AEMC instruments AmpFlex 193-24-BK User manual

CURRENT PROBES & SENSORS

(For Power Quality Meters & Power Energy Loggers)

193-24-BK

193-36-BK

196A-24-BK

MA193-10-BK

MA193-14-BK

MA194-24-BK

MN93-BK

MN193-BK

MR193-BK

SL261

SR193-BK

User Manual

ENGLISH

WITH AEMC

®

INSTRUMENTS

2Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

Copyright©Chauvin Arnoux®, Inc. d.b.a. AEMC®Instruments. All rights reserved.

No part of this documentation may be reproduced in any form or by any means (including electronic

storage and retrieval or translation into any other language) without prior agreement and written consent

from Chauvin Arnoux®, Inc., as governed by United States and International copyright laws.

Chauvin Arnoux®, Inc. d.b.a. AEMC®Instruments

15 Faraday Drive • Dover, NH 03820 USA

Tel: (800) 945-2362 or (603) 749-6434 • Fax: (603) 742-2346

This documentation is provided “as is,” without warranty of any kind, express, implied, or otherwise.

Chauvin Arnoux®, Inc. has made every reasonable eort to ensure that this documentation is accurate;

but does not warrant the accuracy or completeness of the text, graphics, or other information contained

in this documentation. Chauvin Arnoux®, Inc. shall not be liable for any damages, special, indirect,

incidental, or inconsequential; including (but not limited to) physical, emotional or monetary damages

due to lost revenues or lost prots that may result from the use of this documentation, whether or not the

user of the documentation has been advised of the possibility of such damages.

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

3

Thank you for purchasing an AEMC®Instruments current probe.

For the best results from your instrument and for your safety, you must read the

enclosed operating instructions carefully and comply with the precautions for use.

Only qualied and trained operators should use this product.

Symbols

CAUTION - Risk of Danger! Indicates a WARNING. Whenever this symbol

is present, the operator must refer to the user manual before operation

Indicates a risk of electric shock. The voltage at the parts marked with this

symbol may be dangerous

Application or withdrawal authorized on conductors carrying dangerous volt-

ages. Type A current sensor as per IEC 61010-2-032

Refers to a type B current sensor. Application or withdrawal not authorized

on conductors carrying dangerous voltages. Type B current sensor as per

IEC 61010-2-032

Signies that the instrument is protected by double or reinforced insulation

Battery

Indicates important information to acknowledge.

This product complies with the Low Voltage & Electromagnetic Compatibility

European directives (73/23/CEE & 89/336/CEE).

In the European Union, this product is subject to a separate collection

system for recycling electrical and electronic components in accordance

with directive WEEE 2002/96/EC.

Denition of Measurement Categories (CAT)

CAT IV corresponds to measurements performed at the primary electrical supply

(< 1000 V).

Example: primary overcurrent protection devices, ripple control units, and

meters.

CAT III corresponds to measurements performed in the building installation at the

distribution level.

Example: hardwired equipment in xed installation and circuit breakers.

CAT II corresponds to measurements performed on circuits directly connected to

the electrical distribution system.

Example: measurements on household appliances and portable tools.

4Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

PRECAUTIONS BEFORE USE

The protection assured by the current probe can be compromised if it is used in a

way that is not recommended by the manufacturer.

■Comply with the rated maximum voltage and current, and the measurement

category. Do not use the current probe on networks where the voltage or

category exceeds those specied.

■Comply with the conditions of use (e.g. temperature, humidity, altitude, degree

of pollution, location).

■Do not use the current probe if its housing is open, deteriorated, or incorrectly

reassembled. Before each use, check the integrity of the insulation of the unit,

jaws, clamps, housing, and leads.

■Do not subject the current probe to water or other liquids.

■Keep the jaw contacts of the clamp absolutely clean.

■Use suitable personal protective equipment when hazardous voltages may be

accessible in the installation where the measurement is made.

■Any repairs must be carried out by accredited skilled personnel.

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

5

Table of Contents

1. INTRODUCTION.................................................................................4

1.1 Receiving Your Shipment......................................................................4

1.2 Ordering Information.............................................................................4

2. PRODUCT FEATURES.......................................................................5

2.1 Control Features...................................................................................5

2.1.1 MiniFlex®Model MA193-BK .....................................................6

2.1.2 MiniFlex®Model MA194-BK .....................................................7

2.1.3 AC/DC Current Probe Model J93-BK .......................................8

2.1.4 AC Current Probe Models MN93-BK & MN193-BK..................9

2.1.5 AC Current Probe Model MR193-BK......................................10

2.1.6 AC Current Probe Model SL261.............................................11

2.1.7 AC Current Probe Model SR193-BK ......................................12

3. OPERATION .....................................................................................13

4. SPECIFICATIONS.............................................................................15

4.1 Electrical .............................................................................................15

4.2 Environmental.....................................................................................16

4.3 Mechanical..........................................................................................16

4.4 Safety..................................................................................................17

4.5 Conformity To International Standards ...............................................17

4.6 Electromagnetic Compatibility ............................................................17

5. MAINTENANCE................................................................................18

5.1 Cleaning..............................................................................................18

5.2 Battery Replacement ..........................................................................18

5.2.1 Model MR193-BK ..................................................................18

5.2.2 Model SL261 ..........................................................................18

5.2.3 Model J93-BK.........................................................................19

5.3 Repair and Calibration........................................................................19

5.4 Technical Assistance...........................................................................20

5.5 Limited Warranty.................................................................................20

5.5.1 Warranty Repairs....................................................................20

6Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

1. INTRODUCTION

1.1 Receiving Your Shipment

Upon receiving your shipment, make sure that the contents are consistent with the

packing list. Notify your distributor of any missing items. If the equipment appears

to be damaged, le a claim immediately with the carrier and notify your distributor

at once, giving a detailed description of any damage. Save the damaged packing

container to substantiate your claim.

1.2 Ordering Information

NOTE: The current probes in this manual are compatible only with

AEMC®Instruments Power Analyzers (see § 4 for meter compatibility).

