AEM 21-705 User manual

INSTALLATION INSTRUCTIONS

PART NUMBER: 21-705

* NOTE: Legal in California only for racing vehicles which may never be used upon a highway

AEM Induction Systems 1 (800) 992-3000 WWW: http://www.aemintakes.com

2003-2008 TOYOTA 4Runner V6-4.0L SEE

* NOTE

Equipped with AEM®Dryflow™ Filter

No Oil Required!

2

PARTS LIST

Description Qty. Part Number

W

A Hose Clamp #48 3 08601

B Hose, Silicone 3.00x2” Black 1 5-302

C Tube; 03-08 4runner 4.0L 1 2-1468

D Hose; 4mm ID X 18” L 1 08153

E Bolt; Socket 8-32 X 5/16 SS 2 1-2023

F Bolt; M6-1.00 X 16mm Hex Hd. 5 07703

G Washer; 1/4” Lock, Zn 2 08198

H Washer; 1/4”ID X 5/8”OD - SAE 8 08275

I Bracket; Mild Stl., TB/PC 1 07133

J Heat Shield; Mild Stl, TB/PC 1 074005

K Edge Trim; 3/4 Bulb, Top Loc, 83”L 1 102503

L Nut; 6mm Nylock, Hexhead 3 07553

M Bracket; Med “U”, Mild Stl, TB/PC 1 07171

N Bracket; Med. “U”, Mild Stl, TB/PC 1 07172

O Bracket; Sm.”L”, Mild Stl. TB/PC 1 07158

P Bolt; 8mm-1.25 X 16mm, Hexhead 2 07844

Q Washer; 8mm Spring (Wave) 2 08239

R Washer; 5/16”ID X 5/8”OD, Flat 2 08276

S Hose, Adapter 3.00/3.50x3 Blk. 1 5-353

T Hose Clamp #56 1 08620

U Adapter, A/F 1 9-P4510832

V Element Parts Kit; Dry Flow 6”B X 6”H 1 21-210EDK

W Hose Clamp #104 1 08697

3

1. Preparing Vehicle

a.Make sure vehicle is parked on level surface.

b.Set parking brake.

c. If engine has run in the past two hours, let it cool down.

d.Turn off the ignition and disconnect the negative battery cable.

e.Do not discard stock components after removal of the factory system.

2. Removal of stock system

Read and understand these instructions BEFORE attempting to install this product. Failure

to follow installation instructions and not using the provided hardware may damage the intake

tube, throttle body and engine.

a. Loosen the two nuts that secure the engine cover,

then remove the engine cover. b. Loosen the hose clamps at the airbox and resonator.

c. Pull wire harness clip up to release from intake tube. d. Remove intake tube from vehicle as shown.

4

e. Remove the two bolts that secure the resonator to

the inner fender, then remove resonator from vehicle as

shown.

f. Disconnect the two mass air wire harnesses retaining

clips from the airbox, then disconnect the mass air

sensor electrical connection.

g. Remove the crankcase vent hose from the airbox as

shown. h. Remove the fuel pressure regulator hose from the

back side of airbox.

i. Loosen the hose clamp at the throttle body, then re-

move the two bolts that secure the airbox to the engine. j. Remove the airbox assembly from engine as shown.

5

k. On vehicles equipped with the A/C mounting bracket,

remove the A/C mounting bracket and loosen the nut.

Then, remove the power steering reservoir mounting

bolt.

NOTE: The power steering reservoir bolt will be

re-used.

l. Rotate the A/C mounting bracket onto the power

steering reservoir, then secure it using the bolt from the

previous step. Tighten the A/C mounting nut.

m. Remove the 12mm bolt that retains the power steer-

ing reservoir to the vehicle, then mount the provided

bracket (07158) onto the vehicle with the bolt that was

removed.

6

d. Install the heat shield onto the vehicle, then secure

the brackets with the provided hardware. e. Remove the crankcase vent hose from the valve

cover.

f. Flip the crankcase vent hose around and reconnect

the opposite end of the hose to the valve cover. g. Install the provided silicone hose (5-302) onto the

throttle body with the provided hose clamps.

b. Mount the two provided brackets onto the vehicle

with the provided hardware.

NOTE: Bracket (07172) mounts closest to engine.

c. Install the edge trim onto the heat shield as shown.

Trim if needed.

3. Installation of AEM®Intake System

a.When installing the intake system, do not completely tighten the hose clamps or mounting hardware until instructed

to do so.

