AEM 21-718 User manual

Equipped with AEM Dryflow Filter

No Oil Required!

INSTALLATION INSTRUCTIONS

AEM Inducon Systems 1 (800) 992-3000 WWW: hp://www.aemintakes.com

*NOTE: Legal in California only for racing vehicles which may never be used upon a highway

PART NUMBER: 21-718

2012-13 HYUNDAI ELANTRA 1.8L SEE*NOTE

2

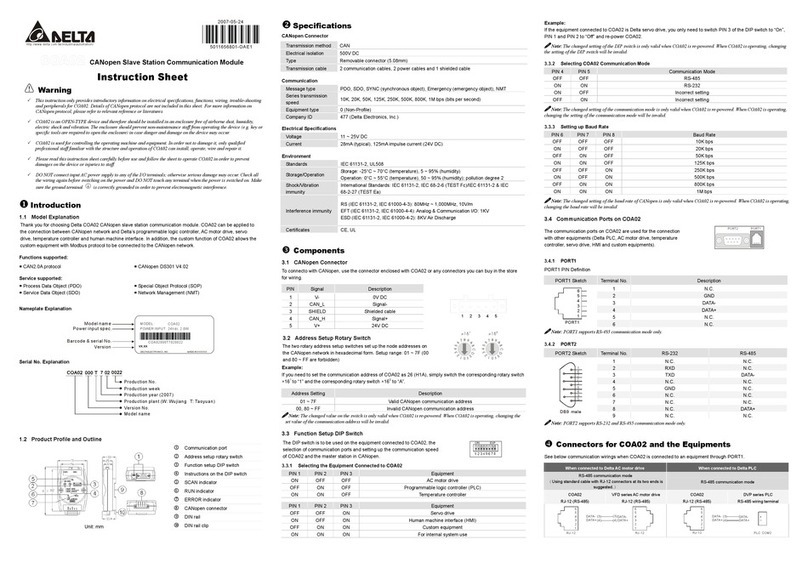

PARTS LIST

Description Qty. Part Number

ATUBE, INTAKE, 2012 HYUNDAI ELANTRA 1.8L 12-1496

BMOUNT, INSULATED, M6 X 0.625 11228598

CWASHER, FLAT, M6 X 1.0 DIA. 108160

DNUT, HEX, FLANGED M6-1.0 1444.460.04

EHOSE, COUPLER, SILICONE 2.75” DIA X 3.0 15-275

F1/2” BNDHOSE CLAMP, #48, 2.56”-3.50” DIA. 39444

GAIR FILTER ELEMENT ASSY. 2.75 X 5.0” OFFSET 121-202DOSK

3

Read and understand these instructions BEFORE attempting to install this product. Failure to follow

installation instructions and not using the provided hardware may damage the intake tube, throttle body and

engine.

The AEM intake system is a performance product that can be used safely during mild weather conditions.

During harsh and inclement weather conditions, you must return your vehicle to stock OEM airbox and intake

tract configuration. Failure to follow these instructions will void your warranty.

1. Preparing Vehicle

a. Make sure vehicle is parked on a level surface.

b. Set parking brake.

c. If engine has run in the past two hours, let it cool down.

d. Disconnect negative battery terminal.

e. Do not discard stock components after removal of the factory system.