AmpFlex®Sensor 24" Model 193-24-BK ..........................................Cat. #2140.34

AmpFlex®Sensor 36" Model 193-36-BK ..........................................Cat. #2140.35

AmpFlex®Sensor 24” Model 196A-24-BK........................................Cat. #2140.75

MiniFlex®Sensor 10" Model MA193-10-BK......................................Cat. #2140.48

MiniFlex®Sensor 14" Model MA193-14-BK......................................Cat. #2140.50

MiniFlex®Sensor 24” Model MA194-24-BK......................................Cat. #2140.80

AC/DC Current Probe Model J93-BK ....................... Discontinued October 2021

AC Current Probe Model MN93-BK..................................................Cat. #2140.32

AC Current Probe Model MN193-BK................................................Cat. #2140.36

AC Current Probe Model MR193-BK................................................Cat. #2140.28

AC Current Probe Model SR193-BK ................................................Cat. #2140.33

AC/DC Current Probe Model SL261* ...............................................Cat. #1201.51

* Adapter for SL261 - BNC Adapter ............................................ Cat. #2140.40

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

7

2. PRODUCT FEATURES

2.1 Control Features

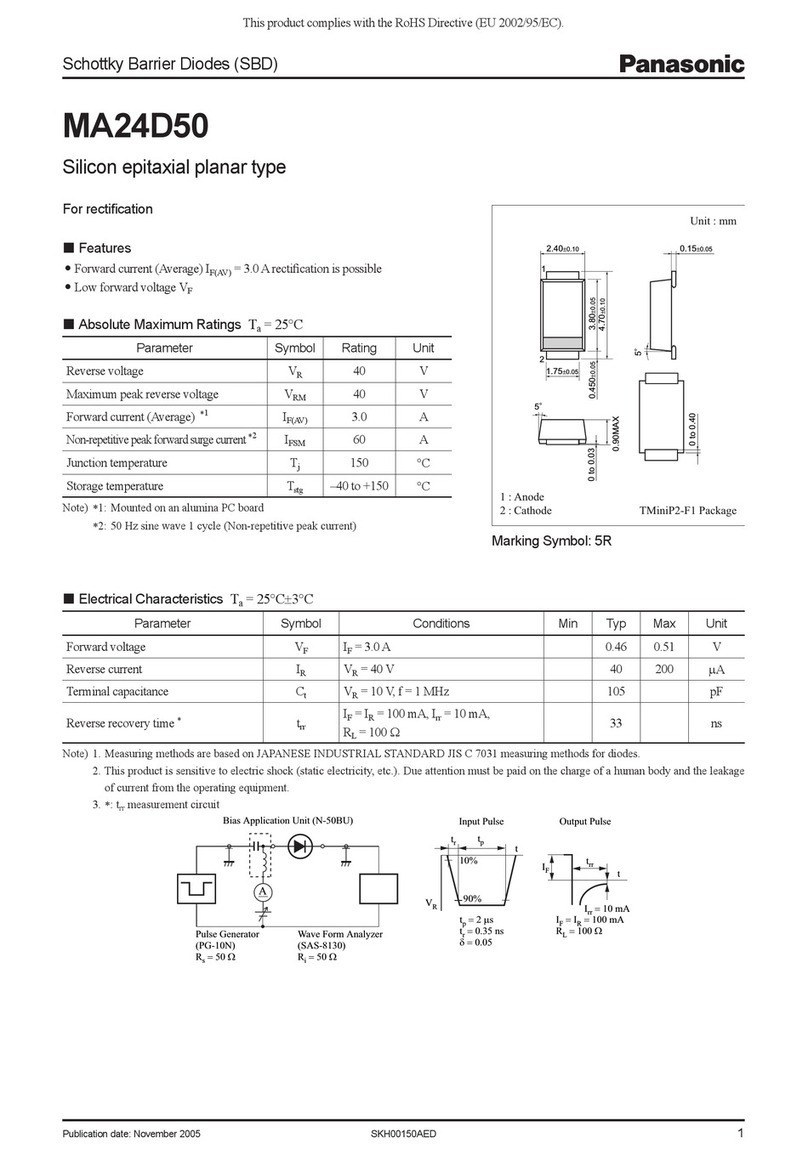

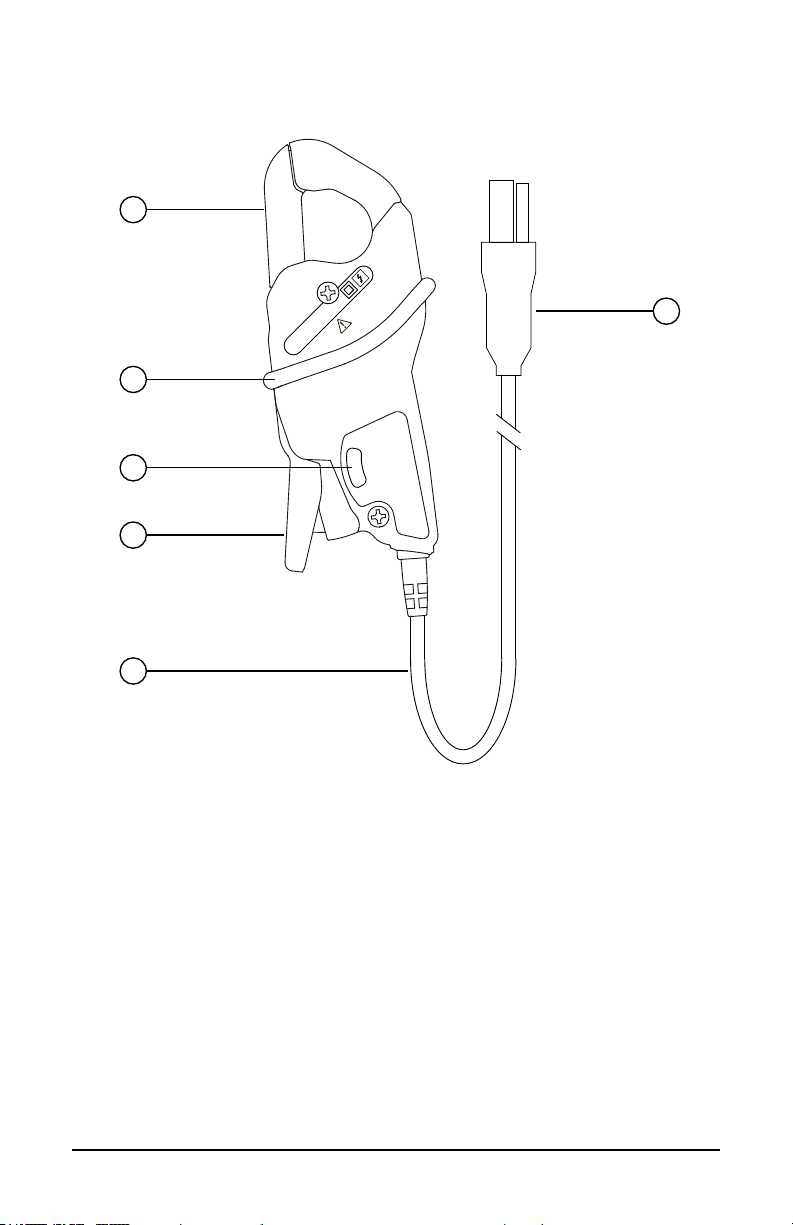

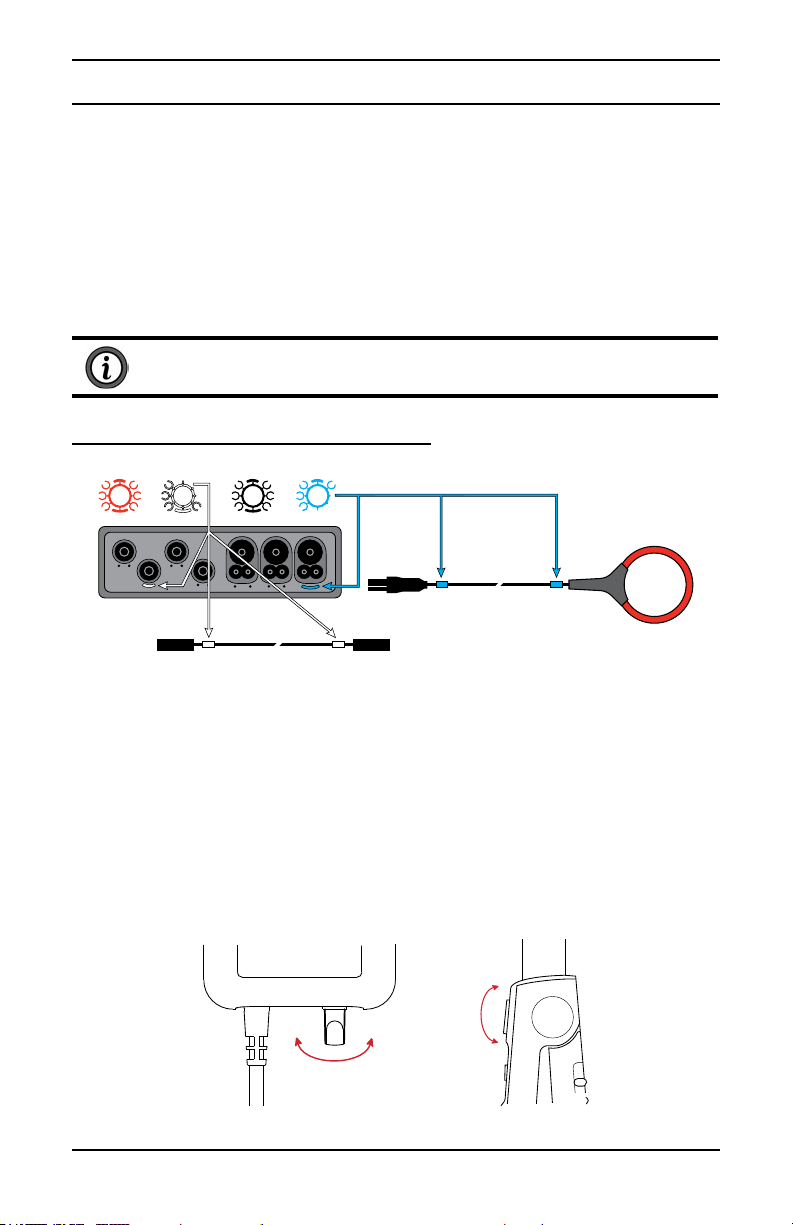

AmpFlex®Models 193-24-BK, 193-36-BK & 196A-24-BK

2

3

4

1

1. Flexible sensor

2. Sensor opening connector

3. Shielded lead

4. Custom 4-pin input connector (available standard or IP 67 compliant,

depending on instrument)

8Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

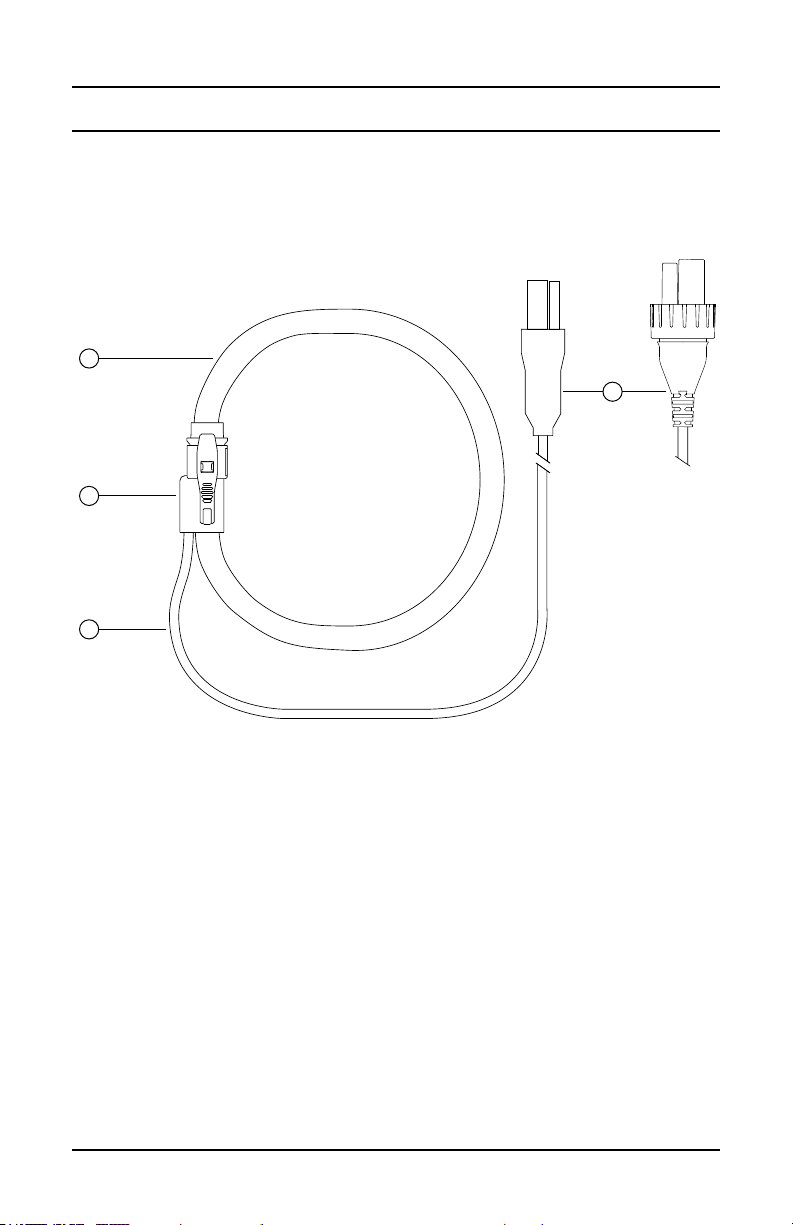

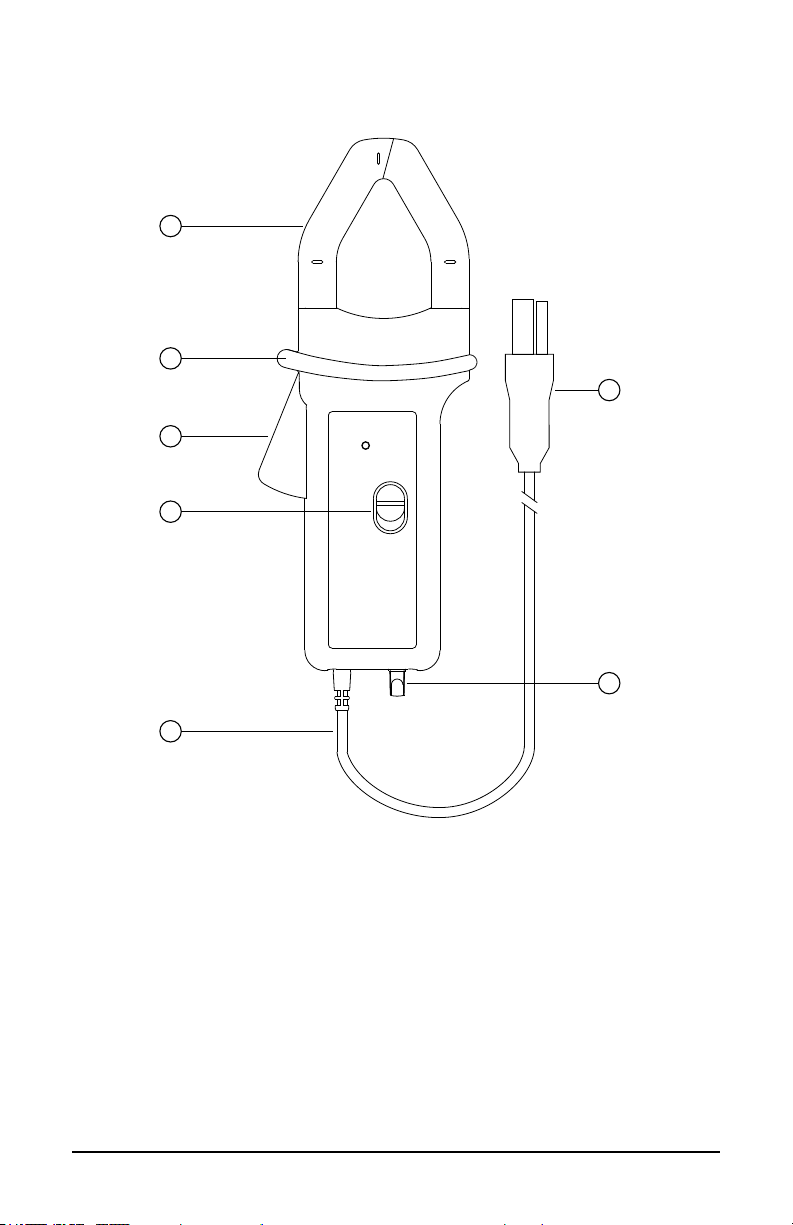

2.1.1 MiniFlex®Model MA193-BK

2

3

4

1

1. Flexible sensor

2. Sensor opening device

3. Shielded lead

4. Custom 4-pin input connector

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

9

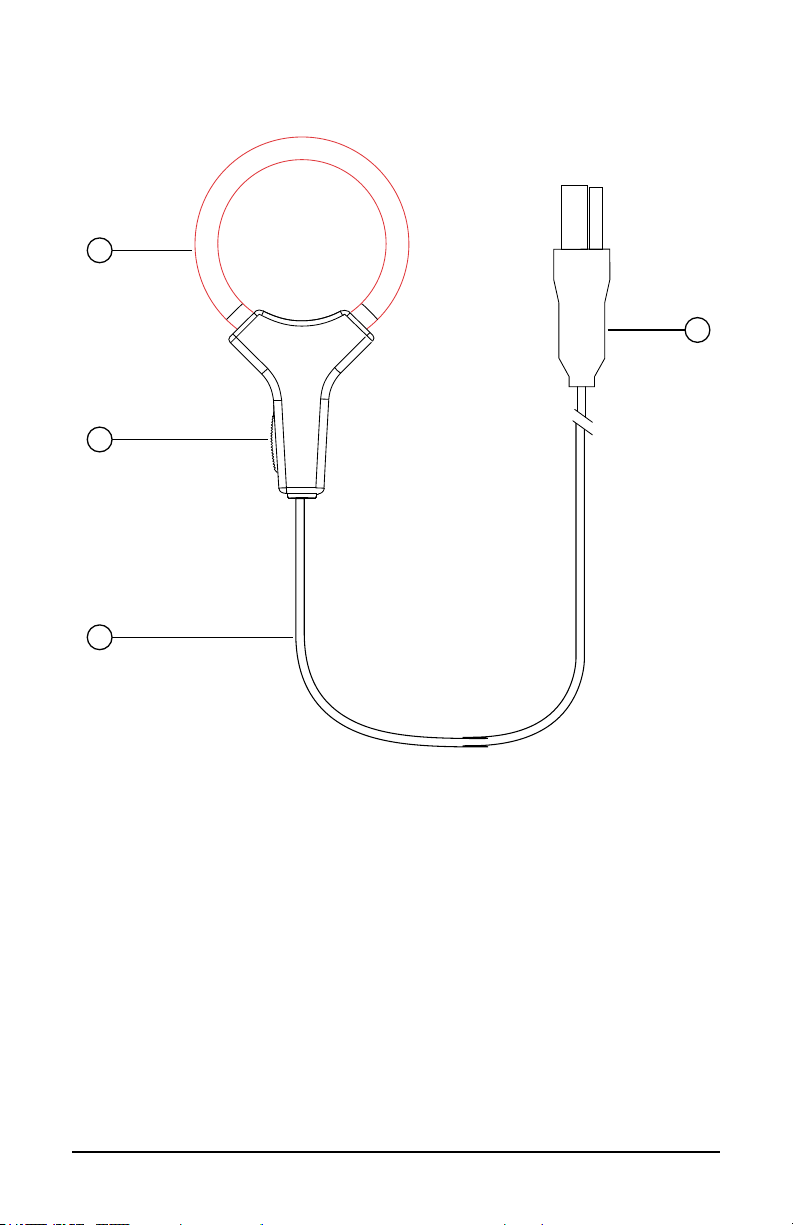

2.1.2 MiniFlex®Model MA194-BK

4

2

3

1

1. Flexible sensor

2. Sensor opening device

3. Shielded lead

4. Custom 4-pin input connector

10 Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

2.1.3 AC/DC Current Probe Model J93-BK

1

2

4

5

6

3

5000A

500A

ZERO

Stop

Test

MARCHE

SORTIE

ZERO

ON

OFF

300 V CAT IV

600 V CAT III

1. Jaws

2. Custom 4-pin input connector

3. Safety guard

4. Zero adjustment knob

5. Power ON/Low battery indicator

6. Three-position switch: ON, OFF, battery test

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

11

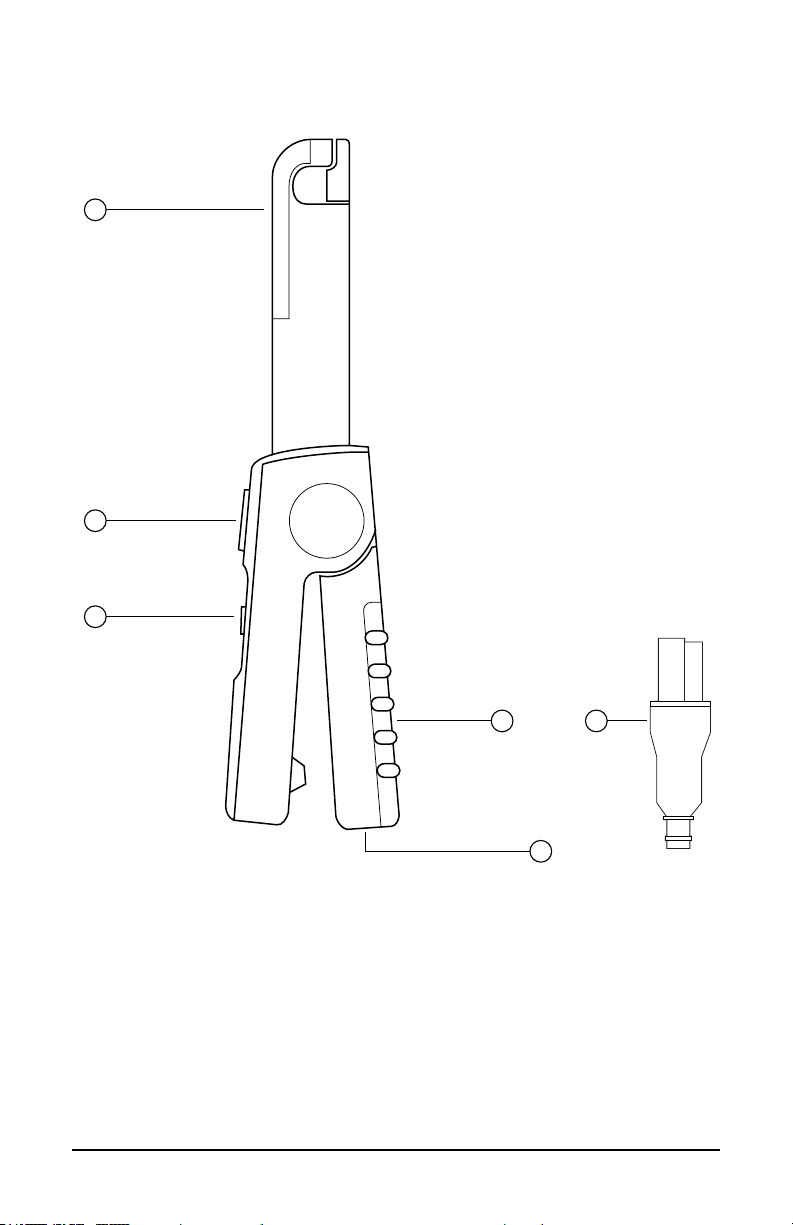

2.1.4 AC Current Probe Models MN93-BK & MN193-BK

200V CAT IV

600V CAT III 200A

5

4

2

3

6

1

1. Jaws

2. Protective guard

3. Two-position range switch (MN193-BK only)

4. Jaw opening lever

5. Shielded lead

