Declaration of conformity ......................................................... 4

1. General standards............................................................5

2. Description and choice of unit.....................................6

2.1 Available versions ..................................................................6

2.1.1 Standard equipment ............................................................6

2.2 Configurator .............................................................................7

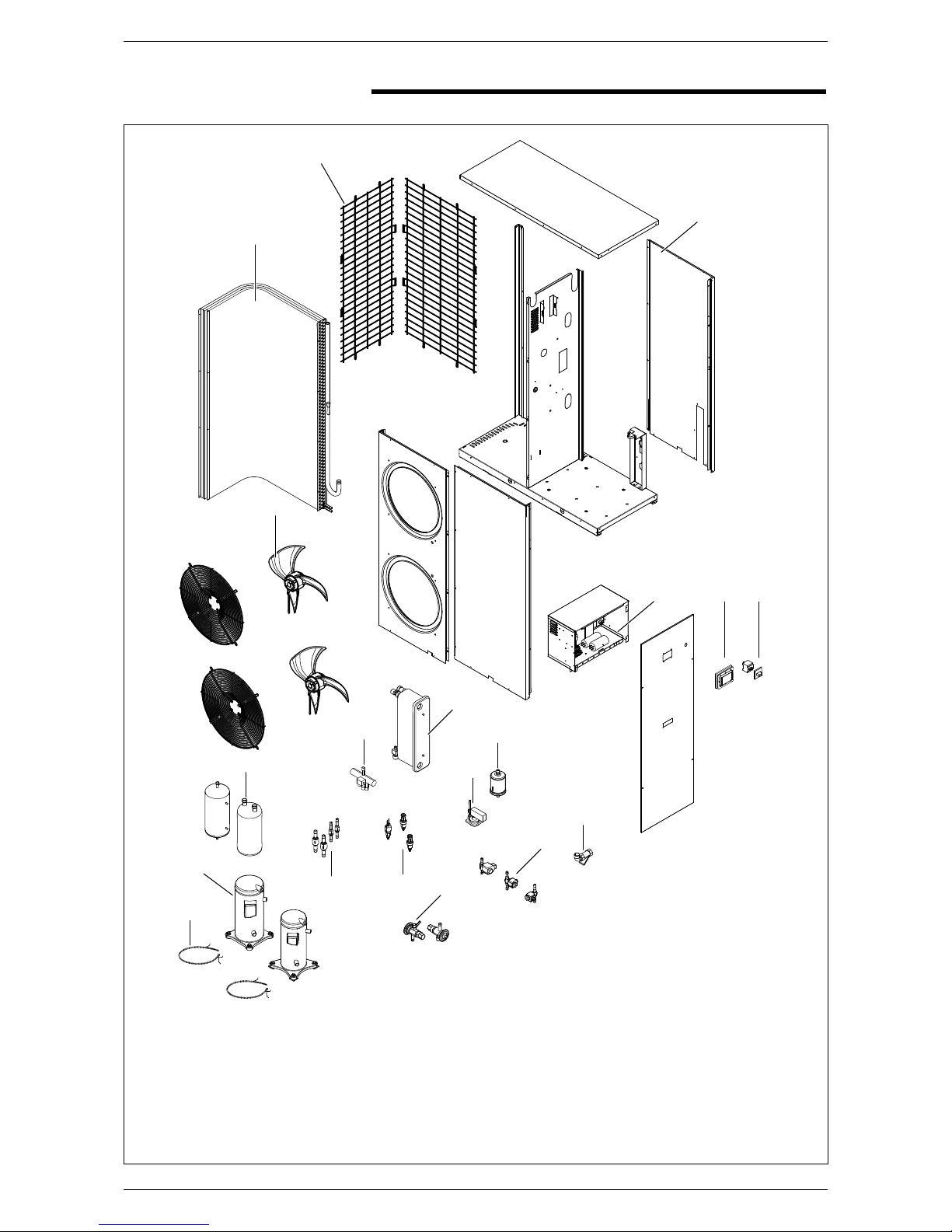

3 Description of components 8

3.1 Standard ANR version (H)..................................................8

3.2 ANR version with accumulation (HA) ............................9

3.3 ANR version with accumulation

and secondary heater (HK).............................................10

3.4 Cooling circuit.........................................................................11

4 Standard equipment 13

4.1 Chiller circuit..........................................................................13

4.2 Frame and fans ...................................................................13

4.3 Hydraulic components .....................................................13

4.4 Safety and control components....................................13

4.5 Electrical components...................................................... 13

4.6 Modu Control electronic adjustment..........................14

5 Accessories......................................................................14

5.1 Table of compatible accessories...................................14

6 Technical data.................................................................. 15

6Standard versions 230V .................................................15

6.1 Versions with accumulation 230V .............................16

6.2 Standard version 400V.....................................................17

6.3 Version with accumulation 400V ................................18

7 Selection criteria............................................................19

7.1 Design data............................................................................19

8 Corrective co-efficients ...............................................20

8.1 ANR502 (HM) ..................................................................... 20

8.2 ANR802 (HM) ..................................................................... 20

8.3 ANR902 (HM) ...................................................................... 21

8.4 ANR502 (HPM-HAM-HKM)............................................ 21

8.5 ANR802 (HPM-HAM-HKM)............................................22

8.6 ANR902 (HPM-HAM-HKM)............................................22

8.7 ANR502 (H)...........................................................................23

8.8 ANR802 (H)...........................................................................23

8.9 ANR902 (H)...........................................................................24

8.10 ANR502 (HP-HA-HK).........................................................24

8.11 ANR802 (HP-HA-HK).........................................................25

8.12 ANR902 (HP-HA-HK).........................................................25

Cooling mode:

8.13 ANR502 (HM)......................................................................26

8.14 ANR802 (HM)......................................................................26

8.15 ANR902 (HM) ...................................................................... 27

8.16 ANR502 (HPM-HAM-HKM)............................................ 27

8.17 ANR802 (HPM-HAM-HKM)............................................28

8.18 ANR902 (HPM-HAM-HKM)............................................28

8.19 ANR502 (H) ......................................................................... 29

8.8 ANR802 (H).......................................................................... 29

8.9 ANR902 (H).......................................................................... 30

8.10 ANR502 (HP-HA-HK)........................................................ 30

8.11 ANR802 (HP-HA-HK)......................................................... 31

8.12 ANR902 (HP-HA-HK)......................................................... 31

9 Ethylene glycol solution ..............................................32

10 Pressure drops...............................................................34

10.1 Useful head.......................................................................34

11 Accumulation...................................................................35

11.1 Minimum/maximum system water

content ...............................................................................35

11. 2 Minimum water content recommended, for

versions without hydronic kit..........................................35

11.3 Maximum water content recommended ................35

11.4 Expansion tank calibration...............................................35

12 Sound data........................................................................36

13 Check and safety parameters setting...................36

13.1 Fan magnetothermals ......................................................36

13.2 Compressor magnetothermals....................................36

13.3 Pressure switch and transducer

thermomagnetic switches.............................................36

14 Versions with electric heater.................................... 37

15 Control logic for the compensation setpoint..... 37

16 Dimensions.......................................................................38

16.1 Minimum technical clearances ....................................38

16.2 ANR 0502-0802-0902...................................................38

To install the unit, please observe the safety warnings included in these instructions

Danger: high temperature

Danger: moving parts

Danger: power supply i

Danger: cut off power supply

General danger

Useful information and warnings