67

Maintenance and care

The hood must always be disconnected from the electricity supply before

beginning any maintenance work.

C eaning the hood

Clean the outside of the hood using a damp cloth and a mild detergent.

Never use corrosive, abrasive or flammable cleaning products.

Never insert pointed objects in the motors protective grid.

Wash the outside surfaces using a delicate detergent solution. Never use caustic

detergents or abrasive brushes or powders.

Only ever clean the switch panel and filter grille using a damp cloth and delicate

detergents.

It is extremely important to clean the unit and change the filters at the

recommended intervals. Failure to do so will cause grease deposits to build up

that could constitute a fire hazard.

Meta grease fi ter

The purpose of the grease filters is to absorb grease particles which form during

cooking and it must always be used, either in the external extraction or internal

recycling function.

ttention: the metal grease filters must be removed and washed, either by hand or in

the dishwasher, every four weeks.

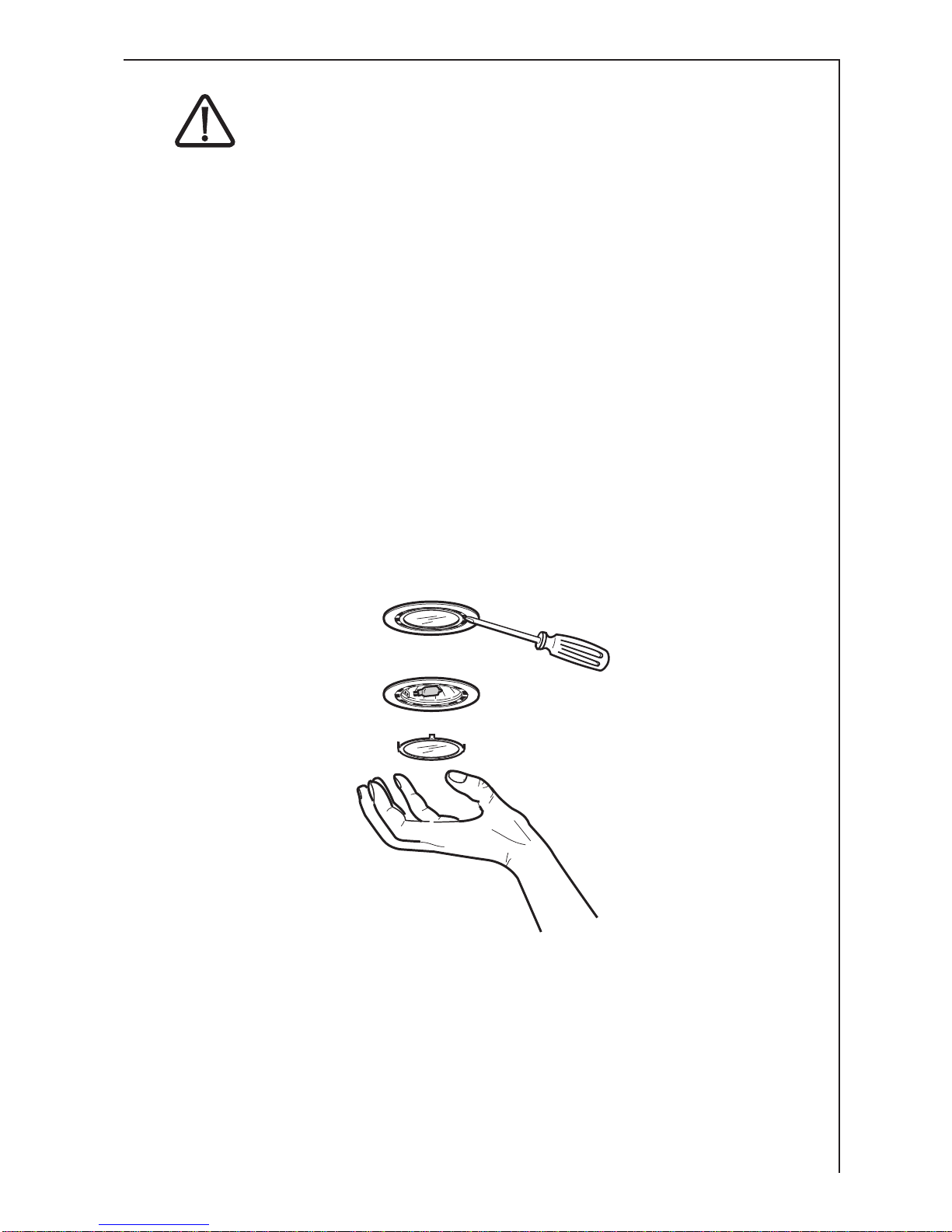

Removing the meta grease fi ter

First, push the metal grease filter stop (f1)

backwards, then extract the filter (f2), pulling

downwards. Fig. 4.

Hand washing

Soak grease filters for about one hour in hot

water with a grease-loosening cleaner, then

rinse off thoroughly with hot water. Repeat the

process if necessary. Refit the grease filters

when they are dry.

Dishwasher

Place grease filters in the dishwasher. Select

most powerful washing programme and highest

temperature, at least 65°C. Repeat the process.

Refit the grease filters when they are dry.

When washing the metal grease filter in the dishwasher a slight discolouration of the

filter can occur, this does not have any impact on its performance.

Clean the inner housing using a hot detergent solution only (never use caustic

detergents, abrasive powders or brushes).

Fig 4

f1

f2