6. Custom 4-pin input connector

12 Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

2.1.5 AC Current Probe Model MR193-BK

5

2

4

3

7

6

1

1. Jaws

2. Protective guard

3. Jaw opening lever

4. Two-position range switch

5. Shielded lead

6. Zero adjustment

7. Custom 4-pin input connector

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

13

2.1.6 AC Current Probe Model SL261

2

3

5 6

4

1

1. Jaws

2. Zero adjust knob

3. Range selection switch

4. Battery compartment screw

5. Battery compartment cover

6. BNC Adapter (sold separately - Cat. #2140.40)

14 Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

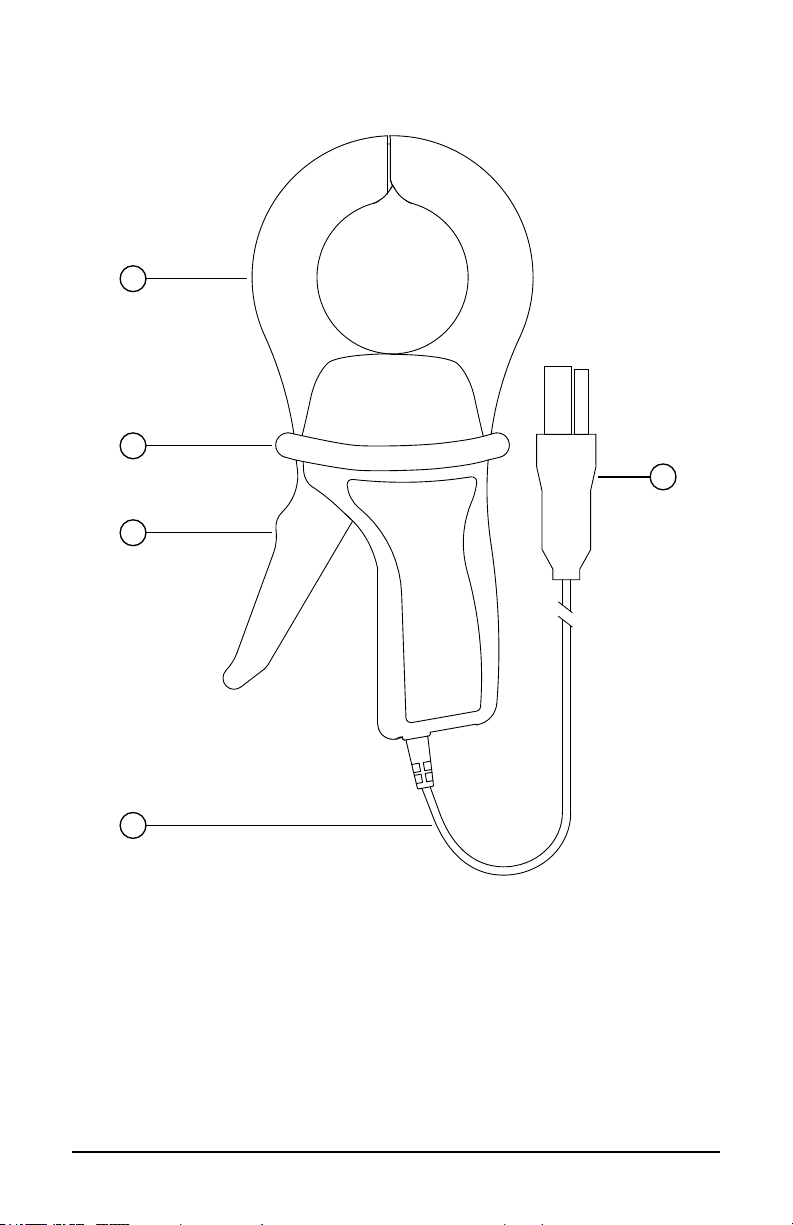

2.1.7 AC Current Probe Model SR193-BK

4

2

3

5

1

1. Jaws

2. Protective guard

3. Jaw opening lever

4. Shielded lead

5. Custom 4-pin input connector

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

15

3. OPERATION

The current probes and exible sensors are used to measure the current owing

in a conductor or bus bar without opening the circuit. They also insulate the user

from dangerous voltages in the circuit.

The choice of current probe or sensor to be used depends on the amperage to be

