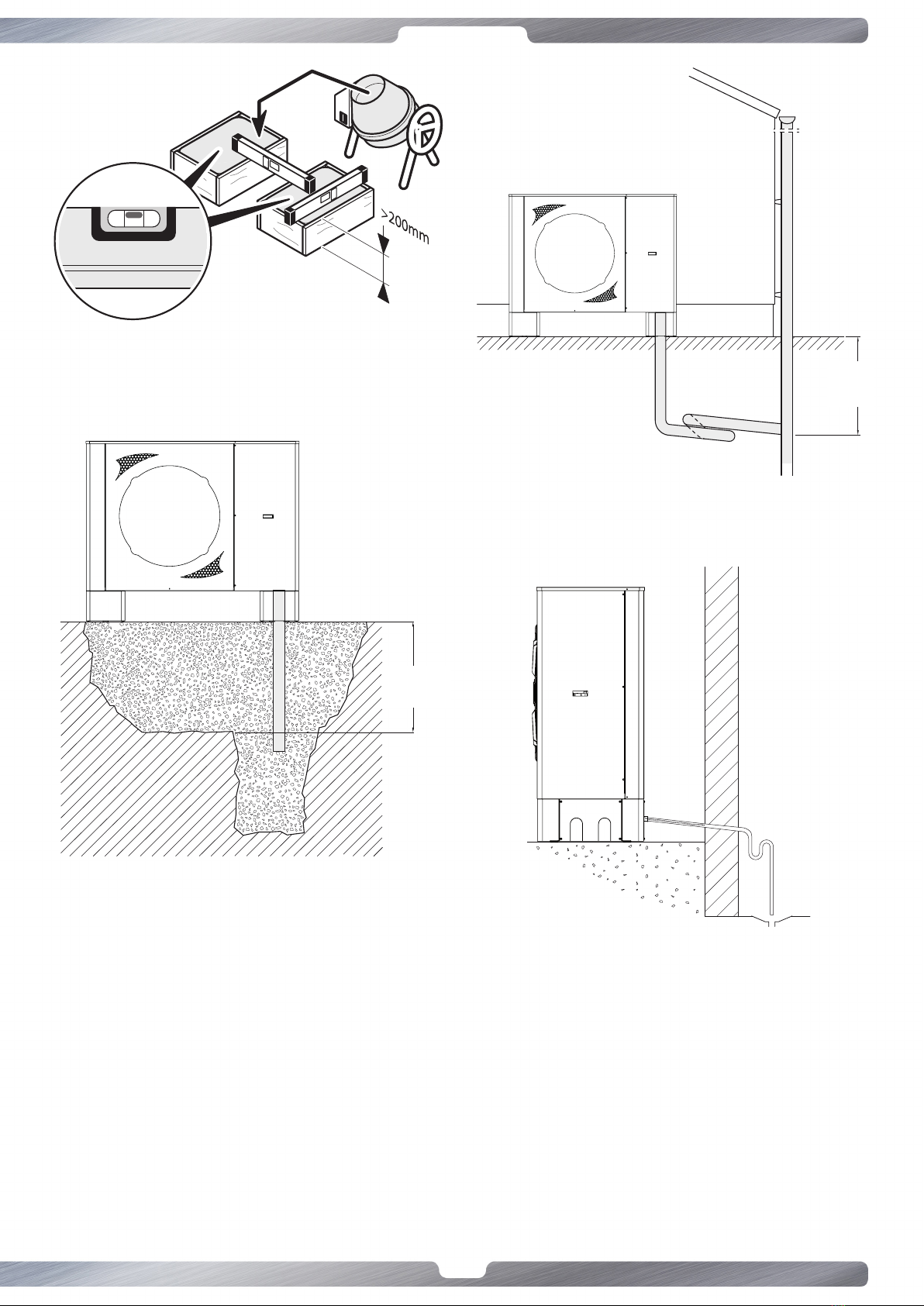

6.6

Preparaon of the condensate drain

The condensate is discharged in a centralized way from the back

of the heat pump KITA Templari®.

Prepare the condensate drain through a drain pipe or a gravel

bed.

WARNINGS!

The condensate frozen on the avenues can cause falls. Verify that

the condensate doesn’t ow on the avenues and can’t freeze on

them.

