AEP F240A Series User manual

Ticketing solutions

Product Description

707405.E00.IT May 21, 2012

© 2011–2012 AEP Ticketing solutions srl. This document cannot be reproduced wholly or in part without previous written authorization of AEP. The product names used in this manual may be trademarks or registered trademarks,

thus belonging to their respective owners.

www.aep-italia.it 1

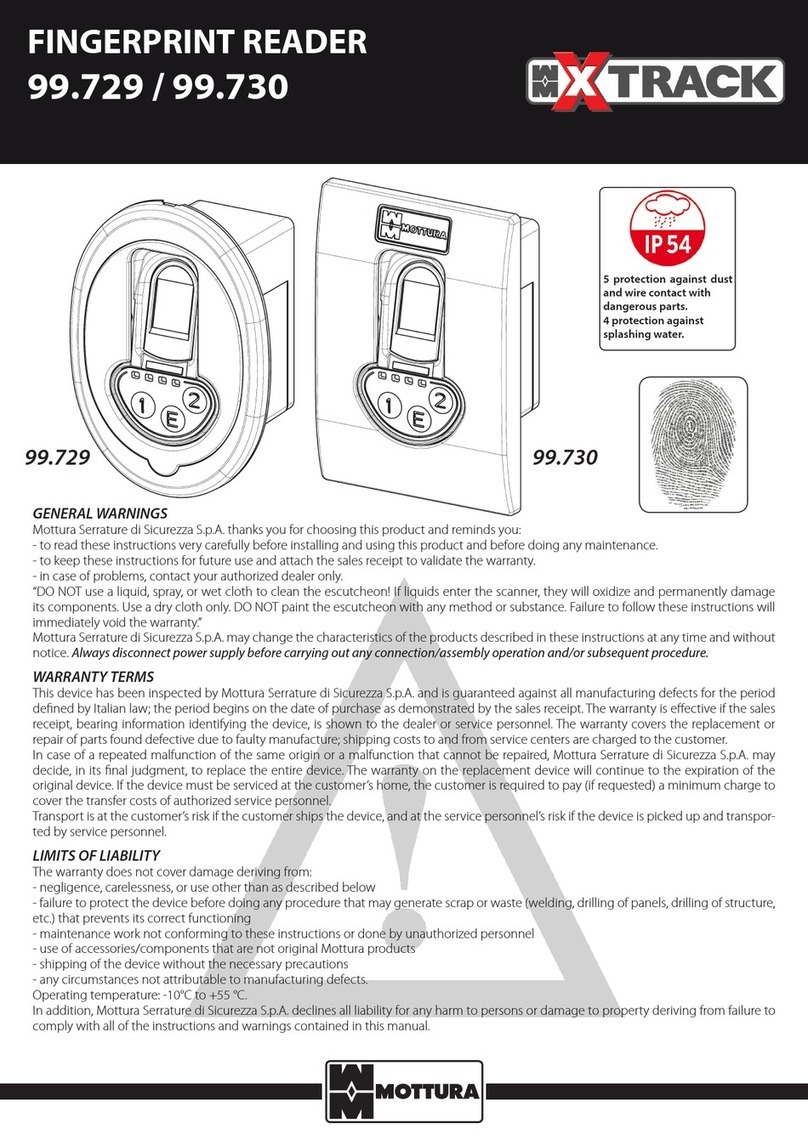

F240A & B

Multimedia validators

• Combovalidatorsforcontactlesssmartcards,paper

ticketsandcontactsmartcards

• Entrylevel,paperticketsF240/Pcanbeupgradedto

F240A

• Highlyconfigurable,richsetoffittingsandoptions

• RuggedRWSversionforrailwaystations

• Highperformancesthankstoembeddedarchitecture

F240, the flexible family

Body

F240 body is made in injection moulded ABS, with self-extinguishing

class UL94 5VA (the best one); color is embedded into material for

longer duration.

The unit is closed by a key lock that has furthermore the purpose of

locking the device to its support (see below). It’s possible:

• to dismount the validator from the support without opening the

box;

• to open the box without dismounting the validator from the sup-

port.