measured and the diameter of the cables or size of the bus bar.

■For three-phase measurements, use the color-coded ID markers to associate

a color for each current input to match the phase identiers on the measured

system.

NOTE: Always connect the probes or sensors with the indicating

arrows pointing toward the load.

For Example Only (instrument’s will vary):

■Connect the current probe or sensor to the current terminals of the instrument.

For MR193-BK and SL261 Probes:

■MR193-BK: Set the switch to 1 mV/A; the ON indicator will light up.

SL261: Set the switch to 10 mV or 100 mV/A; the ON indicator will light up.

■Connect the probe to the instrument.

■Adjust the zero by turning the potentiometer with no conductor in the jaws of the

clamp.

■When the measurement is nished, turn the probe switch to OFF.

16 Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

For Probes:

■Press the jaw opening lever on the probe to open the jaws.

■Clamp the probe around the conductor to be tested. For best results, center the

conductor in the jaws of the clamp.

I

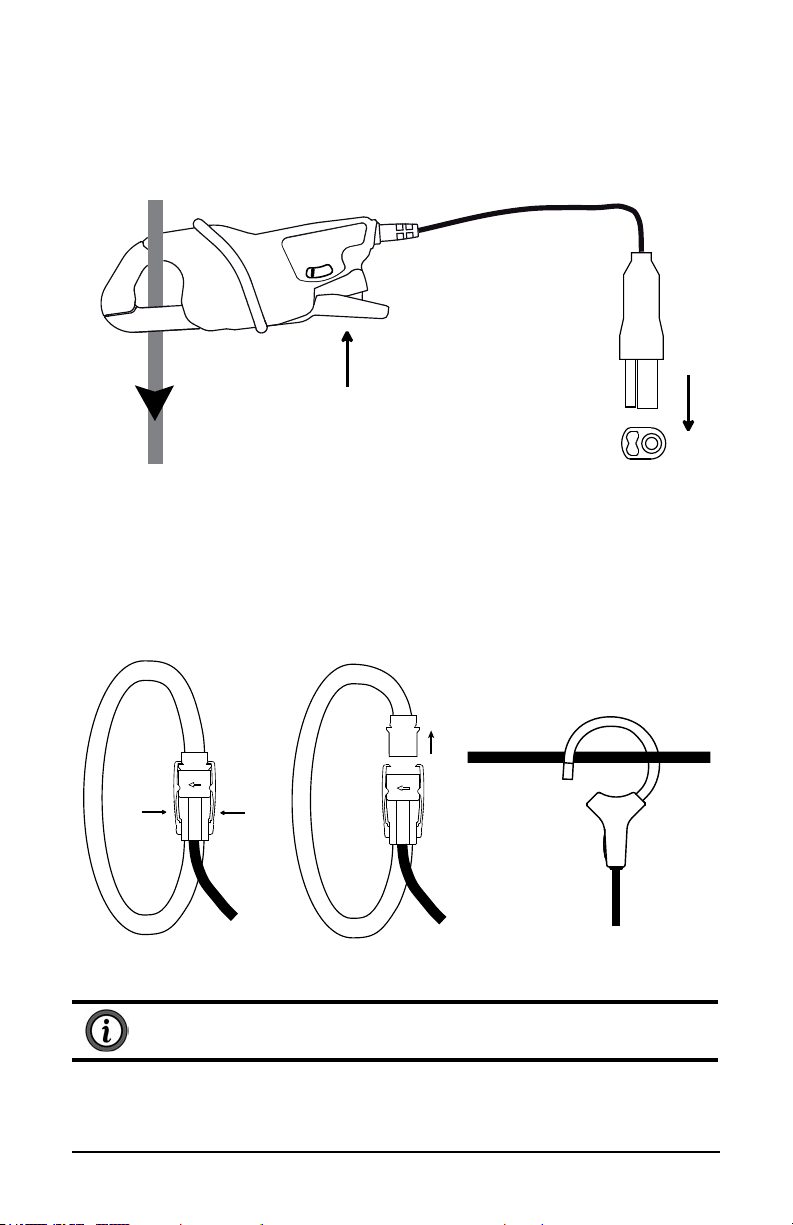

For AmpFlex®and MiniFlex®Sensors:

■AmpFlex®: Press simultaneously on both sides of the opening connector.

