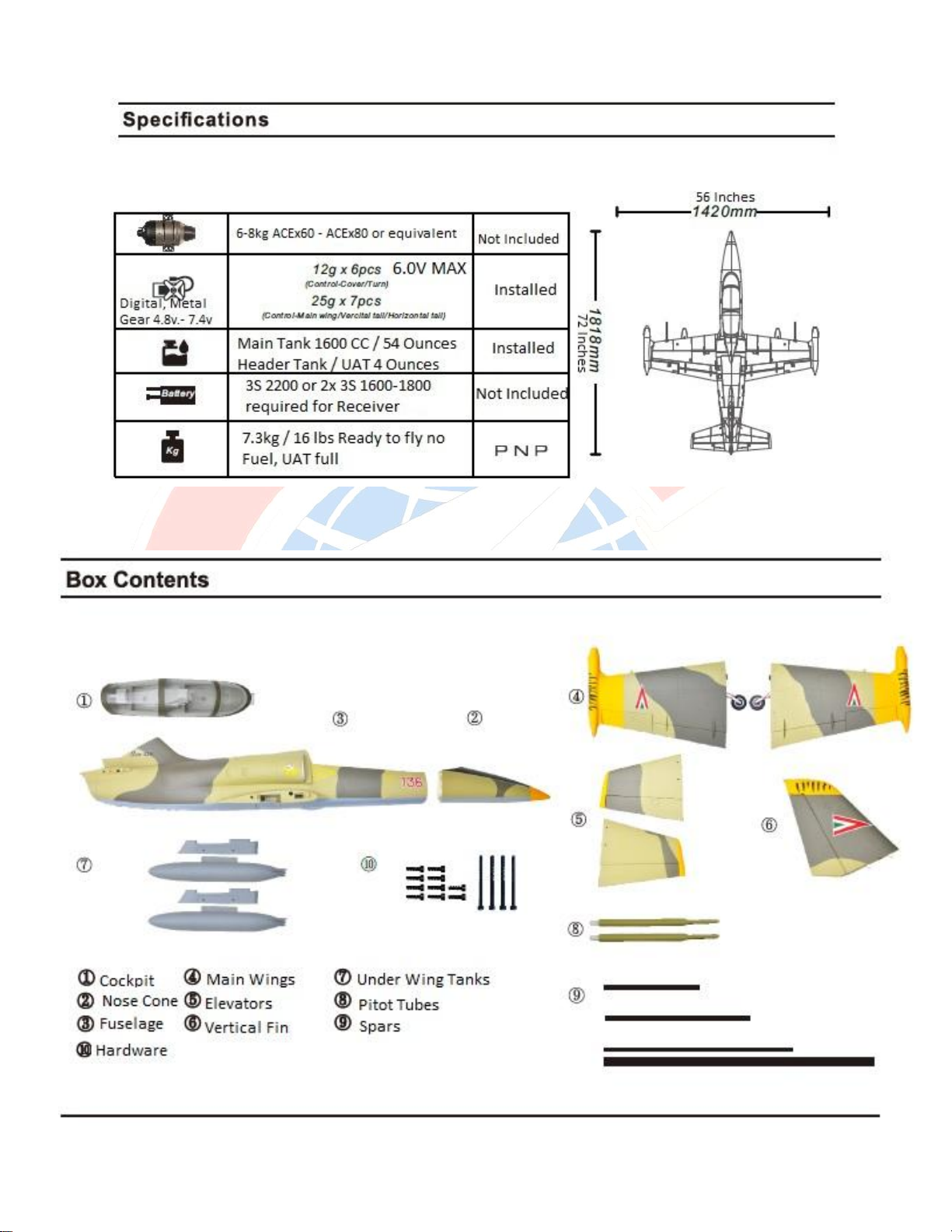

AeroFoam L-39 User manual

L-39

1/6.6th Scale

Length 72 inches (1828 mm)

Wing Span 56 inches (1433 mm)

Weight RTF minus Fuel 16lbs (with AUT full)

Suggested Engine Size: 60n ~ 80n (6kg ~8kg)

Perfect for our ACEx60 or ACEx80

CG 115 mm (4.5 inches) from leading edge at root of wing to fuselage.