Standard colors: yellow RAL 1023 for the front part, black RAL 9017

fortheback.Dierentcolorsareavailableuponrequest.

Internal accessibility: front cover can be removed without dismount-

ing the validator from its support. Removed the front cover, all the

machine parts are immediately accessible for maintenance operations

like, for example, printer ribbon replacement, foreign bodies removal

or for other maintenance operations.

Housing protection: IP40 (IEC EN 60529), when installed on its sup-

ports. It’s possible to use a shower cap to allow jet washing.

Vandalism protection: IK07 (IEC EN 62262), when installed on its

supports.

Dimensions: 300x188x150 mm (packed 400x300x250).

Weight: 2,900 g (packed +1,100 g).

Shock and vibrations resistance: according to IEC EN 50155.

Packaging: designed for protection against accidental bumps during

transport. Packing material comply with 94/62/CE directive.

User interfaces

Display: visible in almost any light condition and protected by a

polycarbonateplate,withV0ammabilitygrade.

• F240 and F240A: backlit alphanumeric LCD display, with 2 rows

of 16 character 8 mm each; visible area 99x24 mm.

• F240B: backlit graphic display, 128x64 pixel. Support for non Lat-

in alphabets as Hebrew, Arabic, Greek, Cyrillic etc. Visible area

70x40 mm.

User keyboard: 4-key user keyboard to select the fare or to perform

otheroperationsrequestedbytheapplicationsoftware.Itispossible

to order the unit without the keyboard.

Internal keyboard: 5-key for parameters setup.

Lights:

• F240 and F240A: 3 x 10x20 mm LEDs, red, green and orange.

• F240B: 4 x 10x20 mm LEDs, red, green and orange1 and orange2.

Beeper: sound level 56 dBA @ 50 cm (F240/P) manca F240B.

Mounting

Unit is placed on the bus by mean of fast mounting supports, to which

itisinsuredthroughacustomizablekeylock.Notoolsarerequired

to mount and dismount the unit. Electrical connection is contextual

withinsertion(nomanualconnectorinsertionisrequired).Cables

are protected and not accessible from outside.

AllF240scanbesuppliedwith3dierenttypesofmountingsystem:

• PSA, industry standard mounting system for electronic validators

F240 is a family of validators composed by F240/P, F240A and F240B

series.

• F240/P is a plain paper validator that can replace any traditional

electromechanical obliterator but that can be upgraded to be-

come F240A intelligent, electronic validator, even at a later time;

• F240Aisanintelligent,electronicvalidatoroeringgreatexibil-

ityandcongurability;

• F240BissimilartoF240Awiththedierencesstatedinthisdocu-

ment.

Generally speaking:

• choose F240/P for obliterator replacement and then upgrade it to

F240Awhenyousubsequentlyneedanelectronicvalidator;

• choose F240B base model when you want at once a paper tickets

and contactless validator. F240B has furthermore graphic dis-

play, suitable also for non Latin alphabets, but cannot accept old

contact smart card.

AllF240validatorscanbeorderedfor3dierentlegacymounting

supports; F240/P can moreover be equipped with emulating soft-

wareformostcommonoldstylevalidators.Otherminordierences

among models are described in this document.

F240 validators fully integrate with any other AEP on board device

and with ET - The Easy Ticketing, AEP automatic fare collection sys-

tem. Like any other AEP product, F240 are open. AEP can supply

interface and development kits (except for F240/P), as well as sup-

port, for writing customized applications and integrating with third

party systems.

Note: “/P” indicates the presence of paper ticket validation unit (see

below “Ordering information”). F240A is an upgraded F240/P, so

it always has paper ticket validation unit (F240A/P). F240B could in

theorybeorderedalsowithout“/P”ingbutinthiscaseotherAEP

products,likeFutura3A,areabeerchoice.

Ticketing solutions

707405.E00.IT

www.aep-italia.it2

(/PSAing).Exclusive,anti-vibrations,AEP“Spring-O-Lock”

male pins on validator side;

• PSC, industry standard mounting system for legacy obliterators

(/PSCing,malepinsonsupportside);

• PSL, industry standard mounting system for previous generation

obliterators(/PSLing,malepinsonsupportside).

