5

1.1. USE IN COMPLIANCE WITH

THE DOCUMENTATION

The DMP is built in compliance with the

acknowledged technical standards and

technical safety regulations. It is assem-

bled and wired completely in the factory,

subjected to sealing tests and an idle

cycle. The units are loaded with R-134a

ecological refrigerant. They undergo a

complete functional inspection before

delivery.

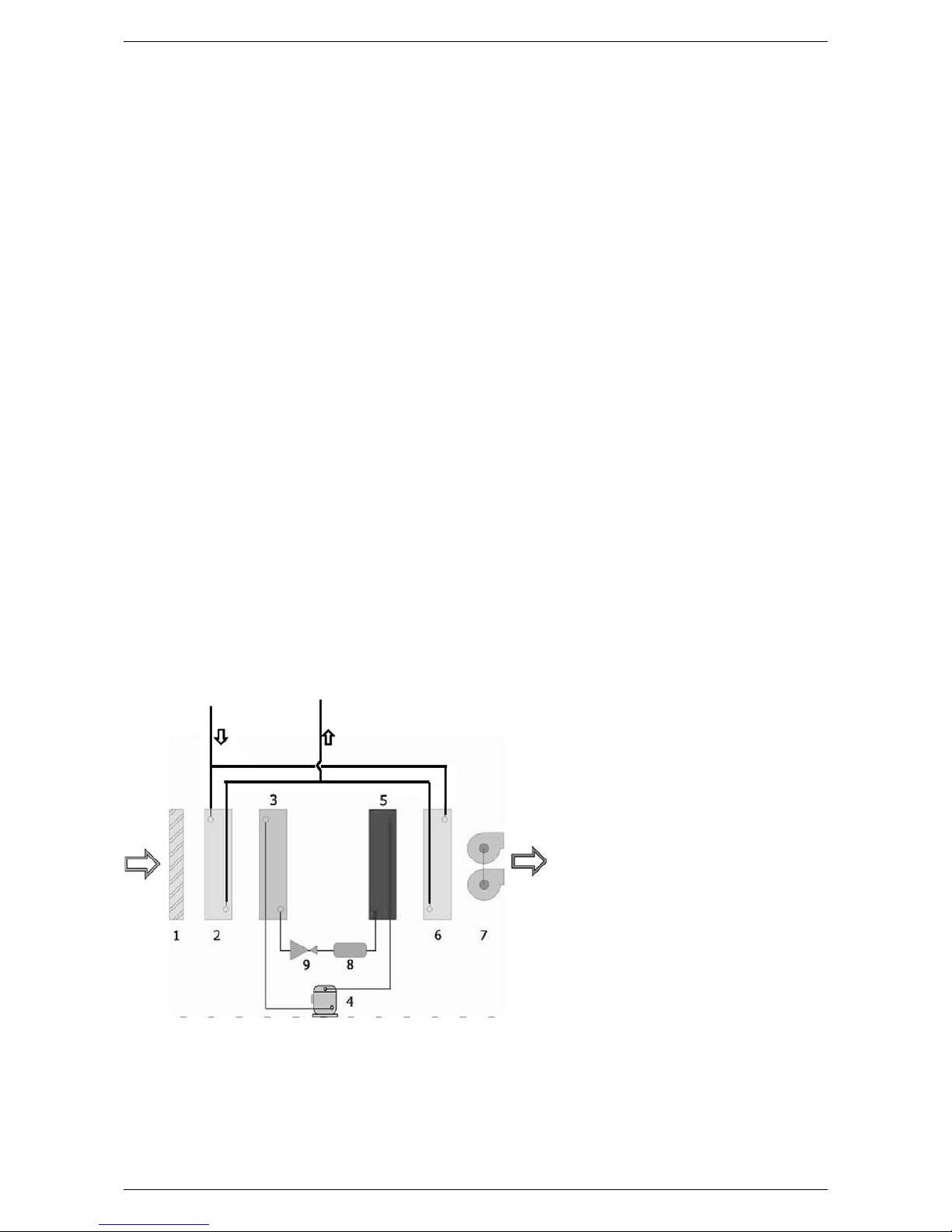

The DMP is an appliance designed to be

coupled with cooling plants with radiant

panels. It is characterised by its silence,

small electricity consumption and high

dehumidification efficiency.

The unit has been designed for vertical

wall installation. However, dangers to the

user or third parties may arise, as well

as damage to the appliance and other

objects, in the event of improper use not

in compliance with the type of use envi-

saged.

Inspection

Any use not expressly indicated in this

manual is not permitted. Consequently

AERMEC will not assume any respon-

sibility for damage that may occur due

to failure to comply with these instruc-

tions.

1.2. PRESERVATION OF THE DO-

CUMENTATION

These installation instructions along with

all the related documentation must be

given to the user of the system, who as-

sumes the responsibility to conserve the

instructions so that they are always at

hand in case of need. READ THIS DOCU-

MENT CAREFULLY, the installation of the

appliance must be carried out by qualified

and suitably prepared staff in complian-

ce with the national legislation effective

in the country of destination. (Ministerial

Decree 329/2004).

The appliance must be installed in such

a way as to enable maintenance and/or

repairs to be carried out. The appliance

warranty does not cover the costs for lad-

der trucks, scaffolding, or other elevation

systems that may become necessary for

carrying out servicing under warranty.

The validity of the warranty shall become

null and void in the event of failure to com-

ply with the above-mentioned indications.

We remind you that the use of products

that employ electrical energy and water

requires that a number of essential sa-

fety rules be followed, including:

−This appliance is not suitable for

use by persons (including children)

with limited physical, sensory, or

mental capacities or those lacking

experience or knowledge, unless

they are supervised or instructed

regarding the use of the appliance

by a person who is responsible for

their safety. Children must always

be supervised to ensure they do

not play with the appliance.

−It is prohibited to carry out any

technical or maintenance ope-

ration before the unit has been

disconnected from the electrical

mains by switching off the master

switch of the system and the main

power switch on the control panel.

−It is prohibited to modify the safety

or adjustment devices without the

manufacturer’s authorisation and

precise instructions

−It is prohibited to pull, detach, or

twist the electrical cables coming

from the unit even if it is disconnec-

ted from the electrical mains.

−It is prohibited to leave any contai-

ners or flammable substances in

the vicinity of the heat pump.

−It is prohibited to touch the applian-

ce when you are barefoot and with

parts of the body that are wet or

damp.

−It is prohibited to open the doors

for accessing the internal parts of

the appliance without first having

turned the master switch "OFF".

−It is prohibited to disperse, aban-

don or leave the packing materials

within the reach of children, as they

are a potential source of danger.