7

j. Remove the engine cover mounting stud shown from

the factory airbox. k. Install the stud removed in step #23 into the threaded

boss on the AEM® intake tube as shown.

l. Install the tube mounting bracket (07133) onto the

AEM® intake tube as shown. m. Install the AEM®intake tube onto the throttle body,

align the mounting bracket with the threaded boss on

the engine valve cover and then secure with the pro-

vided hardware and hose clamp.

h. Remove the two screws that secure the mass air

sensor to the airbox assembly, then remove the mass

air sensor as shown.

i. Secure the mass air sensor to the AEM® intake tube

using the provided bolts as shown.

8

p. Install the filter adapter into the air filter as shown,

secure with the provided hose clamp. q. Install the provided silicone hose (5-353) onto the

filter adapter and secure with the provided hose clamp

as shown.

r. Install the air filter assembly onto the AEM®intake

tube and secure with the provided hose clamp. s. Reinstall the engine cover using the original nuts

removed in step 2a.

n. Remove the stock vacuum hose from fuel pressure

regulator. Install the provided silicone hose, attaching

the hose to the fuel pressure regulator and the AEM®

intake tube nipple.

o. Connect the factory crankcase vent hose onto the

AEM®intake tube as shown.

9

t. Reconnect the mass air sensor electrical connection. u. Reconnect the vehicle’s negative battery cable.Dou-

ble check to make sure everything is tight and properly

positioned before starting the vehicle.

4. Reassemble Vehicle

a. Position the inlet pipes for the best fitment. Be sure that the pipes or any other components do not contact any part

of the vehicle. Tighten the rubber mount, all bolts, and hose clamps.

b. Check for proper hood clearance. Re-adjust pipes if necessary and re-tighten them.

c. Inspect the engine bay for any loose tools and check that all fasteners that were moved or removed are properly

tightened.

d. Reconnect the negative battery terminal and start the engine. Let the vehicle idle for 3 minutes. Perform a final

inspection before driving the vehicle.

5. Service and Maintenance

a. It is recommended that you service yourAEM®Dryflow™ filter every 20,000 miles for optimum performance. Use

AEM Dryflow cleaning kit part # 21-110.

b. Use aluminum polish to clean your polishedAEM®intake tube.

c. Use window cleaner to clean your powder coatedAEM®intake tube. (NOTE: DO NOT USE aluminum polish on

powder coated AEM intake tubes).

For technical inquiries

e-mail us at

or

call us at

800.992.3000

10

AEM Air Intake System Warranty Policy

AEM®warrants that its intake systems will last for the life of your vehicle. AEM will not honor this warranty due to mechani-

cal damage (i.e. improper installation or fitment), damage from misuse, accidents or flying debris. AEM will not warrant

its powder coating if the finish has been cleaned with a hydrocarbon-based solvent. The powder coating should only be

cleaned with a mild soap and water solution. Proof of purchase of both the vehicle and AEM intake system is required for

redemption of a warranty claim.

This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty exceed the original

purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential damages or cost

incurred due to the failure of this product. Warranty claims to AEM must be transportation prepaid and accompanied with

dated proof of purchase. This warranty applies only to the original purchaser of product and is nontransferable. Improper

use or installation, use for racing, accident, abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims

any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by

AEM. Warranty returns will only be accepted by AEM when accompanied by a valid Return Merchandise Authorization

(RMA) number. Credit for defective products will be issued pending inspection. Product must be received by AEM within

30 days of the date RMA is issued.

If you have a warranty issue, please call (800) 992-3000 and our customer service department will assist you. A proof of

purchase is required for all AEM warranty claims.