Supports:AEP oersachoice of PSA andPSCsupports, in many

variantsfordierentapplications.

Connector: multi pole 16 pins male connector, specially designed for

automotive industry. Pin assignment can be customized according

toCustomer’srequest.Connectortype:

• PSA mounting: DIN 41622

• PSC and PSL: WPI 26-159-16

Position detection: 3 digital inputs to identify validator position on

thebusnetwork.Upto8dierentpositionscanbeencodedthrough

a suitable wiring of the connector of support plates. Some supports

are furthermore available with an EEPROM memory to store net-

work address and/or other parameters.

Hot swap: (PSA only) unless validating tickets, F240 validators can

be extracted from supports also when powered. In the same way it

is possible to put them on a powered support. Any eventual recon-

guration/updatingcantakeplaceautomatically.Thesefeaturesde-

pends on software implementation.

Warning: not every validator model carries out on the connector all

the possible signals from the electronics. Validators’ wiring may vary

accordingcustomer’sspecication.

Contactless subsystem

AEP has entirely developed in its own labs the technologies for con-

tactless smart card processing, creating units which are capable of

processing almost any type of smart card existing on the market;

moreover, the internal design allows AEP to upgrade to any future

requirementsimplythroughsoftwareupdates.

Thanks to the modularity of the system, all AEP devices share the

same software functions related to contactless smart card process.

Anyspecicinformationisreportedapartbelow.

Contactlesssubsystemisincludedin/Xing.

Calypso standard

AEP uses, under Innovatron Company license, the Calypso technol-

ogy which is today, both in Italy and in the world, perhaps the most

widely accepted standard for contactless cards in public transport

area.

AnAEPvalidatorwastherstinthewordtosuccessfullypassthe

audit for Calypso 3 registration (see www.calypsotechnology.net).

Technical specifications

Contactless sub system allows to read and write cards according

ISO 14443A & B, ISO 15693, NFC (Near Field Communication), Sony

FELICA etc. For example CD21, Tango, TimeCOS, GTML, CD97,

CT 4002, CTS, MIFARE Classic, MIFARE Ultralight, DESre, MIT

(Maschera Italiana Trasporti) etc.

• Carrierfrequency:13,56MHz.

• Command set: 7816 3-4.

• RF speed: up to 424 kbps (848 with selected types);

• Security features: anticollision, encrypted communication using

DES and 3-DES algorithms, mutual authentication between vali-

dator and card and between card, reader and validator;

• SAM interface: for 4 ISO 7816 modules.

• Antenna type: digital (F240A); analog (F240B).

Performances

Transaction time: less than 110 ms. Test conditions: CD-21 card at

424 kbps; testing operations: Select Application / Select SAM / Open

Session / Read Record / Read Record / Update Record / Close Ses-

sion; in time counting are included Calypso SAM operations. More

complextransactionsmayrequiremoretime.

Reading distance: operating range from 0 to maximum 100 mm

from the antenna, depending on card model (type & manufacturer).

Best performances are obtained with cards provided or approved by

AEP. For other cards, the reading distance depends on the brand and

themodel;optimalperformancemayrequirerecongurationand/or

recalibration of the antenna circuit.

Technical specifications

F240/P

CPU: 16-bit microcontroller @ 14,7 MHz with 2K RAM and 60K

FLASH

Operating system: none

Serial port: 1 x with software selectable RS-232 or RS-485 interface.

Upgraded conguration: when upgraded to F240A, F240/P is used

as a slave device of SCBM2 CPU (see below) to control ticket valida-

tion printer, display, LEDs and keyboard; serial port is used inter-

nally.

F240A & F240B

Architecture:bothF240AandF240BuseuniedSCBM2CPUcom-

mon to many AEP devices that ensures high performances, uniform

andconsistentarchitecture,easysoftwareportabilityacrossdierent

devices and easier maintenance.

CPU: 32-bit processor @ 50 MHz with 8M DRAM, 512K SRAM, 2M

+ 384K FLASH

Operating system: AEP Mxm 5.0.