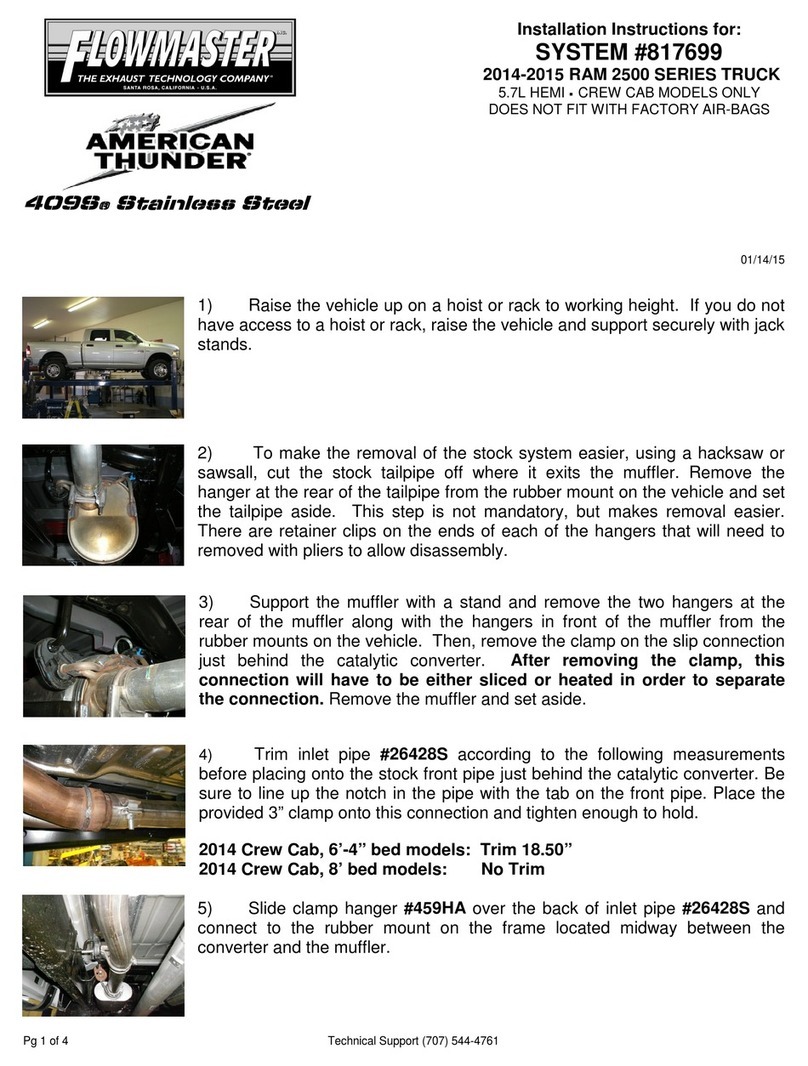

A. Open vehicle hood. Remove the plasc engine

cover.

B. Disconnect the breather return hose at the stock

intake tube.

2. Removal of stock system

C. Disconnect PCV hose on top of the valve cover

and pull it aside to expose the hose clamp at the

throle body below.

D. Loosen the hose clamp at the throle body.

4

E. Unfasten the airbox clamps and remove the

stock airbox lid and intake tube.

I. Using a #2 Phillips screwdriver, unscrew the 2

plasc clips retaining the plasc underside brush

guard to the front bumper on the driver’s side,

then remove the clips.

F. Remove the stock air lter. Do not discard.

G. Remove the 3 M6 mounng bolts with a 10mm

socket. Slide the lower airbox housing to the le

and remove it from the engine bay.

H. Depress the center buons of the two plasc

clips retaining the stock intake scoop to the radia-

tor support. Pull up on the clips to remove them,

then remove the stock intake scoop.

J. Raise the vehicle safely and remove the le front

(driver’s side) wheel. Make sure to set the parking

brake, chock the rear wheels, and use proper jack

stands before working under the vehicle.

5

K. Unscrew and remove the 3 front plasc clips

retaining the drivers’ side fender liner. Pull the

fender liner aside to expose the stock intake silenc-

er.

L. Inside the wheel well area, remove the 3 M6

bolts retaining the intake silencer to the frame

support.

M. Under the hood, remove the 4th and nal M6

bolt retaining the intake silencer to the frame sup-

port.

N. Lower and remove the large intake silencer from

the wheel well.