10-290

09/28/11

Table of contents

Other AEM Automobile Part manuals

Popular Automobile Part manuals by other brands

BBK

BBK POWER-PLUS SERIES installation instructions

BENDIX

BENDIX ET-S SUSPENDED ELECTRON TREADLE manual

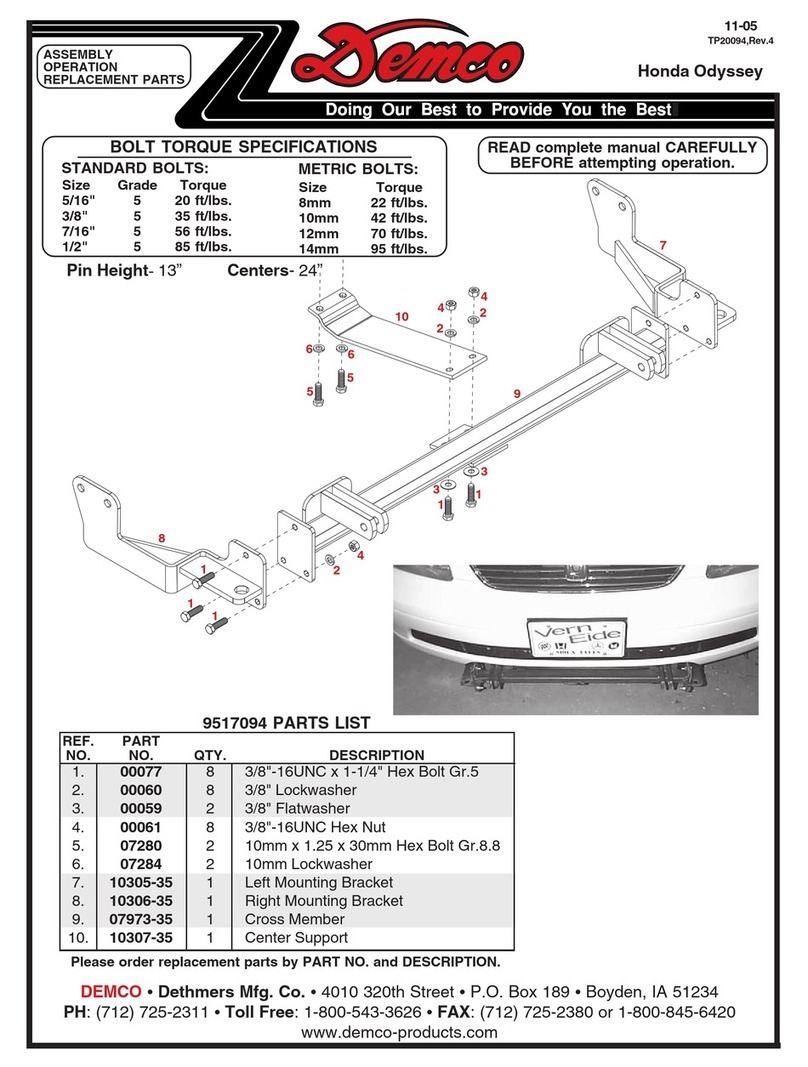

Demco

Demco TP20094 Assembly/operators/parts manual

Edelbrock

Edelbrock 17930 installation instructions

Fabtech

Fabtech FTS8001 instructions

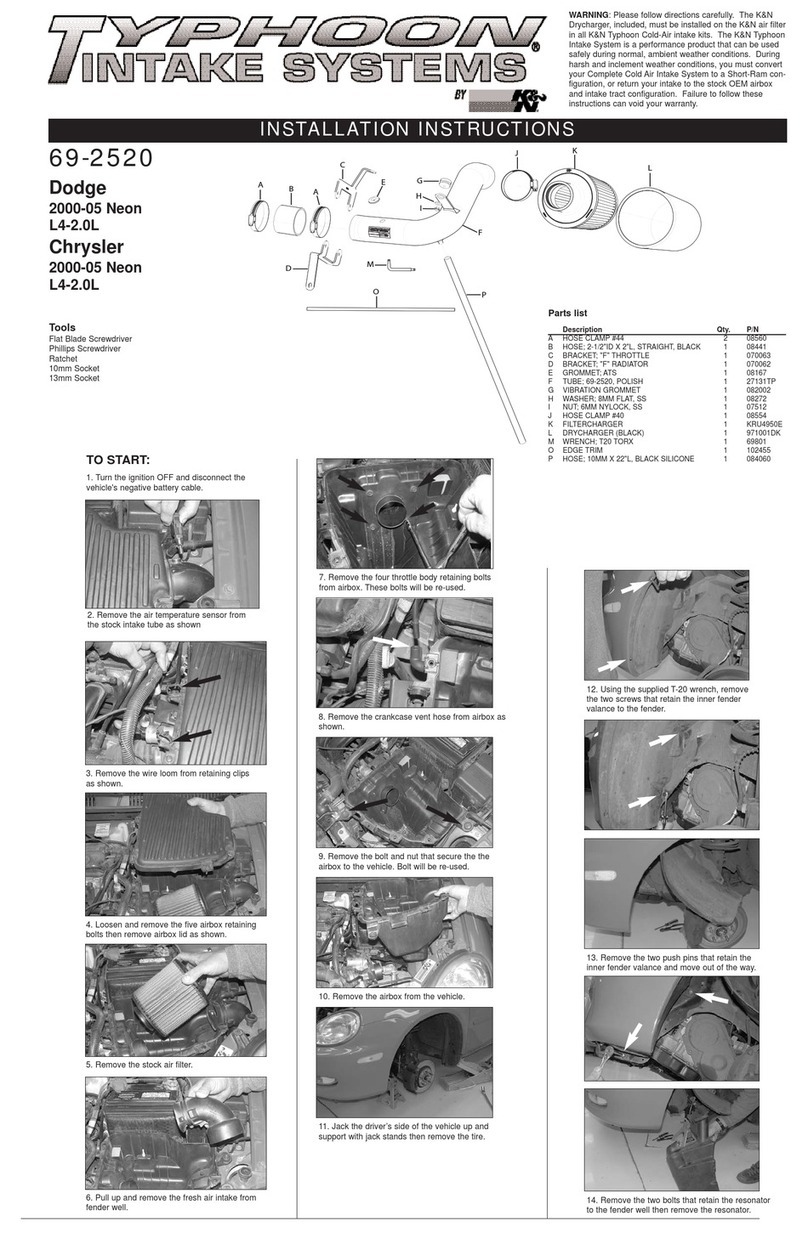

