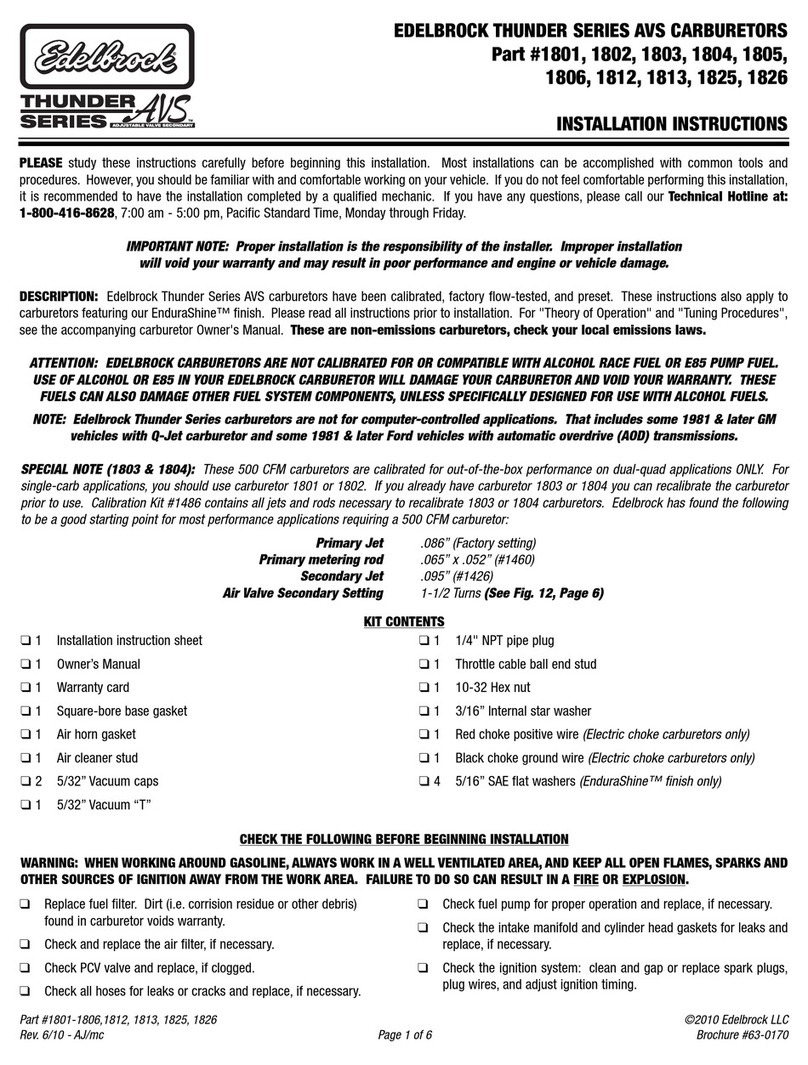

!"#$%&'()*#%+!,-.,

/00120.%34'&5"6%76)'#8&%%%%%%%%%%

/90:%1%;4<9

!"#$%#&'()#*+,-.'#/0/,'1################2345

!"#-=%>4&8%2$'&*5%?6<$*#%%%%%%%%%%%%%%%%@A,0,BC

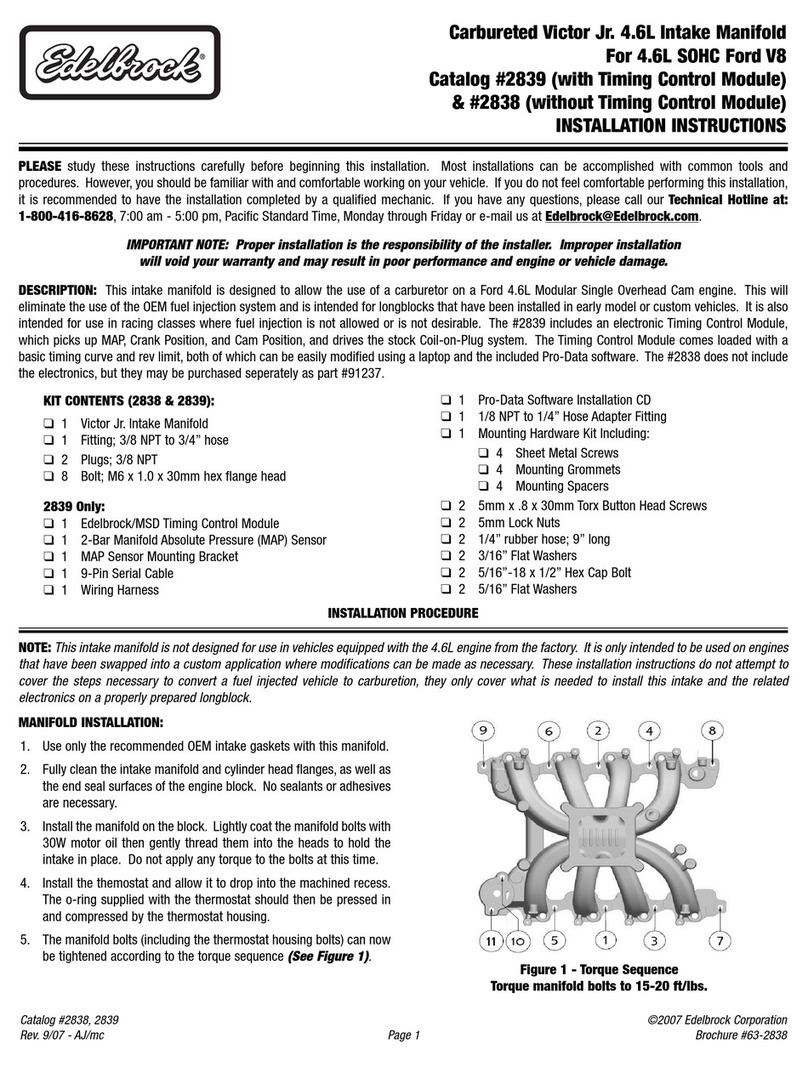

2- 2 3/4” x 3” step hose (#3040)

2- 2 3/4” straight hose (#3043)

6- Power-bands (.312)(.040) (#4003)

2- Power-bands (.362)(.048) (#4004)

1- 6mm vibra-mount (#6020)

1- 6mm flange nut (#6002)

1- fender washer (#6010)

1- 13” vinyl trim (#6023)

1- 5 page instruction

D8$*E 466#7-8,/#-+9#-(('//:8*'/#-8'

-;-*6-<6'#:+"6*+'=##&80#:>8#+'?