Aileron Travel 12mm (15/32)

Elevator Travel 12mm (15/32)

Rudder Travel 25 mm (1 inch)

Flaps: Take off 15-20 Degrees Landing 35 - 45 Degrees

Speed Brakes Landings 60 - 75 Degrees (do not operate at high Speed)

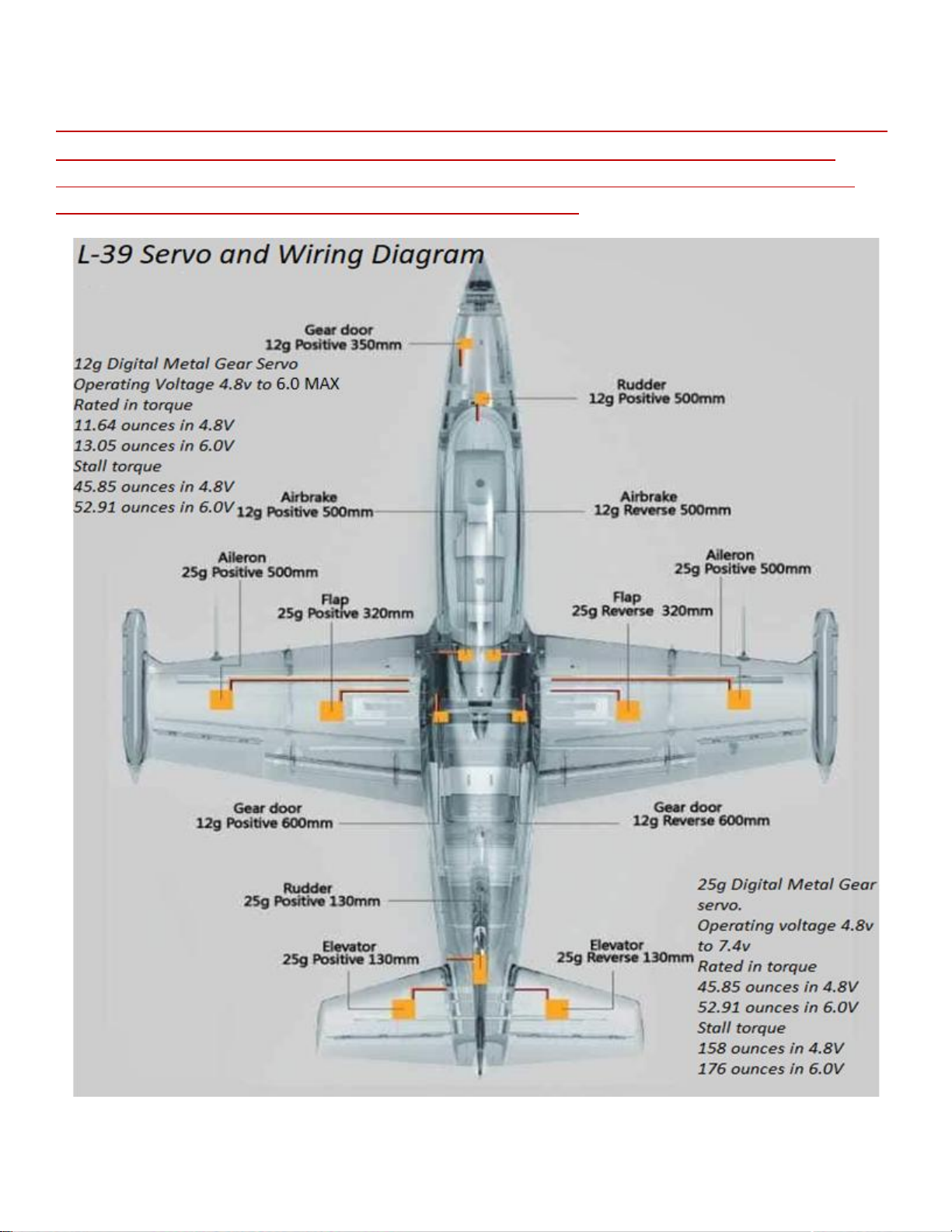

The L-39 comes with Seven 12g Servos and Seven 25g Servos. Use 6.0v MAX

CAUTION: When setting up and connecting the servos on your L-39 for the first time, be

careful not to have the Speed Brakes and the Flaps Binding one example is to have the

model resting on a table and connecting power to the servos and have the Flap or Speed

Brakes in the down position. You will burn out the servos.