K&N Engineering

K&N Engineering Typhoon 69-2520 installation instructions

U.S. General

U.S. General 98135 Set up and operating instructions

ICON

ICON 51201 installation instructions

injen technology

injen technology SP1381 quick start guide

Murphy

Murphy Digital Tach/Hourmeter with Overspeed Trip Point... Specifications

Edelbrock

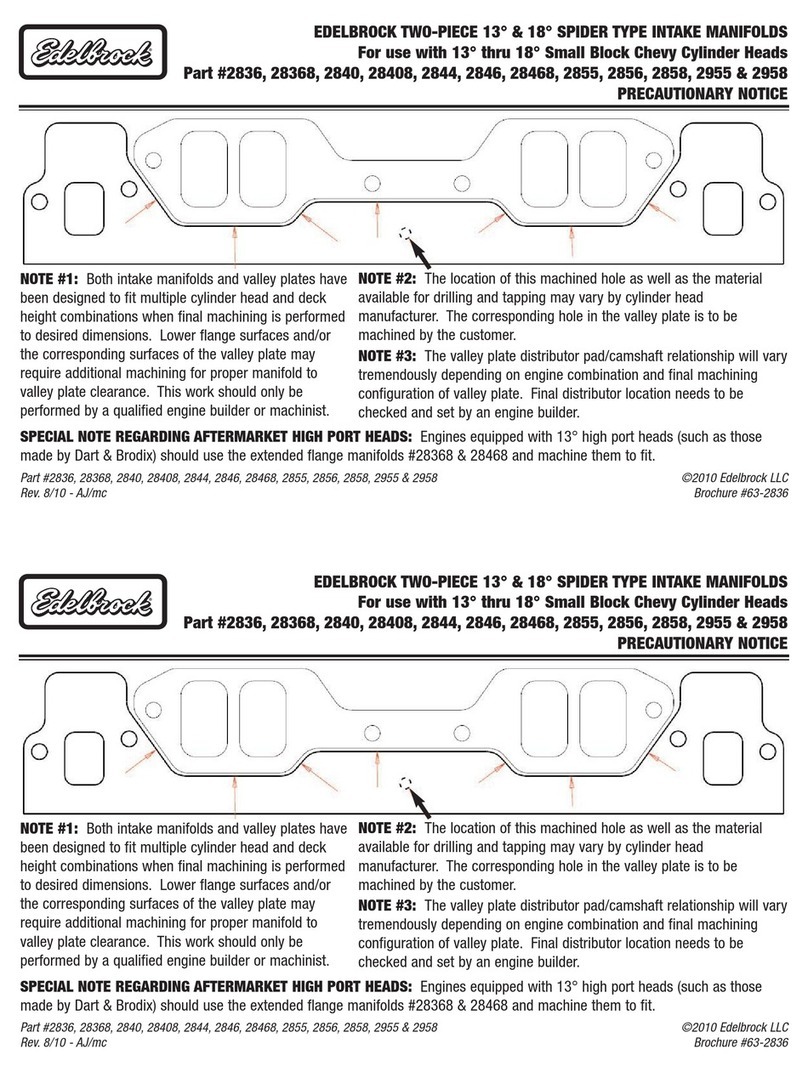

Edelbrock Victor Glidden 18 2858 Notice

Kal-Equip

Kal-Equip 2501 Instructions for use