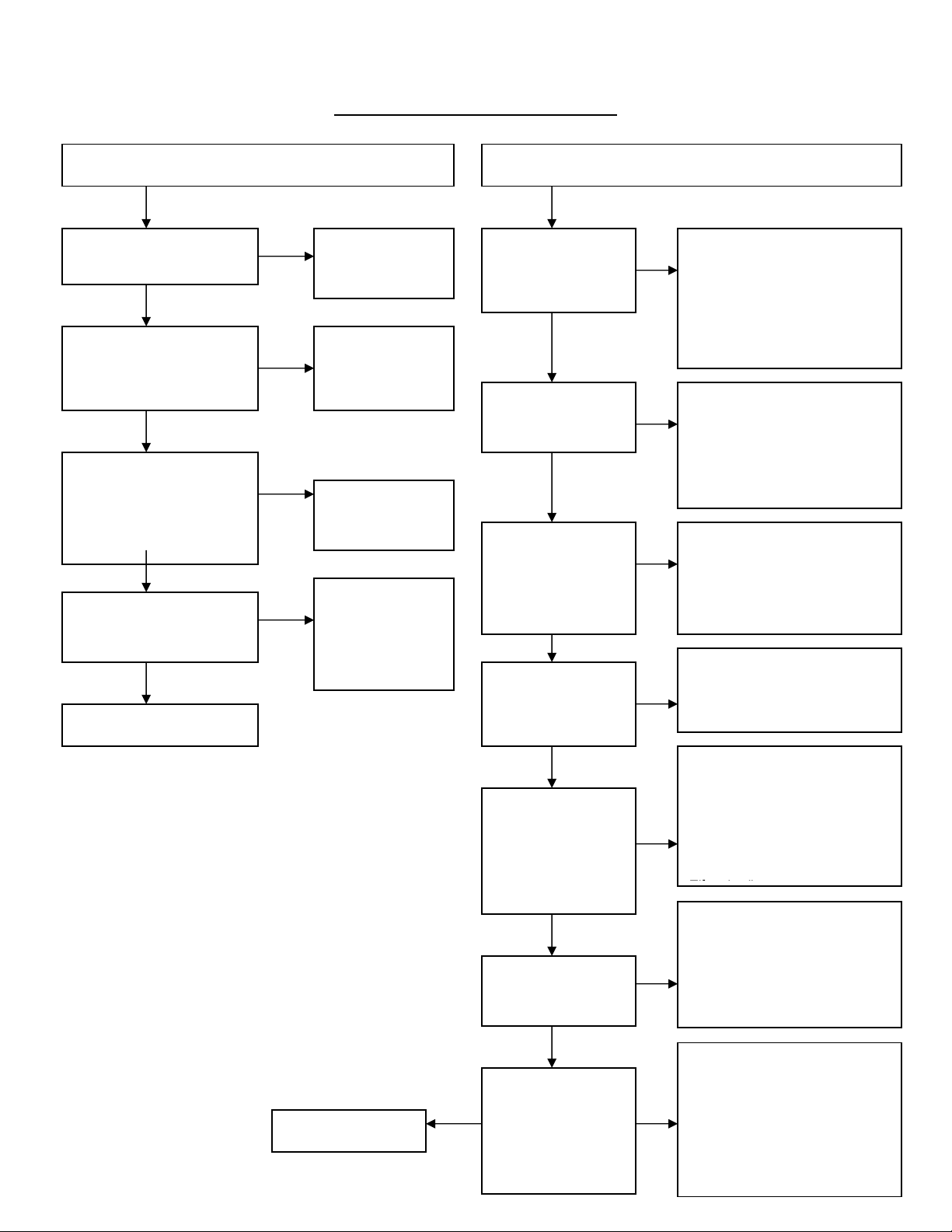

Fuel System Troubleshooting

Pump does not run at all.

Do you have voltage at the

pump terminals?

Is the “+”terminal

connected to +12 V and the

“-“ terminal connected to

Is the fuel line going to the

engine compartment

connected to the same side

of the fuel pump as the

power terminals?

Do you have a 100-micron

fuel filter installed on the

inlet side of the fuel pump?

Contact Aeromotive

Check all

electrical

connections.

Connect power

wires to proper

terminals.

Plumb the fuel

pump in the

proper orientation.

Debris may have

entered the fuel

pump and locked

it up, Contact

Aeromotive.

Pump performs poorly or runs intermittently

Is the fuel pressure

regulator you are

using a by-pass

Are you using a

sumped fuel tank or

a fuel cell?

A by-pass style regulator is

required for proper operation of

this product. For EFI we

recommend Aeromotive p/n

13101 or 13109. For carb

applications we recommend

Aeromotive p/n 13204.

A sumped fuel tank or fuel cell

is required for proper product

performance, refer to

Aeromotive tech bulletin #802

“Pickup tubes -vs- sumped

tanks” for specific details.

Is the fuel line

between the fuel

tank / fuel cell a

minimum of 9/16”

ID or AN-10?

Is the fuel pump

mounted at or below

the half tank fuel

Does the fuel filter

on the inlet side of

the pump have a

100-micron

filtration rating and

have a min. of 60 in

2

Are the fuel filters

in the system been

clean or new?

Clean, high flow inlet plumbing

is required for proper pump

operation, a min. of 9/16” ID or

AN-10 fuel line is required on

the pump inlet side.

Are you driving the

vehicle for periods

of time greater then

30 minute with less

the 10 gallons of

fuel in the tank?

Contact Aeromotive

As the fuel level falls in your

tank it is being recirculated at

an increasing rate, allowing less

time for fuel cool down, in

these cases it is recommended

to use a Fuel Pump Speed

Controller, we recommend

The fuel pump must be

mounted such that it has a good

gravity feed to insure proper

The fuel filter on the inlet side

of the fuel pump is required to

be rated at 100-micron and

have no less then 60 in

2

filtering area. For detailed

information see Aeromotive

tech bulletin #101 titled “Inlet

Insure that all fuel filters are

clean or new, proper filters are

an inexpensive cure to a lot of

fuel system problems. Refer to

Aeromotive tech bulletin #102

titled “Post Pump Filtration”.