Nose section: There are three servo leads coming out of the nose section, make sure you pass

them through to the fuselage. Find the 4 Metric 4x50 (two inches long) screws and washers.

You will need to insert those through the main fuselage into the nose section. You only need

to make them snug enough until all the gap on the side of the fuselage is gone. Do not over

tighten and crush the foam.

ELEVATORS: All the pushrods come is separate bags, the hardware is very tiny, take special

precaution not to lose any. Adjust both ends of the Pushrod, make sure that both ends have

an even spacing. In the example below, the left side is a lot shorter than the other end. On the

flying surface side, there are two positions for you to adjust the travel, on this example we

used the top hole and same on the Servo side. Since not much travel is required on the L-39,

on the servo side, use the lowest hole possible and on the flying surface side use the top hole.

Control Throws: Use the lowest hole possible on the servo arm and the highest

hole on the control surface. Since the required travel is very small on all, but the

rudder on all of our flying surfaces, in order to get the best resolution / control

from your radio, adjust the surfaces to your liking, we recommend settings that

will give you more control over the entire range.

RUDDER: On the Elevators, Rudder and Ailerons, you want to center the servos

and then install your pushrod so that the servo arm and the control horn are 90

degrees to the flying surface like in the picture of the Elevator. On the vertical fin

there is a scale baffle the you will have to glue to the top of the Fin right on at the

top of the rudder. Use your favorite glue, if you use CyA, try to use a Foam Safe

type of your favorite brand. Alternative, you can use Epoxy.

FLAPS: The servo for the flaps, in the UP position, you will have the servo arm at

about 45 Degrees at neutral. Adjust the pushrod as needed and install Again, use

the hole in the servo arm that is closest to the servo and the top hole in the

Control Horn in the Flap. This will give you more control in the entire range of

motion instead of having to limit the amount of travel in your flap channel later.