Mass storage: 2G internal SD module for manual data / program

transfer.

All F240 models can be obtained with PSA (industry standard), PSC (legacy) or PSL

(vintage) mounting system.

F240 was designed for maintenance. In few seconds, cover can be removed and internal

frame tilted to gain access to any internal parts.

Ticketing solutions

707405.E00.IT www.aep-italia.it 3

Clock/calendar: programmed for automatic change of summer time

and for leap years;

Measurement: supply voltage, internal temperature and room light.

Ethernet 10/100 IEEE 802.3

Serial ports:

• 1 x with 3-wire RS-232 interface;

• 1 x with 6-wire RS-232 interface;

• 1 x with RS-485 interface.

USB: 1 x (device).

Digital I/O: 2 x unprotected outputs, NPN type, under software

control. 2 x digital inputs. Odometer input (0/5÷24V).

Watchdog: auto reset in case of software/hardware locks.

Power management:

• theunitcanbeswitchedonorobyaremoteelectricalsignal.

(“activate” line)

• powerocanbeissuedbysoftware;

• automaticprogrammedswitchonatdeneddateandtime.

Baery:3V3internallithiumbaeryforRTC.

Wireless LAN module: optional WI-FI (IEEE 802.11b/g) interface

(-WIFIoptionforF240A;/WIFIingforF240B).

UHF module: (F240A only) legacy 433 (-UHF433 option) or 868 MHz

(-UHF868 option) AEP module, according ETSI EN 300 220. Not rec-

ommended for new applications.

Ticket validation printer

Printer: dot matrix impact. ASCII standard character set, interna-

tional; condensed print software selectable. It prints on top side of

the ticket. Resolution 80 dpi. Print head expected life: 70 millions

characters.

Ink ribbon: Star Micronics Co. endless loop. Expected life in ideal

conditions: 2 millions characters (condensed print).

• violet RC200P, manuf. code 30980021;

• black RC200B, manuf. code 30980121.

Cuer: corner cuing deviceis availableas a /CUTspecial ing.

Any time the ticket is inserted, a small rectangle is cut from the right

side corner. In this way, the next validation shall be printed down

onelinemoretoward the ticket’scenter.Thistechniqueisusedto

executemultiplevalidationsonthesameticket.InF240Athising

isnotcompatiblewiththe/Cing.

/3POS ing: xed oset of thevalidationstring on theticket, so

thatleavefreethersttwolines.

Software architecture

AEP Mxm 5.0 operating system allows high performances and opti-

mummemoryusage.Generally,itrequires10to20timeslessmem-

ory respect Linux or Windows, with speed about 5 to 10 times higher

atthesameclockfrequency.Verycomplexapplicationshardlyreach

500kofmemoryrequirement.Largeamountsofprocessormemory

remain therefore available for fast table searching, e.g. for black and

white lists, while SD/MMC memory modules ensure huge space for

data storage. Mxm makes this product an open product; AEP en-

courages independent developers and supplies software developers

kits (SDK) and related support.

Requirements

Temperature: storage, -20÷60°C; operating, -15÷60°C(-25°inT3t-

tings available only for F240B). Test methods: dry heat IEC EN 60068-

2-2(Bdtest,deviceon),coldIECEN60068-2-1(Adtest,deviceo).

It also conforms to IEC EN 60950-1, par. 4.2.7, “Stress relief test” (7

hours at 70°C) test.

Notes: this device is for use by human operators, therefore not in

the extreme conditions of the above tests. Exposing the unit for pro-

longed periods at a temperature of 60°C may cause thermal printer

reduced operation. As for any ABS unit direct UV exposure might

cause color fading and alter mechanical features. In any case, solar

exposure must not cause environmental conditions exceeding above

limits.

Humidity: 5 to 95%, non condensing; test done from 25 to 45°C. Hu-

mid heat cycle according IEC EN 60068-2-30 test.

Power supply:+24VDC;min.18V(21,6 in /CUT ing),max32V.

F240B exceeds IEC EN 50155 requirements. Insulating class: III

(SELV). Protected against polarity inversion. Maximum current 1,5A

@ 24V. Power up transient: 3A for about 50 ms. Device must be pow-

ered by a limited power source as per IEC EN 60950-1. Pollution de-

gree 2, according CEI EN 60950-1, 2.10.1.2.

Quality and standards

MTBF/MCBF: 50,000 hours 750,000 cycles, evaluated by mean

of theoretical calculation and eld data for similar devices (UNI

10147:2003).

Device is classied as “Information technology equipment” and

complies with:

• RadioEquipmentDirective:99/5CEandsubsequentamendments;

• Directive2002/95CE“RestrictionsontheuseofspecicHarmful

Substances in the manufacture of electrical and electronic com-

ponents (RoHs)”

• Electromagnetic Compatibility Directive: 89/336 CE.

• LowVoltageDirectives:2006/95CEanditssubsequentamend-

ments;

• Automotive Directive: 2004/104/CE with upgrades related to di-

rectives 2005/49/ CE, 2005/83/CE and 2006/28/CE (homologation

and “e” mark by Ministry of Transport of Italian Republic).

This device is therefore compliant with the following international

standards: IEC EN 55024:1999-04; IEC EN 55024/A1:2002-07; IEC EN

55024/A2:2003-06; IEC EN 55022:1999-06; IEC EN 55022/A1:2001-10;

IEC EN 55022/A2:2003-08; IEC EN 55022-A1-A2/EC:2005-12; ETSI

EN 301 489-1 V1.8.1 (2008-04); ETSI EN 301-489-3 V1.4.1 (2002-08);

ETSI EN 302 291-1 v1.1.1 (2005-07); ETSI EN 302 291-2 v1.1.1 (2005-

07); IEC EN 60950-1:2006-04; IEC EN 50371:2004-06.

Tests were performed according the following standards, where

applicable: IEC EN 61000-4-2 (IEC 210-34); IEC EN 61000-4-3 (IEC

210-39); IEC EN 61000-4-4 (IEC 210-35); IEC EN 61000-4-5 (IEC 110-

30); IEC EN 61000-4-6 (IEC 210-40); IEC EN 61000-4-8 (IEC 110-15);

IEC EN 61000-4-11 (IEC 110-29); IEC EN 50155 for shocks and vibra-

tions tolerance (EN 61373); IEC EN 60529; IEC EN 60068-2-1; IEC EN

60068-2-3; IEC EN 60068-2-30.

For further information refer to document “AEP Quality System and

Standards”, P/N 702547.

On the right, F240B easily recognizable for graphic display. On the left, an F240 boxed

in *RWS version, suited to railway stations and harsh environment.

Ticketing solutions

707405.E00.IT

www.aep-italia.it4

Order encoding

AEPproductsoeragreatexibilitytosatisfythewidestrangeof

applications.Formostproductsfollowingcongurationparameters

aredened:

• versions,thatidentify the basetype of machine.Dierent ver-

sionscorrespondusuallytoverydierentdevices,evenfromvi-

sual point of view.

• ings,thatdenesoptionalfeaturestobeselectedatthetimeof

construction. In general, the above said characteristics cannot be

modiedand/ormodiedatalatertimeinaneasyway.

• options, that specify features that can be added or removed even

after the construction of the product, without the need of return-

ing it to the factory.

• accessories, other products which can be easily used together

with this unit.

Please refer to the above table for ordering codes of all available ver-

sions,ingsandoptions.Unlessotherwiseindicated,theycanbe

combined each other.

Sample ordering code

F240B/PX /PSA /ETH /WIFI -W45

F240B validator with contactless reader, for PSA mounting support,

wired for Ethernet, with WI-FI module. Ticket slot 45 mm wide.

Warranty and support

Any AEP product has 12 months basic warranty against defects

or failures. In this period of time, products will be repaired free of

charge at AEP factory or at any AEP Technical Support Center.

AEP grants support service and spare parts availability for 10 years

since end of production of the purchased model.