■MiniFlex®: Press the opening device to open the exible sensor.

■Clamp the sensor around the conductor to be tested. For best results, center the

conductor in the jaws of the clamp.

■Close the sensor by pushing the moving part into the connector until it clicks.

NOTE: For details of the measurement conguration and technical

specications, refer to the user manual of the connected instrument.

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

17

4. SPECIFICATIONS

4.1 Electrical

NOTE: The measurement ranges specied are for the probes and

sensors. In some cases, they may dier from the ranges that can be

measured by the connected instrument.

NOTE: For complete specications refer to the product user manual

that is supplied with each compatible instrument.

Model Measurement Range Compatibility

AmpFlex®193-24-BK (1)

24 in (610 mm)

200 mA to 10 kAAC (2)

(12,000 A) (3)

All PowerPads and

PEL 100 Series

AmpFlex®193-36-BK (1)

36 in (910 mm)

200 mA to 10 kAAC (2)

(12,000 A) (3)

All PowerPads and

PEL 100 Series

AmpFlex®196A-24-BK (1)

24 in (610 mm)

200 mA to 10 kAAC (2)

(12,000 A) (3) 8435, 8436, and PEL 105

MiniFlex®MA193-BK (1)

10 in (250 mm)

200 mA to 3000 A

(10,000 A peak)

All PowerPads and

PEL 100 Series

MiniFlex®MA193-BK (1)

14 in (355 mm)

200 mA to 3000 A

(10,000 A peak)

All PowerPads and

PEL 100 Series

MiniFlex®MA194-BK (1)

24 in (606 mm)

100 mA to 3000 A

(10,000 A peak)

All PowerPads and

PEL 100 Series

J93-BK 50 to 3500;

50 to 5000 (DC only)

8333, 8336, 8435, 8436

and PEL 100 Series

MN93-BK 2 to 240 AAC

(I >200 A not permanent)

All PowerPads and

PEL 100 Series

MN193-BK 5 A: 0.005 to 6 AAC

100 A: 0.1 to 120 AAC

All PowerPads and

PEL 100 Series

MR193-BK 10 AAC to 1000 AAC;

10 APEAK AC+DC to 1300 A PEAK AC+DC

All PowerPads and

PEL 100 Series

SL261 100 mV/A: 100 mA to 10 A peak

10 mV/A: 1 to 100 A peak

All PowerPads and

PEL 100 Series

SR193-BK 1 AAC to 1200 AAC

(I > 1000 A not continuously)

All PowerPads and

PEL 100 Series

(1) 10 to 6500 AAC for Model 8435; 100 mA to 6500 A for Model 8436

(2) 200 mA to 10,000 A measurement range for the PEL 100 Series.

(3) 12,000 A is specied for the PEL 100 Series only.

Battery: 9 V Alkaline NEDA 1604 A, 6LR61

Battery Life: MR193-BK - 100H typical

SL261 - 55 h typical

J93-BK - 70 h typical

NOTE: Battery life is twice the typical value when using Lithium

batteries.

18 Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

4.2 Environmental

Indoor use

Operating Temperature: (14 to 131) °F (-10 to 55) °C); (10 to 85) % RH

Storage Temperature: (-40 to 158) °F (-40 to 7) °C; (10 to 90) % RH

Degree of pollution: 2

Altitude: < 2000 m

4.3 Mechanical

Model

Lead

Length

(nominal)

Clamping

Diameter Dimensions Weight

AmpFlex®193-24-BK

24 in (610 mm)

10 ft

(3 m)

7.64 in

(190 mm)

(6.6 x 6.2 x 0.98) in

(170 x 158 x 25) mm

7.7 oz

(270 g)

AmpFlex®193-36-BK

36 in (910 mm)

10 ft

(3 m)

11.46 in

(290 mm)

(11 x 10.4 x 0.98) in

(280 x 265 x 25) mm

9.5 oz

(220 g)

AmpFlex®196A-24-BK

24 in (610 mm)

10 ft

(3 m)

7.64 in

(190 mm)

(6.6 x 6.2 x 0.98) in

(170 x 158 x 25) mm

7.7 oz

(270 g)

MiniFlex®

MA193 -10-BK

10 in (250 mm)

10 ft

(3 m)

2.75 in

(70 mm)

(4.0 x 2.5 x 1.1) in

(103 x 64 x 28) mm

1.94 oz

(55 g)

MiniFlex®

MA193-14-BK

14 in (350 mm)

10 ft

(3 m)

3.94 in

(100 mm)

(4.0 x 2.5 x 1.1) in

(103 x 64 x 28) mm

2.11 oz

(60 g)

MiniFlex®

MA194-24-BK

24 in (606 mm)

10 ft

(3 m)

7.64 in

(190 mm)

(4.0 x 2.5 x 1.1) in

(103 x 64 x 28) mm

2.11 oz

(60 g)

J93-BK 10 ft

(3 m)

2.84 in

(72 mm)

(13.23 x 5.00 x 1.65) in

(336 x 127 x 42) mm

3.75 lbs

(1.7 kg)

MN93-BK 10 ft

(3 m)

0.8 in

(20 mm)

(5.47 x 2.00 x 1.18) in

(135 x 51 x 30) mm

24 oz

(690 g)

MN193-BK 10 ft

(3 m)

0.8 in

(20 mm)

(5.47 x 2.00 x 1.18) in

(135 x 51 x 30) mm

24 oz

(690 g)

MR193-BK 10 ft

(3 m)

One 1.6 in

(42 mm)

or two 0.98 in

(25 mm)

or two bus bars

(1.96 x 0.19) in

(50 x 5) mm

(8.8 x 3.82 x 1.73) in

(224 x 97 x 44) mm

19 oz

(540 g)

SL261 6.5 ft

(1.9 m)

0.46 in

(11.8 mm)

(9.09 x 1.42 x 2.64) in

(231 x 36 x 67) mm

11.6 oz

(330 g)

SR193-BK 10 ft

(3 m)

2 in

(52 mm)

(8.5 x 4.4 x 1.8) in

(216 x 111 x 45) mm

24 oz

(690 g)

Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

19

4.4 Safety

Protection index IP 40 for the probes and IP 30 jaws open, according to IEC 60 529

■IP 65 for the AmpFlex®according to IEC 60 529

■IK 04 according to IEC 50102

Drop test: According to IEC 61010-1

Electrical safety according to IEC 61010-2-032.