O. The stock intake silencer.

6

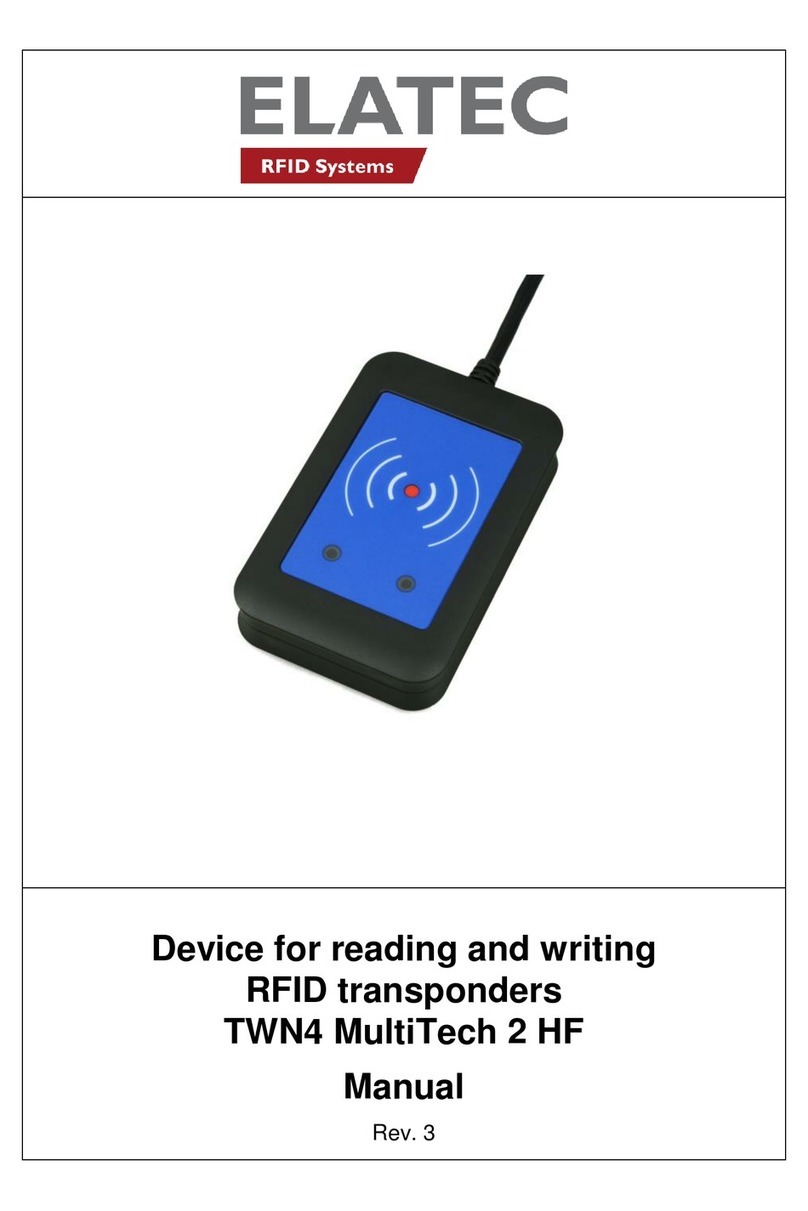

D. Then insert the outlet end of the intake tube

into the silicone hose at the throle body.

C. Carefully install your new AEM Cold Air Intake

tube (A) by rst inserng the inlet into the fender

well access hole and aligning the bracket mount to

the insulated M6 mounng stud as shown.

A. Install two #48 hose clamps (F) onto the silicone

hose (E), then install the hose over the throle body

ange. Tighten the hose clamp over the throle

body ange and leave the other clamp loose.

B. Install the insulated M6 mounng stud (B) into

the fender well and fully ghten by hand. Use the

M6 threaded hole to the le of the hole actually

used to mount the stock air box.

3. Installation of AEM Intake System

a. When installing the intake system, do not completely tighten the hose clamps or mounting hardware until

instructed to do so.

7

E. Loosely install the at washer (C) and M6

anged hex nut (D) over the M6 mounng stud as

shown. Do not ghten yet.

H. If you drive regularly in inclement weather, con-

sider installing an AEM® Pre-Filter Wrap to protect

your Dryow™ lter for added peace of mind. See

www.aemintakes.com for more info.

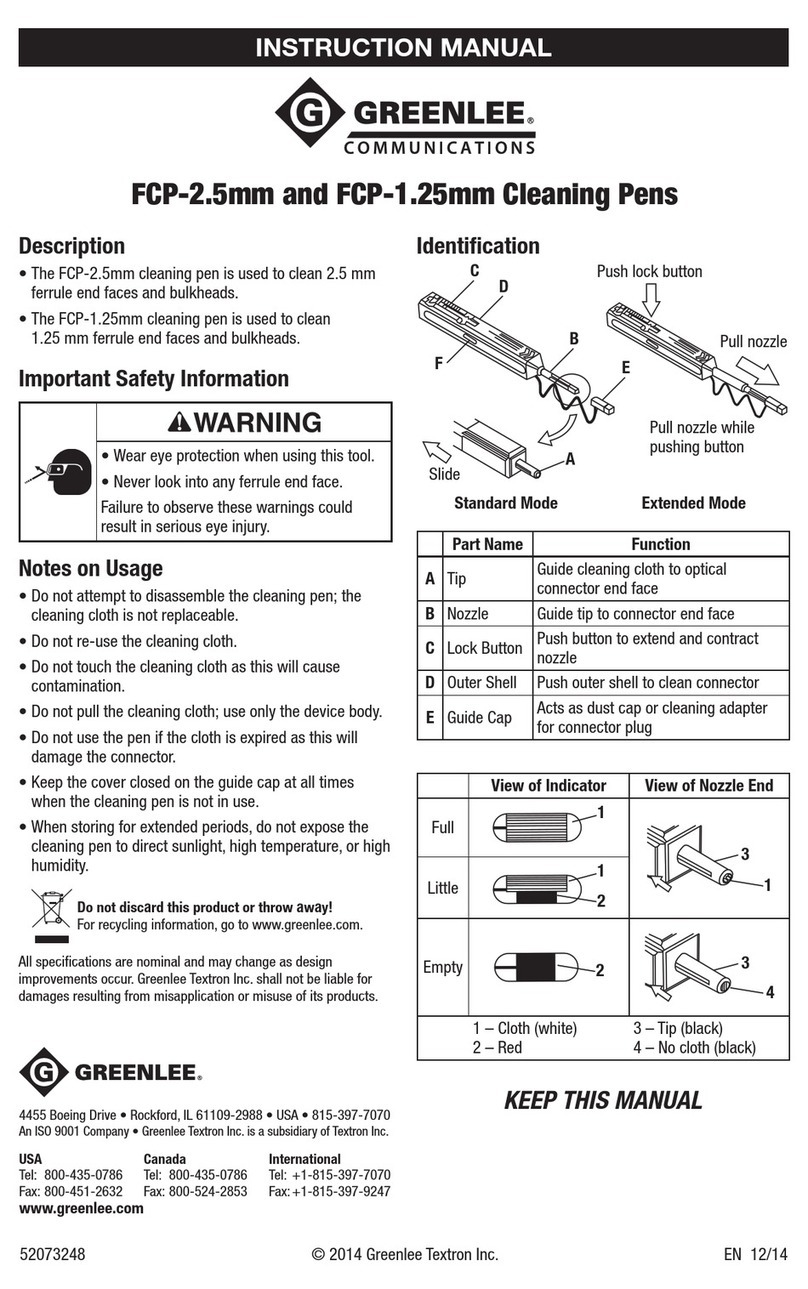

G. Inside the fender well, mount your new AEM® Dry-

ow™ Air Filter (G) onto the intake tube inlet. Rotate

the oset lter to clear the fog lamp and the wheel

well cover, and then secure with the hose clamp.

F. Once properly seated, ghten the second hose

clamp at the intake tube outlet connected to the

throle body.

G. Connect the breather hose onto the intake tube

at the breather nipple using the stock clamp as

shown.

F. Re-connect the PCV hose at the valve cover.

3/20/2013 810-407

I. Reposion the plasc fender liner and brush

guard under the bumper, and then re-install the 5

plasc clips you removed earlier. You can simply

push them into each hole to lock in place.

AFTER: AEM 21-718 Cold Air Intake System.

BEFORE: The stock intake system.

J. Now fully ghten the M6 hex nut (D) at the

mounng bracket to secure the pipe into place.

K. Re-install the driver’s side wheel and torque

down the lug nuts to the factory specicaons

found in your Vehicle Owner’s Manual using a

torque wrench.

L. Re-install the stock engine cover.

3/20/2013 910-407

4. Reassemble Vehicle

a. Position the inlet pipes for the best fitment. Be sure that the pipes or any other components do not contact

any part of the vehicle. Tighten any rubber mounts (if applicable), all bolts, and hose clamps.

b. Check for proper hood clearance. Re-adjust pipes if necessary and re-tighten them.

c. Inspect the engine bay for any loose tools and check that all fasteners that were moved or removed are

properly tightened.

d. Reconnect the negative battery terminal and start the engine. Let the vehicle idle for 3 minutes. Perform

final inspection before driving the vehicle.

5. CARB Sticker Placement

a. The C.A.R.B. exemption sticker, (attached), must be visible under the hood so than an emissions inspector

can see it when the vehicle is required to be tested for emissions. California requires testing every two

years, other states may vary.

6. Service and Maintenance

a. AEM® Induction Systems requires cleaning the intake system’s Dryflow™ air filter element every 100,000

miles. When used in dusty or off-road environments, our filters will require cleaning more often. We recom-

mend that you visually inspect your filter once every 25,000 miles to determine if the screen is still visible.

When the screen is no longer visible some place on the filter element, it is time to clean it. To clean, pur-

chase our Synthetic Air Filter Cleaner, part number 1-1000 and follow the easy instructions.

b. Use window cleaner to clean your powder coated AEMintake tube. NOTE: DO NOT USE aluminum

polish on powder coated AEM intake tubes.

For Technical inquiries

E-mail us at

Or

Call us at

800.992.3000

AEM Air Intake System Warranty Policy

AEM warrants that its intake systems will last the life of your vehicle. AEM will not honor this warranty due to

mechanical damage (i.e. improper installation or fitment), damage from misuse, accidents or flying debris. AEM will not

warrant its powder coating if the finish has been cleaned with a hydrocarbon-based solvent. The powder coating should

only be cleaned with a mild soap and water solution. Proof of purchase of both the vehicle and AEM intake system is

required for redemption of a warranty claim.

This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty exceed the original

purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential damages or cost

incurred due to the failure of this product. Warranty claims to AEM must be transportation prepaid and accompanied

with dated proof of purchase. This warranty applies only to the original purchaser of product and is nontransferable.

Improper use or installation, use for racing, accident, abuse, unauthorized repairs or alterations voids this warranty.

AEM disclaims any liability for consequential damages due to breach of any written or implied warranty on all products

manufactured by AEM . Warranty returns will only be accepted by AEM when accompanied by a valid Return

Merchandise Authorization (RMA) number. Credit for the defective products will be issued pending inspection. Product

must be received by AEMwithin 30 days of the date RMA is issued.

If you have a warranty issue, please call (800) 992-3000 and our customer service department will assist you. A proof of

purchase is required for all AEMwarranty claims.

Table of contents

Other AEM Other manuals

Popular Other manuals by other brands

HEIDENHAIN

HEIDENHAIN POSITIP 8000 operating instructions

Redi-Chek

Redi-Chek ET-808C instruction manual

Painless Performance Products

Painless Performance Products 10106 installation instructions

ZKTeco

ZKTeco SC700-T user manual

Hilka

Hilka 84991253 instruction manual

Bosch

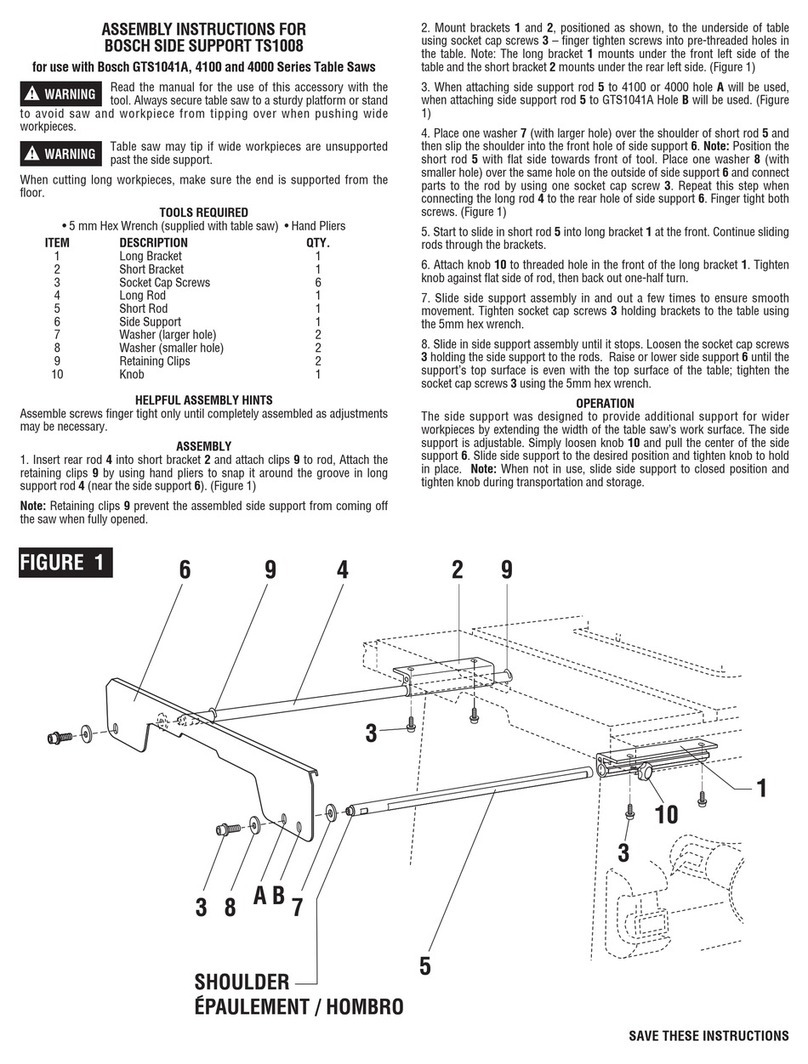

Bosch TS1008 Assembly instructions