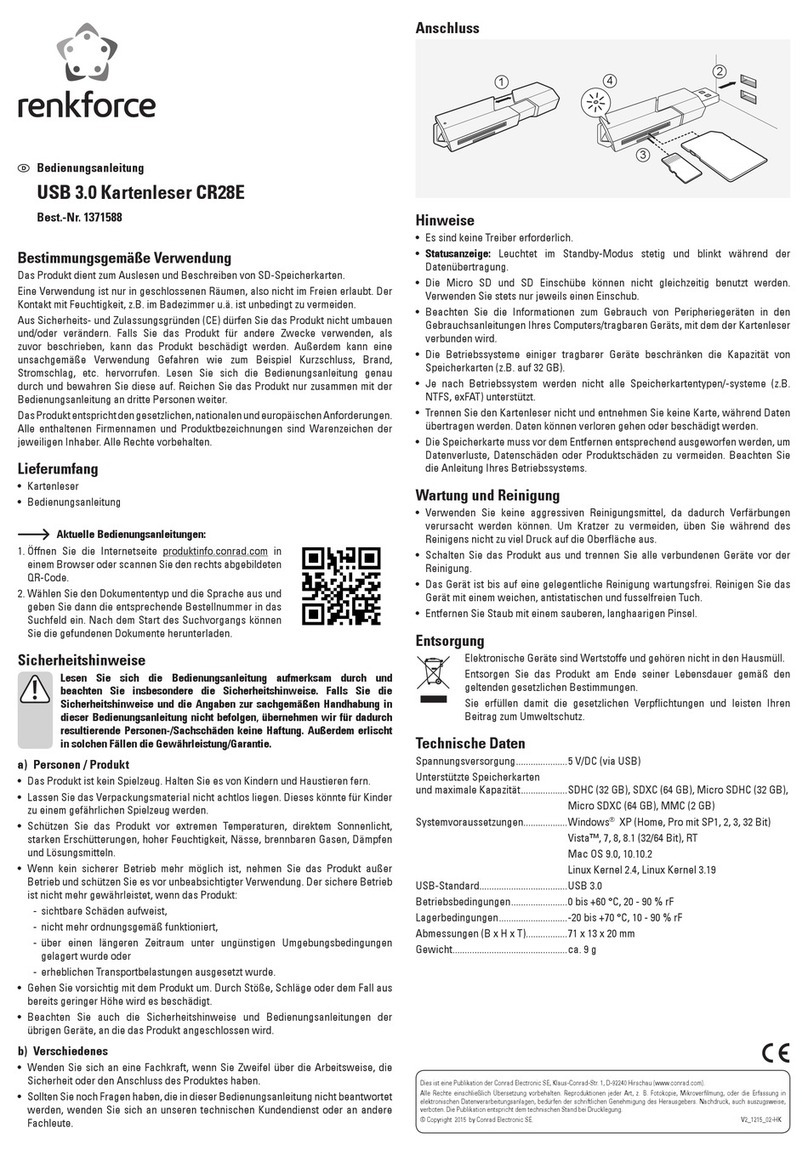

Type F240/P(4) F240A F240B Description

*RWS VERSION Special iron standing box version for railway stations or anyway in harsh environment. It includes power supply, GPRS/UMTS modem

and can withstand hot, cold, rain, power failures and vandalic acts. Can automatically send SMS alert for maintenance or alarms.

/P FITTING × Paper ticket validation unit with dot matrix impact printer and endless replaceable ribbon.

/X OPTION Contactless smart card validation unit with AEP multistandard reader.

/C FITTING × × Contact smart card validation unit, with card retention and electromagnetic release.

/CUT FITTING Corner cutting device to execute multiple validations on the same paper ticket. Not compatible with /C. Reduced voltage range (24V

-10%+20%).

/PSA FITTING PSA, industry standard mounting system for electronic validators. Exclusive, anti -vibrations, AEP “Spring-O-Lock” male pins on valida-

tor side. DIN 41622 connector.

/PSC FITTING PSC, industry standard mounting system for legacy obliterators (male pins on support side). WPI 26-159-16 connector.

/PSL FITTING PSL, industry standard mounting system for previous generation obliterators (/male pins on support side). WPI 26-159-16 connector.

/3POS FITTING Fixed offset of the validation string on the paper ticket, so that leave free the first two lines.

/T3 FITTING × × Extended temperature range according IEC EN 50155 T3 temperature class. It includes general and display specific heating system.

/NOKBD FITTING No user keyboard. Internal service keyboard anyhow present.

/ETH FITTING × Ethernet interface is standard on F240A & F240B. This fitting is related to wiring of main connector only.

/USB FITTING × USB interface is standard on F240A & F240B. This fitting is related to wiring of main connector only.

/WIFI FITTING × × Wi-Fi IEEE802.11b/g interface. This is a fitting for F240B only, must be ordered with base model.

-WIFI OPTION × × Wi-Fi IEEE802.11b/g interface. This is an option for F240A only, can be added at a later time.

-Wxx FITTING Ticket entry slot xx mm wide - standard 45; 43,54,84 are available, different width upon request (subject to approval by AEP)

-UHF433 OPTION × × Legacy 433 MHz AEP communication module, according ETSI EN 300 220. Not recommended for new applications.

-UHF868 OPTION × × Legacy 868 MHz AEP communication module, according ETSI EN 300 220. Not recommended for new applications.

-GPRS OPTION × × Internal GPRS modem for data communication.

-UMTS OPTION × × Internal UMTS modem for data communication.

-Sxxxx OPTION Customized key lock. “xxxx” is the required key code.

/AS FITTING Special fitting upon customer’s request. It may include body coloring, special cabling, personalized labels etc. Special fittings may

require additional fee and/or minimum quantity.

.

included in base model optional × not available

Specification F240/P F240A F240B

Architecture µC Master/slave Single core

CPU µC SCBM2 SCBM2

Clock MHz 14.7 50 50

SRAM 2K 2M 2M

DRAM × 8M 8M

FLASH 60K 2M+384K 2M+384K

SD card × 1x2G 1x2G

RTC

Battery Soldered Soldered Holder

Watchdog

Display α2x16

24x99 mm

α 2x16

24x99 mm

graph 128x64

70x40 mm

Keys 5 0 5

Beepers 2 0 3

LEDs 3 0 4

RWS

Digital Out 1 2 2

Digital In 1 2 2

3 x position In ×

Auto switch on ×

Auto switch off ×

Activate in ×

Reversed voltage protection

Voltage measurement

Temperature measurement

DIP switches × 4 1

Contactless reader (/X) ×

Contactless reader SAMs × 4 4

Contactless reader antenna × Active Passive

RS-232 3-wire (1)

RS-232 6-wire ×

RS-485 (1)