@8:"&'()#A*6,'8#()-8B'8#.*,#-+9

C098:"/)*'69=

/:69#:+"6*+'#-,D

F6&G*&8&<6&*9;8(=

+8<5%8&2<6&*%6H%$I*%345#82HI6*<5J%("5*%$8%

*&I"&;*%$I*%<6?*%8?%$I*%?6<$*#9

!"#$%A%,0-K

L8&M#"$'<"$68&HN%O8'%I"P*%G'H$%Q'#;I"H*5%$I*%)*H$%*&M6&**#*5J

54&82Q#8P*&%;8<5%"6#%6&$"R*%H4H$*(%"P"6<")<*9

!<*"H*%;I*;R%$I*%;8&$*&$H%8?%$I6H%)8S%6((*56"$*<49

%'7:8,#-+0#9'A'(,*;'#:8#1*//*+B#7-8,/#,:#,)'#4>,):8*E'9#F+G'+#

&'()+:6:B0#9'-6'8#0:>#7>8()-/'9#,)*/#78:9>(,#A8:1=

H'A:8'#*+/,-66*+B#-+0#7-8,/#:A#,)*/#/0/,'1I#76'-/'#8'-9#,)'#*+/,8>(,*:+/

,):8:>B)60=##FA#0:>#)-;'#-+0#J>'/,*:+/#8'B-89*+B#*+/,-66-,*:+#76'-/'