Maximum applicable voltage:

AmpFlex® 193-BK: 1000 V CAT III; 600 V CAT IV

AmpFlex® 196A-BK: 1000 V CAT IV

MiniFlex®-BK: 1000 V CAT III; 600 V CAT IV

J93-BK: 600 V CAT III; 300 V CAT IV

MN93 / MN193-BK/

MN194-BK: 600 V CAT III; 300 V CAT IV

MR193-BK: 600 V CAT III; 300 V CAT IV

SL261: 600 V CAT III

SR193-BK: 1000 V CAT III; 600 V CAT IV

4.5 Conformity To International Standards

The instruments are compliant with IEC 61010-2-032.

The equipment is protected by double or reinforced insulation .

Type of current sensor per IEC 61010-2-032:

Type A or Type B for the Ampexes.

4.6 Electromagnetic Compatibility

The instruments conform with standard IEC 61326-1.

Specications are subject to change without notice.

20 Current Probes & Sensors for Power Quality Meters and Power Energy Loggers

5. MAINTENANCE

Use only factory specied replacement parts. AEMC®instruments will not be held

responsible for any accident, incident, or malfunction following a repair done other

than by its service center or by an approved repair center.

CAUTION: Risk of electric shock. Disconnect the instrument from

any source of electricity.

5.1 Cleaning

■Use a soft cloth, dampened with soapy water. Rinse with a damp cloth

and dry rapidly with a dry cloth.

■Do not use alcohol, solvents, or hydrocarbons.

■Do not splash water directly on the instrument.

5.2 Battery Replacement

5.2.1 Model MR193-BK

■Disconnect the MR193-BK completely and turn the rotary switch to

OFF.

■Use a screwdriver to unscrew the screws and remove the battery

compartment cover on the backside of the unit.

■Withdraw the battery from its compartment.

■Disconnect the old battery without pulling on the wires and replace with

a new one, observing the polarity.

■Put the battery into its compartment.

■Put the cover back in place and screw the screws back in.

5.2.2 Model SL261

■Disconnect the SL261 completely and turn the rotary switch to OFF.

■ Unscrew the battery compartment screw and pull o the battery

compartment cover.

■Replace the battery with a new one, observing the polarity.

■Put the cover back in place and screw the screw back in.

Other manuals for AmpFlex 193-24-BK

3

This manual suits for next models

10

Table of contents

Other AEMC instruments Accessories manuals

Popular Accessories manuals by other brands

Hubbell

Hubbell Electric Cable Reels TMR Series Installation and maintenance instructions

Kistler

Kistler 6190CA Series Quick Start Installation

ORELL

ORELL DEK Installation, operation and maintenance manual

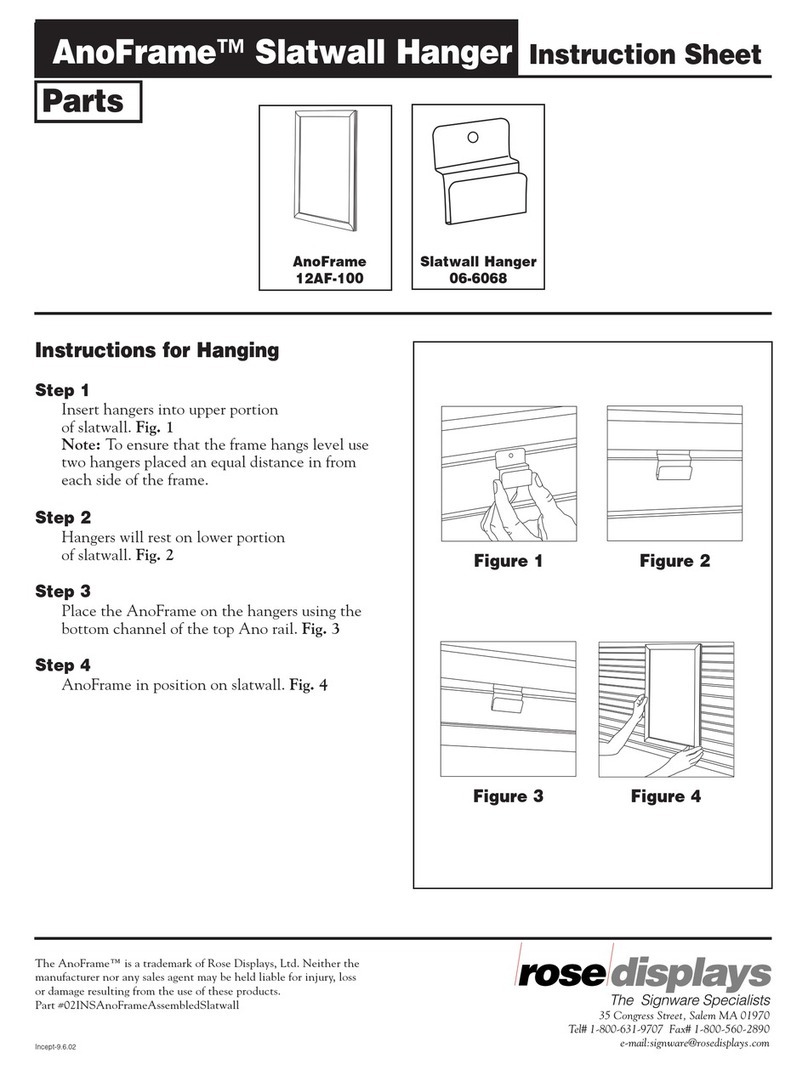

ROSE DISPLAYS

ROSE DISPLAYS ANOFRAME ROUND ASSEMBLED-SLATWALL manual

EASYOU

EASYOU SYWB- AD004 user manual

CAS

CAS HDI user manual