Frost proof

depth

min 200mm

Frost

proof

depth

Frost proof

depth

min 200mm

Frost

proof

depth

15

www.templari.com

• Example 2 condensate drain

• Example 3 condensate drain with condensate drain element

The condensaon water accumulated during the operaon must be

carried away without it can freeze. To ensure the correct oulow the

heat pump must be in a horizontal posion. The condensaon water

pipe must have a minimum diametre of 18mm and must ow in the

drain channel without it can freeze. Don’t discharge the condensate

directly into puricaon basins and moats. The aggressive fumes

and the condensaon pipe, if it isn’t protected against frost, can

cause irreparable damages to the evaporator.

In places where there are snowfalls, install the heat pump at least 25

cm from the oor to avoid clogging in the sucon and condensate

drain area.

• Preparaon of the base for condensate drain

• Example 1 condensate drain (it is advisable inter the

condensate drain pipe to avoid ice if you don’t buy the

oponal heang element for the condensate drain).

Frost proof

depth

min 200mm

Frost

proof

depth

Frost proof

depth

min 200mm

Frost

proof

depth

Frost proof

depth

min 200mm

Frost

proof

depth

16

www.templari.com

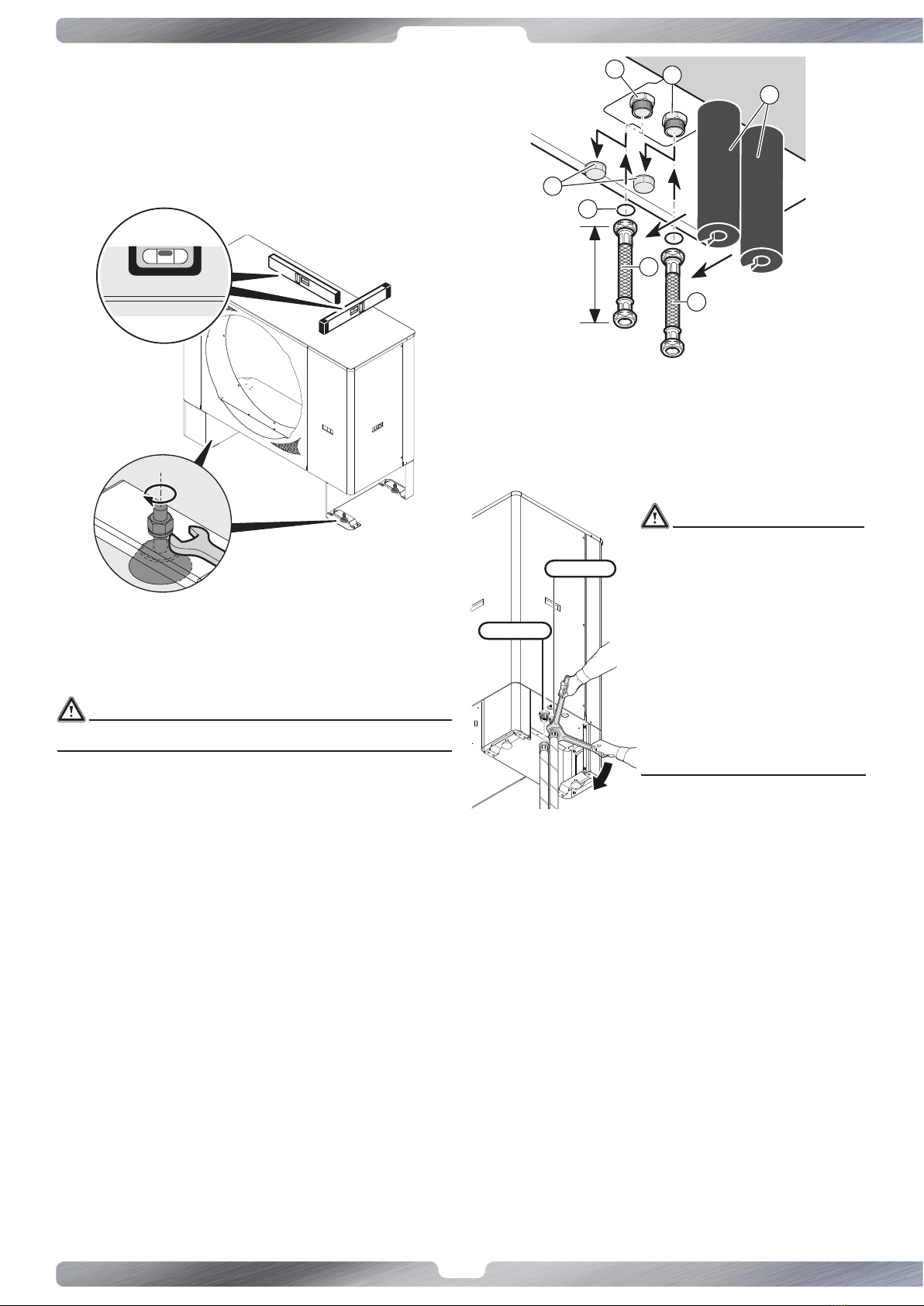

6.7 Alignment of the heat pump KITA

Templari®

Put horizontally the heat pump KITA Templari® so that the

condensate can ow. The product must be installed with

amorzed feet, purchased separately. The amorzed feet

increase the height of the product, facilitang the ow of

condensate and reducing vibraons.

6.8 Probe installaon

All probe used for the operaon of the plant must be installed

properly in the appropriate wells using a suitable thermal paste.

WARNINGS!

Installing the probes not in a proper way will voids the warranty.

7 Hydraulic connecons

7.1 Equipment control

1 Insulate wires (even underground) between product and

heang system con un isolamento resistente ai raggi UV e

alle alte temperature.

2 To avoid the transmission of vibraons on adjacent

buildings, use connecon lines to product with a lenght of

at least 0,75 m.

3 If the product isn’t installed in the hightest point of heang

circuit, install then in a suitable point some addional vent

valves.

4 Remove the covers (3) from the hydraulic ngs of the

circuit.

5 Install in the return of the heang circuit, between two

shut-o valves, an an-dirty lter to clean at regular

intervals.

6 Install a fexible pipe (1) e (6) (to be made on site) with a

gasket and a closing valve in the discharge ngs and the

riturn of the heang circuit of the heat pump.

7 Control the connecon seal.

5

4

7

3

2

2

6

0,75m min.

1 Flexible connecon tube in the

return of the heang to the building

(in place)

2 Gasket

3 Cover

4 Juncon (Ø 1”) return of the heang

to the building

5 Juncon (Ø 1”) heang supply to the

heat pump

6 Flexible connecon pipe in the

heang supply towards the heat

pump (in place)

7 Insulaon (in place)

WARNINGS!

If you use glycole, collect it on the

safety valve to avoid the polluon of

the environment.

The welding residues, slivers, hemp,

stucco, rust, dirt

and similar coming from the

pipelines can stand in the product

causing anomalies.

Rince thoroughtly the heat system

bifore of connecng the product to

remove possible residues!

Obligatory Y lter, contrary the

warranty will expire.

outlet

inlet

Operarate according to the rules in force, make sure the unit sia is

stably balances before of doing any operaons and always adopt

sempre protecon systems. The posioning indicaons shown

below are necessary for the correct operaon of the machine,

the maintenance and the operator protecon near the unit.

7.2 Parcular Components

The installer has to make the choice and the installaon of the

necessary components of the system, here below are listed

useful devices for the operaon of the machine:

• Shut-o valves at the entrance and exit of the circuit

allow maintenance operaons senza without draining the

system;

• Safety valve hydraulic side

• Thermometers and pressure gauges at the entrance and

exit of the main components ensure a beer monitoring

and facilitate the maintenance;

• Vent valves in the hightest points of the system ensure the

air vent from the circuit;

• Drain cocks in the boom of the system to facilitate the

emptying;

• Expansion vessel to keep the correct water pressure

17

www.templari.com

compensang thermal expansions, has to be sized

considering water total volumes in the system;

• The installaon of a Y lter is necessary.

WARNINGS!

Install hydraulic system side a safety valve.

7.3 Installaon of hydraulic part

• Thorough washing of the system with clean water lling

and emptying it many mes. This operaon allows to

riduce the number of maintenances and avoid damages to

exchangers and other components;

• Test of possible losses in the circuit;

• Insulate all the pipelines to reduce heat losses and avoid

the formaon of condensaon;

• Free up the service points like wells vents etc...;

• Verify that the quality of the water is suitable, contrary:

performance penalty, higher loading losses, possible

damages.