(:+,-(,#,)'#9'-6'8#0:>#7>8()-/'9#,)*/#78:9>(,#A8:1=

F+/,-66-,*:+#KLMN#8'J>*8'#/:1'#1'()-+*(-6#/.*66/=##4#J>-6*A*'9

1'()-+*(#*/#-6?-0/#8'(:11'+9'9=

OK:#+:,#-,,'17,#,:#*+/,-66#,)'#*+,-.'#/0/,'1#?)*6'#,)'#'+B*+'#*/#):,=

&)'#*+/,-66-,*:+#1-0#8'J>*8'#8'1:;-6#:A#8-9*-,:8#A6>*9#6*+'#,)-,#1-0

<'#):,=

F+G'+#&'()+:6:B0#:AA'8/#-#6*1*,'9#6*A',*1'#?-88-+,0#,:#,)'#:8*B*+-6

7>8()-/'8#-B-*+/,#9'A'(,/#*+#1-,'8*-6/#-+9#?:8.1-+/)*7=#P-88-+,0

(6-*1/#1>/,#<'#)-+96'9#,)8:>B)#,)'#9'-6'8#A8:1#?)*()#,)'#*,'1#?-/

7>8()-/'9=##

F+G'+#&'()+:6:B0##QRR#@*:+''8#@6-('#@:1:+-I#34#S!TUV#WN4

Please check the contents of this box immediately.

Note: This intake system was Dyno-tested with an Injen filter and

Injen parts. The use of any other filter or part will void the

warranty and CARB exemption number.

Parts and accessories are available on line at “Injenonline.com”

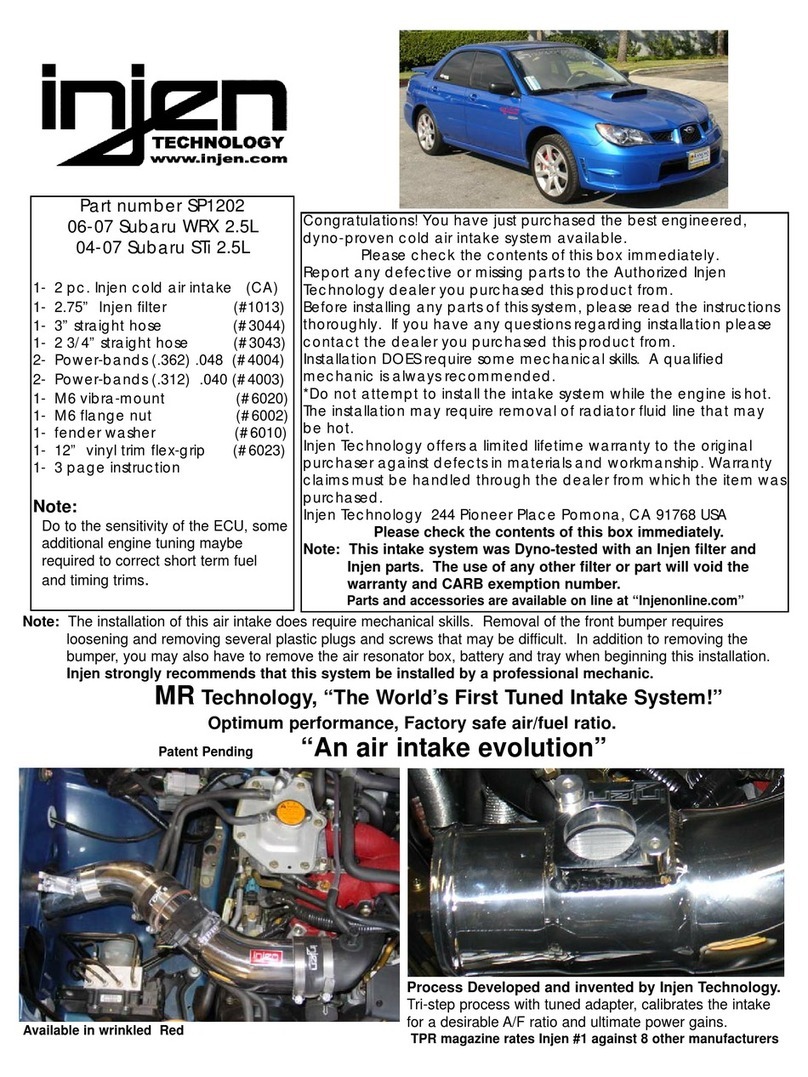

Note: The installation of this cold air intake does require mechanical skills. Removal of the front bumper requires