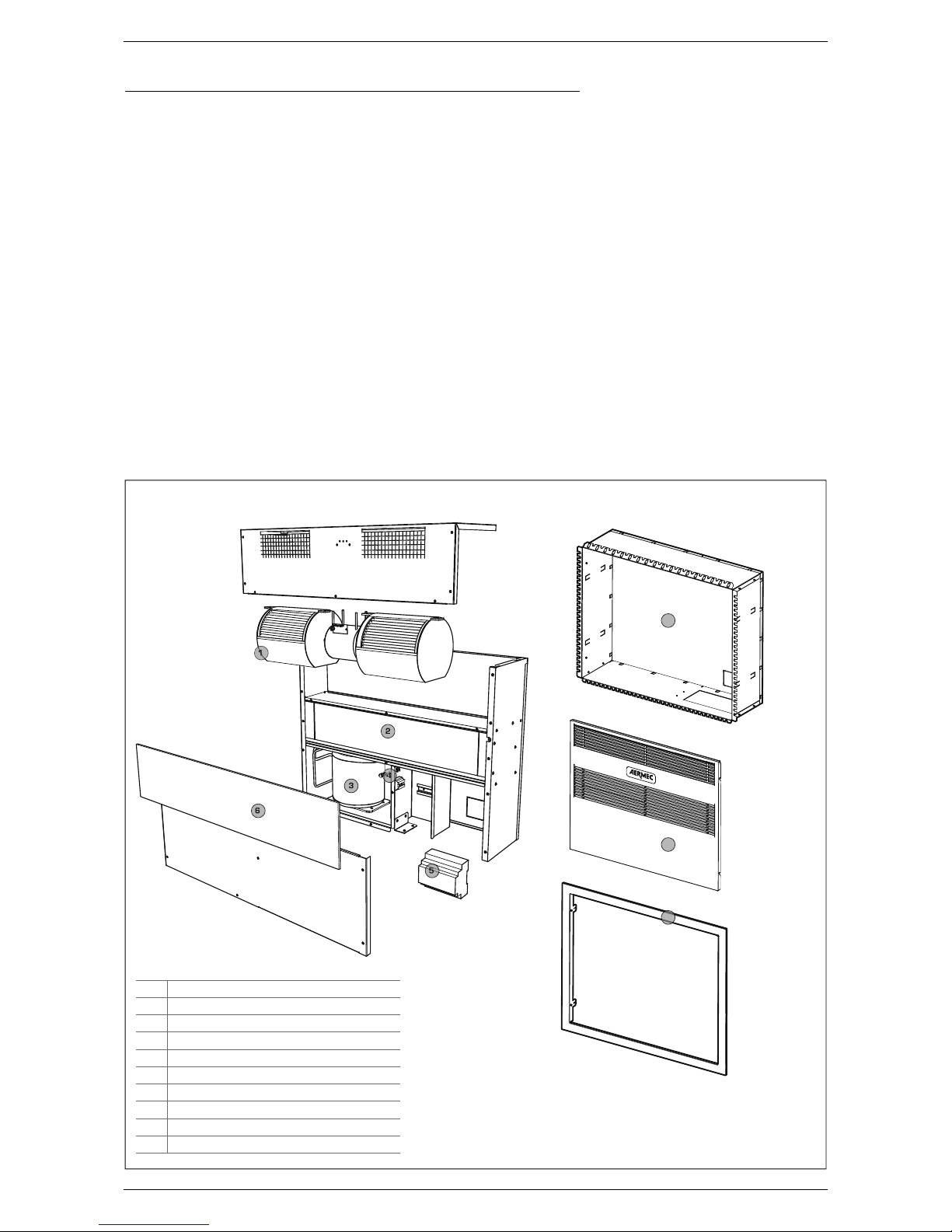

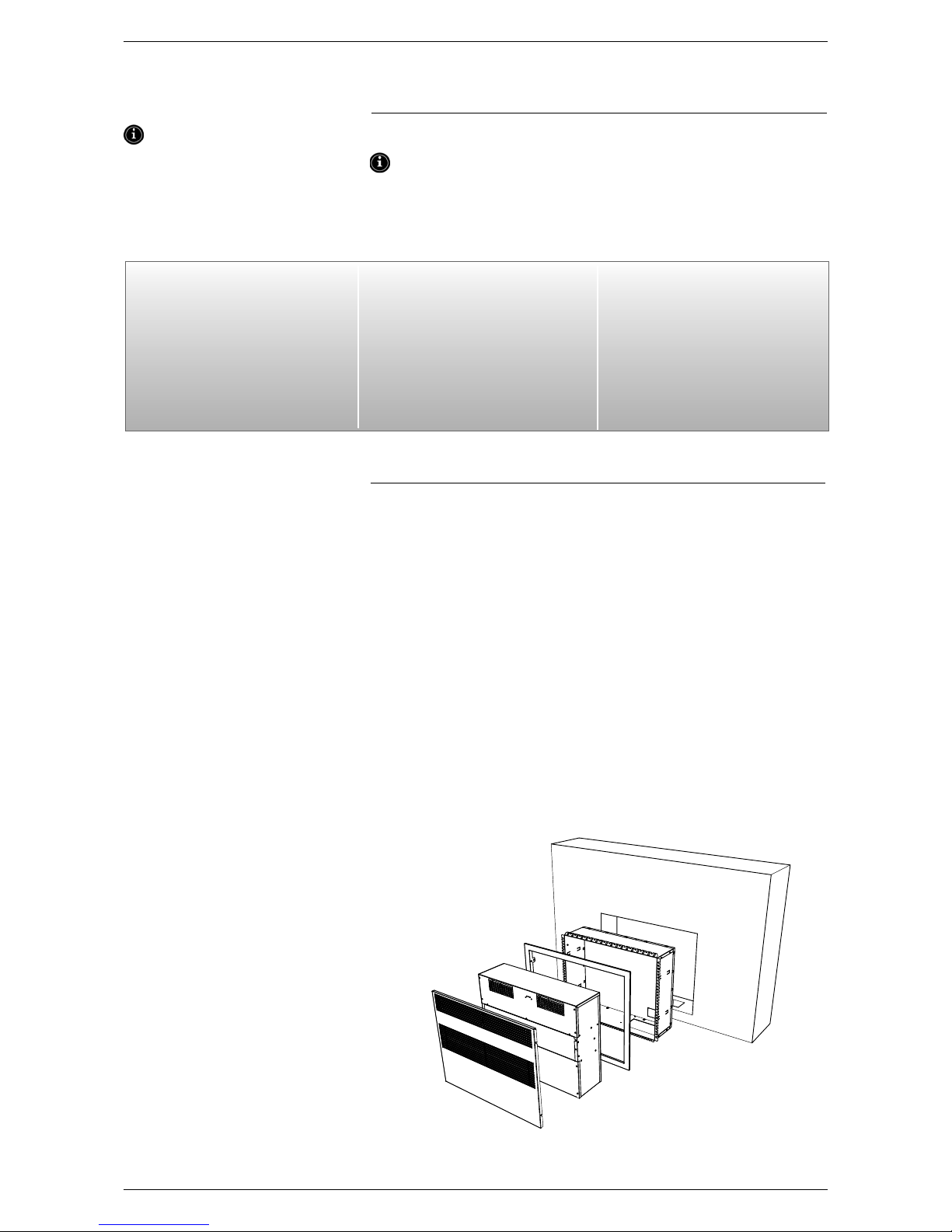

The dehumidifier is supplied in two se-

parate packages:

3.1. MACHINE PACKAGE

−DMP machine with direct front in-

troduction

−Technical instruction, installation

and use manual

−Cardboard box

−Straps

3.2. CASSAFORMA SYSTEM AND

FRONT PANEL PACKAGING

−Cassaforma system that can be as-

sembled

−Front frame + Painted front panel

−Cardboard box

−Straps

NOTE

Tampering, removal, lack of the identifi-

cation plate or other does not allow the

safe identification of the product and

will make any installation or maintenan-

ce operation to be performed difficult.

1. WARNINGS REGARDING DOCUMENTATION

2. FUNDAMENTAL SAFETY RULES

3. PRODUCT IDENTIFICATION