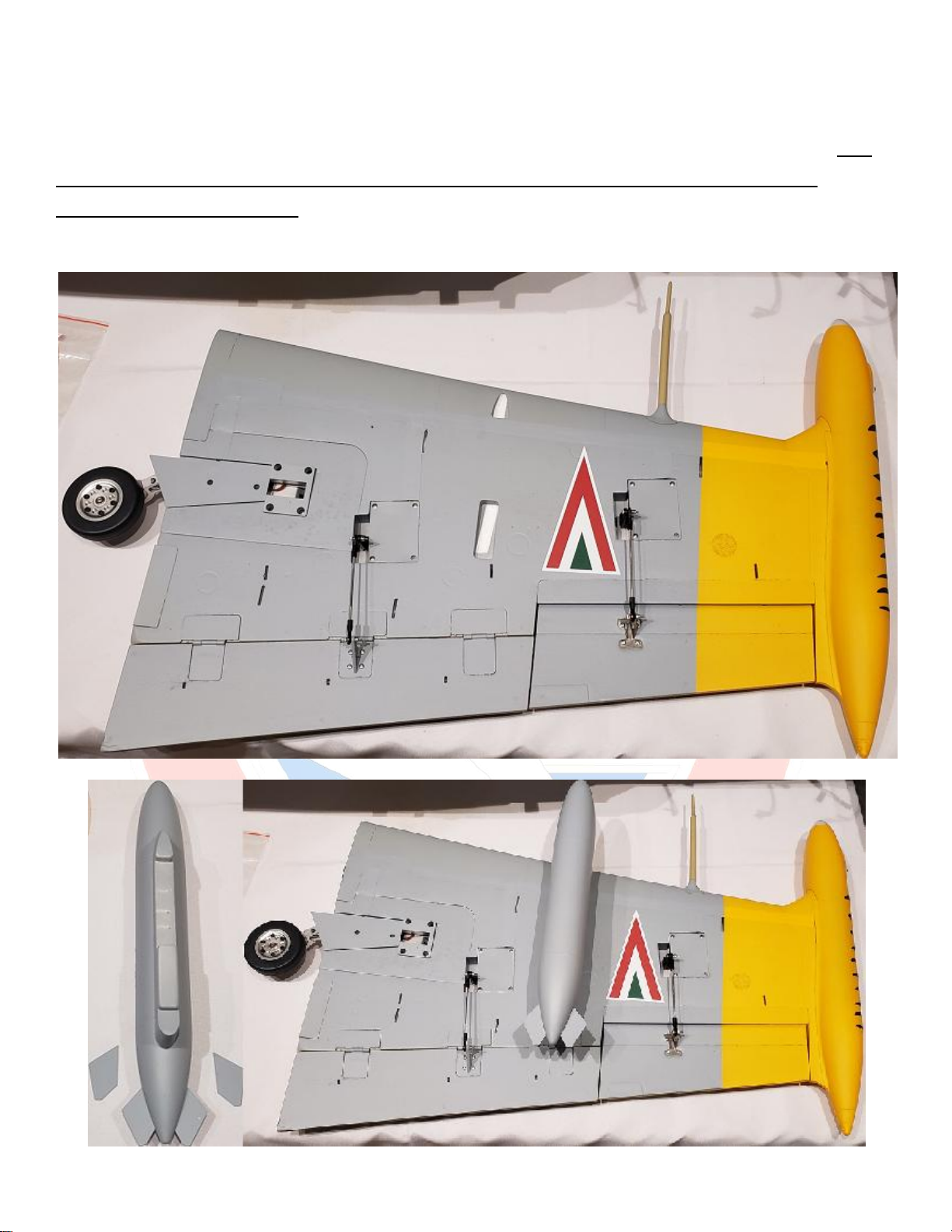

WING ASSEMBLY: Find the two Wing Spars, the bigger one is about 29.5 inches

and the smaller, thinner wing spar is about 26.5 inches. Insert both through the

fuselage and slide one wing into the pars. The first time you insert the wings, you

will notice that the landing gear strut will probably touch the foam in the wheel

well. This is normal, and will NOT interfere with the operation of the Landing Gear.

Just push the wing into place and it will automatically connect the Landing Gear,

Brakes, Servos and Lights for you. Install two Metric 3x10 screws on each wing

ELEVATORS: Find the elevator spar which is about 19.5 inches, feed the spar

through the fuselage and then install each elevator half making sure to connect

the servo extension on each side first, then use two Metric 3x10 screws to hold the

elevator into the fuselage.

RUDDER / VERTICAL FIN: Find the spar that is about 12.5 inches long and insert

into the fuselage. slide the vertical fin into the spar and connect the servo

extension, as you slide the vertical fin down, make sure to slide all the servo cable

into the slots in the base of the fin and into the vertical fin itself. Install the two

metric 3x10 screws to hold in place.

The retract covers: look great if used but you have to take many precautions to

make sure they are installed correctly. There must be sufficient gap between the

landing gear door that is attached to the strut and the actual landing gear cover. It

might be necessary for you to trim the landing gear door on the strut to make sure

you have enough clearance. The first two photos shot the stock gap and then the

clearance i had to make. The third picture will show what can happen when the

cover is loose or not glued properly. You will need to trim slots in the cover in

order to have it seat properly. If you are not comfortable taking all these

precautions, simply do not install the retract cover.

Equipment Installation: There are many ways to install your Receiver, turbine and

batteries. The airplane will come with all the servo leads routed to the front of the

jet and coming out the top of the Receiver tray. All the leads will be marked. If you

remove the receiver tray, you will find the UAT it is up the end user to decide to

what level of installation they are comfortable with. It is highly recommended that

take the time to at the very minimum place safety wire on all fuel connections

(example below of the UAT tank) . You may also go the extra step and install Fuel

Barbs and then the safety wire on each side of a fuel line connection. The Fuel

pump can be installed in the radio compartment or moved closer to the engine.