loosening and removing several plastic plugs and screws that may be difficult. In addition to removing the

bumper, you will also have to remove the air resonator box, battery and tray when beginning this installation.

Injen strongly recommends that this system be installed by a professional mechanic.

MR Technology, “The World’s First Tuned Intake System!”

Optimum performance, Factory safe air/fuel ratio.

Tools required:

1- 8mm socket

1-10mm socket

1- ratchet

1- Phillips screwdriver

1- Flat head screwdriver

Install time: 1 1/2 Hours

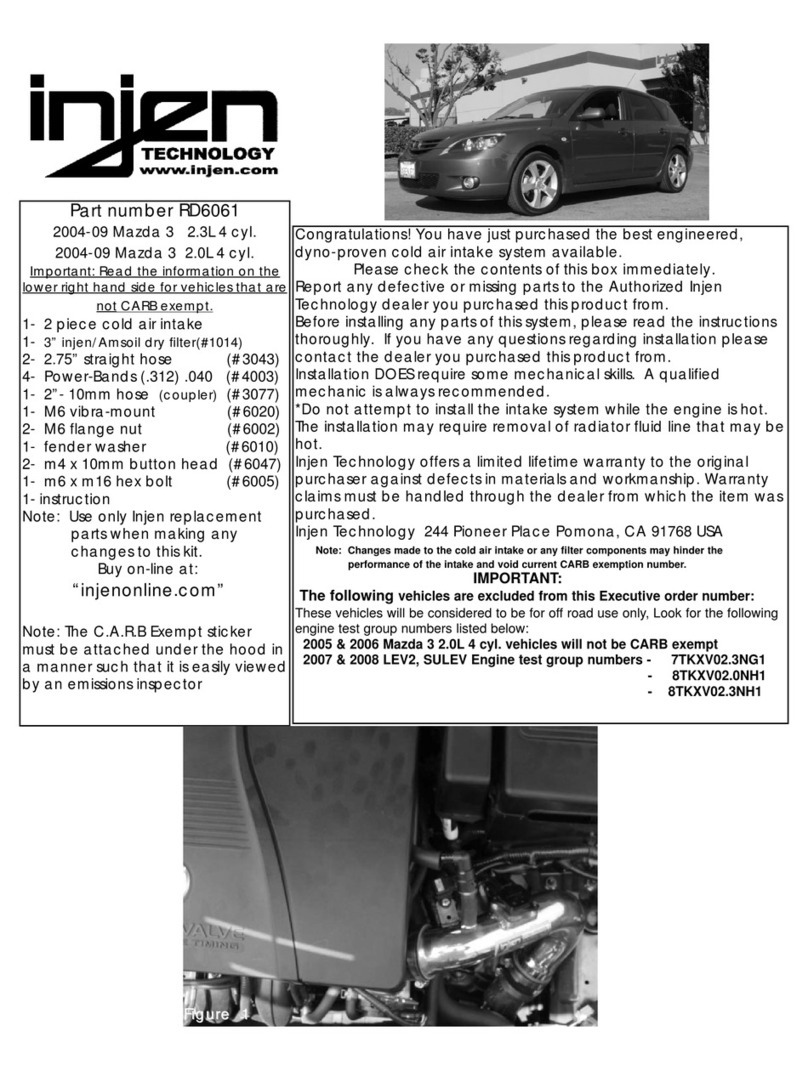

Figure 1

Contents: