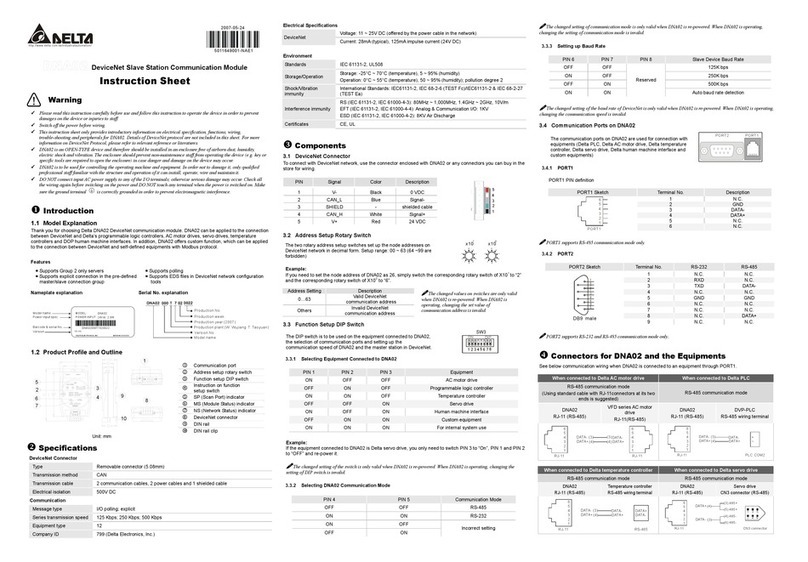

When connected to Delta temperature controller When connected to Delta servo drive

RS-485 communication mode RS-485 communication mode

COA02

RJ-12 (RS-485)

DTA series temperature

controller

RS-485 wiring terminal

COA02

RJ-12 (RS-485)

ASDA series servo drive

CN3 connector (RS-485)

(3)

(4)

1

2

3

4

5

6

DATA-

DATA+

DATA-

(4)

(3)

1

2

3

4

5

6

(5) 485+

(4) 485-

(6) 485-

When connected to Delta human machine interface

RS-485 communication mode

COA02

RJ-12 (RS-485)

DOP series HMI

DB9 connector (RS-485)

DATA+

DATA-

(4)

(3)

1

2

3

4

5

6

RJ-12

(3) 485+

(1) 485-

(4) 485-

See below communication wirings when COA02 is connected to an equipment through PORT2.

When connected to Delta AC motor drive When connected to Delta temperature controller

RS-485 communication mode RS-485 communication mode

COA02

DB9 female (RS-485)

VFD series AC motor drive

RJ-12 (RS-485)

COA02

DB9 female (RS-485)

DTA series temperature

controller

RS-485 wiring terminal (RS-485)

(3)

(8)

5

9

4

8

3

7

2

6

1

1

2

3

4

5

6

(3)

(4)

DATA-

DATA+

(3)

(8)

5

9

4

8

3

7

2

6

1

DATA-

When connected to Delta PLC

RS-232 communication mode

(Using standard communication cable

DVPACAB215/DVPACAB230 is suggested)

RS-485 communication mode

COA02

DB9 female (RS-232)

DVP series PLC

8 pin Mini DIN male (RS-232)

COA02

DB9 female (RS-485)

DVP series PLC

RS-485 wiring terminal (RS-485)

5

9

4

8

3

7

2

6

1

TX

RX

RXD

TXD

(2)

(3)

GND (5)

(5)

(4)

(8)GND

DATA-

DATA+

(3)

(8)

5

9

4

8

3

7

2

6

1

When connected to Delta servo drive

RS-232 communication mode RS-485 communication mode

COA02

DB9 female (RS-232)

ASDA series servo drive

CN3 connector (RS-232)

COA02

DB9 female (RS-485)

ASDA series servo drive

CN3 connector (RS-485)

5

9

4

8

3

7

2

6

1

TX

RX

RXD

TXD

(2)

(3)

GND

(5)

(2)

(4)

(1)GND

5

9

4

8

3

7

2

6

1

DATA+

DATA-

(8)

(3)

(5) 485+

(4) 485-

(6) 485-

When connected to Delta human machine interface

RS-232 communication mode RS-485 communication mode

COA02

DB9 female (RS-232)

DOP series HMI

DB9 connector (RS-232)

COA02

DB9 female (RS-485)

DOP series HMI

DB9 connector (RS-485)

5

9

4

8

3

7

2

6

1

TX

RX

RXD

TXD

(2)

(3)

GND

(5)

(3)

(2)

(5)GND

5

9

4

8

3

7

2

6

1

DATA+

DATA-

(8)

(3)

(3) 485+

(1) 485-

(4) 485-

Communication between COA02 and the Equipments

COA02 is able to read, write and set up the parameters of all equipments (Delta PLC, AC motor drive, servo drive,

temperature controller, HMI and custom equipments).

5.1 Setting up Baud Rate and Format (when connected to AC motor drive)

Before connecting Delta AC motor drive to the BUS, first set up the communication address of the AC motor drive

as 01, baud rate as 38,400bps and communication format as 8, N, 2; RTU (the format is fixed; other formats will

be invalid). To adjust the baud rate, follow the steps listed below.

Set up the DIP switch of COA02 to custom equipment mode.

Connect COA02 to the BUS of CANopen and enable the operation of COA02.

Modify the index parameter 5003/02 (main index: H5003, sub index H02).

1. 5003/02 = 1 →19,200; 8, N, 2; RTU

2. 5003/02 = 2 →38,400; 8, N, 2; RTU (default)

Return the DIP switch of COA02 back to AC motor drive mode and re-power COA02.

Adjust the baud rate of the AC motor drive to the corresponding one.

5.2 Setting up Baud Rate and Format (when connected to PLC)

Before connecting Delta PLC to the BUS, first set up the communication address of the PLC as 01, baud rate as

115,200bps and communication format as 7, E, 1; ASCII (the format is fixed; other formats will be invalid). To

adjust the baud rate, follow the steps listed below.

Set up the DIP switch of COA02 to custom equipment mode.

Connect COA02 to the BUS of CANopen and enable the operation of COA02.

Modify the index parameter 5003/03 (main index: H5003, sub index: H03).

1. 5003/03 = 1 →19,200; 7, E, 1; ASCII

2. 5003/03 = 2 →38,400; 7, E, 1; ASCII

3. 5003/03 = 3 →57,600; 7, E, 1; ASCII

4. 5003/03 = 4 →115,200; 7, E, 1; ASCII (default)

Return the DIP switch of COA02 back to PLC mode and re-power COA02.

Adjust the baud rate of the PLC to the corresponding one.

5.3 Setting up Baud Rate and Format (when connected to temperature controller)

Before connecting Delta temperature controller to the BUS, first set up the communication address of the

temperature controller as 01, baud rate as 38,400bps and communication format as 7, E, 1; ASCII (the format is

fixed; other formats will be invalid). Before communicating with DTA series temperature controller, first set the

content of H471A as H0001 to allow the write-in of communication. To adjust the baud rate, follow the steps listed

below.

Set up the DIP switch of COA02 to custom equipment mode.

Connect COA02 to the BUS of CANopen and enable the operation of COA02.

Modify the index parameter 5003/04 (main index: H5003, sub index: H04).

1. 5003/04 = 1 →19,200; 7, E, 1; ASCII

2. 5003/04 = 2 →38,400; 7, E, 1; ASCII (default)

Return the DIP switch of COA02 back to temperature controller mode and re-power COA02.

Adjust the baud rate of the temperature controller to the corresponding one.

5.4 Setting up Baud Rate and Format (when connected to servo drive)

Before connecting Delta servo drive to the BUS, first set up the communication address of the servo drive as 01,

baud rate as 115,200bps and communication format as 7, E, 1; ASCII (the format is fixed; other formats will be

invalid). To adjust the baud rate, follow the steps listed below.

Set up the DIP switch of COA02 to custom equipment mode.

Connect COA02 to the BUS of CANopen and enable the operation of COA02.

Modify the index parameter 5003/05 (main index: H5003, sub index: H05).

1. 5003/05 = 1 →19,200; 7, E, 1; ASCII

2. 5003/05 = 2 →38,400; 7, E, 1; ASCII

3. 5003/05 = 3 →57,600; 7, E, 1; ASCII

4. 5003/05 = 4 →115,200; 7, E, 1; ASCII (default)

Return the DIP switch of COA02 back to servo drive mode and re-power COA02.

Adjust the baud rate of the servo drive to the corresponding one.

5.5 Setting up Baud Rate and Format (when connected to HMI)

Before connecting Delta HMI to the BUS, first set up the communication address of the HMI as 01, baud rate as

115,200bps and communication format as 7, E, 1; ASCII (the format is fixed; other formats will be invalid). HMI as

the master and COA02 as the slave. There are 64 virtual D devices (D0 ~ D63) in COA02 and CANopen master

and HMI are able to read and write the virtual D devices in COA02. In this case, set up the address of the slave

(COA02) monitored by HMI as 01 by the HMI editing software. To adjust the baud rate, follow the steps listed

below.

Set up the DIP switch of COA02 to custom equipment mode.

Connect COA02 to the BUS of CANopen and enable the operation of COA02.

Modify the index parameter 5003/06 (main index: H5003, sub index: 06).

1. 5003/06 = 1 →19,200; 7, E, 1; ASCII

2. 5003/06 = 2 →38,400; 7, E, 1; ASCII

3. 5003/06 = 3 →57,600; 7, E, 1; ASCII

4. 5003/06 = 4 →115,200; 7, E, 1; ASCII (default)

Return the DIP switch of COA02 back to HMI mode and re-power COA02.

Adjust the baud rate of the HMI to the corresponding one.

5.6 Setting up Baud Rate and Format (when connected to custom equipment)

Before connecting the custom equipment to the BUS, first set up the communication address of the equipment as

01, baud rate as 19,200bps and communication format as 8, N, 2; RTU (the format is fixed; other formats will be

invalid). To adjust the baud rate, follow the steps listed below.

Modify the index parameter 5003/07 (main index: H5003, sub index: H07).

1. 5003/07 = 1 →19,200; 8, N, 2; RTU (default)

2. 5003/07 = 2 →38,400; 8, N, 2; RTU

3. 5003/07 = 3 →57,600; 8, N, 2; RTU

4. 5003/07 = 4 →115,200; 8, N, 2; RTU

Re-power COA02.

Adjust the baud rate of the custom equipment to the corresponding one.

LED Indicators & Trouble-shooting

There are 3 LED indicators on COA02, RUN, ERROR and SCAN, for displaying the connection status of the

communication in COA02.

6.1 RUN LED

LED Status COA02 Status How to deal with it

Off No power

Check the power of COA02 and make sure the

connection is normal.

Green light 1 flash Stop

Green light flashes Pre-operation

Green light On Operating

Red light On NODE-ID error Check if the setting of NODE-ID of COA02 is correct.

6.2 ERROR LED

LED Status COA02 Status How to deal with it

Off No error COA02 operation is normal.

Red light 2 flashes Erroneous control occurs.

1. Check if the connection between COA02 and the

master station is intact.

2. Check if the communication between COA02 and the

master station is normal.

Red light On BUS OFF 1. Check if the BUS connection is normal.

2. Re-power COA02.

6.3 SCAN LED

LED Status COA02 Status How to deal with it

Off No power Check the power of COA02 and make sure the

connection is normal.

Green light flashes

The correct information of the

equipment connected has not

been detected.

Re-connect COA02 to the equipment.

Green light On

The communication with the

equipment connected is

normal.

Red light flashes CRC check fails

1. Check if the communication cable between COA02

and the equipment is correct.

2. Check if there is electromagnetic interference nearby.

Red light On Connection fails, or no

connection

1. Check if the communication format of the equipment

is correct.

2. Check if COA02 and the equipment are correctly

connected.

3. Restart the connection and make sure the

communication cable meets the specification.

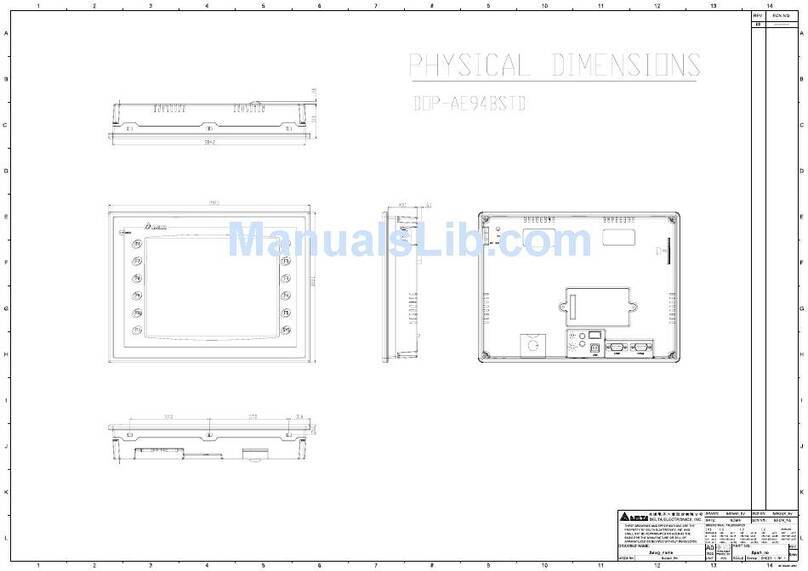

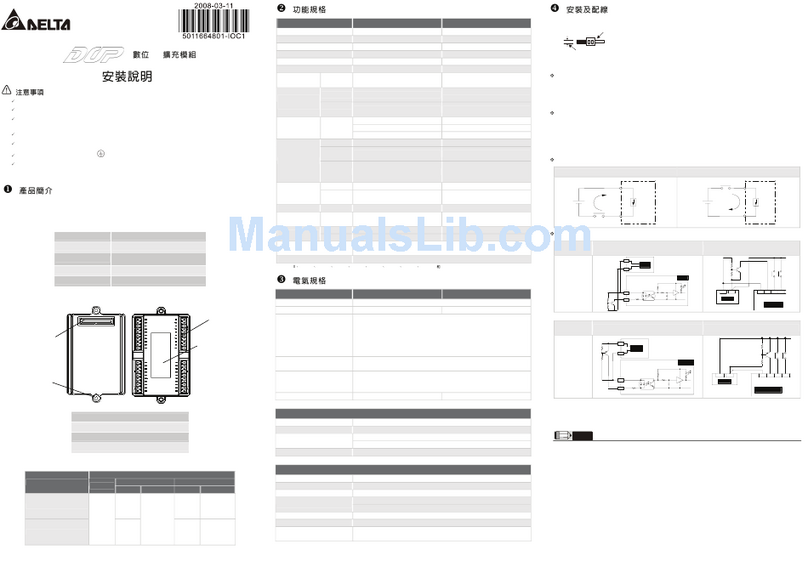

t Installation & Wiring

Install COA02 in an enclosure with sufficient space around it to

allow heat dissipation (see the figure).

DO NOT place the I/O signal wires and power supply wire in the

same wiring circuit.

COA02

D

D

D

D

Use 28-12AWG (1.5mm) single or multiple core wire on I/O wiring terminals.

See the figure for its specification.

The terminal screws shall be tightened to 5.19 kg-cm (4.5 in-lbs).

Use 60°C /75°C copper wires only.

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or

download the most updated version at http://www.delta.com.tw/industrialautomation