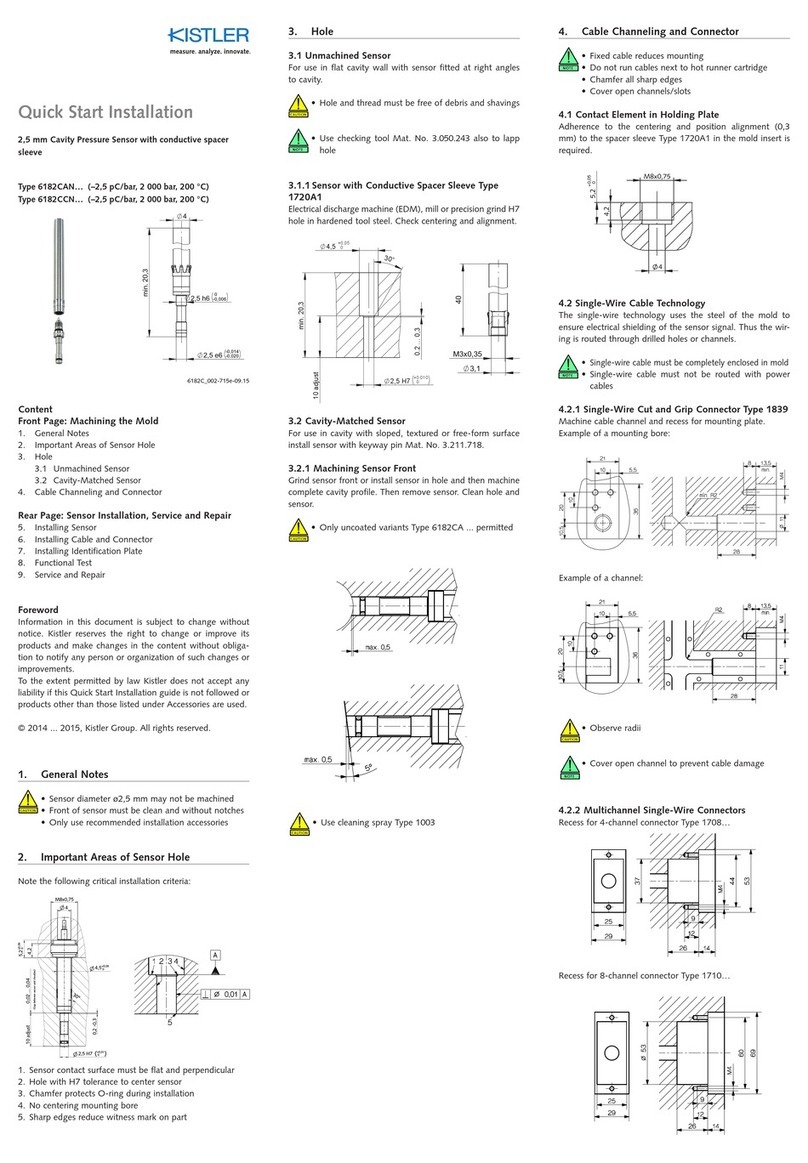

5. Installing Sensor

Ensure all sensor hole and threads are clean•

A chamfered cable channel or cable hole prevents•

damaged cables

5.1 Sensor Installation with Mounting Nut Type 6457

Install sensor into hole with extraction tool Type 1315A.

Lightly tighten mounting nut Type 6457 with socket wrench

Type 1383. Do not over tighten; sensor may not be pre-

loaded. Ensure a clearance of 0,01 … 0,03 mm.

8. Functional Test

On completion of mold assembly, test sensor insulation and

sensitivity.

Ensure that connector is dry•

Use cleaning spray Type 1003•

8.1 Insulation Test

Use insulation tester Type 5493 to check sensor insulation.

Resistance >1013 Ω.

8.2 Sensor Functional Check

Test the sensitivity of the installed sensor using Test Set Type

5993A1.

Approx. measured value: ±8 % of sensitivity as stated cali-

bration sheet or identification plate.