Ordering information

Base models technical data summary

This manual suits for next models

2

Popular Card Reader manuals by other brands

ACS

ACS ACR310 Operation manual

Equip

Equip USB 2.0 Ultimate Card Reader manual

Lexar

Lexar FIREWIRE 800 READER - DATASHEET REV A datasheet

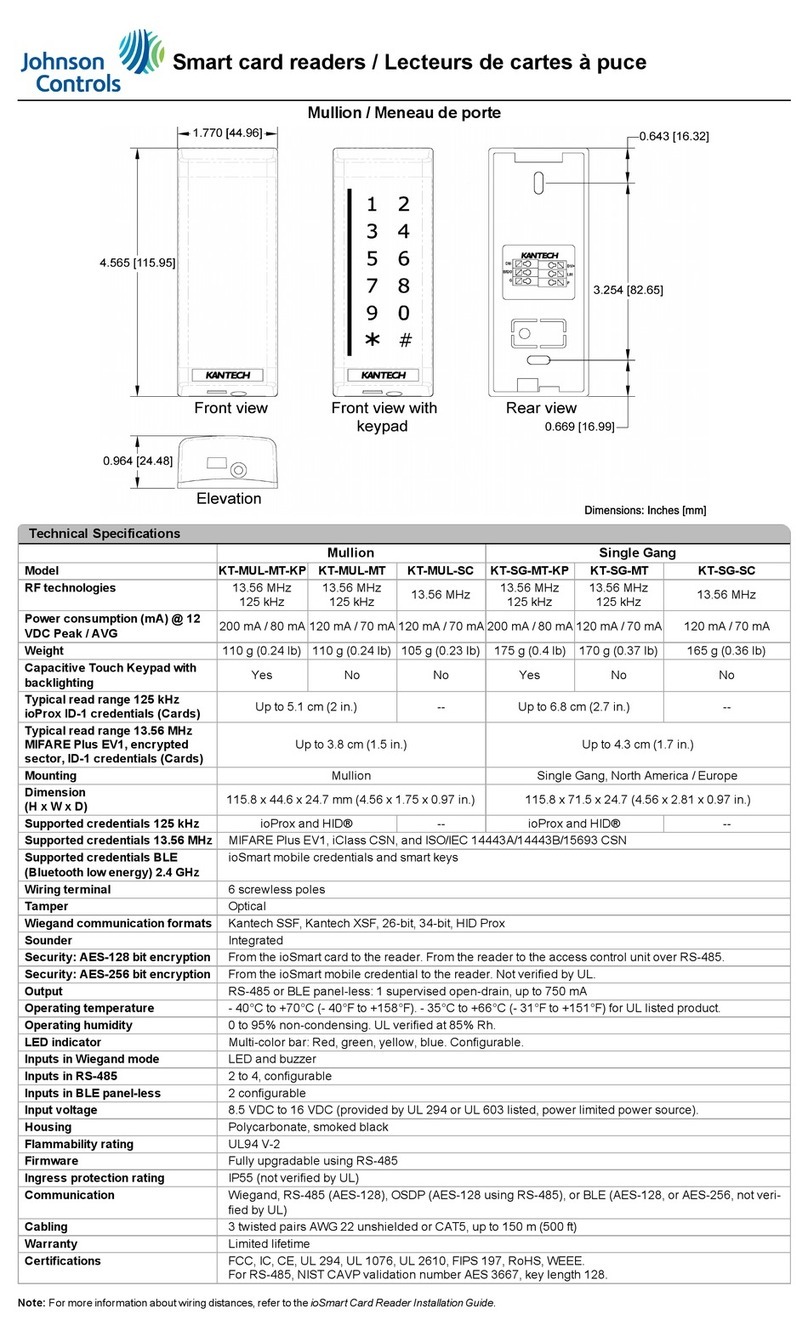

Johnson Controls

Johnson Controls KT-MUL-MT-KP Installation sheet

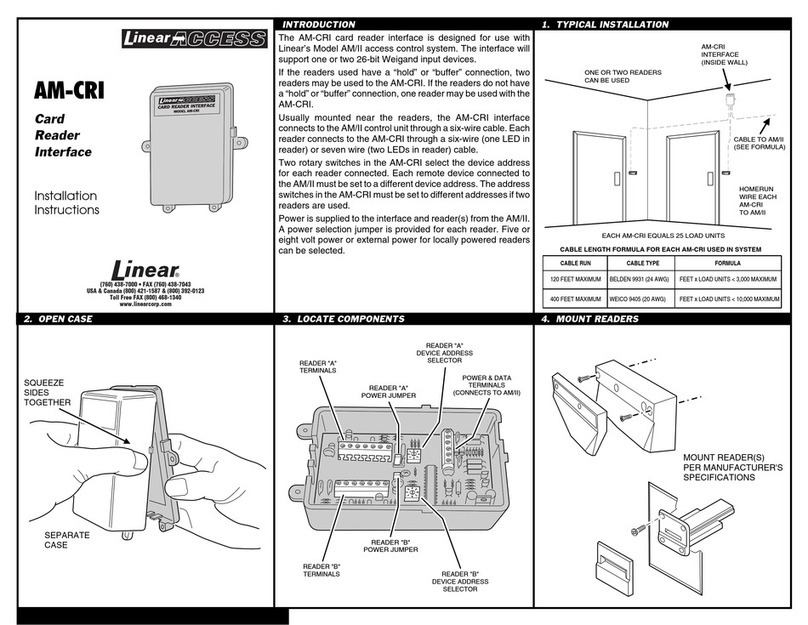

Linear Access

Linear Access AM-CRI installation instructions

StarTech.com

StarTech.com 525FCREADAL Instruction guide