If there is the risk of water freezing in the system take the

following prevenve measures:

• Always powered machine for frost protecon;

• Mix water with ethylene glycol or propylene glycol

considering that the pressure losses increse and you have

to verufy the compability of all the hydraulic parts of all

these compounds;

• In case of long stops completely empty the system opening

all the cocks and pay aenon to avoid water stagnaon

points.

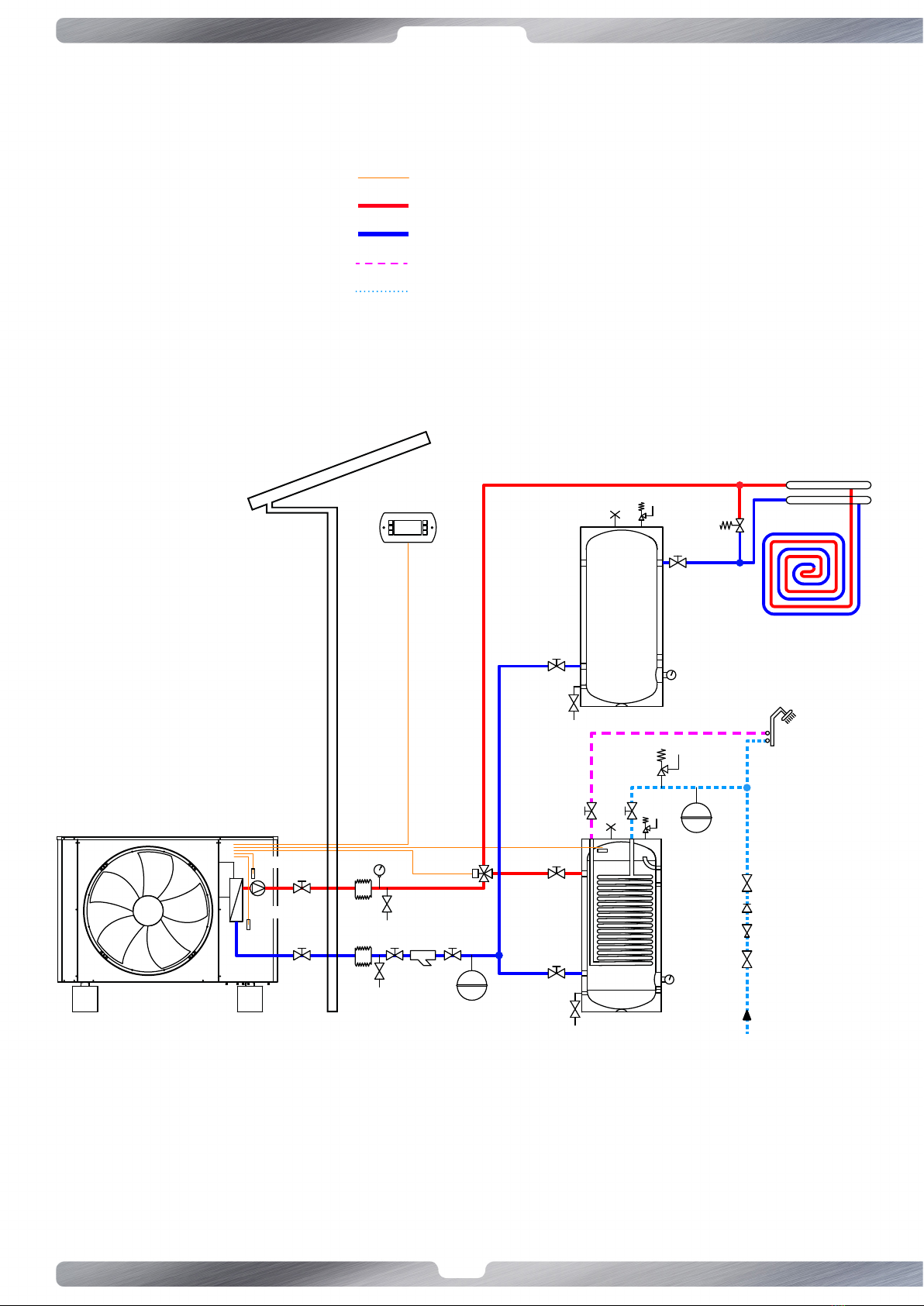

7.4 Choice of the system scheme

Make reference to the schemes shown in the following pages for

the realizaon of the hydraulic system according to your needs

and adapng it to the installaon context.