9. Service and Repair

Piezoelectric pressure sensors are maintenance-free. Insulation

and sensitivity of the installed sensor should, however, be

checked after each molding run.

Ensure that connector is dry•

Cover sensor hole during cleaning•

Use cleaning spray Type 1003•

9.1 Insulation Test

Use insulation tester Type 5493 to check sensor insulation.

Resistance >1013 Ω.

9.2 Sensor Functional Check

Test the sensitivity of the installed sensor using Test Set Type

5993A1.

Approx. measured value: ±8 % of sensitivity as stated cali-

bration sheet or identification plate.

9.3 Removing Sensor

Remove sensor with extraction tool Type 1315A or use a flat

ejector pin to press on the sensor front.

Do not use a hammer on the sensor front•

Do not use a sharp center punch•

9.4 Cable Repair

Damaged cables cannot be repaired. Replacement cable Type

2219B... can be ordered from Kistler local sales office.

Fragile contacts, remove cable only for repair•

9.5 Repairs at Kistler

Factory repairs at Kistler are arranged by the local sales

office

Information: www.kistler.com

9.6 Disposal Instructions for Electrical and Electronic

Equipment

Do not discard old electronic instruments in

municipal trash. For disposal at end of life,

please return this product to an authorized

local electronic waste disposal service or

contact the nearest Kistler Instrument sales

office for return instructions.

Do not preload sensor•

Take care not to wrap single-wire cable around•

socket wrench

Use extraction tool Type 1315A to install sensor•

Use socket wrench Type 1383 to tighten mounting•

nut

5.2 Sensor Installation with Spacer Sleeve Type 6459

Install sensor into hole with extraction tool Type 1315A or

directly with spacer sleeve.

5.2.1 Machining Spacer Sleeve

Cut spacer sleeve so that it has an overlength of 2 … 3 mm.

Place sensor and sleeve into hole and determine exact length,

ensuring a clearance of 0,01 … 0,03 mm. Sleeve must be

ground so the end is square and planar. Remove any burrs.

For multi-cavity applications each spacer sleeve should be

numbered and allocated to a sensor.

5.2.2 Spacer Sleeve and Retaining Plate

Install sensor and spacer sleeve. Ensure a clearance of 0,01 …

0,03 mm.

Sensor may not be preloaded when assembling the mold.

Do not preload sensor•

Use extraction tool Type 1315A to install sensor•

For multi-cavity applications each spacer sleeve•

should be numbered

Kistler Group

Eulachstrasse 22

8408 Winterthur, Switzerland

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

info@kistler.com www.kistler.com

6190C_002-433e-08.08 Kis120 ©2008, Kistler Group

6.1.1 Cut/Grip Connection

Cut the single-wire cable to length and do not strip the

insulation. Loosen the knurled connector by hand without

removing the rear section.

When using the temperature amplifier Type 2205A... strip

thermocouple cables. Attach green cable (+) to terminal and

white cable to (–) terminal.

Installation of Connector Type 1839 and Mounting Plate

Installation of Multi-Channel Connector Type 1708A... and

Temperature Amplifier Type 2205A...

This installation is for sensor Types 6190CAG... and 6833A02...

only: A typical installation uses up to 4 sensors.

Assemble 4-channel connector and temperature amplifier in

adapter plate Type 5700A25 and then install in the recess.

6.1.2 Installing Single-Wire Connector and Temperature Con-

nector with Mounting Plate

Install connector and mounting plate in recess. Attach cap

using one of the screws. Place caps on open connectors.

Take care not to damage the gray single-wire cable•

when stripping the green sensor cable sheath

Use sheath stripper Type 1367 to remove green•

sheathing

Refer to Instruction leaflet 002-450•

6. Cable and Connector Installation

Check again that edges of cable duct are chamfered•

Use a metal plate to cover open channels•

Attach cap and place on connector•

6.1 Single-Wire Technique

Single-wire cable must be completely enclosed in•

the mould

Single-wire cable may not be ducted together with•

power cables

Ensure that all contact surfaces and threads are clean•

and dry

7. Installing Identification Plate

Rivet plate to side of mold or fit with four M2,5 screws.