Take the three pieces of wood and secure them with CyA to hold your main tank in

place.

Turbine Installation: If you purchased one of our ACEx60 or ACEx80 Turbines, then

you will see that the mounting holes have already been drilled on the wood

Turbine mounts and there is no other guesswork to be done. The will also insure

the you have a gap of 1.5 inches from the rear tail cone of the Turbine to the start

of the actual pipe. This gap should not be confused with the start of the aluminum

bell mouth.

This view of the Turbine installation, show the Pump and the manual shut off valve

installed in the engine compartment, the equipment installation is left up to the

customer's choice.

So, you want Smoke or Longer Flight Times? Sold Separately, We offer a smoke

tank that is made to fit into the cavity in the front fuselage. We also offer a tiny,

lightweight brushless smoke pump. This can be used as a Smoke tank or for

additional fuel. Should you wish to modify your L-39 you can remove the cross-

brace and install up to a Dubro 12oz tank in the same cavity. Again, this can be for

Smoke or Fuel.

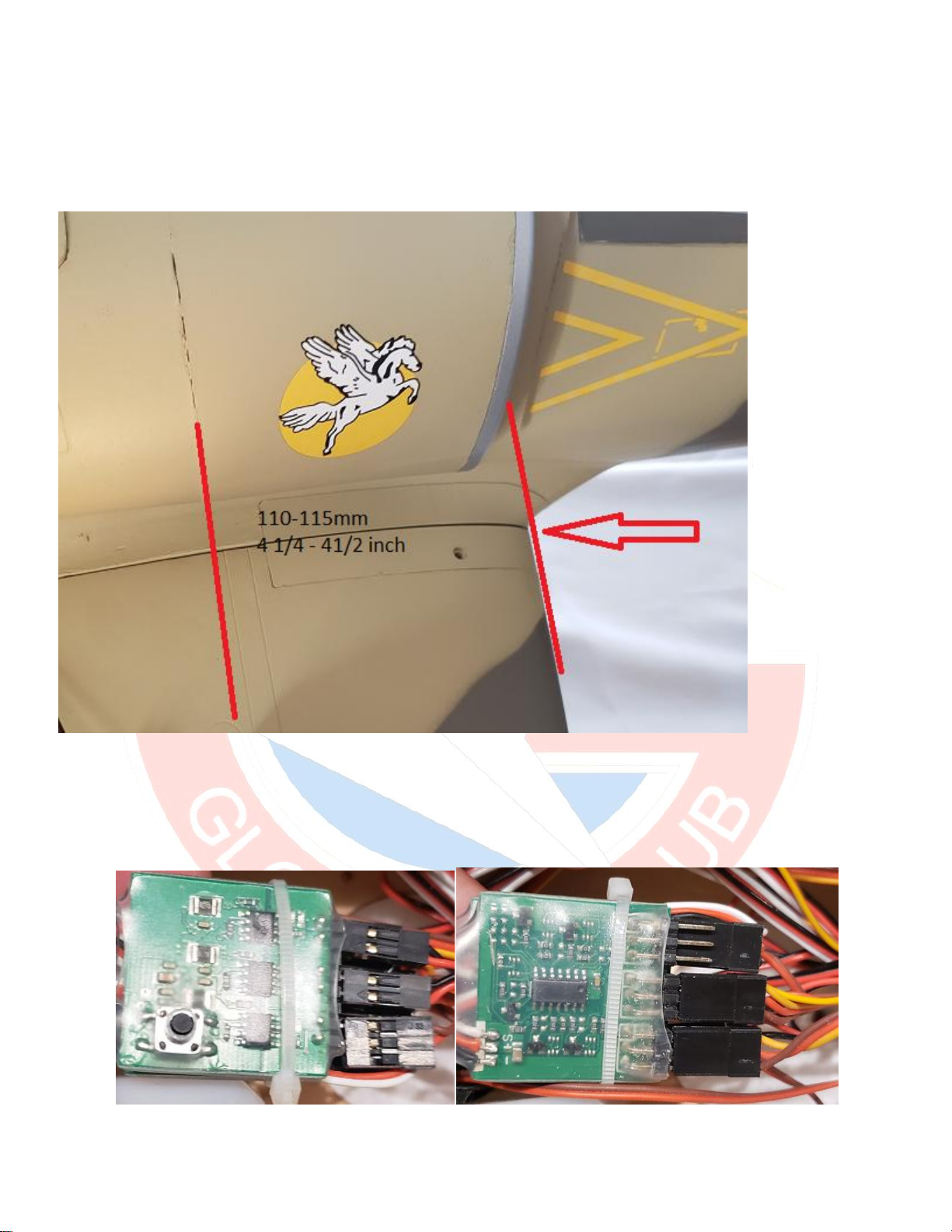

CG: The CG of your L-39 is 110-115 MM 41/4 - 41/2 inches from the leading edge of

the wing at the Fuselage. This is basically measured where the wing meets the

fuselage.

The Retract and Brake controller continue to evolve, so we are not going to spend

too much time on them One servo lead goes out to your Receiver for the retracts,

the controller will do all the timing of the gear and doors

Other AeroFoam Toy manuals

Popular Toy manuals by other brands

Harbor Freight Tools

Harbor Freight Tools 92304 Assembly & operating instructions

Model Engines

Model Engines TWM24G1 instructions

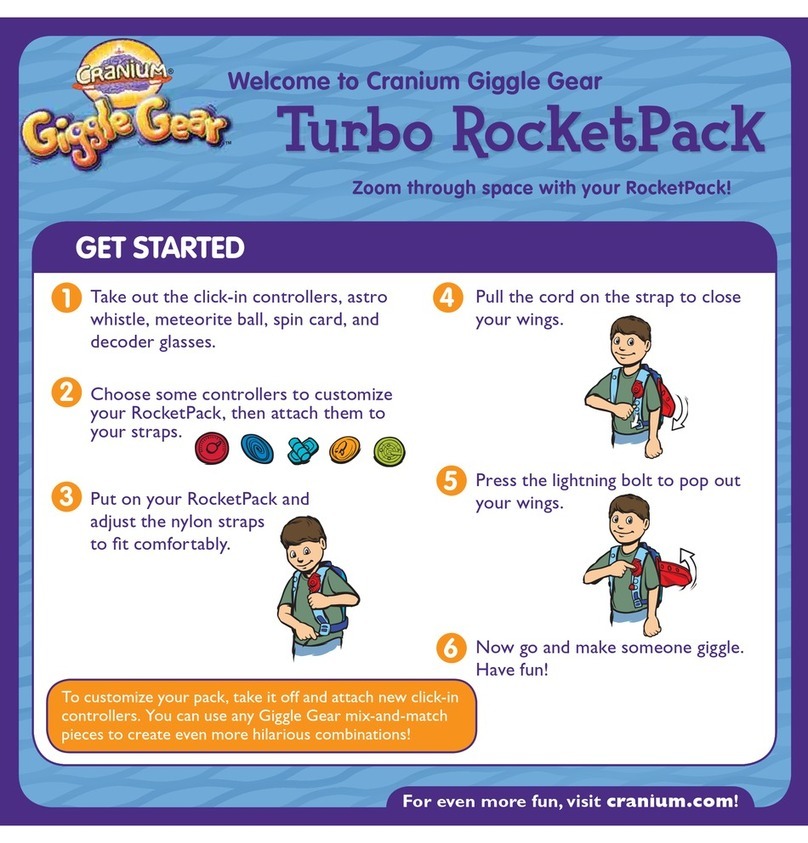

Cranium

Cranium Turbo Rocket Pack instructions

WARCRADLE STUDIOS

WARCRADLE STUDIOS Dystopian Wars Enlightened Frontline... Assembly instructions

Makrlin

Makrlin 37183 user manual

POLA G

POLA G BUS manual