WARNINGS!

The buer, if on outlet pipe, must always comply with a minimum

quanty of liters according to the heat pump KITA used:

KITA S 200 Liters

KITA M 300 Liters

KITA L 500 Liters

WARNINGS!

If you have a pressure drop of more than 7 meters it is mandatory

to use an increased circulator.

WARNINGS!

Probe B2, when used, must always be placed in a buer mounted

on outlet pipe, never inlet.

WARNINGS!

The following diagrams are purely an example and Templars

s.r.l. will not be responsible for any reason for the plant made at

home. The plant shall be designed and manufactured exclusively

by qualied personnel.

WARNINGS!

For the producon of domesc hot water always use a puer-

type tank with rapid DHW producon or through outside

exchangers, contrary the warranty will be void.

WARNINGS!

it is extremely important that the puer dedicated to domesc

hot water producon, if used, is adequate for the power

produced by the heat pump.

Adequate puer must accumulate technical water, and not

domesc hot water.

pompa di calore ritorno

pompa di calore mandata

heat-pump

outlet DHW

technical

water heang

integraon

solar thermal

technical water

DHW

heat-pump

inlet

SUITABLE

BUFFER EXAMPLE*

heat-pump

outlet

DHW

plate heat

exchanger

instant

producon

DHW

technical water

technical water

heat-pump

inlet

SUITABLE

BUFFER EXAMPLE*

pompa di calore ritorno

pompa di calore mandata

DWH technical

water heang

integraon

heat-pump

outlet

heat-pump

inlet

DWH

NOT SUITABLE BUFFER EXAMPLE*

*

The image is intended only to indicate the main internal components and are

just examples.

Using a not suitable buer causes the compressor warranty to

vanish.

18

www.templari.com

7.5 Scheme 1: Cooling/heang system ad DHW, with buer on return pipes.

In this conguraon, you MUST always keep open at least 25% of the collector area.

The bypass valve must have a broad scope to ensure the proper operaon of the heat pump when the radiant system allows lile

water passage.

PROBE B7

PROBE B4

GA

GA

RD

MA

USER INTERFACE

PROBE B3

COLLECTOR

FY

VE

UE

VE

RD

3W

SIGNAL CABLES

OUT

IN

GA

MA

RD

3W

VE

FY

UE

An�-vibra�on joint

Manometer

Drin tap

3 way valve

Expansion vessel

Y-filter

External unit

DHW

DW

19

www.templari.com

7.6 Scheme 2: Cooling/heang system, with buer on return pipes.

In this conguraon, you MUST always keep open at least 25% of the collector area.

The bypass valve must have a broad scope to ensure the proper operaon of the heat pump when the radiant system allows lile

water passage.

PROBE B7

PROBE B4

GA

GA

RD

MA

USER INTERFACE

COLLECTOR

FY

VE

RD

SIGNAL CABLES

OUT

IN

GA

MA

RD

VE

FY

UE

An�-vibra�on joint

Manometer

Drin tap

Expansion vessel

Y-filter

External unit

20

www.templari.com

7.7 Scheme 3: System only DHW, with buer.

GA

GA

RD

UE

MA

USER INTERFACE

PROBE B3

FY

VE

VE

RD

PROBE B7

PROBE B4

SIGNAL CABLES

OUT

IN

GA

MA

RD

VE

FY

UE

An�-vibra�on joint

Manometer

Drin tap

Expansion vessel

Y-filter

External unit

DHW

DW

This manual suits for next models

11

Table of contents

Other Templari Heat Pump manuals

Popular Heat Pump manuals by other brands

Carrier

Carrier 50ZH Series Product data

ThermoPlus Air

ThermoPlus Air KHPE Series Installation, operation and maintenance manual

emmeti

emmeti MIRAI SMI 4.0 Installation and use manual

Nibe

Nibe F1345 Series operating manual

Kripsol

Kripsol Komfort RC2200 Installation instructions manual

Carrier

Carrier 50PEC09-18 Aquazone Installation, Start-Up and Service Instructions